07

Cliprail Zone Pack

06 Cliprail Zone Pack

6.0 Risk Assessment for Screed Application

General

Construction sites have a number of general risks associated

with them and these should be detailed in the main contractors

site Health and Safety policy or Risk Assessment. Any special

risks with a particular site should highlighted.

The use of hard hats, high visibility jackets and safety boots is

normal practice for all installation operatives. Where necessary,

ear protection and goggles will be worn during the use of

certain items of plant and equipment.

Installation of MYSON FLOORTEC underfloor heating systems

do not significantly add to these risks and normally applied

safety actions by other contractors on site should be

satisfactory.

Underfloor Heating Installation

The following is a detailed examination of each stage of the

installation of MYSON underfloor heating. MYSON underfloor

heating method statements are used as a reference (copies

available from MYSON). Risks associated with each stage of the

installation are detailed and the appropriate actions to limit any

risk are given.

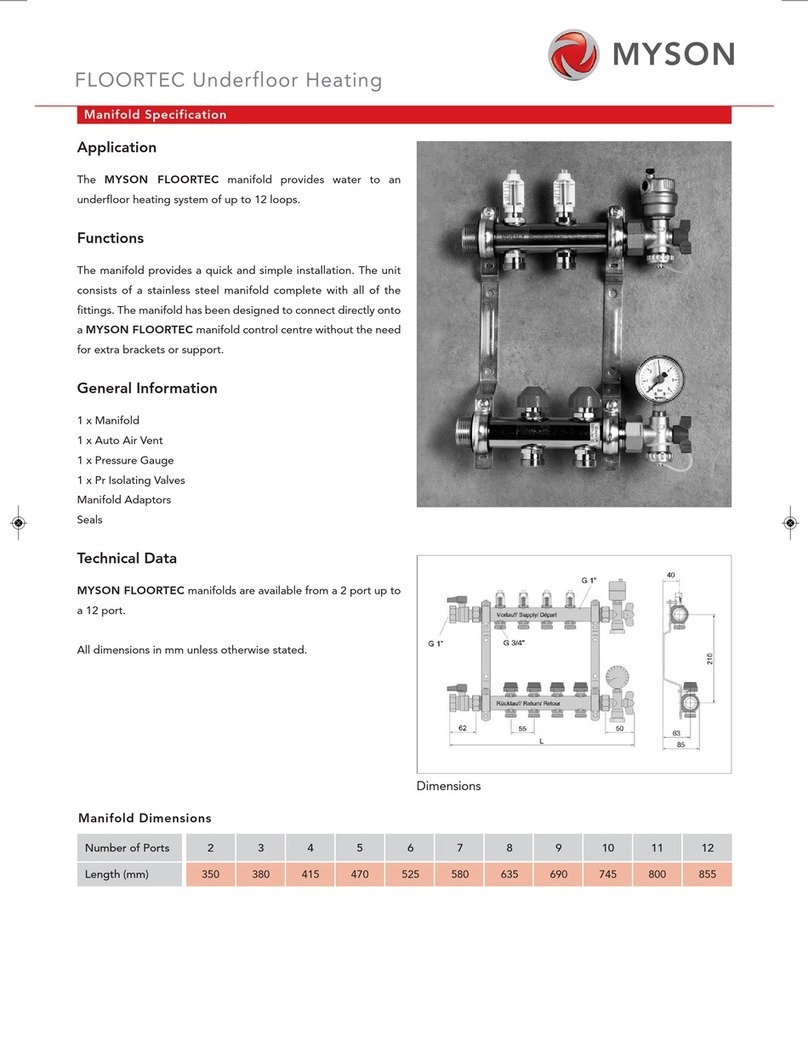

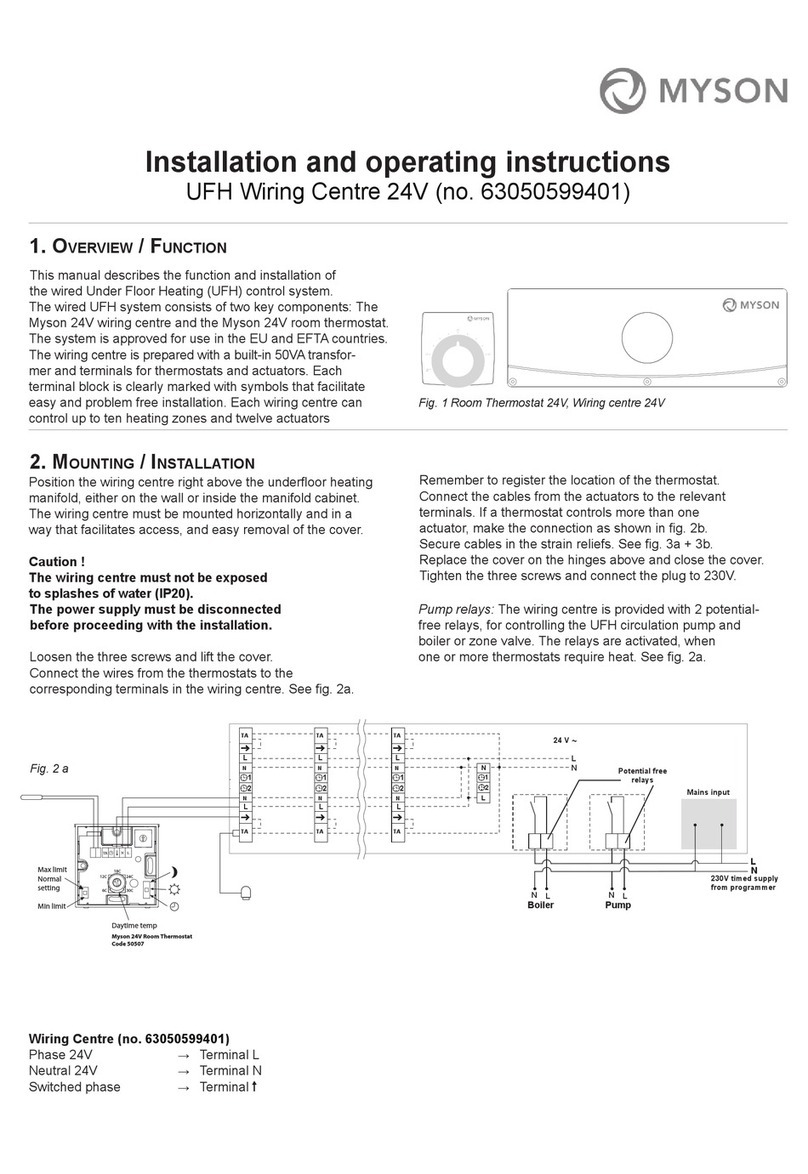

Fitting of Control System

The manifold is made up and then fixed to a wall or temporary

structure using wall plugs and screws.

Tools: Power drill/cordless power drill, screw driver,

spanners/pipe wrench

Risk: With power tools there is always the risk of ‘flying

chips’. Due to the exposed nature of some sites and the

presence of other trades there is an increased risk of

electrocution from trailing cables and the like.

Action: Safety glasses are to be worn whilst drilling issued

under PPE. See electrical section for use of electrical

equipment.

Fitting Pipe to Control System

Pipework is cut and fitted to the manifold using a mechanical

joint.

Tools: Pipe cutters.

Risk: No significant risk.

Laying of Pipe

Pipe is decoiled and fixed to the insulation by means of a

plastic clip.

Risk: Pipe coils are heavy and must be considered under

manual handling. Coils are available in 120m and 240m

lengths. Both the 120m and 240m can be utilised without

mechanical assistance.

No other significant risks.

Action: Operatives should be trained in manual handling.

Filling and Pressure Testing

Hydraulic Pressure Test to be Used on Site

The underfloor heating system should be filled with mains

potable water. A suitable hydraulic pressure pump may be

required.

Tools: Hydraulic pressure pump, Spanners/Pipe wrench.

Risk: Use of hydraulic pressure tests has a medium risk,

however the following procedure must be followed:

(i) Ensure the area to be tested is cordoned off and that

no other site personnel are able to readily access the

area signage to be erected.

(ii) Whilst filling the system check for leaks.

(iii) Gradually raise the pressure to a maximum 3bar.

Check for leaks at all joints and mechanical fittings.

(iv) Re-check that all other site personnel are kept clear of

the test area.

(v) Leave pressurised for 2 hours to check for leaks. There

may be a small drop in pressure initially due to the pipe

work relaxing/temperature

(vi) After 2 hours the pressure should be released to 1 bar

gauge, which should be held during concreting.

COSHH Assessment

The installation of MYSON underfloor heating does not involve

the use of any substances as defined by the ‘Control of

Substances Hazardous to Health’ regulations.

4.0 Installation (continued...)

5.0 Post Screeding

The slab must be allowed to cure for a minimum of 21 days

before the heating system can be turned on. Following this

period the heating system should be allowed to reach

operating temperature by increasing the temperature 3ºC per

day from a commencing temperature of 30ºC until the final

operating temperature is reached. Failure to observe these

instructions could result in damage to the screed.

Floor Coverings

Underfloor heating doesn’t dictate to you in any way. It can be

used with almost any kind of flooring or floor covering.

There are four basic floor finish types which should be

considered: ceramic tiles, vinyl, timber and carpets. Ceramic

finished has the least thermal resistance with carpets having the

greatest.

Ceramic & Vinyl: Ceramic, plastic or vinyl flooring, have a low

thermal resistance, and will function very well with MYSON

underfloor heating systems.

Timber: Timber flooring is compatible with MYSON underfloor

heating systems however you must ensure that it is stored in

the room in which it is to be laid 2 weeks prior to installation.

Carpets: Carpets are generally compatible with MYSON

underfloor heating systems however heavy carpets with felt

underlay should be avoided as this may reduce the heat output

in the floor.

lProve adhesion. Provide additional fixing of Cliprail by

securing each end using special plastic Cliprail pins.

Continue to butt-joint Cliprails in accordance with pipe

configuration requirements.

lHolding the pipe coil in both arms walk backwards away

from the manifold, turning the coil whilst playing out the

pipe.

lWalk along the pipe and ensure piping is spaced according

to the design drawing requirements. Insert the pipe into the

pre-formed slots of the Cliprail, ensuring “snap fit”.

Insert the pipe into Cliprail at the following spacings:

(a) Straight runs - 1 per 3 metres

(b) Bends - 1 at 300mm from bend

The maximum bend radius for PeX-a pipe is 8 x pipe

diameter i.e. 17 x 2mm pipe - 136mm radius

lAdditional “Anchor Clips” are provided to secure the pipe

during changes of direction. These red clips are screwed into

the insulation and provide a robust fixing where required.

lBlack pipe bend supports are placed where the pipe

direction changes from horizontal to vertical, under the

manifolds. These supports are designed to relieve stress on

the manifold connections and must be fitted.

6. PeX-a Pipe; Coupling Set

lGradually complete the layout of piping according to the

required configuration. Final pipe run should be returned to

the opposing flow or return connection as in (5) above.

7. PeX-a Pipe Length

lPeX-a pipe is marked in metre lengths.

lNote the pipe length marking at both flow and return

connections and record the length of each loop to ensure

the pipe in economically utilised.

8. Complete Steps 4 to 8 for Each Loop

9. Filling, Venting and Pressure Test

lAttach a temporary mains water connection to the flow (red)

connection on the MYSON Underfloor Heating Compact

Control Unit, and connect a temporary drain connection to

the return (blue) connection. Open the isolating valves and

allow mains pressure water to enter the system. Run water

through the system until the drain water contains no air.

lClose the return isolating valve and allow mains pressure to

raise the water pressure of the underfloor heating system to

3 bar. If the mains water pressure is inadequate, a separate

hydraulic pump may be utilised.

lClose both isolating valves and leave the system pressure at

3 bar for 30 minutes. Check for any leaks and rectify if

necessary. Once system integrity has been proven, reduce

the pressure to 1 bar and prepare for screeding.

5.0

6.0 4.0