North American Clutch & Driveline

Rockford, Illinois

Phone: (800) 383-9204

(815) 282-7960

Fax (815) 282-9160

www.naclutch.com

5

2.5 Maximum Safe Operating Speeds

Maximum safe operating speed is 2200 rpm for NACD Power Take-Offs with 14” HD,

14” HD (DP) or 14” HD (TP) clutches used for either in-line or side load drives.

2.6 Required Clutch Torque Capacity

To determine the actual torque capacity required of a clutch used for any given

application the maximum engine torque and torque service factor must be considered.

See the following chart and formula to calculate the proper clutch capacity required for

the application.

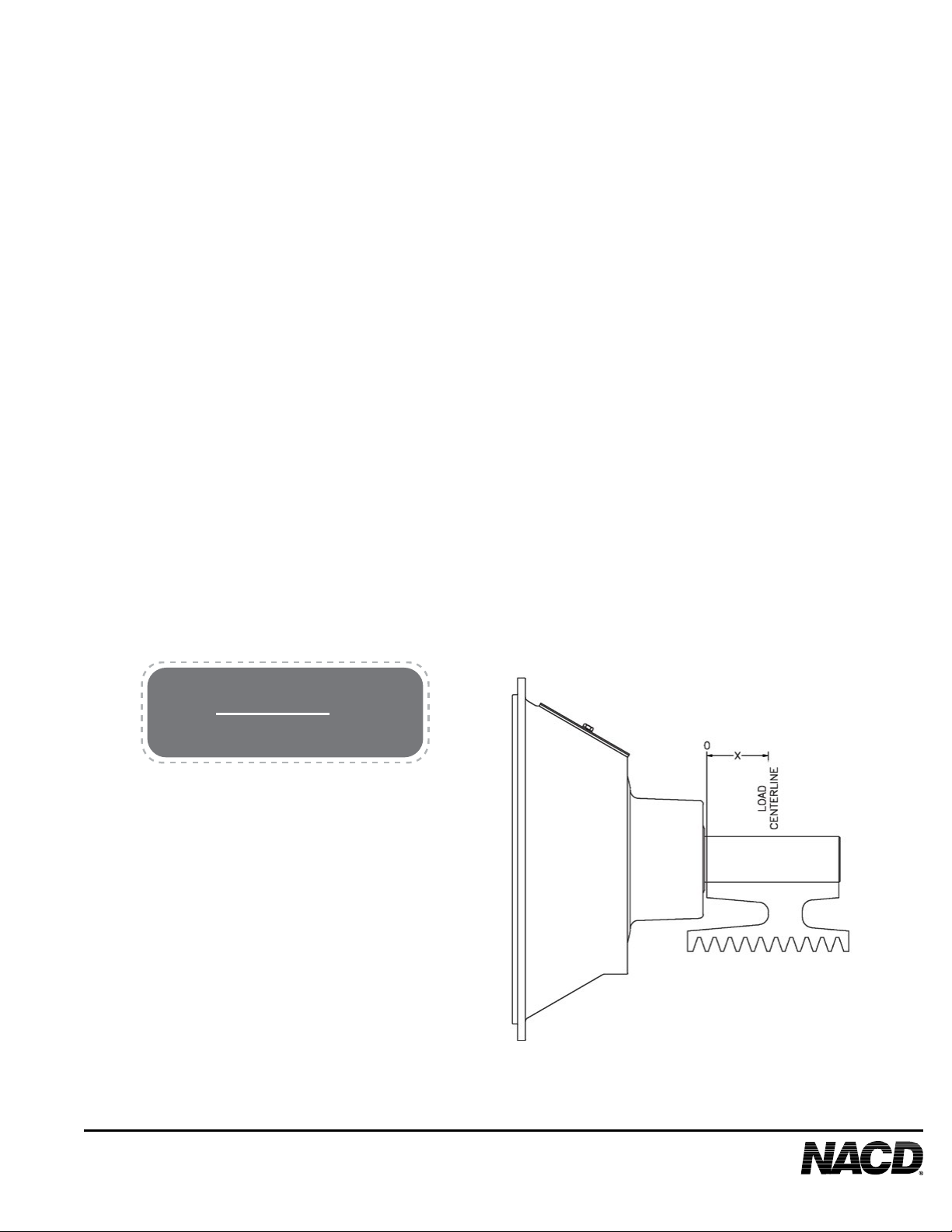

2.7 Alignment Tolerances For Flywheels & Flywheel Housings

NOTE: NACD recommends that engine ywheel housings used with NACD PTO’s be

made of quality cast iron or other material of equal or better strength. Aluminum ywheel

housings have been found to provide insufcient strength to properly maintain bearing

alignment and support the weight and forces related to the application.

Check the alignment of the engine ywheel and the engine ywheel housing. Excessive

bore and face runout of the ywheel, ywheel housing, and ywheel housing adapters,

if used, can adversely affect the performance of the PTO and the system of which it is

part. A dial indicator will be required to measure alignment.

Required Clutch Torque Capacity Calculation:

Required Clutch Torque = Maximum Engine Torque x Service Factor

Blower or Vacuum

Centrifugal with free ow of air

With high start-up inertia or subject

to choking of air supply

Compressors

Reciprocating, 1 or 2 cylinders

Reciprocating, 3 or more cylinders

Roto screw or turbine

Conveyor

Fed uniformly

Not fed uniformly

Recriprocating

Drills

Generator

Pump

Centrifugal or Turbine

Dredge

Mud or reciprocating

Rock Crusher, Hammer Mill

Snow Blower

Wood Chipper, Saw Mill

Ratings: Shafts, bearings and clutch capacities are rated on a conservative

basis. For unusually heavy starting loads, frequent engagment service,

or if prime mover is engine of less than 4 cylinders, consult our sates

representatives for recomendations. Extremely low speed engines require

special consideration.

1.7

4.0

4.0

2.5

2.0

1.5

2.0

3.0

2.0

2.0

1.5

2.0

3.0

3.0

2.0

3.0