Whenusingelectrictools,basicsafetyprecautionsshouldalwaysbefollowedtoreducetheriskoffire,electrical

shockandpersonalinjury,includingthefollowing.

Readalltheseinstructionsbeforeoperatingthisproductandsavetheseinstructions.

IMPORTANTINSTRUCTIONSANDWARNING-ElectricDevices

WARNING!

GROUNDINGINSTRUCTIONS

1.Intheeventofamalfunctionorbreakdown,groundingprovidesapathofleastresistanceforelectriccurrent

toreducetheriskofelectricshock.Thistoolisequippedwithanelectriccordwithagroundingconductor

andagroundingplug.Theplugmustbepluggedintoamatchingoutletthatisproperlyinstalledand

groundedinaccordancewithalllocalcodesandordnances.

2.Don'tmodifytheplugprovided-ifitwillnotfittheoutlet,havetheproperoutletinstalledbyaqualified

electrician.

3.Improperconnectionofthegroundingconductorcanresultinelectricshock.Theconductorwithinsulation

havinganoutersurfacethatisgreenwithorwithoutyellowstripesisthegroundingconductor.Ifrepairor

replacementoftheelectriccordorplugisnecessary,donotconnectthegroundingconductortoalive

terminal.

4.Checkwithaqualifiedelectricianorservicepersonifthegroundinginstructionsarenotcompletely

understood,orifindoubtastowhetherthetoolisproperlygrounded.

5.Useonly3-wireextensioncordsthathave3-pronggroundingplugsand3-polereceptaclesthatacceptthe

tool'splug.

6.Repairorreplacedamagedorworncordimmediately.

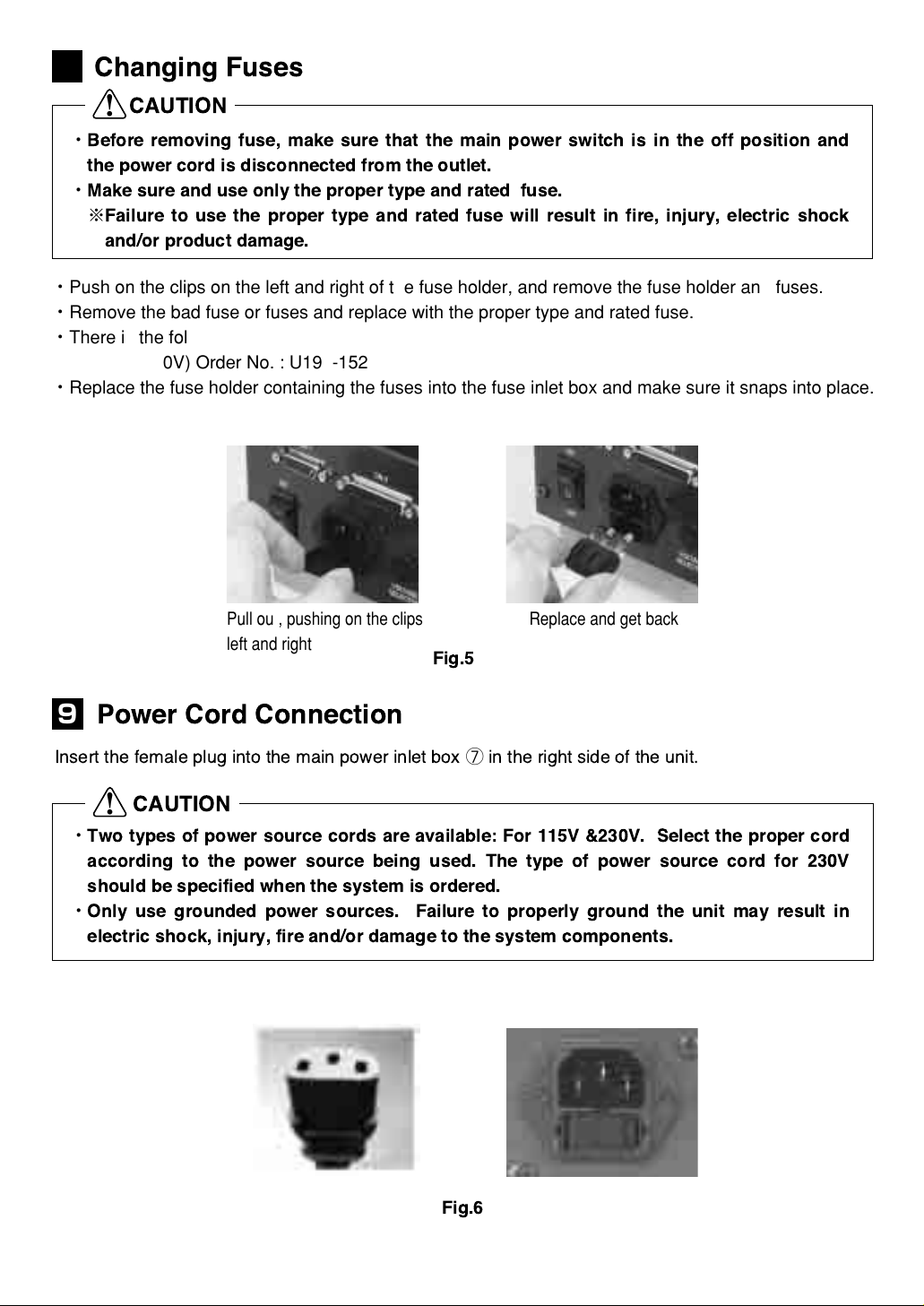

7.ThistoolisintendedforuseonacircuitthathasanoutletthatlooksliketheoneillustratedinSketchAin

Figure(below)(115V).ThetoolhasagroundingplugthatlooksliketheplugillustratedinSketchAinFigure

(below).Atemporaryadapter,whichlooksliketheadapterillustratedinSketchesBandC,maybeusedto

connectthisplugtoa2-polereceptaclesasshowninSketchBifaproperlygroundedoutletisnotavailable.

Thetemporaryadaptershouldbeusedonlyuntilaproperlygroundedoutletcanbeinstalledbyaqualified

electrician.Thegreen-coloredrigidear,lug,andthelike,extendingfromtheadaptermustbeconnectedtoa

permanentgroundsuchasaproperlygroundedoutletbox.

8.USEPROPEREXTENSIONCORD.Makesureyourextensioncordisingoodcondition.Whenusingan

extensioncord,besuretouseoneheavyenoughtocarrythecurrentyourproductwilldraw.

Anundersizedcordwillcauseadropthelinevoltageresultinginlossofpowerandoverheating.

Table(below)showsthecurrentsizetousedependingoncordlengthandnameplateampererating.

Ifindoubt,usethenextheaviergage.Thesmallerthegagenumber,theheavierthecord.

!

1

GROUNDING

PIN

(A)

METALSCREW

COVEROFGROUND

OUTLETBOX

(C)

ADAPTER

GROUNDING

MEANS GROUNDING

PIN

(D)

GroundingMethod

AmpereRating

More

Than

Not

More

Than

0

6

10

12

6

10

12

16

Volts

120V

240V

Totallengthofcotd

7.5m(25ft.)

15m(50ft.)

15m(50ft.)

30m(100ft.)

30m(100ft.)

60m(200ft.)

45m(150ft.)

90m(300ft.)

18

18

16

14

16

16

16

12

16

14

14

14

12

12

NotRecommended

OnlytheapplicablepartsoftheTableneedtobeincludede.Forinstance,

a120-voltproductneedincludethe240-voltheading.

Minimumgageforcord

(B)