2

WARNING

•Immediatelyafterasurgery,thehandpieceshouldbecleaned,lubricatedandsterilized.Failuretoproperly

maintainthehandpiececanleadtocontaminantsremaininginsidethehandpiece.Unremovedbloodmay

resultinproductfailureduetotheinternalbloodcoagulation.Impropermaintenancemayalsoleadto

overheating,causingburninjuries,productfailure,ordifficultyinattachinganddetachingthebur.(Referto

"8.Post-useMaintenance")

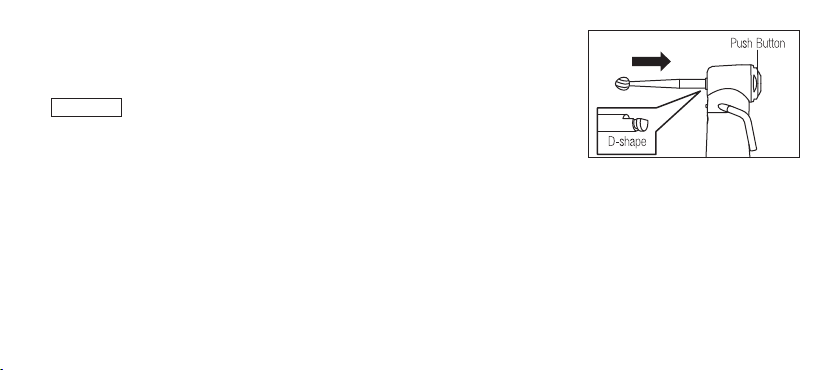

•DepressingthePushButtonwhilethehandpieceisinrotationmayleadtooverheating,causingburninjuries

orproductfailure.Avoidthepushbuttontocontactwithanyoraltissue.

•Supplycoolantwaterwhileusingthehandpiece.Nosupplyingthecoolantwatermayleadtooverheating,

causingburninjuriesorproductfailure.

•Donotusethehandpieceforpolishingpurposes.Polishingpastecouldenterthehandpiece,causingthe

failureofthePushButtonorburninjuriesduetotheoverheatingofthehandpiecehead.

•Keepanydebrisorotherforeignmaterialsawayfrominsidethegearorthehandpiece.Foreignmaterials

remaininginsidemayleadtooverheating,causingburninjuriesorotheraccidents.

1_C0596E000_X-SG93L_93_25L_EN_180704.indd 2 2018/07/04 17:47:23