4

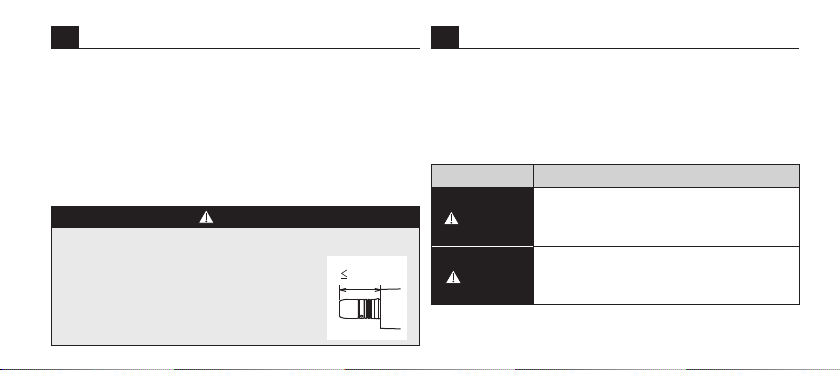

CAUTION

•Do not use burs with problems listed below as the bur may

break, seize up or disengage from the chuck.

- Bent, deformed, worn, rusted, broken, deficient bur.

- Bur which is cracked on the edge or axis.

- Non-ISO(EN ISO) standard, or tampered bur.

•Do not use burs other than specified in “11 Specifications” as

such burs may be accidentally released or break during

rotation.

•Always keep the bur shank clean. Dirt or debris in the chuck

could cause poor bur concentricity or low chuck retention

force.

•Always insert the bur all the way into the chuck. If insertion is

insufficient, premature failure of the bearings or accidental

release of the bur may occur.

•Do not exceed Max. Bur Length shown in “11 Specifications”.

CAUTION

•Always follow the instructions provided by the bur

manufacturer.

•Do not exceed the bur speed recommended by the bur

manufacturer.

•Should the handpiece function abnormally during use, stop

using the handpiece immediately and contact your Authorized

NSK Dealer.

•Do not use the following fluids to wipe, immerse or clean the

product; strong/super acid water, strong acid/alkaline

chemicals, chlorinecontaining solutions, solvents such as

benzine or thinner.

•The handpiece is delivered in a non-sterile condition and must

be autoclaved prior to use.

•Perform regular function and maintenance checks. (Refer to

“10 Periodical Maintenance Checks”)

N-605_nano_contra_EN_WCS5_200824.indd 4 2020/08/24 13:31:30