12.

On/Off

13. .

14. .

15. .

16. .

AWG.

17. .

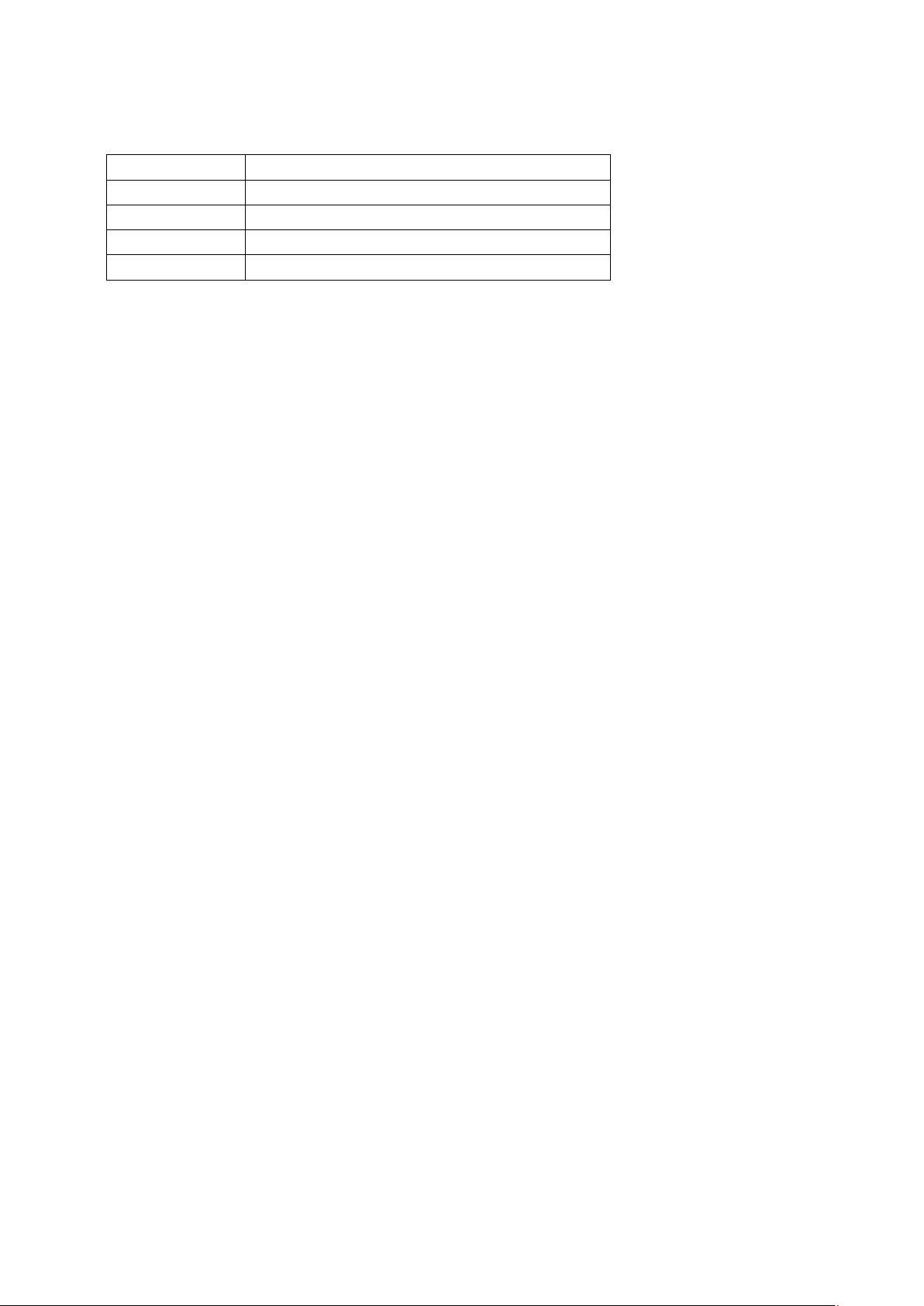

18. .

:

:

.

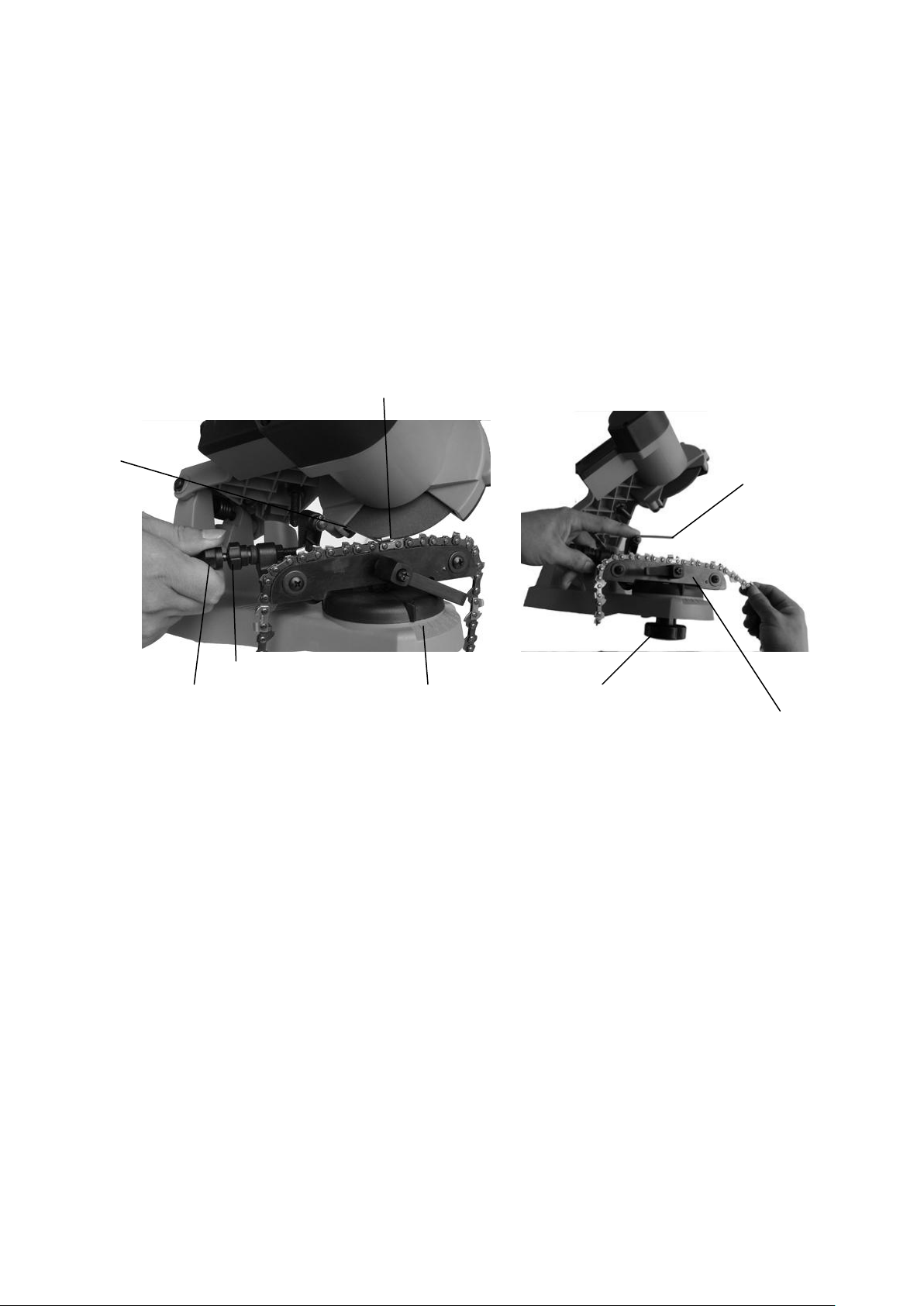

1. .

2.

3.

.

4. (#11).

5. (#8) .

6.

7.

8.

9.

10.

: