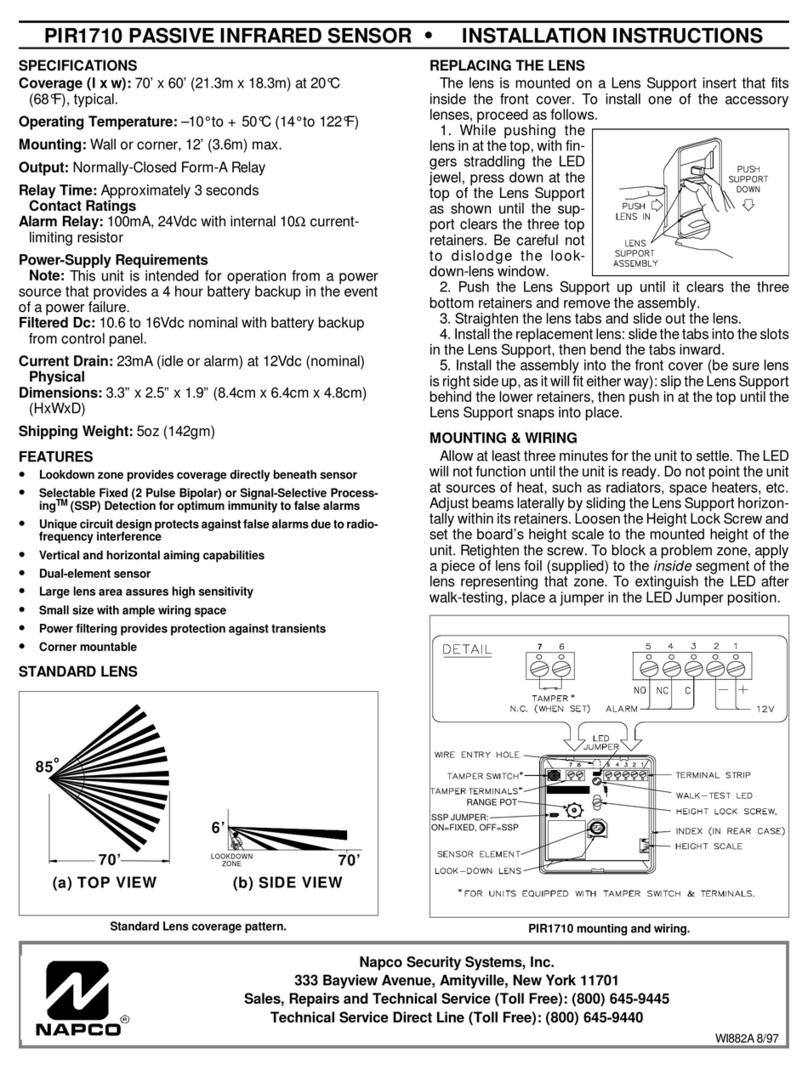

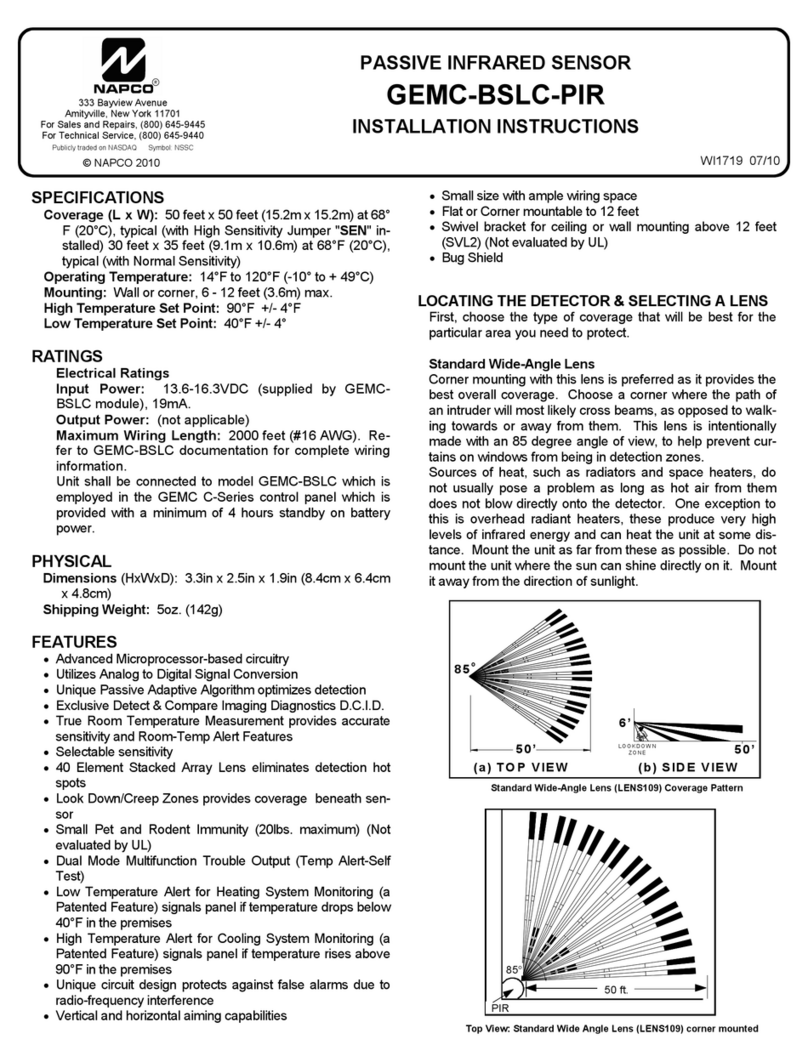

CHANGING THE LENS

The lens is “sandwiched” between the front

case and a Lens Support Insert, which also

servesto hold the LED jewelinplace. Toinstall

one of the accessory lenses, proceed as fol-

lows.

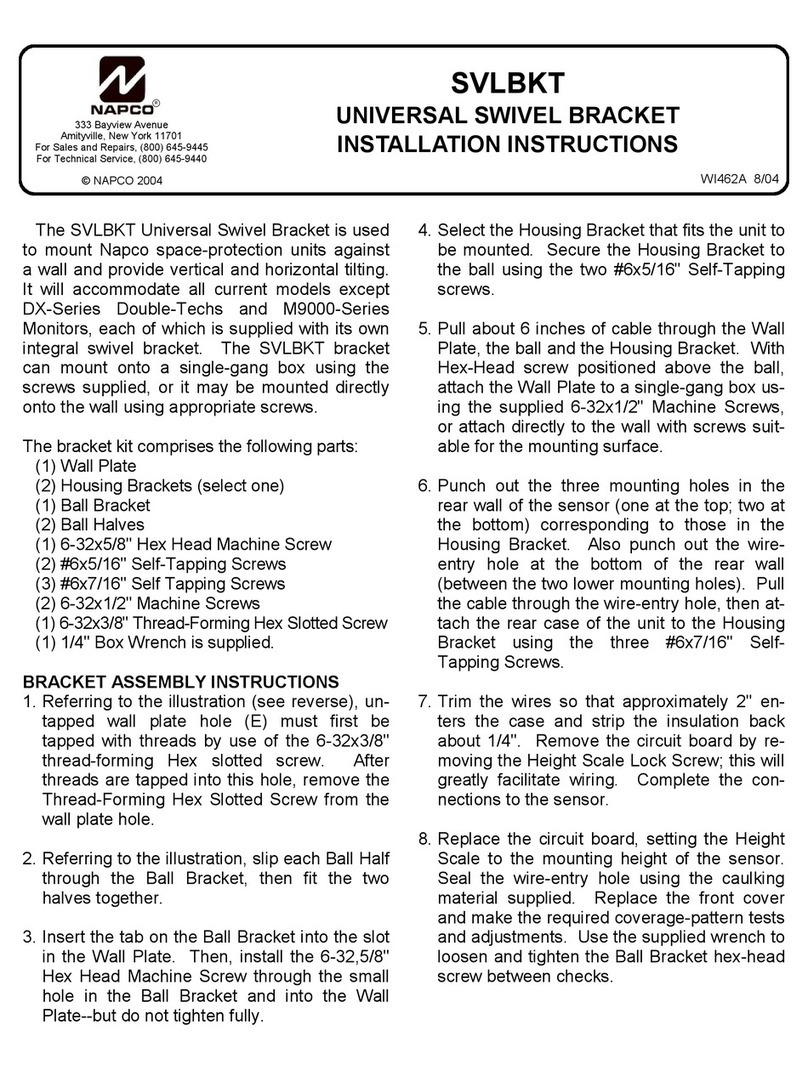

1. Push up on the lower edge of the Lens

Support (see Fig. 3) until it is clear of its retain-

ers, then pull out the Lens Support from the

bottom. Be careful not to dislodge the LED

jewel. Note: If the jewel pops out, re-insert it

with the small index key positioned at the top.

2. Slide out the lens and install the replace-

ment correctly oriented.

3. Replace the Lens Support: Slip the Lens Support under the top lens

guides with its two tabs straddling the LED jewel, then push in at the bottom

until the Lens Support snaps into place.

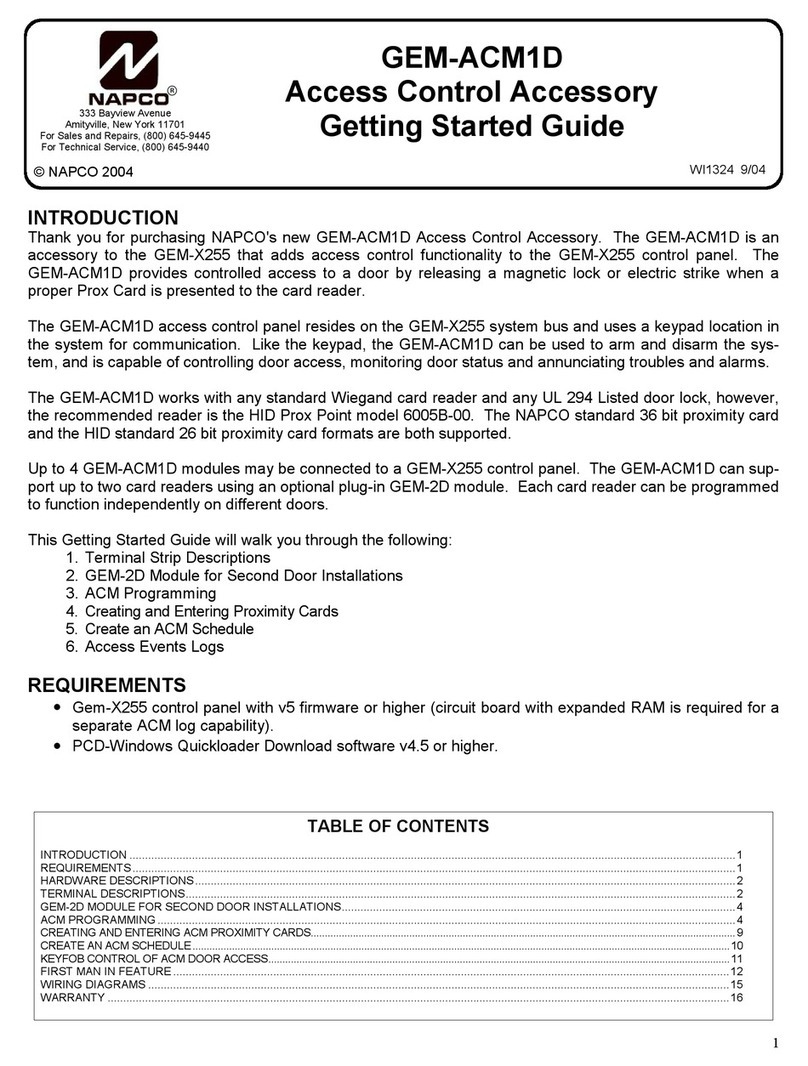

WIRING

Removethewireentryhole(seeMOUNTINGTHE SENSOR)to gainaccess

to the terminal strip. (Be sure to caulk around the wires where they exit the

case; see previous Note.) Route wires to the terminal strip as shown in Fig.

4 and connect as follows:

Power (Terminals 1 [+] & 2 [–]). Apply 12Vdc to Terminals 1 [+] and 2 [–].

The power source may be regulated or unregulated. Power should be

suppliedfromacontrolpanelorotherpowersourceequippedwitharecharge-

ablebatterybackuptomaintainoperationintheeventofapowerfailure.Refer

to SPECIFICATIONS for power-supply requirements.

Alarm Relay (Form A) Contacts (Terminals 3 & 4). These contacts are

rated at 100mA, 24Vdc and are normally closed. When the sensor is operat-

ing,eitherdetectionofan intruderorlossofpowerwillcausetherelaycontacts

to open. (This mode of operation is required in UL installations.)

Alarm Relay (Form C) Contacts (Terminals 3, 4 &5). These contacts are

ratedat 100mA, 24Vdc.Terminal 4is common. Terminal3 isnormallyclosed;

Terminal 5 is normally open. When the sensor is operating, either detection

of an intruder or loss of power will cause the relay to trip. (In UL installations,

normally-closed terminals (3 and 4) must be used.)

Status (Form-A Version only) and Trouble (Where equipped)

Wiring to Terminals 5 (Status) and 6 (Trouble) are only required if using the

specialfeaturesof thisunit. Refer toADVANCED FEATURES andthe Wiring

Diagrams at the back.

Status Input (Form-A Version only, Terminal 5). Connect to the Status

terminal (Arm Lug) of the control panel. A low at Terminal 5 tells the sensor

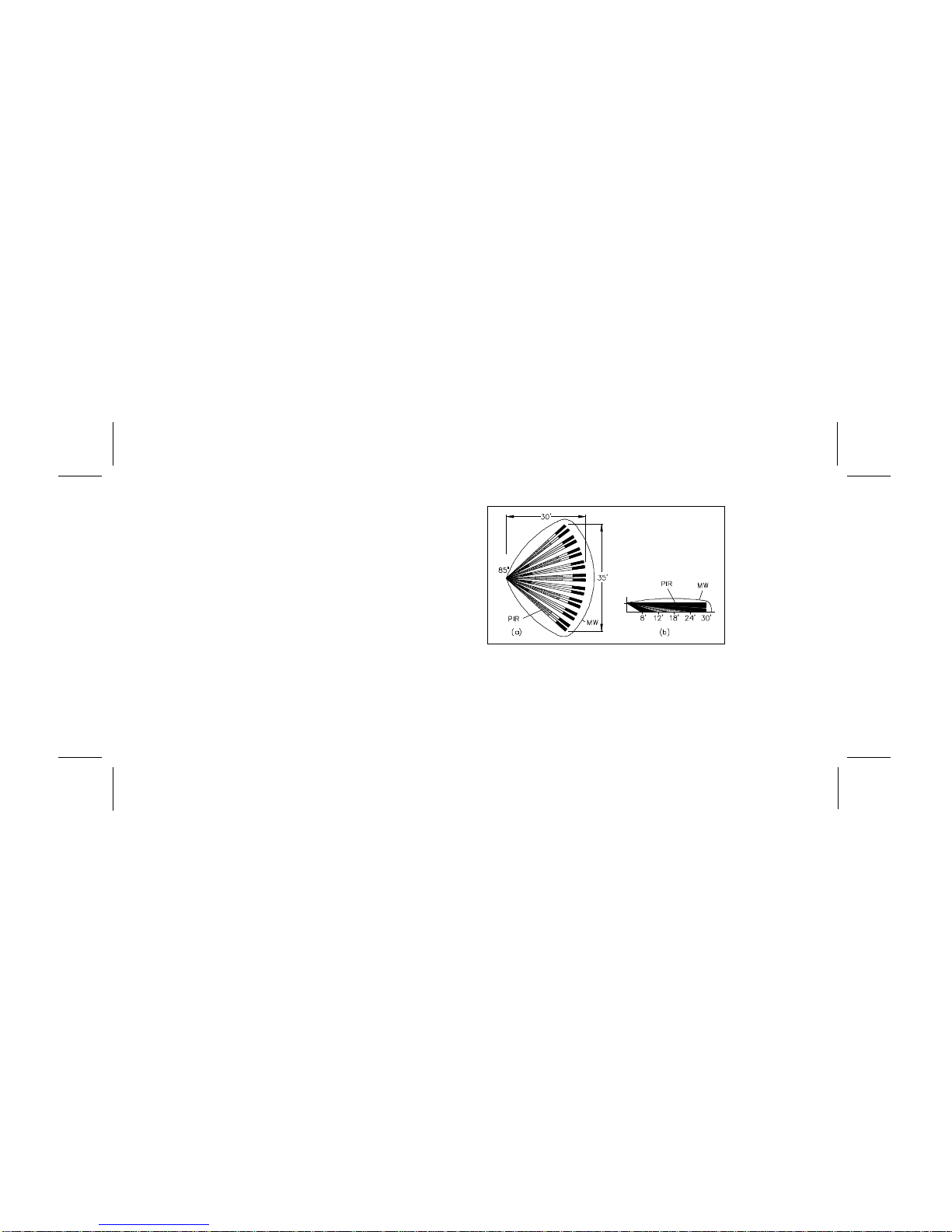

Fig. 3. Removing the

8