napcopipe.com 4

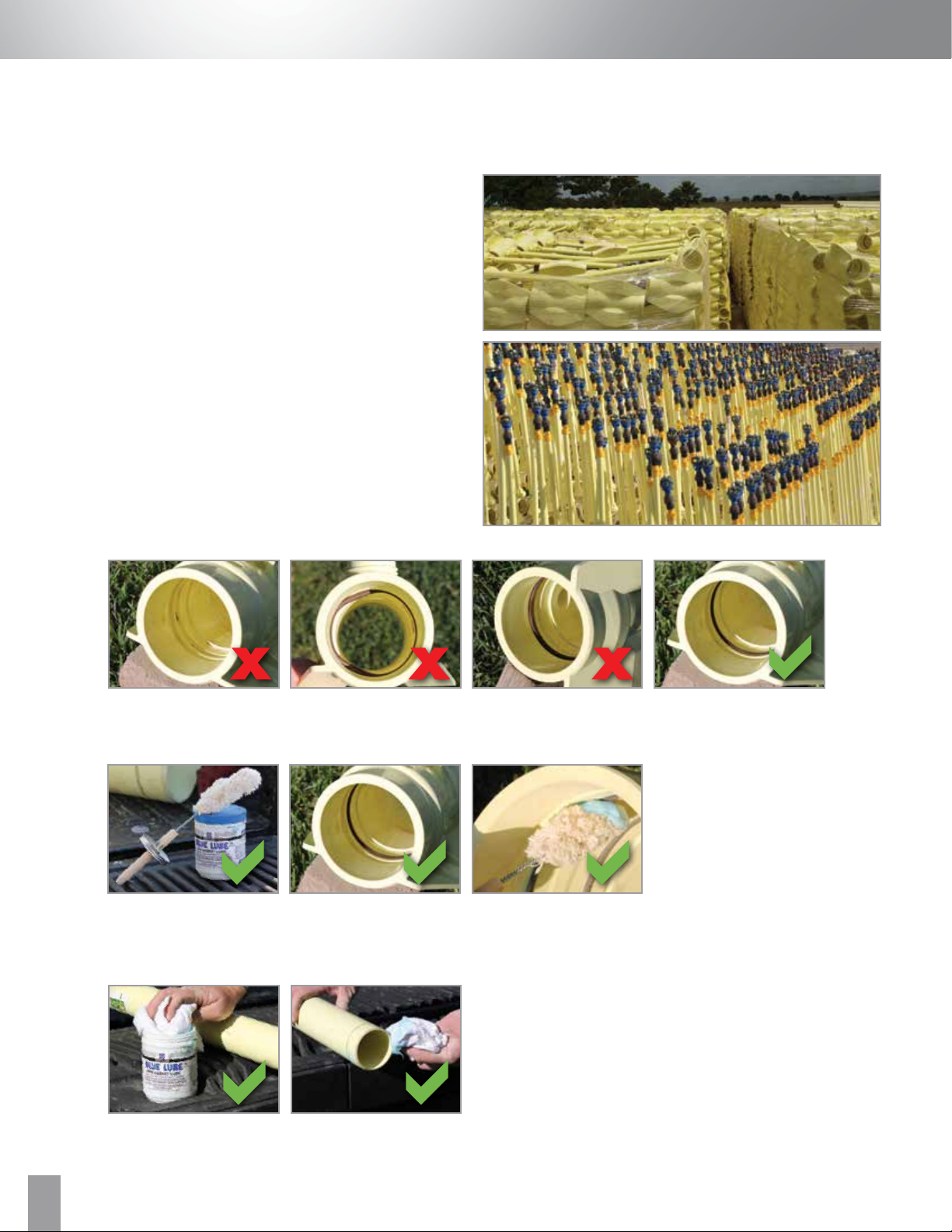

2. Insert chevron gasket into sled coupling “open side down” without lubricant. Screw ½" riser cap (clockwise) until

it is hand tight and seated.

3. Insert ½" riser and turn until the hook is engaged against the stop. Hand tighten until it is seated. No tools are

required. Do not overtighten.

4. Once riser and coupling are assembled, attach the sprinkler to the sprinkler end of the riser.

In-correct gasket positioning Align gasket with the sled

coupling before inserting the

gasket into the top opening

Hand tighten riser capCorrect gasket positioning

Align riser with riser cap Hook engaged with stopRotate riser

Place [MRDC] [MR] or [MDC]

onto riser first

Place sprinkler head onto

[MRDC] [MR] or [MDC]; hand

tighten

Place [MRDC] [MR] or [MDC]

onto riser first

Notes:

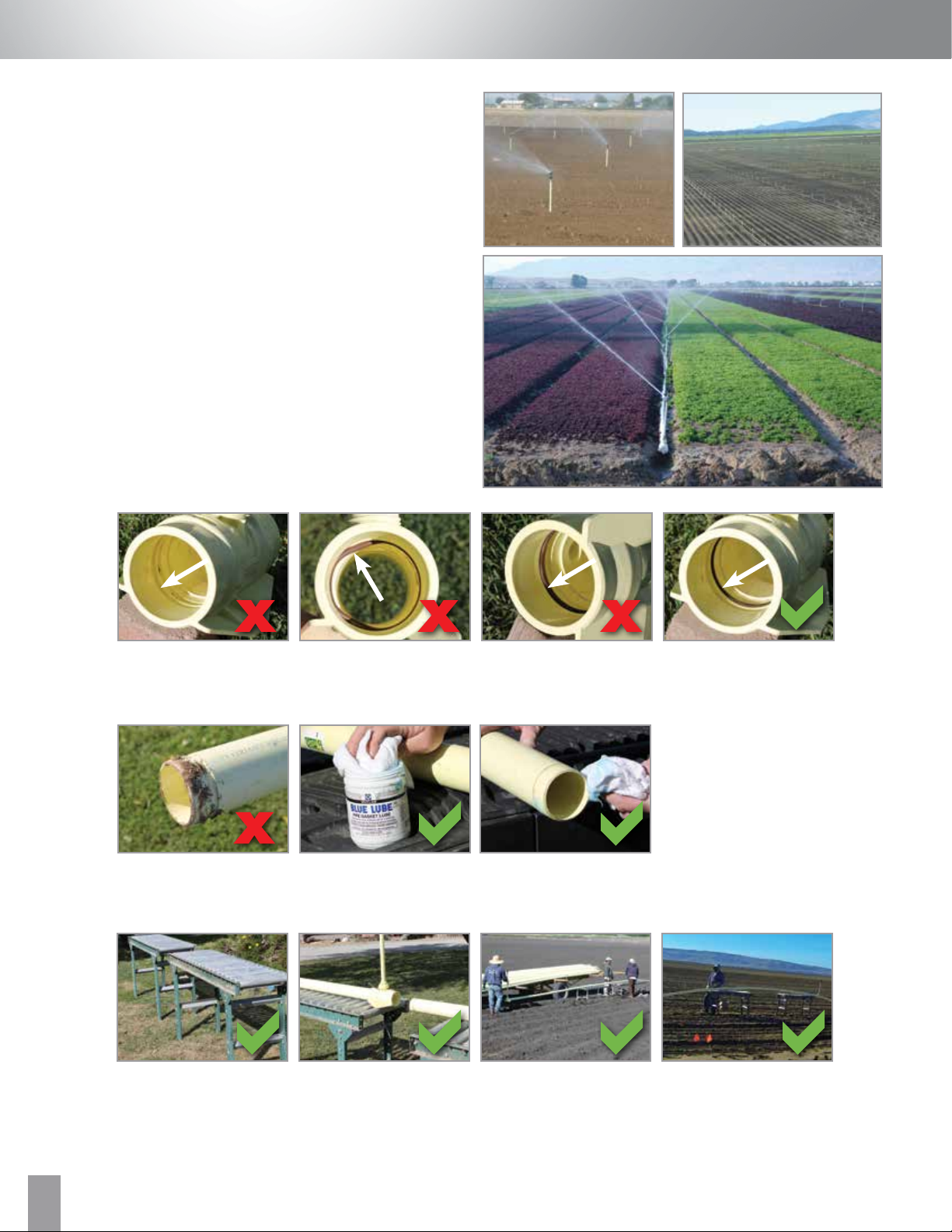

1. Splines should be inserted the same direction to facilitate the removal of the splines when the pipe is removed from

the field with the automatic pipe removal system. Please refer to the Field Layout Planning Guide and the Lateral

Field Installation sections.

2. All 1/2" riser stubs below the quick disconnect hook must be a minimum of 2.25" in length to ensure full

engagement of the coupling boss for proper riser support. Riser OD shaft specification 0.840 +/- 0.010". Maximum

height for the riser is 36 inches when used with rotator sprinklers and 24 inches when used with impact sprinklers.

When using a riser that is higher than the stated dimensions, it is recommended that stakes be utilized to stabilize

the system.

7. Load the assembled 3" Certa-Set piping onto the trailer to transport to the field.

Please refer to the Lateral Field Installation section for additional information.