INSTRUCTIONS BOOK OF WELD POSITIONER TS10 2

INDEX

1. CHARACTERISTICS OF THE MACHINE ...............................................................................

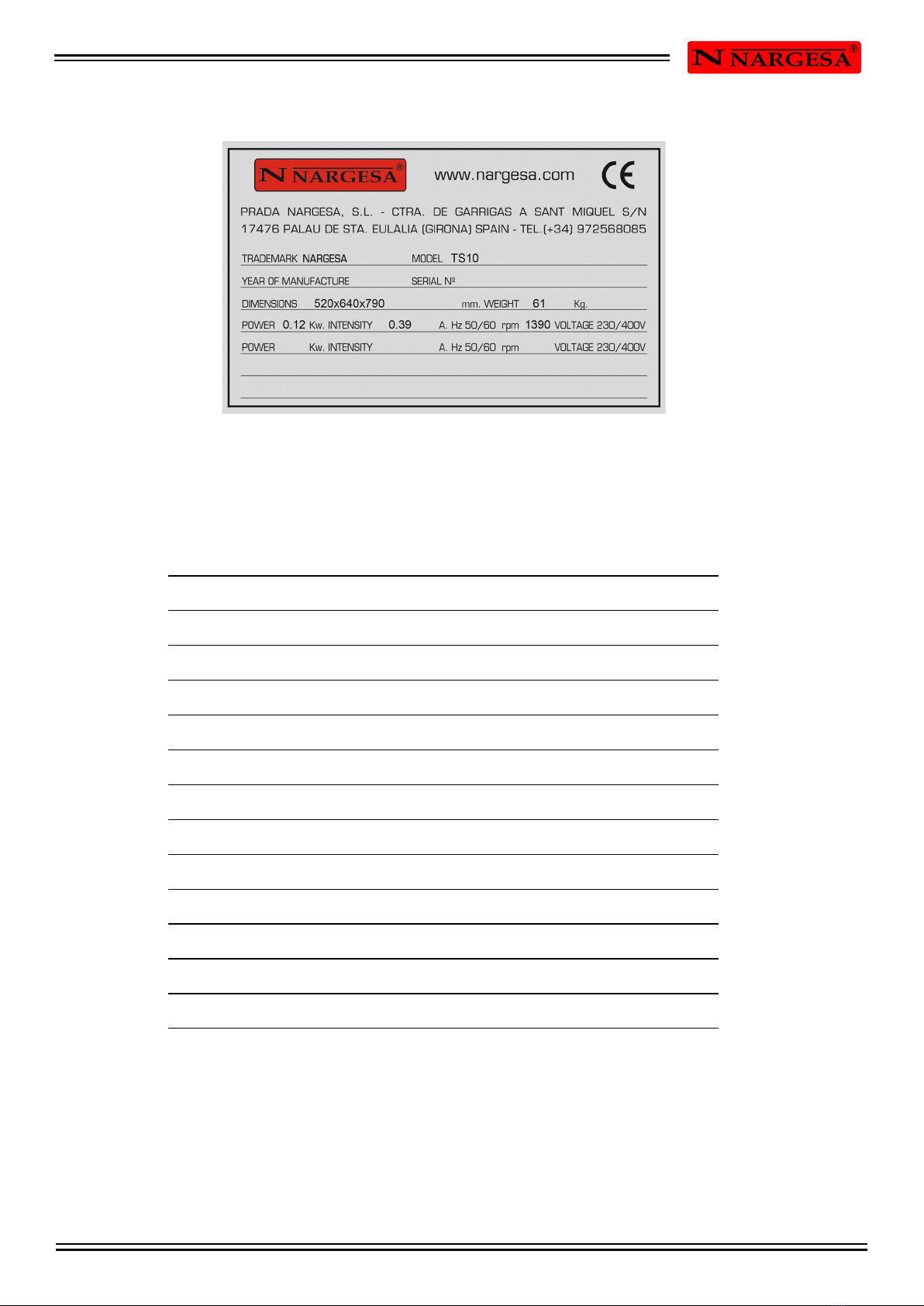

1.1. Identification of the machine .......................................................................................

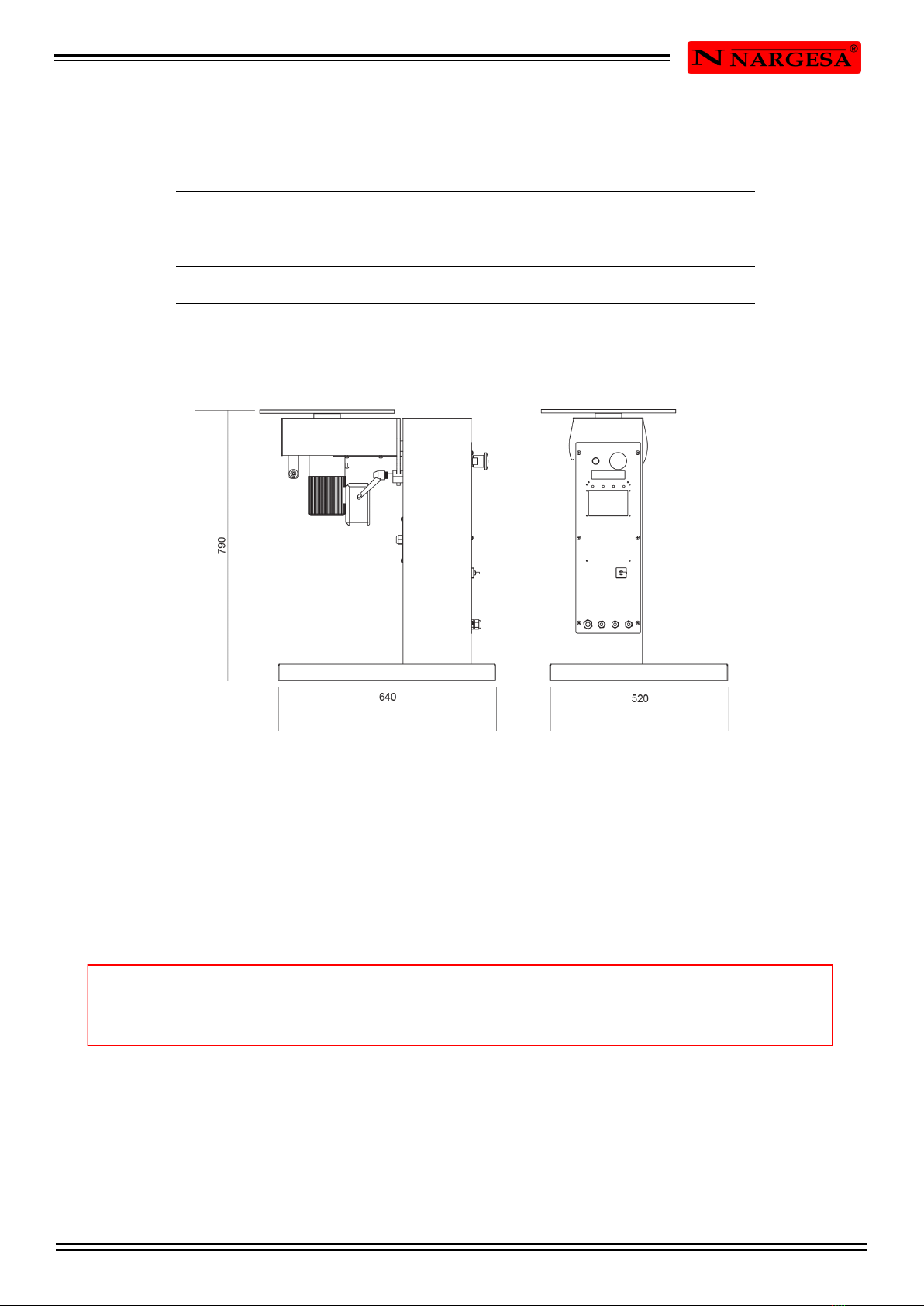

1.2. Dimensions .................................................................................................................

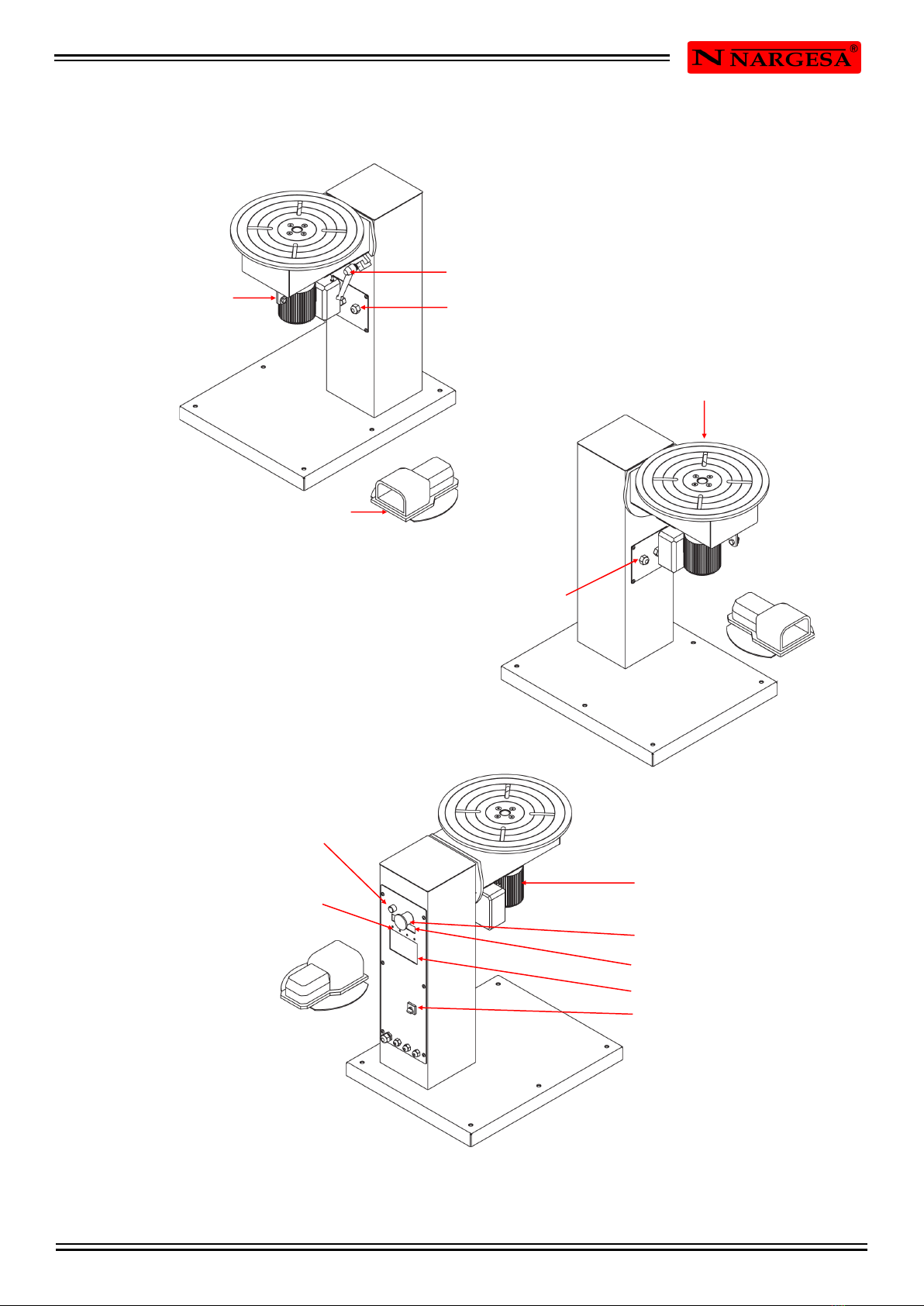

1.3. Description of the machine ..........................................................................................

1.4. Identification of the components .................................................................................

1.5. General characteristics ...............................................................................................

2. TRANSPORT AND STORAGE ...............................................................................................

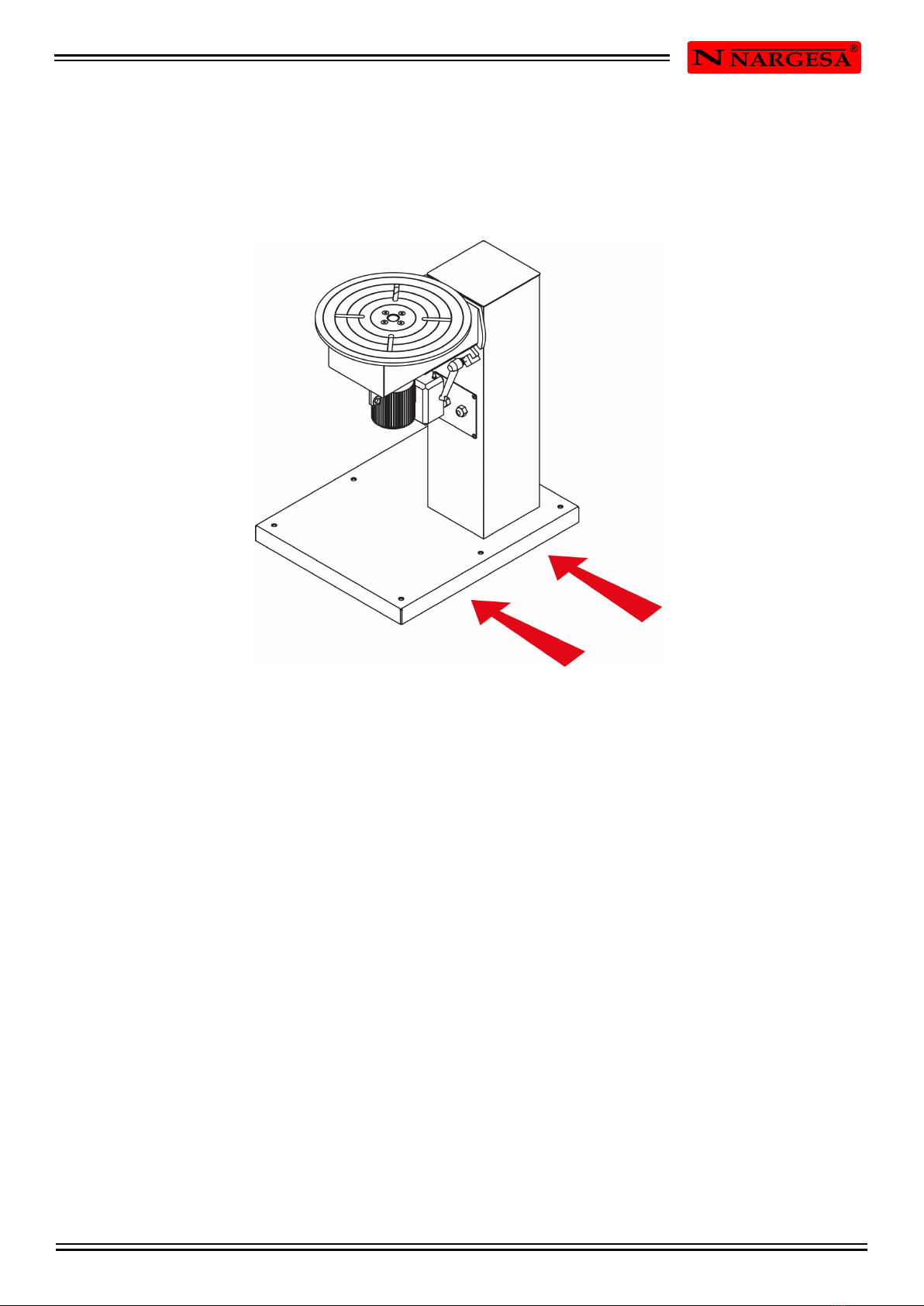

2.1. Transport .....................................................................................................................

2.2. Storage conditions ......................................................................................................

3. INSTALMENT AND STARTING UP ........................................................................................

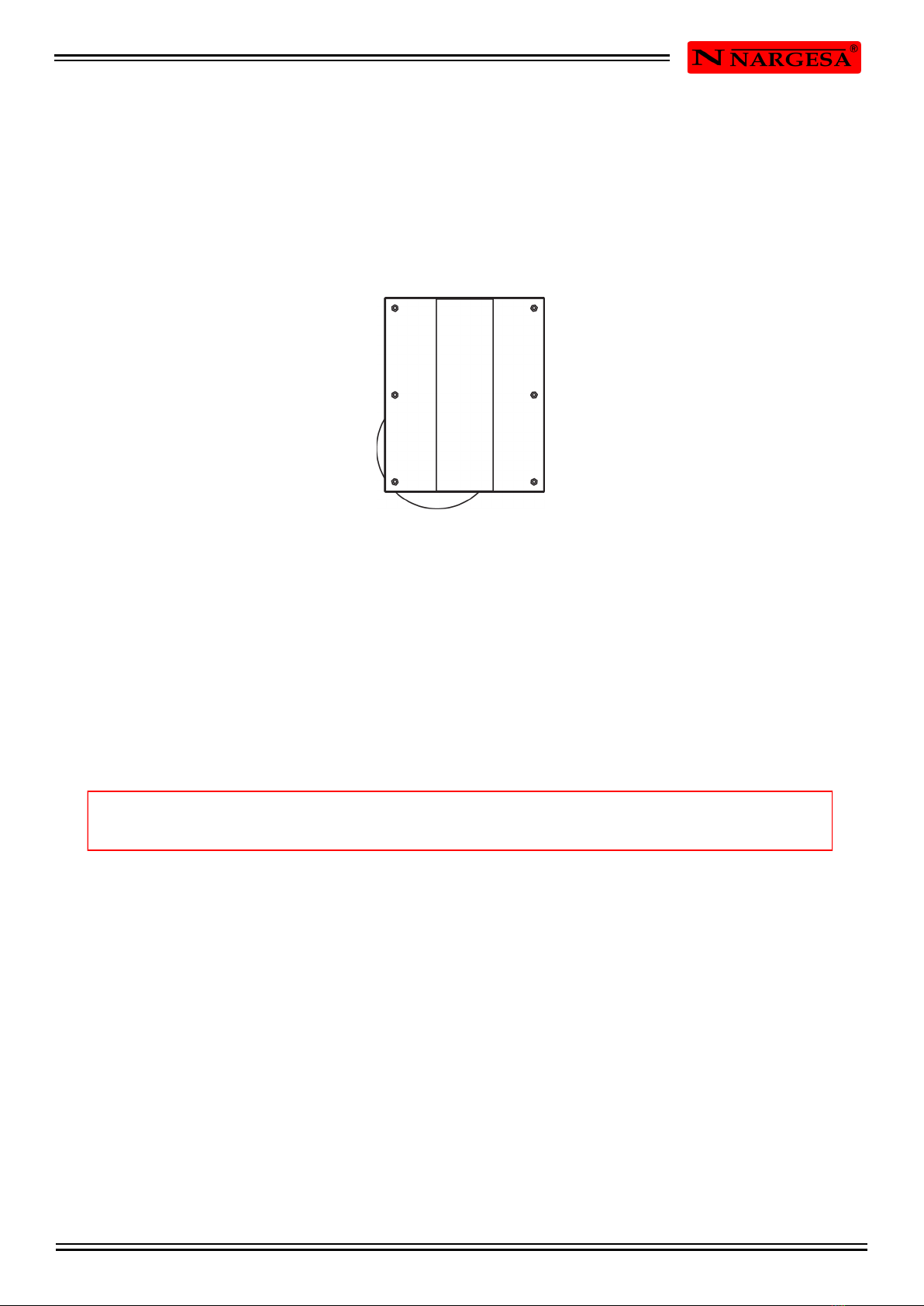

3.1. Location of the machine ..............................................................................................

3.2. Admissible outer conditions ........................................................................................

3.3. Connection to the power supply ..................................................................................

4. INSTRUCTIONS FOR USE .....................................................................................................

4.1. Panel description .........................................................................................................

4.2. Introduction .................................................................................................................

4.3. Feeding of the Positioner TS10 ...................................................................................

4.4. Activation of the Positioner TS10 ................................................................................

4.5. Memories of continous welding ...................................................................................

4.6. Memories of discontinous welding ..............................................................................

4.7. Robot mode .................................................................................................................

4.8. Memories of continous welding at robot mode ............................................................

4.9. Memories of discontinous welding at robot mode .......................................................

5. WARNINGS .............................................................................................................................

TECHNICAL ANNEX

3

3

3

3

4

5

6

6

6

7

7

7

7

8

8

10

10

10

11

12

14

15

16

19