Table of Contents

3

Table of Contents .......................................................................................................................................................... 3

Features and Specications......................................................................................................................................... 4

Safety.............................................................................................................................................................................. 6

General Rules for Safe Operation ......................................................................................................................... 6

Recommended Electrical Practices ....................................................................................................................... 7

Main Controls and Components .................................................................................................................................. 8

Operation...................................................................................................................................................................... 10

Unpackaging ........................................................................................................................................................ 10

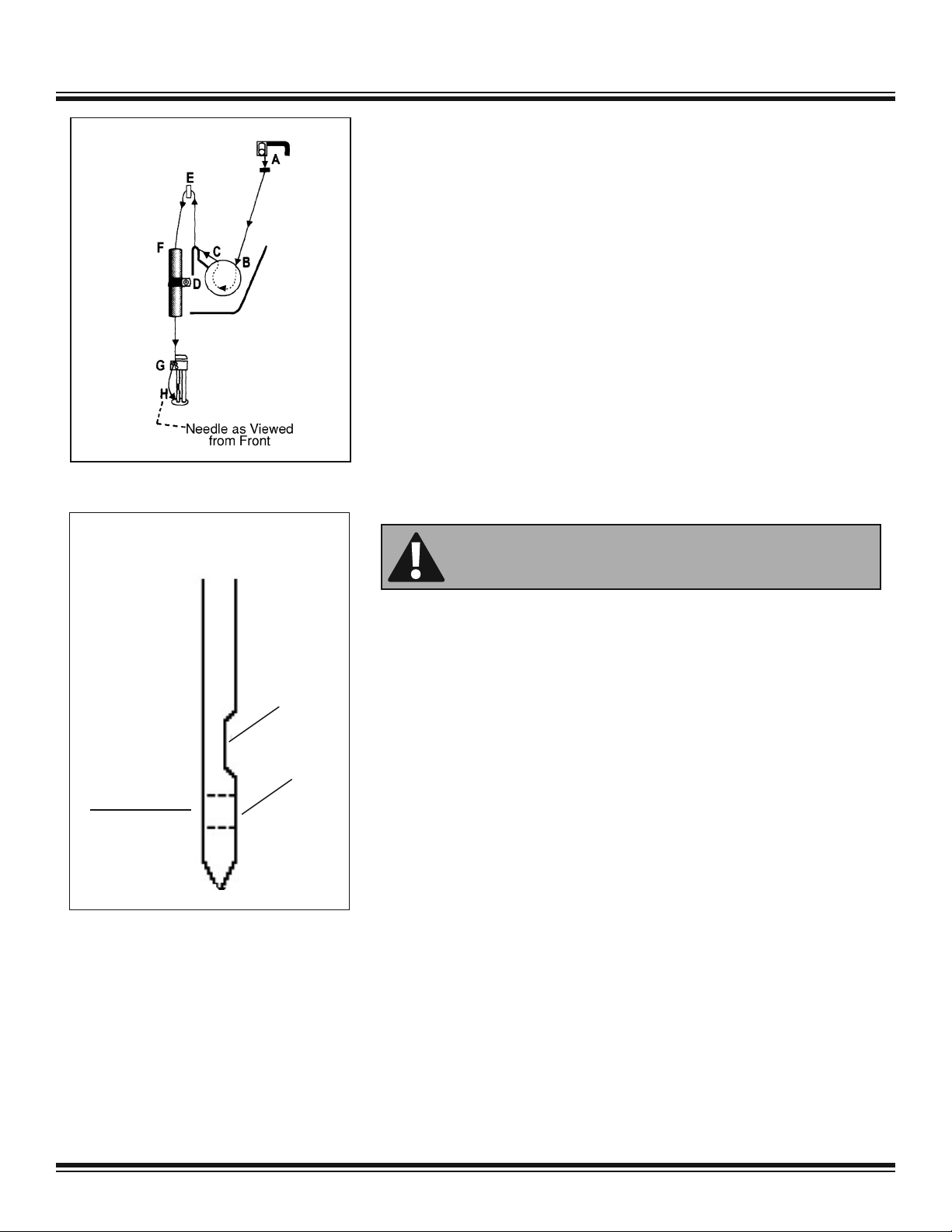

Threading the Machine ........................................................................................................................................ 10

Thread Tension .................................................................................................................................................... 12

Proper and Improper Thread Tension .......................................................................................................... 12

Upper Thread Adjustment ............................................................................................................................ 12

Lower Thread Adjustment ............................................................................................................................ 12

Installation and Threading of Binding Tape .................................................................................................. 13

Stitching ............................................................................................................................................................... 14

Changing Between Zigzag and Straight Stitch Modes ................................................................................ 14

Preparing to Stitch ....................................................................................................................................... 14

Stitching ....................................................................................................................................................... 14

Stitching Around a Corner............................................................................................................................ 15

Removing Carpet ......................................................................................................................................... 15

Important Points........................................................................................................................................... 15

Binding Corners .................................................................................................................................................. 16

Outside Corners........................................................................................................................................... 16

Inside Corners ............................................................................................................................................. 18

Folder Options ..................................................................................................................................................... 20

Operating Tips ..................................................................................................................................................... 21

Maintenance................................................................................................................................................................. 22

Lubrication ........................................................................................................................................................... 22

Needle Height Adjustment ................................................................................................................................... 23

Needle-To-Driver Setting & Race Cover Spring Clearance ................................................................................. 24

Folder Adjustment ................................................................................................................................................ 25

Troubleshooting Guide ............................................................................................................................................... 26

Complete Parts List..................................................................................................................................................... 28

Accessories & Attachments ....................................................................................................................................... 30

Warranty ....................................................................................................................................................................... 33