www.stingerworld.com

CS150ST Cap Stapler

CS150ST

IMPORTANT INFORMATION

AIR SUPPLY AND CONNECTIONS

•!Use only clean, regulated compressed air as a power source for this tool. Do not use bottle gases, combustible

gases or oxygen as a power source for the tool as the tool may explode.

•!Do not use air supply pressures that exceed 110 PSI (7.7 bar). Exceeding the recommended maximum operating

air pressure will greatly increase tool wear.

•!The air supply must be capable of maintaining the operating air pressure of the tool. Pressure drops in the air

supply can reduce the tool’s driving power.

•!Use a pressure regulator and gauge to allow visual inspection of the air pressure being delivered to the tool.

•!Use air hoses that have rated pressures of up to 150% of the maximum pressure that can be generated by the

power source. The supply hose should contain fittings that will provide quick disconnecting from the male plug on

the tool.

•!Use quick connect fittings that allow the tool to be unhooked from the air supply quickly and easily.

•!Do not use fittings that will not allow the tool to exhaust when the air supply is disconnected.

2

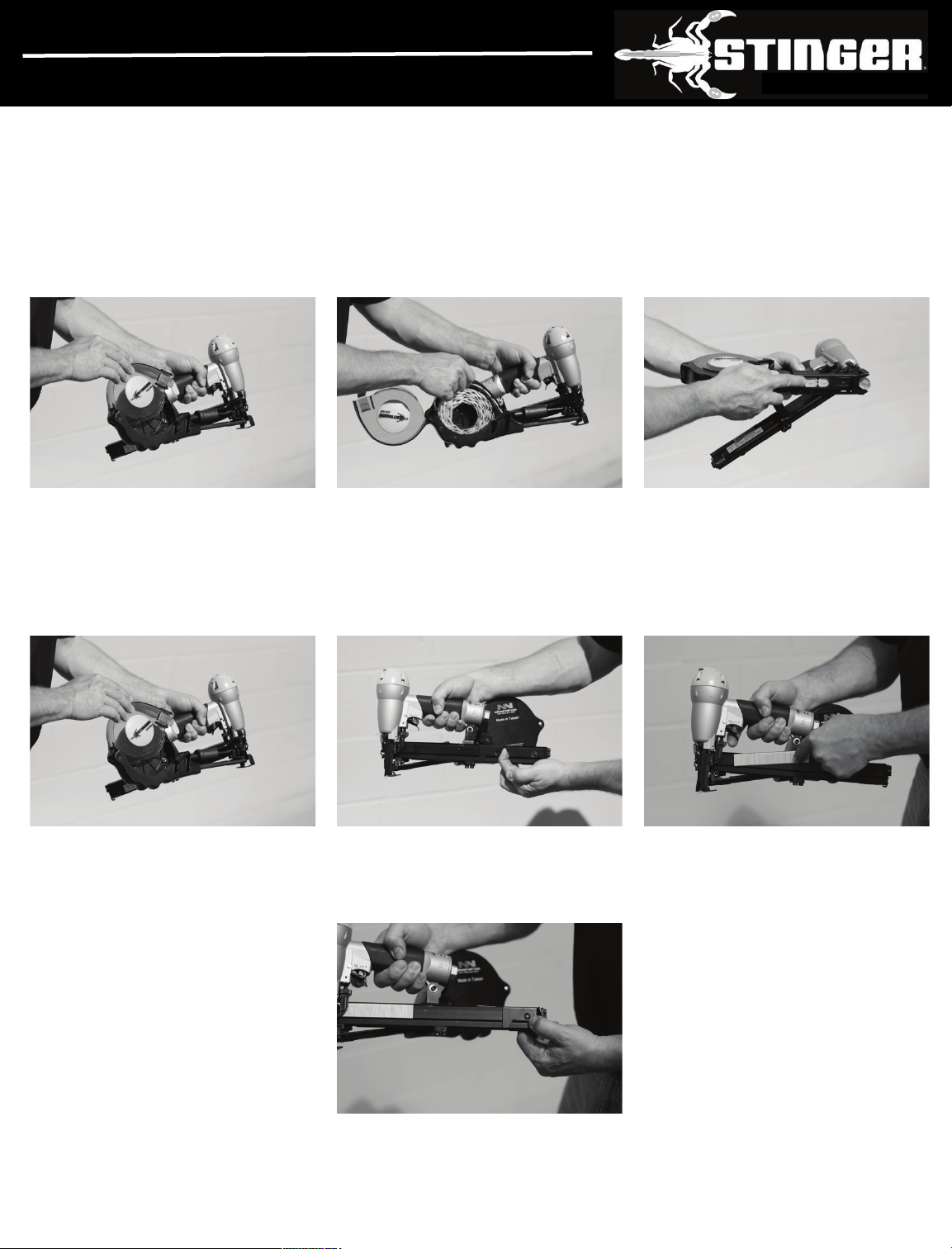

OPERATION OF THE TOOL

•!Never inspect, maintain, repair, adjust, clear a jam or store the tool with the air connected.

•!Never use the tool in proximity of flammable gases or liquids, as some tools will create sparks that can be an

ignition source for a fire or explosion.

•!Always inspect the safety device for damage and proper operation prior to operation.

•!Never assume the tool is empty of fasteners.

•!Never point the tool toward yourself or any other persons.

•!Never cycle the tool unless it is in contact with the work-piece.

•!Never use the tool as a hammer or wedging device or drop to the floor from any height.

•!Always remove your finger from the trigger when pausing from cycling.

•!Never tamper with the safety device or use the tool if the safety device is not functioning properly.

•!Use only 7/8”/22.1mm, 1-1/4”/31.75mm, or 1-1/2”/38.1mm STINGER StaplePac®cap fasteners or STINGER

Collated Plastic Caps with 5/8”/15mm AERFAST®aluminum staples in the STINGER CS150ST Cap Stapler.

Never use any fasteners that are not specified for use in this tool. The CS150ST holds 1 coil of plastic caps (200

caps) and 2 strips of staples (100 staples each).

!