9

Before beginning installation of your deck, you will need the following:

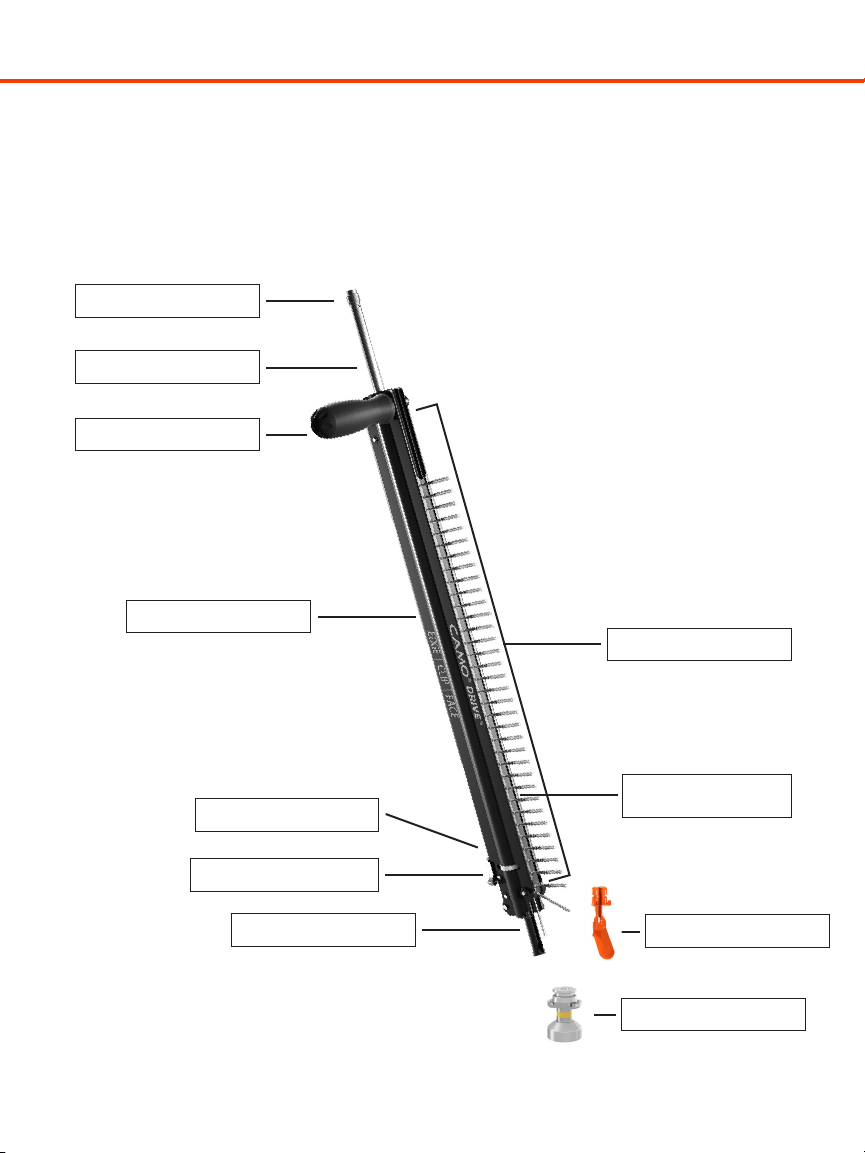

• CAMO®DRIVE™Tool

• CAMO®Collated Fasteners

• Driver Drill (Corded or cordless)

• Optional: Secondary Spacers if a gap is desired

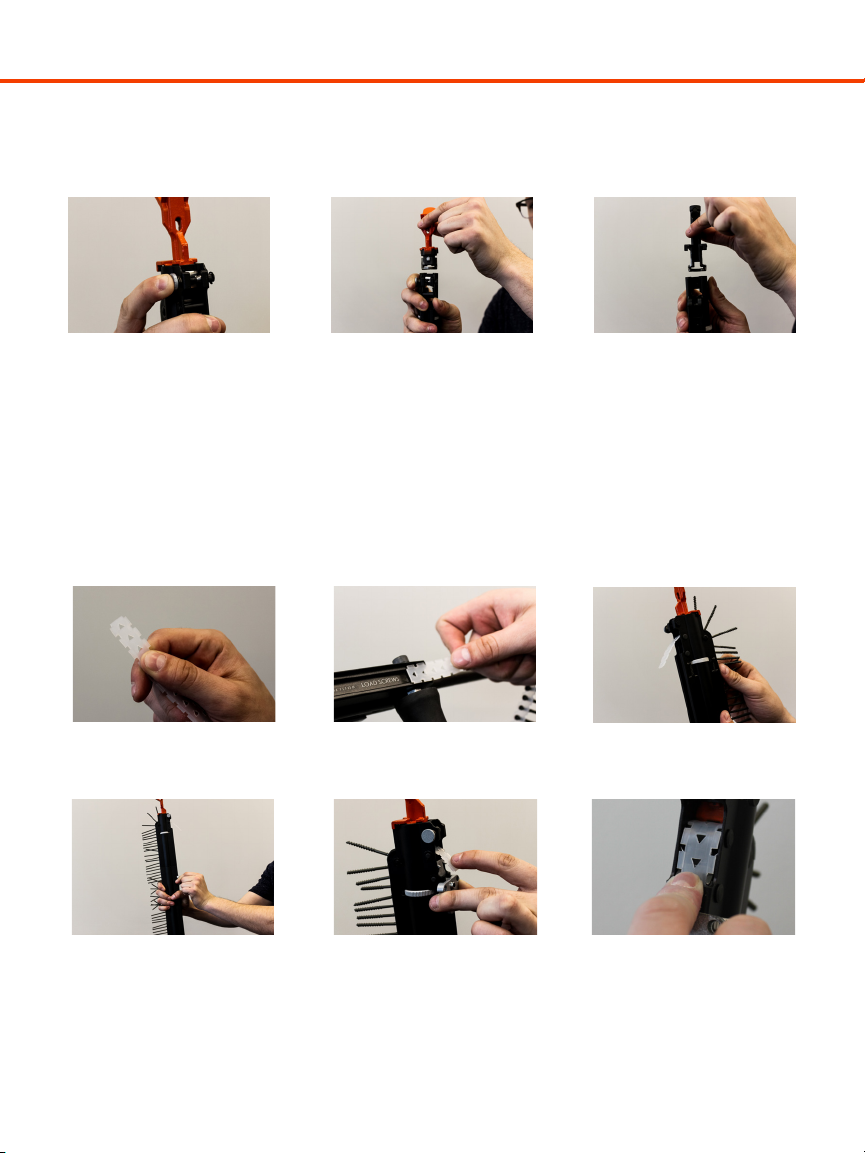

DRIVE tool setup:

• Make sure you have a T15 DRIVE bit installed in the DRIVE tool. The T15 bit is identified with a yellow and orange color

band on the bit.

• Attach the edge guide on the DRIVE tool (see changing the guide section on page 7).

• Drill clutch setting: If your driver drill has a clutch setting it should be in “drill or maximum torque” setting position.

FASTENER INSTALLATION - EDGE SCREW

Edge Screw Fastening with the DRIVE™enables you to install a beautiful fastener-free deck surface at an incomparable speed.

Engineered for no gap installation of treated lumber. If gapped installation is desired, use secondary spacers.

Gap Options:

The CAMO®DRIVE™allows for multiple gap options when installing deck boards. For wet treated lumber, the zero gap option

allows builders to butt deck boards tightly together. If a gap is desired, secondary spacers may be used between the boards.

Board Installation:

To begin deck installation, lay the first board that abuts the structure into position. Starting with the outside edge of the board,

fasten the deck board at each joist using the CAMO®DRIVE™as follows:

For the outer board end of the deck board, align the Edge Guide with the joist below the deck board (a minimum of 1’’ from

board ends). Place the nose of the DRIVE™tool so that the Edge Guide is flat to the board surface, with the Edge Guide tight to

the board edge.

Using the Tool Handle, apply downward pressure to make sure that the nose stays firmly in position with the board edge

throughout the drive process.

While maintaining positive pressure on the DRIVE™tool, push the Driver Drill down to engage the bit and screw. Depress the

drill trigger and, running the drill at full RPM, drive the screw applying pressure throughout. DO NOT FORCE THE SCREW. Allow

the Edge screw to spin and auger the surface. After a moment, the screw will grab and pull into the board. The drill and tool

will be fully compressed when the screw is fully seated. When driven fully and correctly, the finished position of the Edge screw

should be just below the surface of the edge. It should not protrude from the side of the board. (Adjust if necessary.)

Once the fastener is driven, retract the driver drill fully allowing the next screw to be pulled into place for driving. The next

fastener will automatically be loaded into drive position. Repeat down the length of the board.

Place the next deck board in position and push tight to the board abutting the structure. Repeat process above.

For the inside edge of the deck board, align the Edge Guide with the joist below the deck board, positioning the Edge Guide

between the two adjoining deck boards. Make sure that the Edge Guide is parallel with the surface of the deck board and

the Edge Guide is firmly against the radius of the edge of the deck board. Maintain firm pressure against the deck board

throughout the drive process.

Repeat down the length of the board until the board is secured at every joist and both sides of the board.. Do not skip any

joists. Repeat for remaining deck boards.

Visit www.camofasteners.com/videos for video instructions.