10 11

www.vexve.com

3.2. Drilling

When starting the drilling, i.e. when drilling the pilot hole, use high RPM (460 RPM), area 2 and scale F.

Feed the drill through steadily and smoothly. During drilling, it is recommended to keep the draining valve

open to remove the cuttings.

Stop after only drilling through with the pilot drill bit. Adjust the speed of rotation area (1 or 2) and scale

(A-F) for the actual hole cutting and close the draining valve.

Feed the hole saw through steadily and smoothly. During cutting, you may keep the draining valve open;

close it after finishing.

Release the shaft locking mechanism and slide the shaft to its outermost position (due to pressure in

the valve, the shaft slides out automatically), then close the hot tapping valve. Open the draining valve to

release the pressure from the hot tapping valve.

WARNING: Before releasing the shaft’s locking mechanism, move your head away from

shaft’s end to avoid impact. The shaft will slide out rapidly under water pressure.

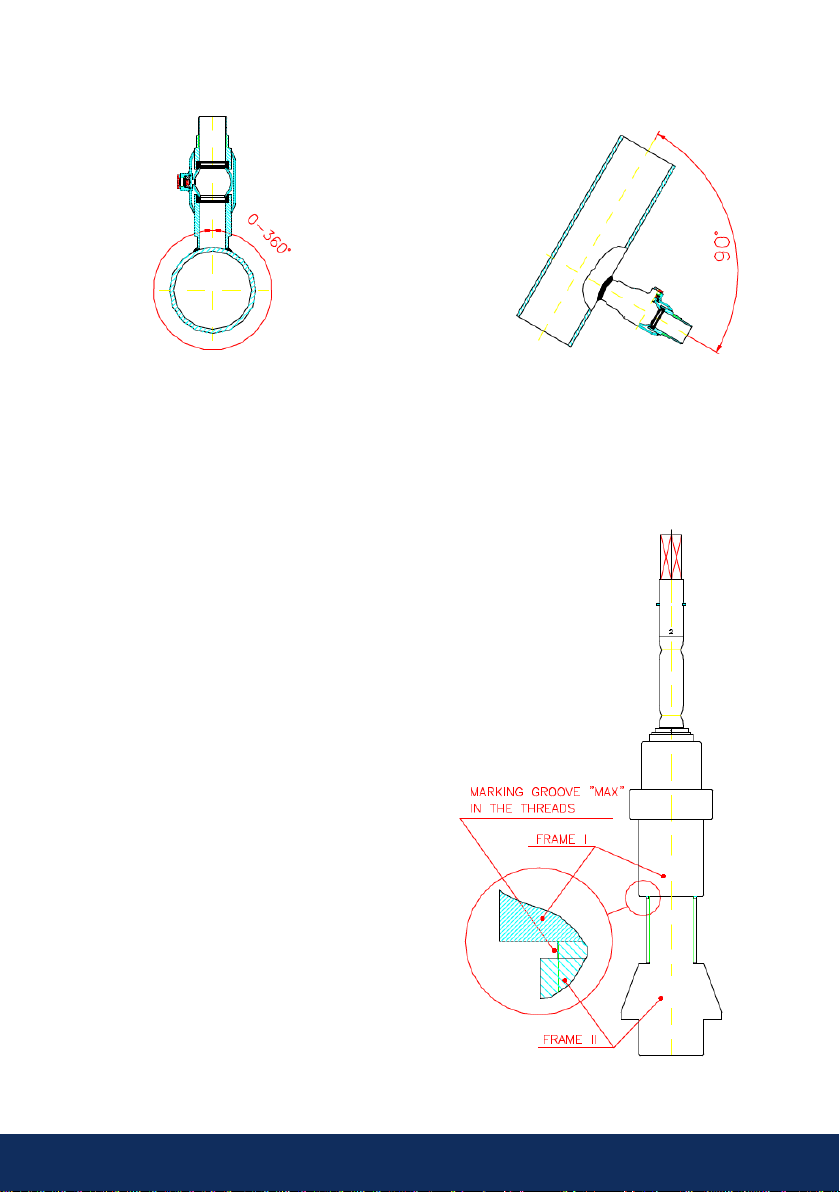

NOTE: Before removing the drilling tool from the hot tapping valve, make sure that the valve

is fully closed; check the markings at the stem. The tightness of the hot tapping valve must

be verified by using the draining valve: no water must flow through the draining valve after the

hot tapping valve is closed.

After the drilling is finished, it is important to clean the hot tapping tool from any metal chips and other

impurities that have come in the drilling process.

Disassemble the hot tapping drill: first, remove the draining valve and after that remove the tool (incl.

adapter) from the hot tapping valve. Then disassemble the drill in the reverse order as you had assembled

it.

Closing the stem by welding: If required, the stem can be permanently closed by welding. Remove the

PTFE sealing underneath the cap before welding.

3.3 Technical criteria for power drill

We recommend the following power drills:

Milwaukee PD2E 24RS

AEG SB2E 1200 RST

If you use another drill, make sure that it fulfills the following criteria:

· input power min. 1000 W

· speed of rotation areas: Area 1: 0 – 1000 RPM Area 2: 0 – 3000 RPM

· required speed adjustments are available for dierently-sized hole saws

· the drill’s neck diameter must be 43 mm

NOTE: If you select another brand or model, please check with the manufacturer that it fulfills

above mentioned criteria.