BWG-SERIES OPERATION & MAINTENANCE MANUAL

12838 Stainless Drive, Holland, MI 49424 Phone: 616/399-5600 Fax 616/399-3084

Copyright 2018 BRAWN Mixer www.BRAWNMIXER.com Page 1 of 11

11/27/2018

CONTENTS

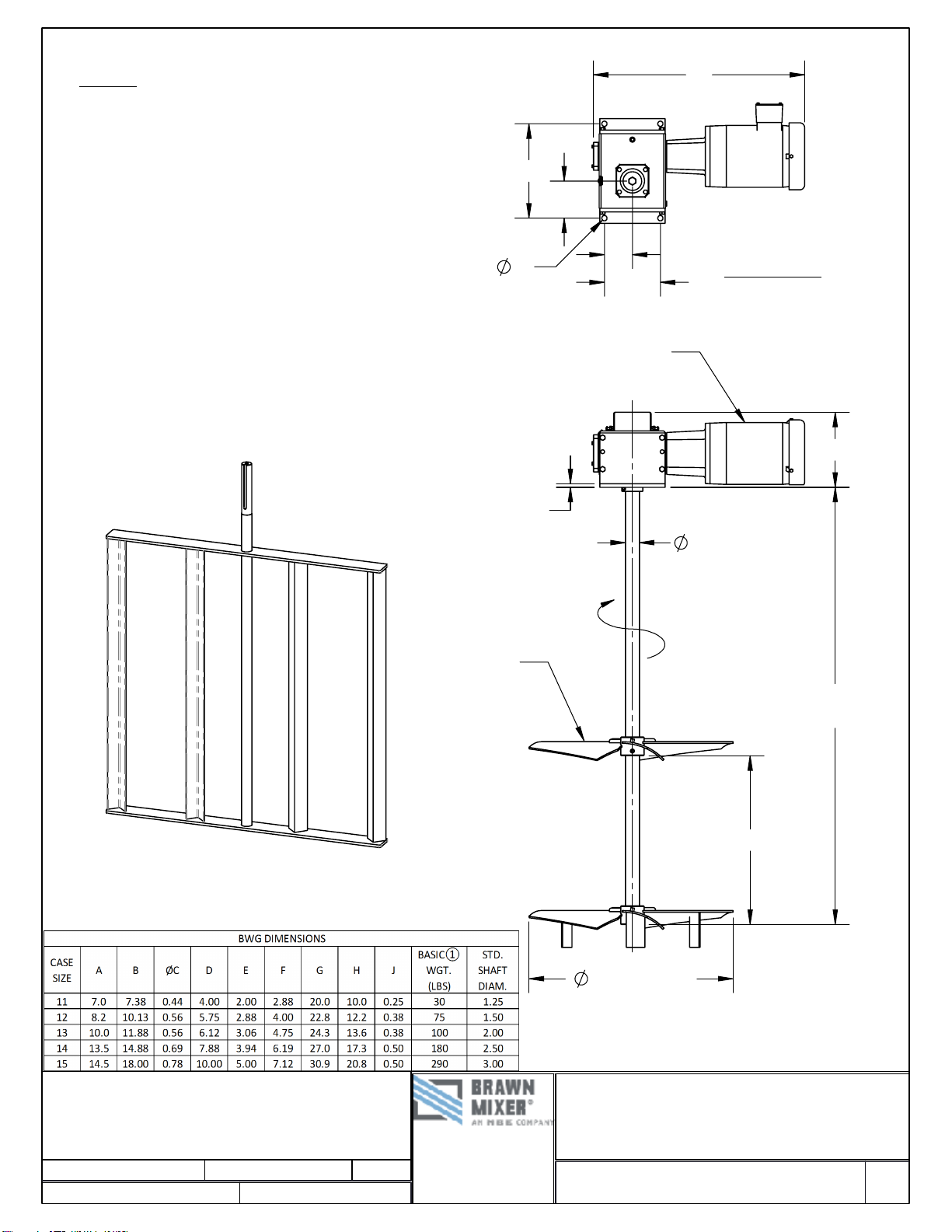

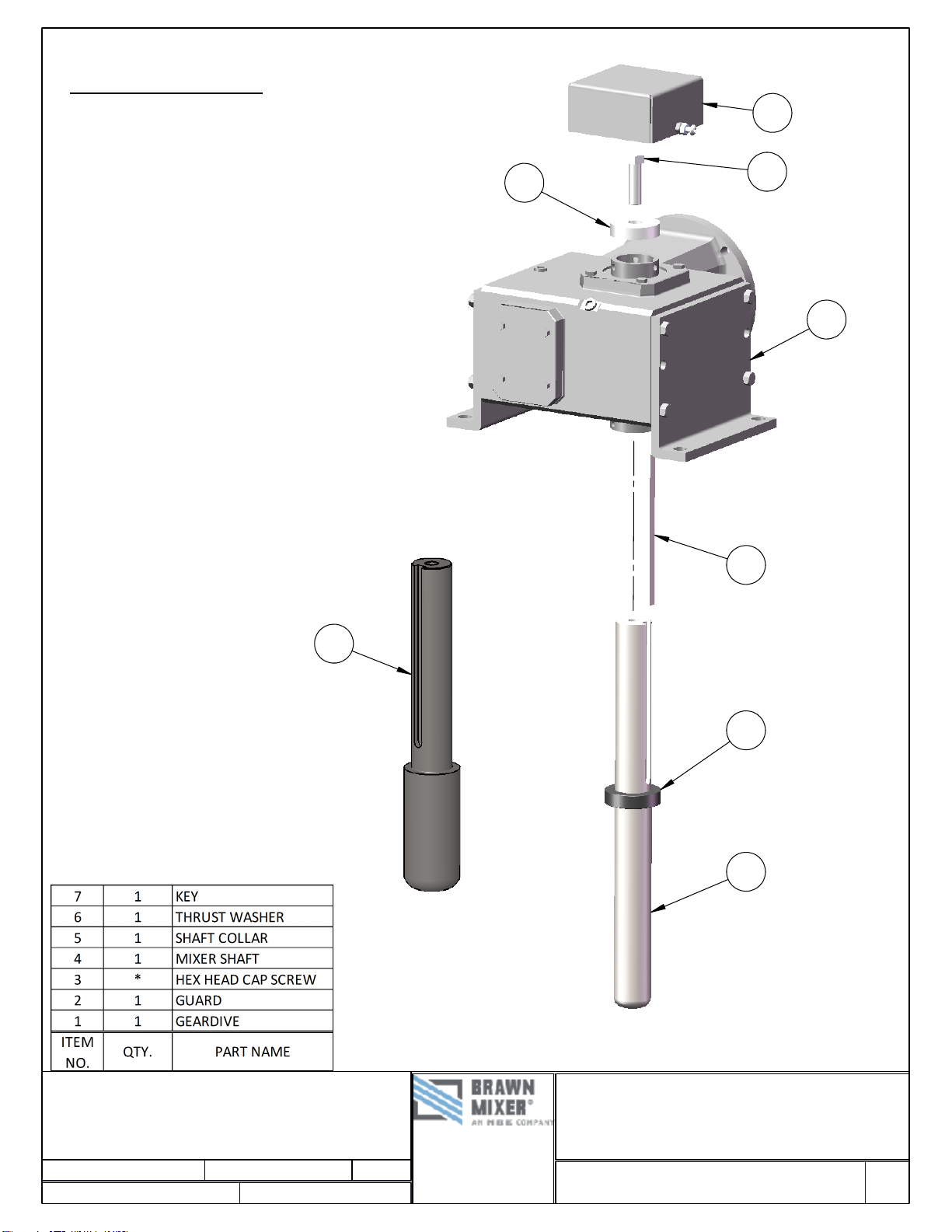

Mixer Installation / Assembly / Dimension Drawings

Safety ............................................................................ 1

Customer Service Contact ............................................ 1

Initial Inspection............................................................. 2

Installation ..................................................................... 2

Shaft and Impeller Assembly...................................2 & 3

Start-Up......................................................................... 4

Electric Motors..........................................................4 - 6

Maintenance/Lubrication ............................................... 7

Storage.......................................................................... 8

Gearbox Features ......................................................... 8

Gearbox Features Drawing........................................... 9

Warranty...................................................................... 10

SAFETY

The precautions mentioned in this manual are not

intended to cover all hazards that may exist in a plant or

on this equipment. Using safety mechanisms requires

the constant attention of everyone in the vicinity of this

(or any) equipment.

A plant and the related equipment are only as safe as the

personnel are safety-minded. Proper equipment

maintenance and the use of personal safety devices will

contribute as much toward safety as will any number of

mechanical safety devices.

WARNING

To assure maximum safety, optimum performance,

and to gain knowledge of the product, it is essential

that you or any other operator of this equipment read

and understand the contents of this manual before

the mixer is operated.

Installation, operation and maintenance must be

performed only by qualified personnel.

Do not operate this equipment unless all safety

devices are installed and working properly. Check all

devices prior to starting the equipment.

Disconnect and lock out electrical power before

installing or servicing the mixer.

Do not touch rotating parts (keep all guards and

safety devices installed while operating).

Develop a safety checklist for this equipment and

perform regular maintenance to ensure continued

and proper operation. Develop a safety checklist for

this equipment and perform regular maintenance to

ensure continued and proper operation.

Do not make any field changes or modifications

without reviewing the change with your BRAWN

sales representative or the BRAWN Customer

Service Department.

CUSTOMER SERVICE

Mixer Model #........................................... BWG-SERIES

Mixer Serial #_________________________________

Contact:

Customer Service............................... 616/399-5600

E-Mail ................................brawn@brawnmixer.com

You have received a quality engineered and

manufactured BRAWN Mixer. We value your business,

and we will strive to provide you with the proper service

and equipment to meet your needs.

The information contained in this BRAWN Mixer

Operator's Manual is designed to assist you in putting

your BRAWN Mixer into operation without further delay.

Please read the entire manual before attempting to

start your mixer. If you have any further questions or if,

by some chance, there are some missing components,

contact your BRAWN Mixer Representative or the factory

immediately.

We welcome your comments and suggestions

concerning any BRAWN Mixer product. Please direct

these comments in writing to the National Sales Manager

at BRAWN Mixer, located in Holland, Michigan. To

expedite troubleshooting service, please make your initial

contact through your BRAWN Mixer Representative. If,

for whatever reason, your representative cannot be

reached and you have an emergency condition, please

call us directly at 616/399-5600 and ask for the

Customer Service Department.

Remember, you are backed by your BRAWN Mixer

Technical representative and the factory support team.

We are here to assist you; let us know how we can be of

help.