2

© by NECTA VENDING SOLUTIONS SpA 0401 171 - 02

IN THE EVENT OF FAILURES

In most cases, any technical problems are corrected by

small repair operations; however, before contacting the

manufacturer we recommend that this manual be read

carefully.

Should there be serious failures or malfunctions, then

contact the following:

NECTA VENDING SOLUTIONS SpA

Via Roma 24

24030 Valbrembo

Italy - Tel. +39 035606111

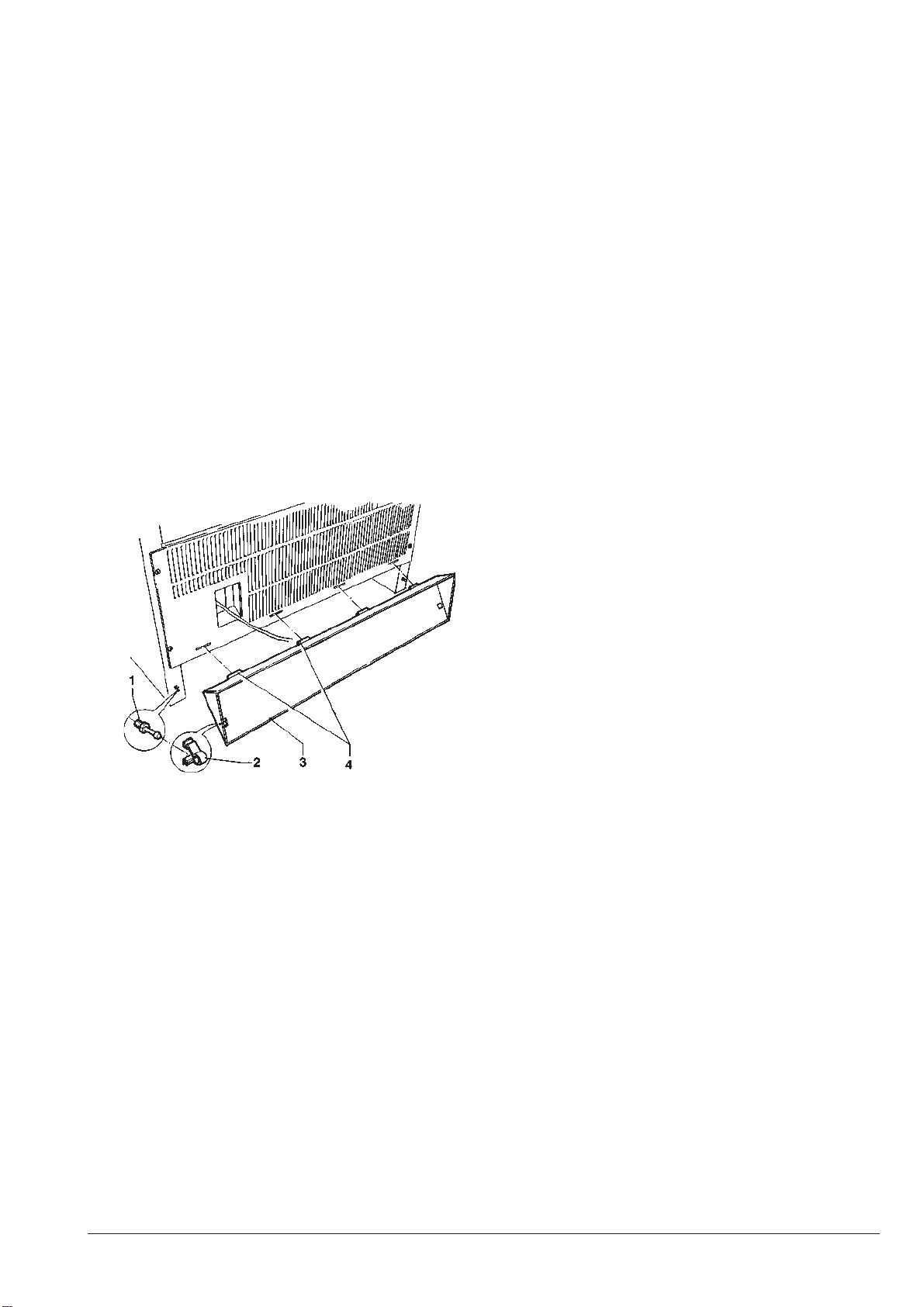

TRANSPORT AND STORAGE

To prevent any damage, special care should be taken

when loading or unloading the vending machine.

The machine can be lifted by a motor-driven or manual

forklifttruck,andtheforksaretobeplacedunderneaththe

machine from the side clearly indicated by the symbol on

the cardboard package.

Do not:

- overturn the vending machine;

- drag the vending machine with ropes or similar;

- lift the vending machine by its sides;

- lift the vending machine with slings or ropes;

- shake or jolt the vending machine and its packing.

The machine should be stored in a dry room where the

temperature remains between 0°C and 40°C.

Avoid stacking machines one on top of the other and

always keep it upright as indicated by the arrows on the

packing.

USING THE VENDING MACHINE FOR

HERMETICALLY SEALED PRODUCTS

Adifferentsalepricecanbesetforeachproductselection

by the machine electronic control. The various functions

areprogrammedthroughtheselectionbuttonswithoutany

need for additional equipment.

All models are fitted with variable configuration drums,

permitting the number of partitions to be either increased

orreducedtoadaptthemachinetothesizeoftheproducts

to be dispensed, thus optimising the machine capacity.

INTRODUCTION

Thistechnicaldocumentationispartandparcelofthe

vendingmachineandmustalwaysfollowthemachine

in case it is moved or transfer of ownership, so as to

allow consultation by different operators.

Beforestartinginstallationandusingthemachine,itisfirst

necessary to carefully read and understand the instruc-

tions contained in this manual, as they offer important

information on installation safety, operating instructions

and maintenance.

This manual is divided into three chapters.

Thefirst chapterdescribestheloadingandroutinemain-

tenance operations which are carried out in areas of the

machine accessible with simple use of the door key,

without using any other tools.

The second chapter contains the instructions for correct

installationandallinformationnecessaryforoptimumuse

of the machine.

The third chapter describes maintenance operations

whichinvolvetheuseoftoolstoaccesspotentiallydanger-

ous areas.

The operations described in the second and third

chapters must be carried out only by personnel who

havethespecific knowledgeofthe machine function-

ing from a point of view of electrical safety and health

regulations.

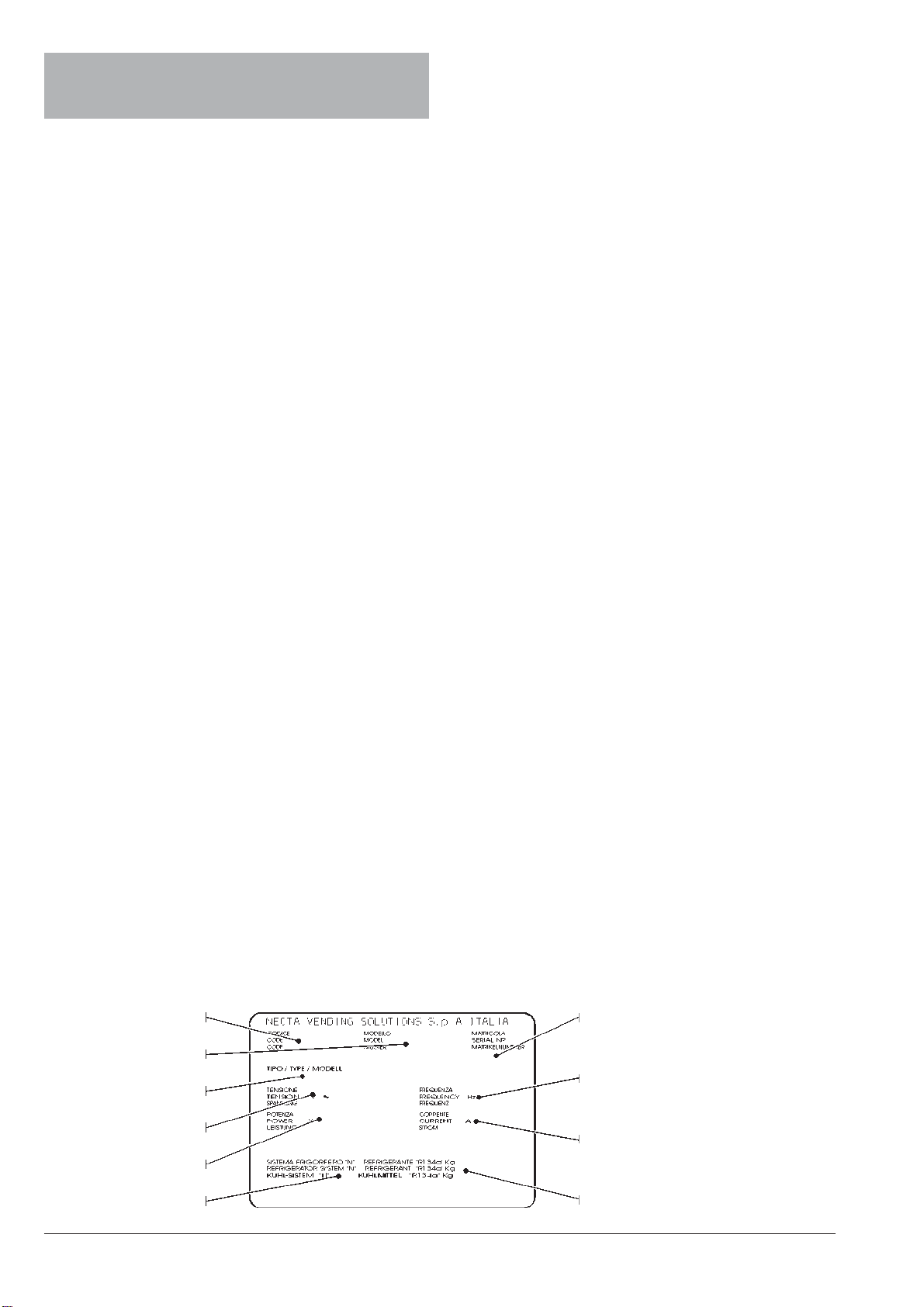

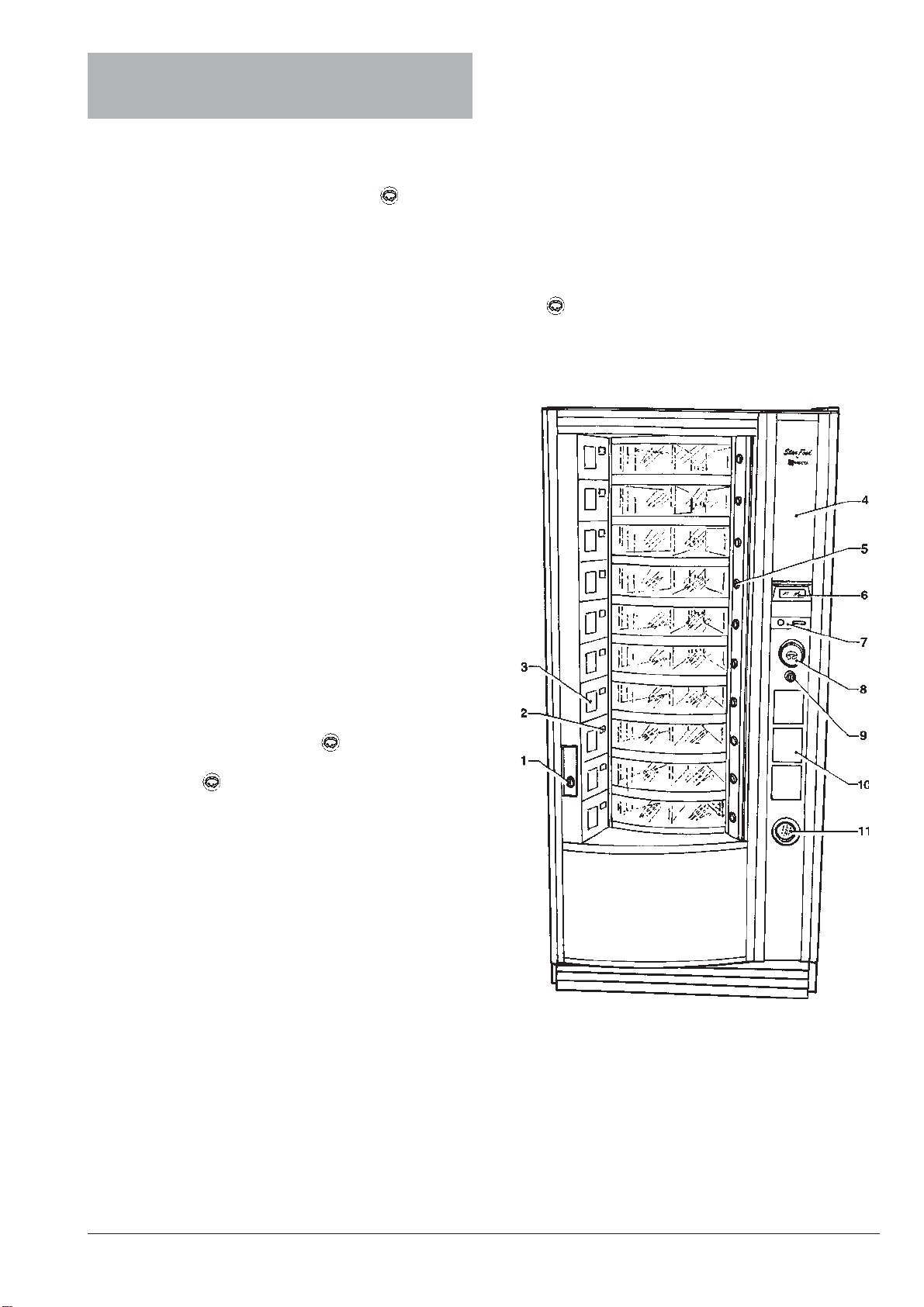

IDENTIFICATION OF THE VENDING

MACHINE AND ITS CHARACTERISTICS

Each machine is identified by its own serial number,

indicatedontheratingplateattachedinsidethecabineton

the right side.

This plate is the only one acknowledged by the manufac-

turer as identification of the machine, and carries all data

which readily and safely gives technical information sup-

pliedbythemanufacturer.Italsoassistsinthespareparts

management.

Absorbed power

Operating voltage

Type

Current

Frequency

Serial number

Model

Product code

Refrigeration system class Type and amount

of refrigerant