Jofemar Coffeemar G-250 Product manual

Other Jofemar Vending Machine manuals

Jofemar

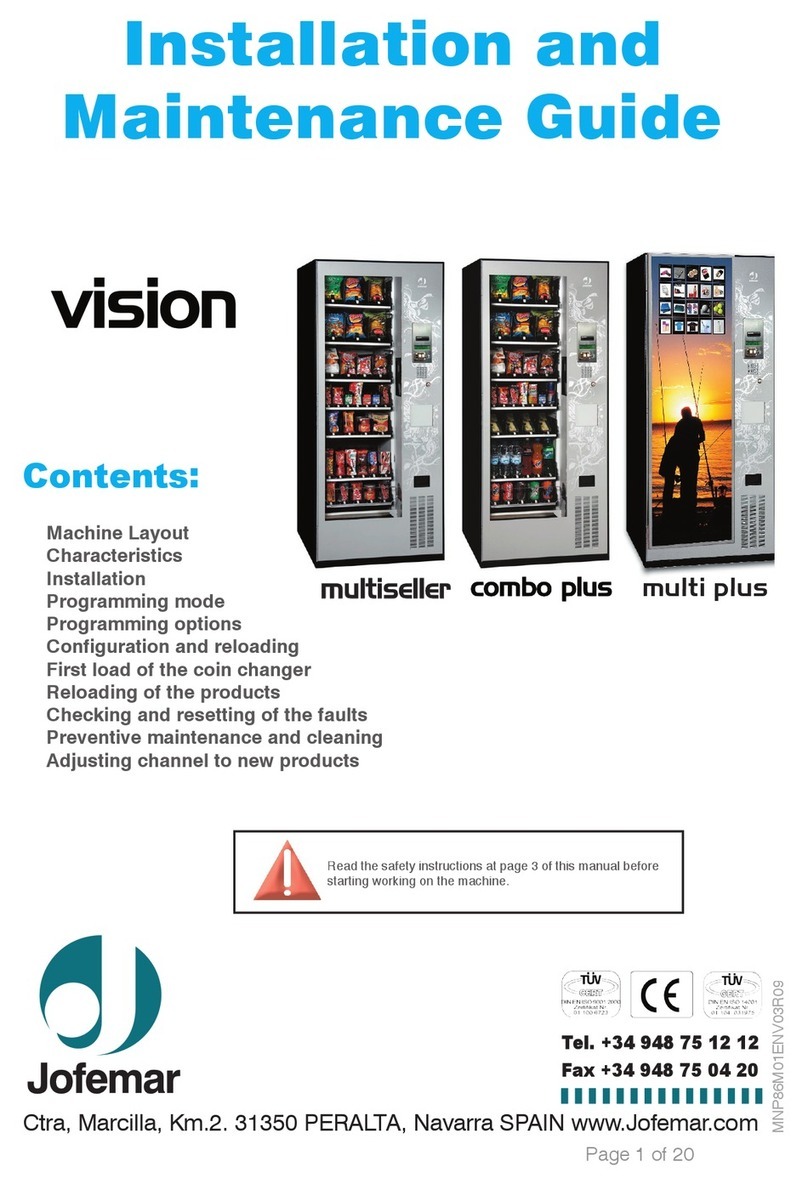

Jofemar vision multiseller Product manual

Jofemar

Jofemar Vision ES-PLUS User manual

Jofemar

Jofemar TAOS Series User manual

Jofemar

Jofemar Coffeemar G-250 User manual

Jofemar

Jofemar COFFEEMAR G-500 V2 User manual

Jofemar

Jofemar Vision Easy Combo Operating manual

Jofemar

Jofemar Vision Snack Plus User manual

Popular Vending Machine manuals by other brands

Azkoyen

Azkoyen Zensia technical information

Azkoyen

Azkoyen STEP 74 technical information

SandenVendo

SandenVendo Snack Safety Point SVE SSP Programming manual

Intralot

Intralot Dreamtouch Smart manual

Westomatic

Westomatic Primo Compact Cleaning manual

Crane

Crane Dixie-Narco Glassfront BevMax 3 5800 Installation & setup guide