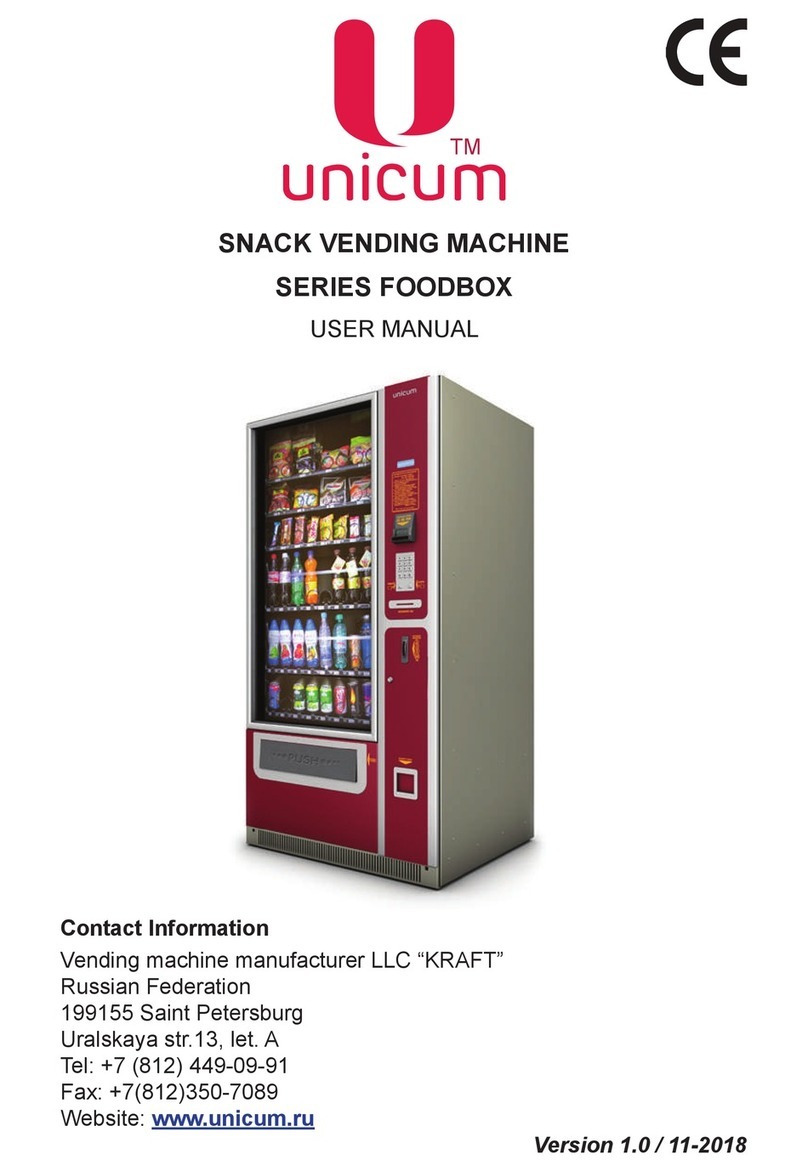

FOODBOX TOUCH, FOODBOX LONG TOUCH, FOODBOX LIFT TOUCH

Page 3Version 1.3 / December 2018

ТМ

CONTENT

1.0 GENERAL INFORMATION ....................................................................................... 4

2.0 SAFETY .................................................................................................................... 6

3.0 SPECIFICATIONS ..................................................................................................... 7

4.0 VENDING MACHINE DESCRIPTION ....................................................................... 8

4.1 Interior ................................................................................................................. 8

4.2 Control compartment........................................................................................... 9

4.3 Selling process.................................................................................................... 10

4.4 Vending machine components ............................................................................ 11

4.4.1 Giving out compartment ............................................................................ 11

4.4.2 Control compartment................................................................................. 11

4.4.3 Touch screen ............................................................................................. 11

4.4.4 Lock........................................................................................................... 12

5.0 INSTALLATION ......................................................................................................... 13

5.1 Location selection ............................................................................................... 13

5.2 Safety precautions .............................................................................................. 14

5.3 Installation ........................................................................................................... 14

5.4 Electrical connection ........................................................................................... 15

5.5 Wall mounting...................................................................................................... 15

5.6 Vending machine activation ................................................................................ 16

5.7 Vending machine deactivation ............................................................................ 16

5.8 Products loading ................................................................................................. 17

6.0 COOLING UNIT......................................................................................................... 18

6.1 Operating Modes................................................................................................. 18

7.0 CONTROL ................................................................................................................. 20

7.1 Controller board .................................................................................................. 20

7.2 Service buttons .................................................................................................. 22

8.0 USER MENU ............................................................................................................ 23

9.0 SERVICE MENU - MENU TECHNICIAN................................................................... 25

9.1 System ................................................................................................................ 27

9.1.1 General..................................................................................................... 27

9.1.2 Security .................................................................................................... 28

9.1.3 Franchising............................................................................................... 29

9.1.4 Resets ...................................................................................................... 30

9.1.5 Power ........................................................................................................ 31

9.1.6 EVA-DTS ................................................................................................... 32

9.1.7 Modem ...................................................................................................... 33

9.1.8 Ethernet..................................................................................................... 35

9.1.9 About ......................................................................................................... 36

9.2 Snack .................................................................................................................. 37

9.2.1 Service ...................................................................................................... 37

9.2.2 Setup ......................................................................................................... 38

9.2.3 Thermal setup ........................................................................................... 42

9.3 Payment Systems ............................................................................................... 45

9.3.1 Changer..................................................................................................... 45

9.3.2 General Setup ........................................................................................... 47

9.3.3 Change Setup ........................................................................................... 48

9.4 Errors .................................................................................................................. 50

10.0 SERVICE MENU - OPERATOR MENU................................................................... 52

11.0 LOADING PRODUCT IMAGES TO VENDING MACHINE...................................... 52

12.0 CHANGING THE CONFIGURATION OF SHELVES............................................... 54

13.0 MAINTENANCE ...................................................................................................... 59