3

© by NECTA VENDING SOLUTIONS SpA 0404 211-02

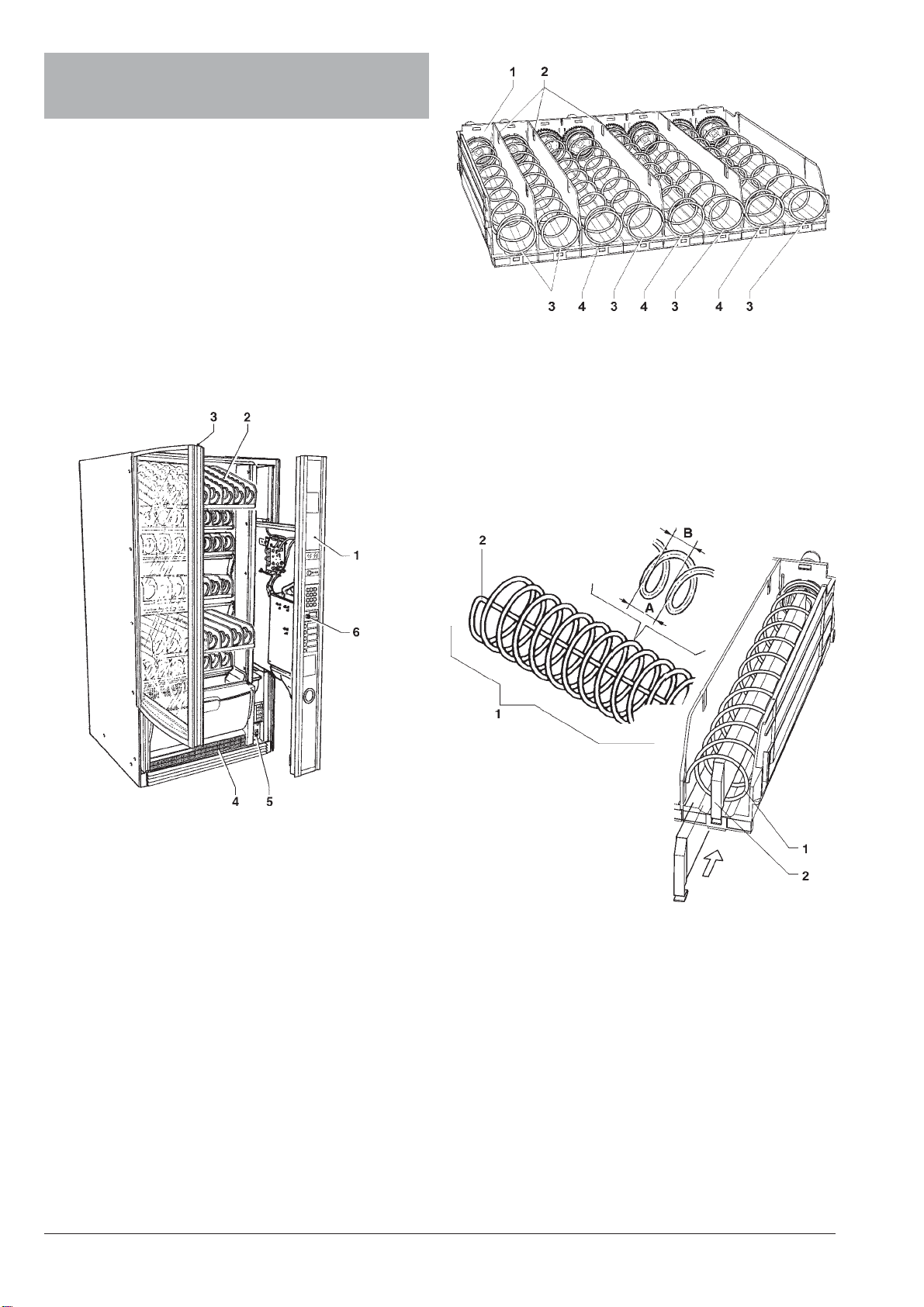

USING THE VENDING MACHINE FOR

PACKAGED PRODUCTS

Adifferentsalepricecanbesetforeachproductselection

by the machine electronic control. The various functions

areprogrammedthroughtheselectionkeypadwithoutany

need for additional equipment.

Allmodels are equipped with variableconfiguration trays,

addingorremovingdividers,spiralsandratiomotors;there-

fore the machine can be easily suited to specific needs.

All trays are preset for the operation of up to 8 selections

(maximum setting).

The product holders are equipped with independent mo-

tors and spirals; each selection will continue its operation

autonomously even if the other selections are discon-

nected.

Thisvending machineshouldonlybeusedtosell and

dispense packaged products that do not need refrig-

eration to be preserved.

Strictly comply with the producer’s specifications

regarding storage temperature and expiry date for

each product.

Any other use is unsuitable and thus potentially dan-

gerous.

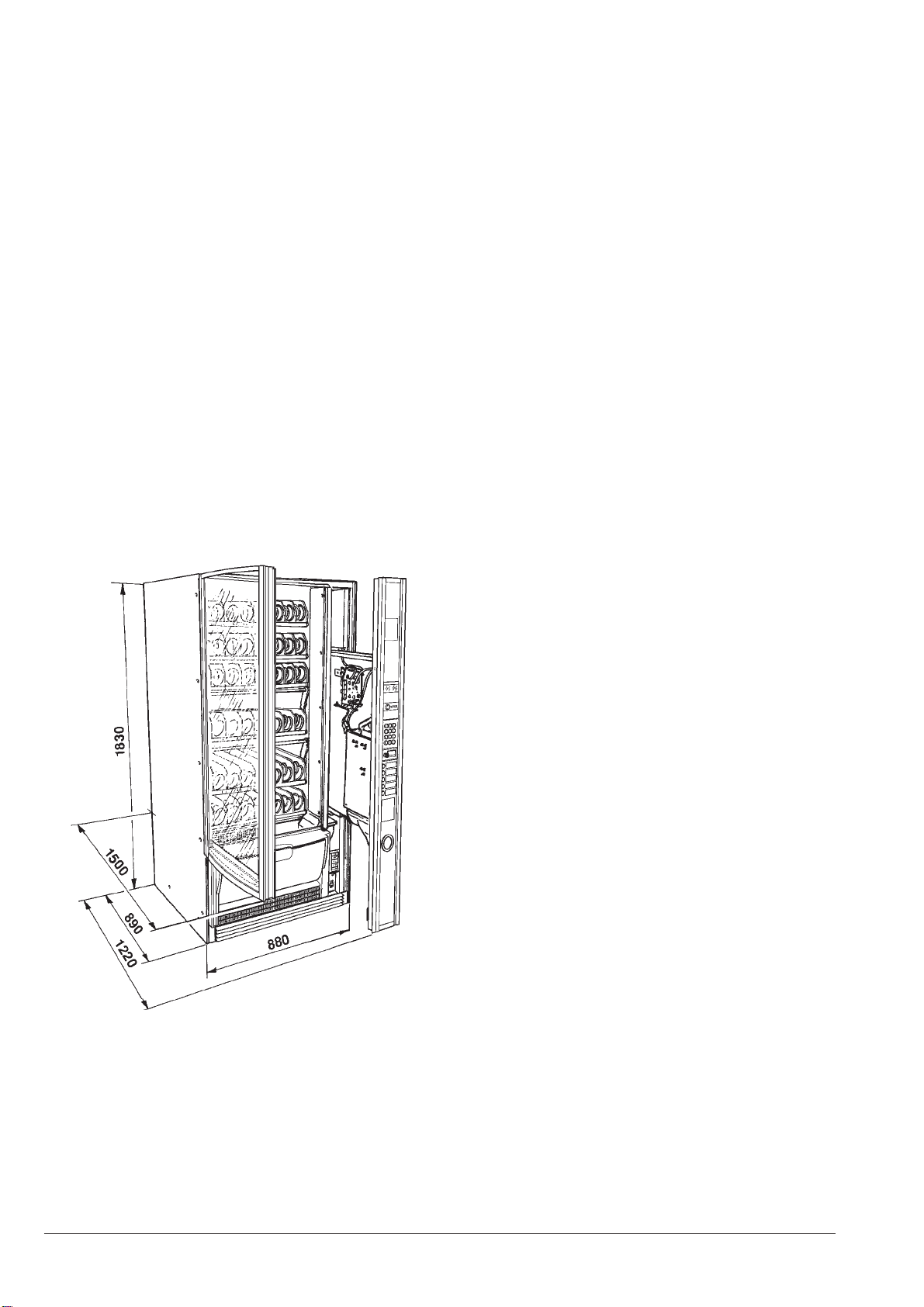

POSITIONING THE VENDING MACHINE

The vending machine is not suitable for outdoor installa-

tion.Itmustbepositionedinadryroomwherethetempera-

tureremainsbetween5°Cand32°C,andnotwherewater

jets are used for cleaning (e.g. in large kitchens, etc.).

The machine should be placed close to a wall.

Theventilationsystem allowsthebackpanel tobeleaned

against the wall, thus saving space, as air is drawn from

under the machine and exhausted through a grille at the

front.

Warning!

Incorrectventilationmaycompromisetheproperfunc-

tioning of the cooling unit.

The machine should be positioned with a maximum incli-

nation of 2°.

Ifnecessaryprovideproperlevellingbywayoftheadjust-

able feet included.

WARNING FOR INSTALLATION

The machine installation and the following mainte-

nance operations should be carried out by qualified

personnel only, who are trained in the correct use of

the machine according to the standards in force.

The machine is sold without payment system, therefore

the installer of such a system is responsible for any

damage to the machine or to things and persons caused

byfaultyinstallation.

The integrity of the machine and compliance with the

standardsoftherelevantsystemsmustbecheckedat

least once a year by qualified personnel.

PRECAUTIONS IN USING THE MACHINE

The following precautions will assist in protecting the

environment:

- use biodegradable products only to clean the machine;

- adequately dispose of all containers of the products

used for loading and cleaning the machine;

- keep the machine away from heat sources;

- regularly check the condition of the door seal to limit

any heat dispersion;

- limit as much as possible door opening time during

loading operations to avoid temperature increase

inside the cabinet and subsequent power consumption.

WARNING FOR SCRAPPING

Wheneverthemachineistobescrapped,thelawsinforce

regarding environment protection should be strictly ob-

served. More specifically:

- ferrous and plastic materials and the like are to be

disposed of in authorized areas only;

- insulating materials should be recovered by qualified

companies;

- the gas inside the cooling unit, regardless of the type

(see the identification plate), should be recoveredby

qualified companies by means of special equipment.