NEX D/DX

3

1 Preface.............................................................................................................................................................................................................14

2 Hazard Notices ................................................................................................................................................................................14

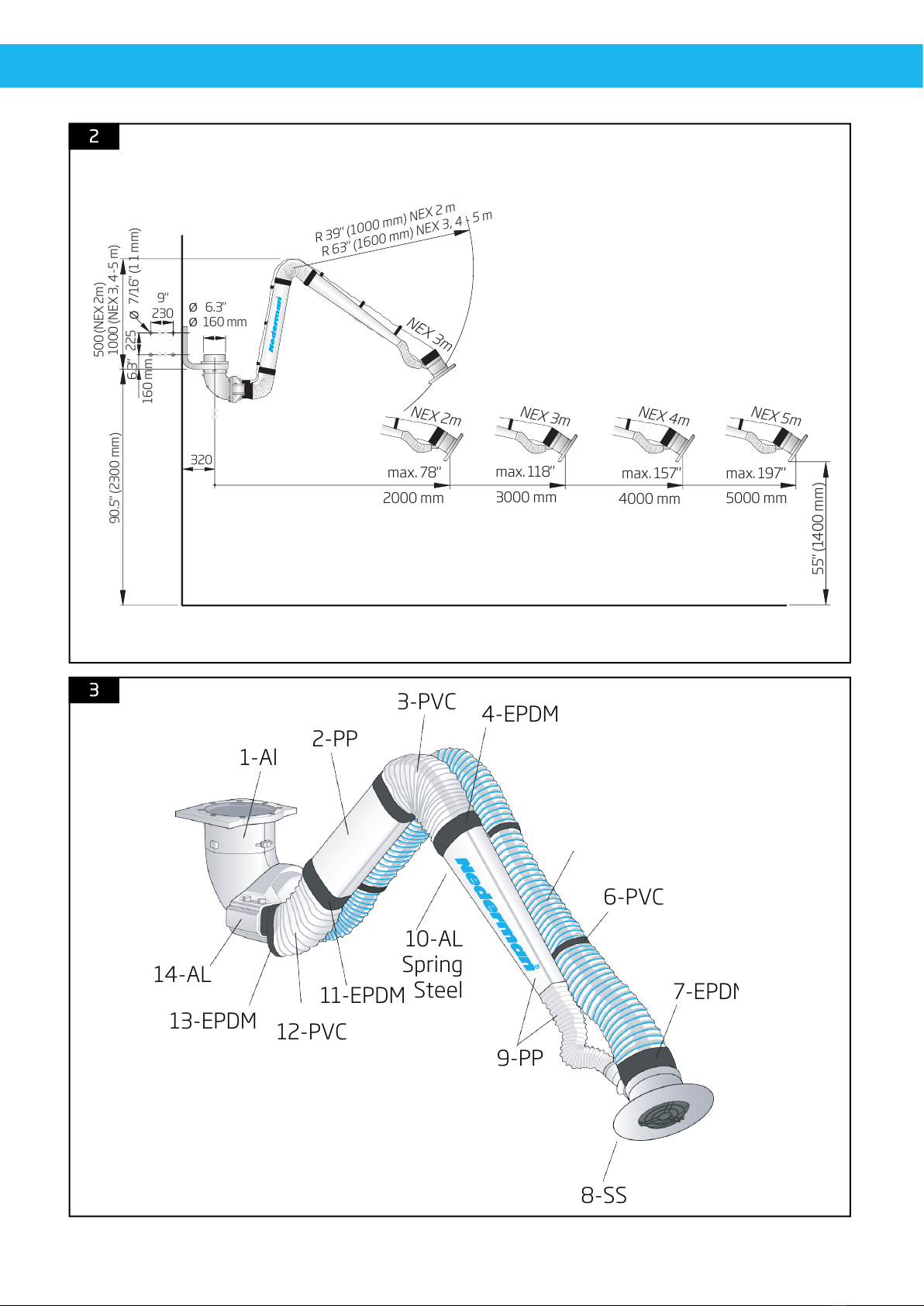

3 Description ..............................................................................................................................................................................................14

3.1 Technical data ...........................................................................................................................................................................15

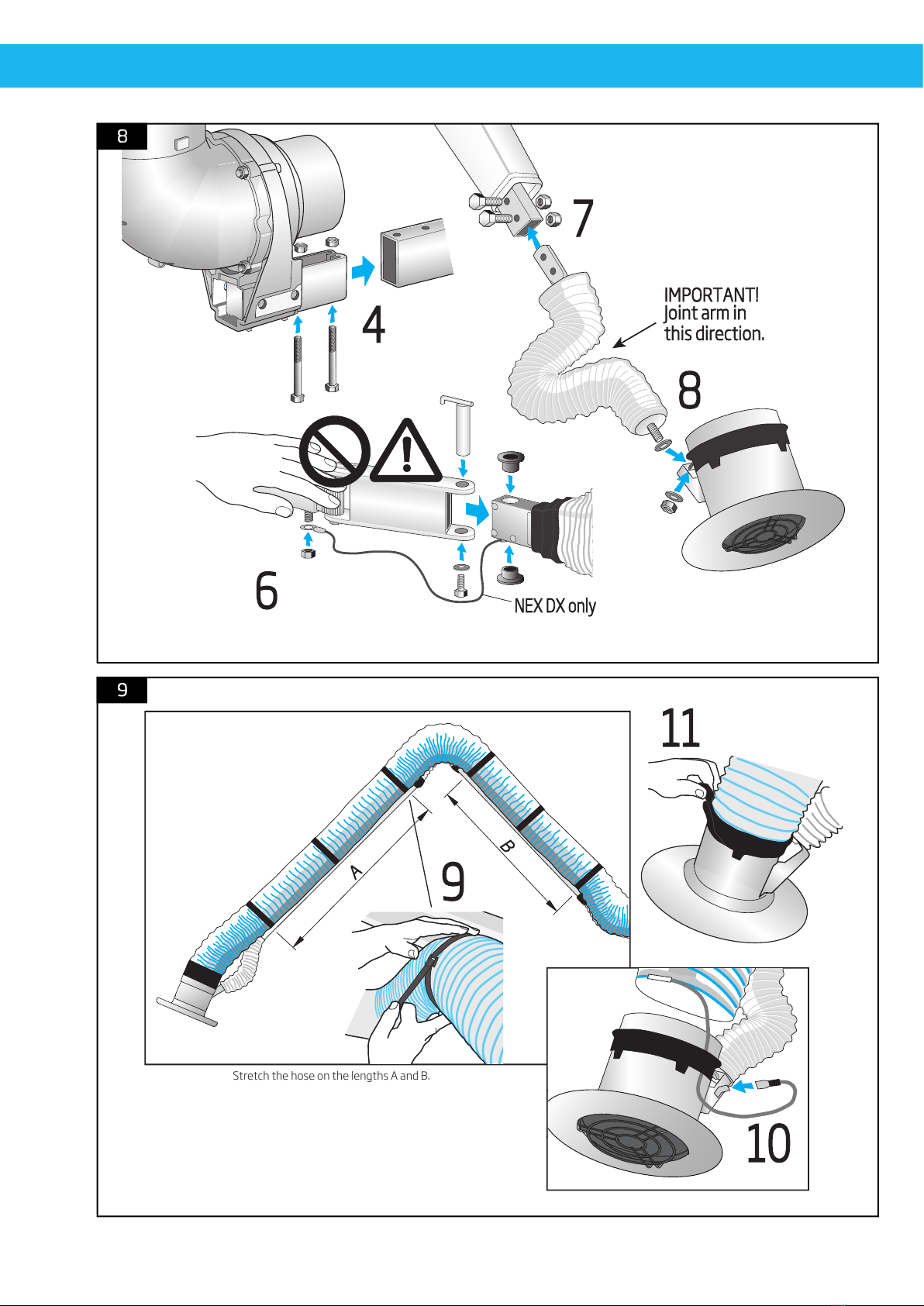

4 Installation ................................................................................................................................................................................................15

4.1 900 bend in hanging or standing position ........................................................................................15

4.2 Mounting ........................................................................................................................................................................................16

4.2.1 Rotary stop ............................................................................................................................................................................16

4.3 Grounding ......................................................................................................................................................................................16

5 Operation ....................................................................................................................................................................................................17

6 Service and Cleaning ..............................................................................................................................................................17

6.1 Internal cleaning of hood, hose and 900 bend ...........................................................................17

6.2 Internal cleaning, arm system ...........................................................................................................................18

6.3 Regular maintenance .....................................................................................................................................................18

6.4 Adjusting the links ..............................................................................................................................................................18

7 Spare Parts................................................................................................................................................................................................19

8 Recycling .......................................................................................................................................................................................................19

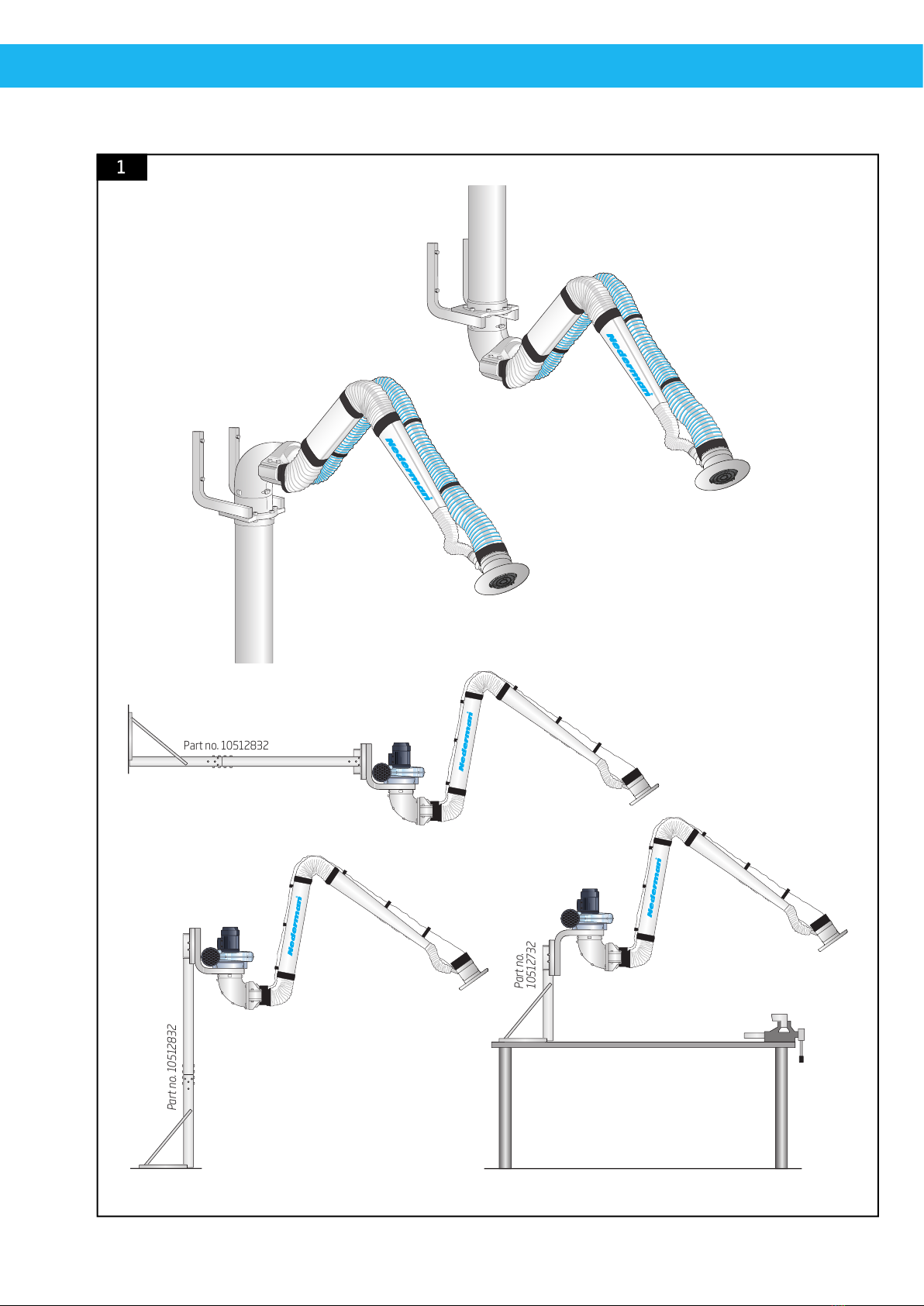

Installation Figures .......................................................................................................................................................................5

Table of Contents

Declaration of Conformity ............................................................................................................................................4