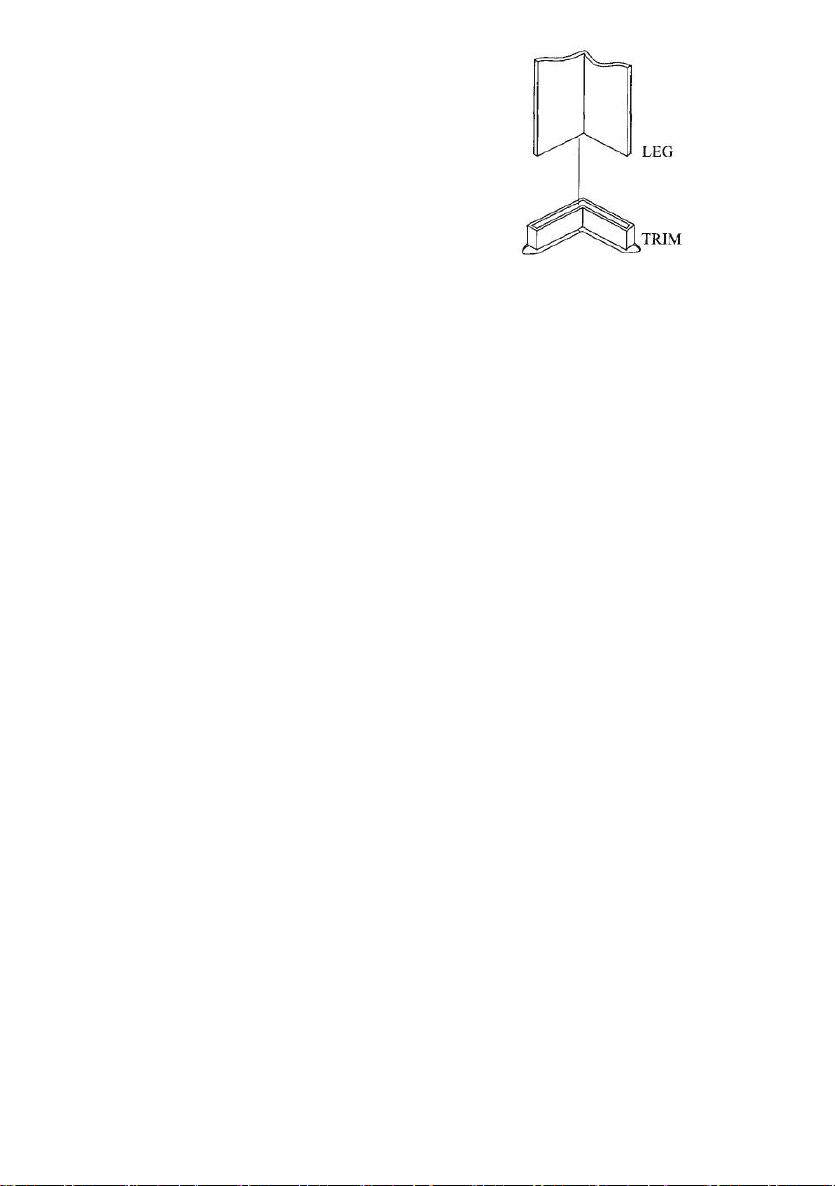

CABINET LEG TRIM MOULDING

Enclosed are four trim Mouldings for

bottom of cabinet legs. They may be

pushed in place, without tools.

AIR REQUIREMENTS:

For best results, we recommend a good 5

HP air compressor. A small nozzle/air jet

combo is use with a 3 HP air compressor.

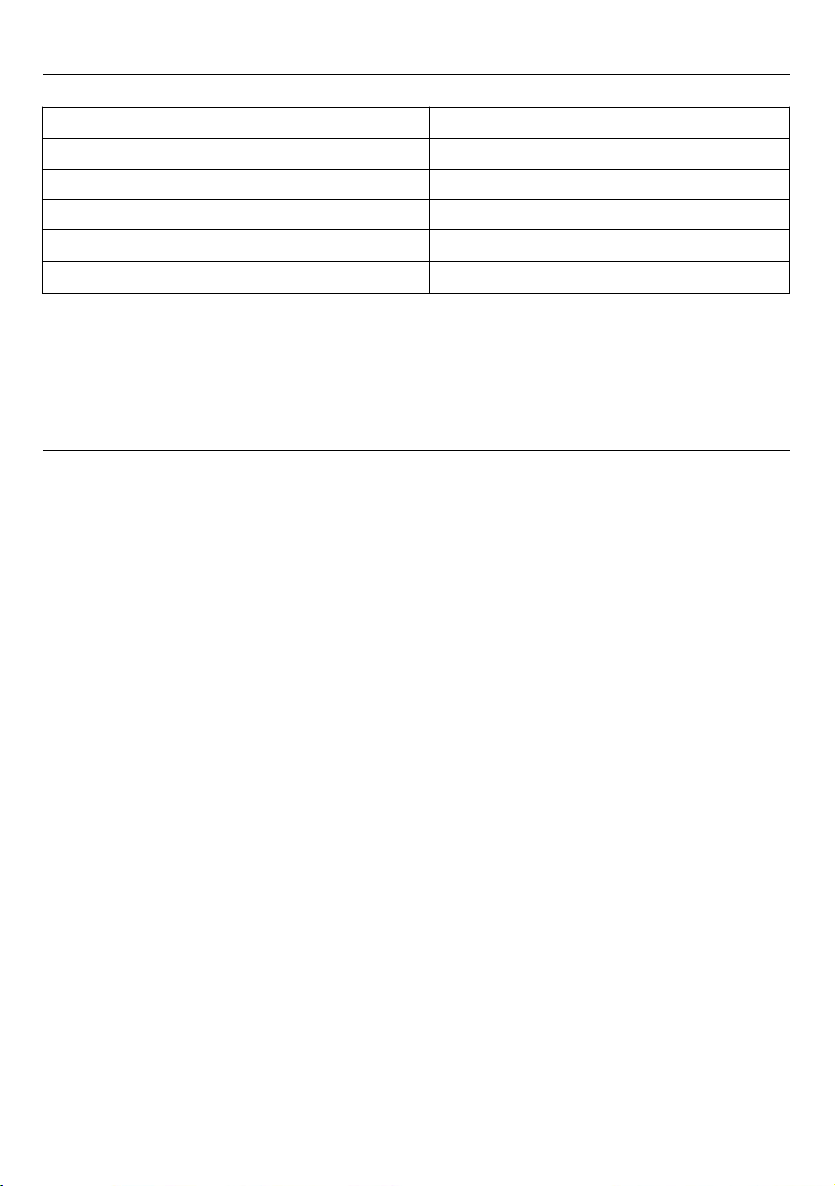

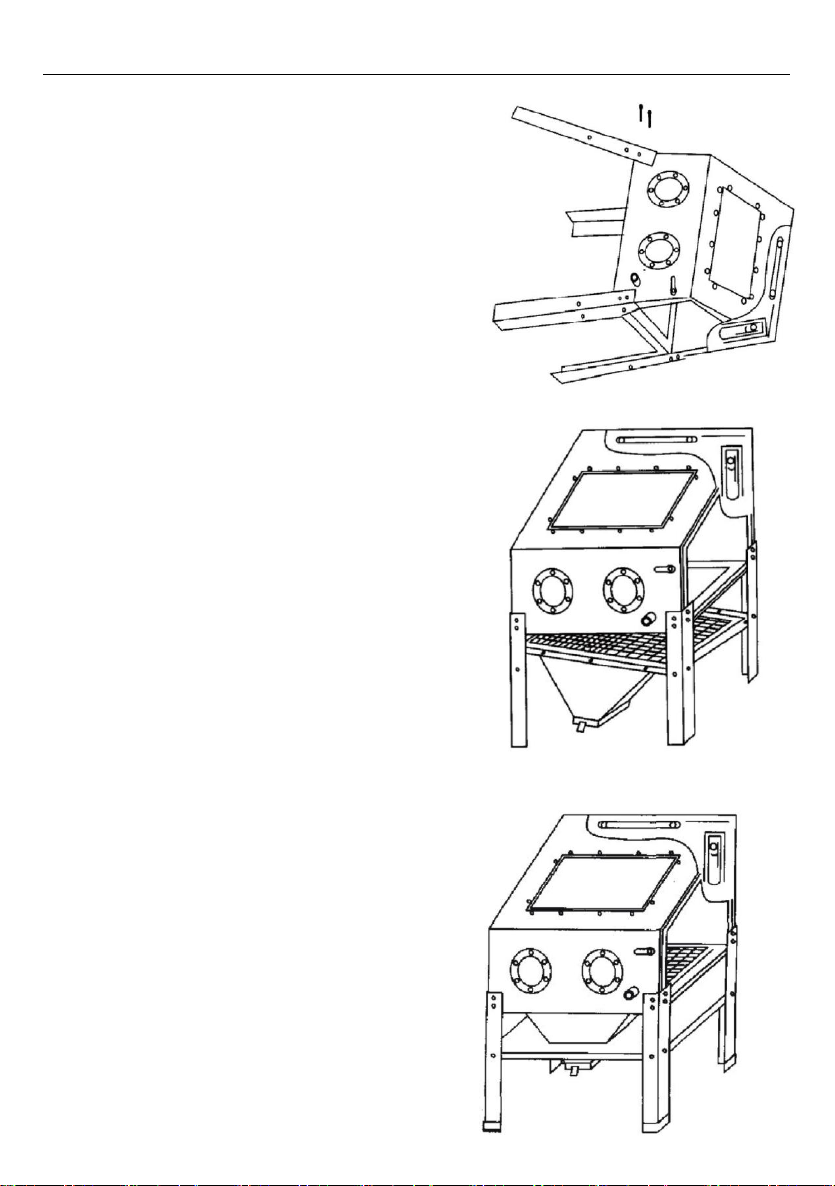

HOW IT WORKS

Your shop air hose enters front opening of cabinet and is connected to the air

inlet of power gun. Bottom handle of gun has 1/4" pipe threads which will fit most

air hose. Cabinet pickup tube leads to clear siphon hose which connects to gun

head assembly.

Pour glass beads or other abrasive into cabinet hopper through the side loading

door. Place parts to be blasted in cabinet and close door. With hands in cabinet

gloves aim power gun at object, pull trigger and let our unique siphon recycling

system do the rest. Rust, paint and scale are quickly removed, leaving the

original metal clean and intact. Abrasive drops to the bottom of cabinet for

continual recycling each time power gun is activated.

Abrasive can be re-used until it eventually breaks down or becomes dusty. To

discard worn abrasive simply place empty box under spring loaded trap door.

Add more abrasive and resume blasting.

Your shop vac connects to vacuum ferrule is necessary to remove the dust

created in blasting. When using a shop vacuum, be sure to install the paper filter

over the standard filter. Otherwise, abrasive could work its way into the vacuum

motor, causing bearing failure.

At right front of cabinet is an opening for your air hose from your compressor. An

ordinary 3/8” ID air hose should fit through this opening, connect your air hose

should fit through this opening. Connect your air hose to bottom handle of power

gun by screwing into place(use teflon tape or pipe compound-do not over tighten).

Close door and pull trigger a few times to test operation. You are now ready to

add abrasive.

Add suitsble abrasive by pouring through side door opening and allowing it to fill