It can be used when assembling and disassembling the removal parts, structal part, which

need lifted, descended transported,it’s the ideal tool for assembling and repairing in motor

repair shop, mobile garage.

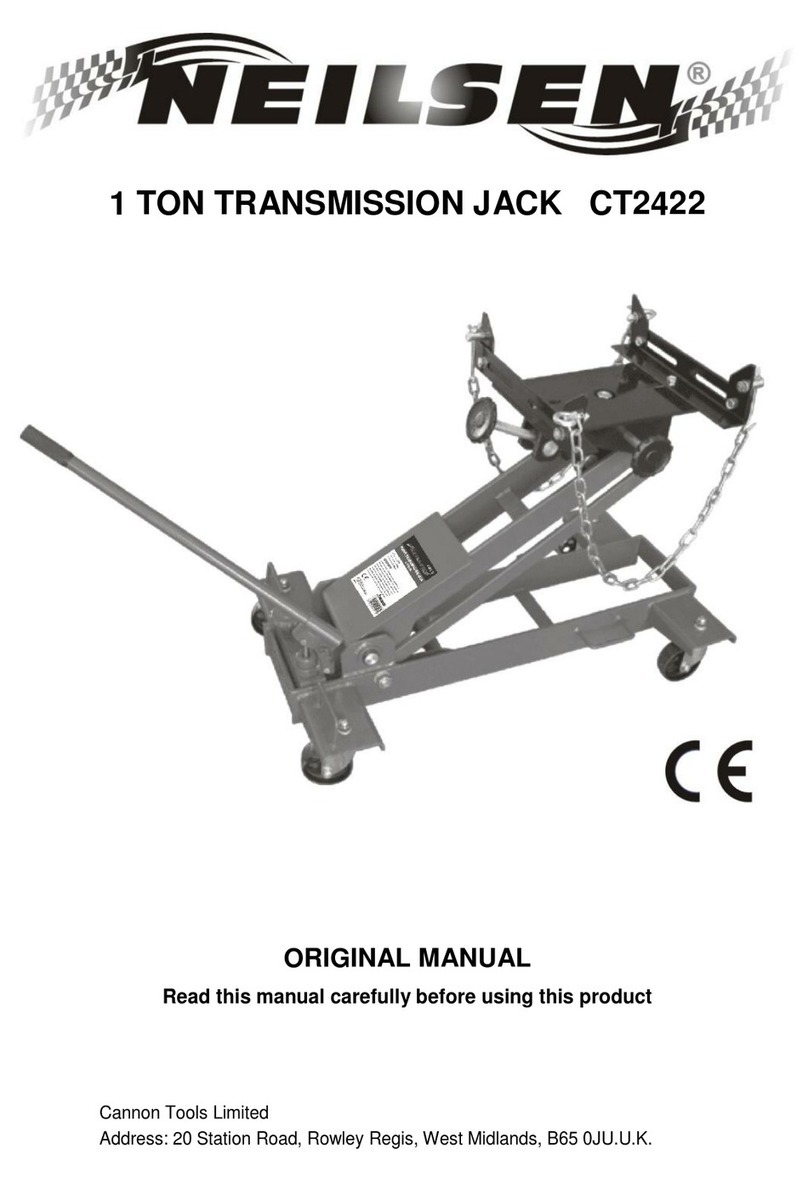

Ⅱ.Main construction

This jack is combined by

(1) Power unit (2) whole stand unit (3) saddle unit

Ⅲ.Assembling before use

For transportation, the jack is separated into three components. When used first time

assembling according to the No.1 drawing

1. Wheel stand

①Connect the two wheel stands ①with the power unit ④by inserting the in six-angled

bolt ②(M12X70) and washer ③into the proper hole on the power unit and tighten the

screw. ②Assembling four castor wheels ⑤together with spring washer ⑥on the four

feet of the wheel stands①and tighten the nuts②.

2. Make the first part of piston into the hole (φ28) of the saddle unit⑧at the proper

position and tighten the screw(M8)⑨

3. Fasten the two cramps⑩with bolt(11)(M12x25)and washer③to the nut(12)(M12)on

the saddle unit ⑧and close the screw, the distance between the two cramps can be

adjusted if needed.

4. Change the air vent valve(13) with a hole in the centre instead of the one without a

hole.

That’s all for assembling

Ⅳ.Instruction

1. Raising the saddle

Tighten the release valve handle (15) by turning in a clockwise direction and operate

the foot pedal(14) if by hand, place the handle in the foot operated handle sleeve,

operate the handle up and down.

2. Lowering the saddle

For safety, turn the release valve handle very slowly in counter-clockwise. Be sure not

exceed 25mm per second. If it lowers too fast, turn the release valve handle in

clockwise.

Ⅴ.Warning

①Be sure not exceed the rated capacity 0.6T

②Be sure to load firmly on centre of the transmission jack. If not, adjust the handle to close

it.

③After putting the load on it, use safety chain.

④When lifting load, need work under it, must use the safety stand.

⑤There must be enough oil in the cylinder so that the cylinder can operate regularly.

⑥When remove the transmission jack, the saddle must be at the lowest position.

⑦Keep the removal parts oiled, to avoid rusted.