NELSEN WATER Signature Series User manual

Signature Series

User Guide

Softeners & Filters

1", 1-1/4", 1-1/2", 2" & Twin Control Valves

Signature Series

Single Tank

AIO

Twin Tank

AANelsen Water Solutions User Guide

Table of Contents

Display Screen Color Code........................................................................................................................................................................................... A

Regeneration & Error Screens.................................................................................................................................................................................... A

Bypass Operation .................................................................................................................................................................................................................... 1

Button Operation & Function....................................................................................................................................................................................... 1

Setting Time of Day............................................................................................................................................................................................................... 1

User Displays................................................................................................................................................................................................................................ 2

User Displays - Resetting Salt Level ................................................................................................................................................................... 2

Nelsen Water Solutions Systems........................................................................................................................................................................... 3

Water Softener Maintenance...................................................................................................................................................................................... 4 - 5

Error Codes..................................................................................................................................................................................................................................... 6

Troubleshooting......................................................................................................................................................................................................................... 7 - 8

Warranty............................................................................................................................................................................................................................................. 9

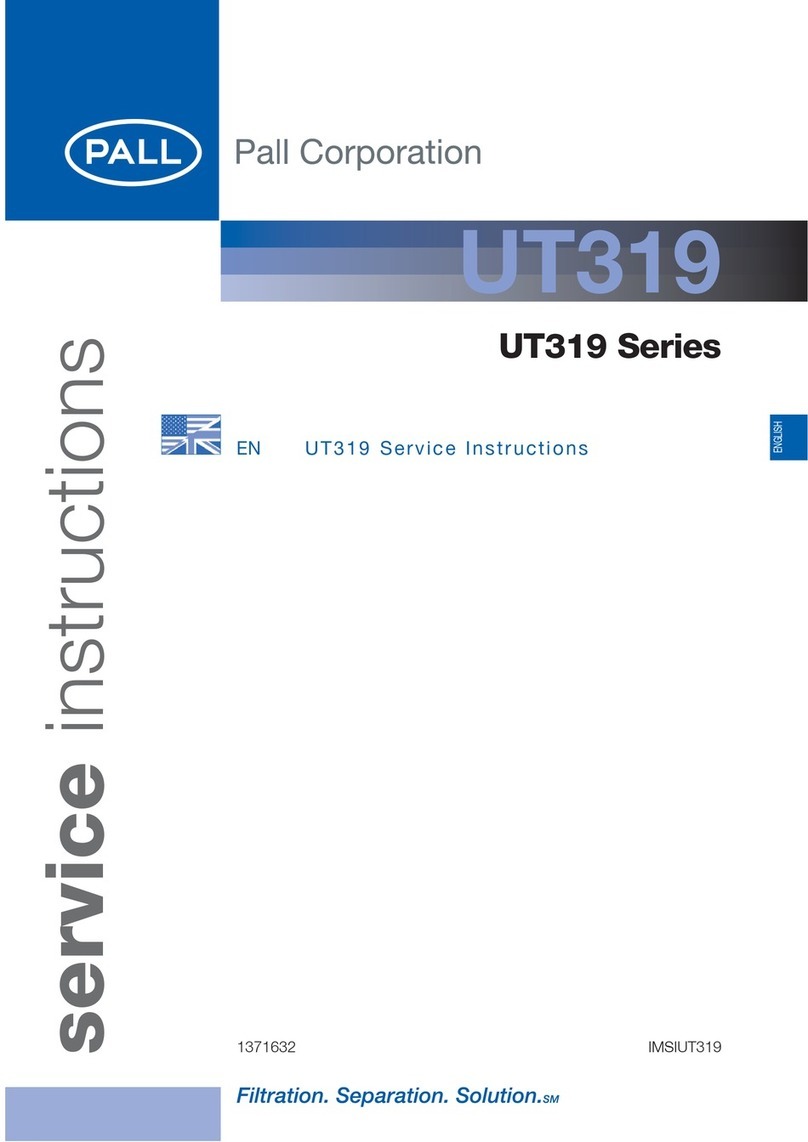

Regen Screen

Displays the time remaining

in the current cycle. 2nd

backwash cycle will flash.

Pressing REGEN advances

to the next cycle.

In Alternator Systems

when a unit is waiting to

initiate the first cycle step

of regeneration, “REGEN

PENDING” is displayed.

“STAND BY” is displayed

in Alternator Systems

when a valve is in Standby

state.

“DELAYED RINSE+FILL” is displayed whenever a

zero-capacity tank has transferred to an off-line state

and is currently waiting to initiate the second portion

of a regeneration cycle. Viewed only when Delayed

Rinse and Fill is set to ON.

Regen & Error Screens

BACKWASH

6:36

MIN2

REGEN PENDING

ALT MAV

STAND BY

AUX MAV

DELAYED RINSE+FILL

PENDING

Error Screens

ERROR Screen displays

when an error occurs and

no Dealer Information is

present. Top line will display specific error while the 3

digits in the lower right side will display specific error

code. Top line error display longer than 18 characters

will scroll across display from right to left.

Alternating ERROR and Dealer Contact Information

will display when an error occurs and Dealer Contact

Information is present.

EEEEEEEEEEEEEEEEEEE

ERROR

ccc

CLOCK NEXT UP DOWN REGEN

PPPPPPPPPPPPPPPPPP

NNNNNNN

TEL

Alternate

EEEEEEEEEEEEEEEEEEE

ERROR

ccc

Nelsen Water Solutions 1", 1¼", 1½", 2" & Twin Control Valves

Press NEXT to return to the

Time of Day screen.

Time of day should only

need to be set after power

outages lasting more than

8 hours, if the battery has

been depleted and a power

outage occurs, or when daylight savings time begins

or ends. If a power outage lasting more than 8 hours

occurs, the time of day will flash on and off which

indicates the time of day should be reset. If a power

outage lasts less than 8 hours and the time of day

flashes on and off, the time of day should be reset

and the battery replaced.

11

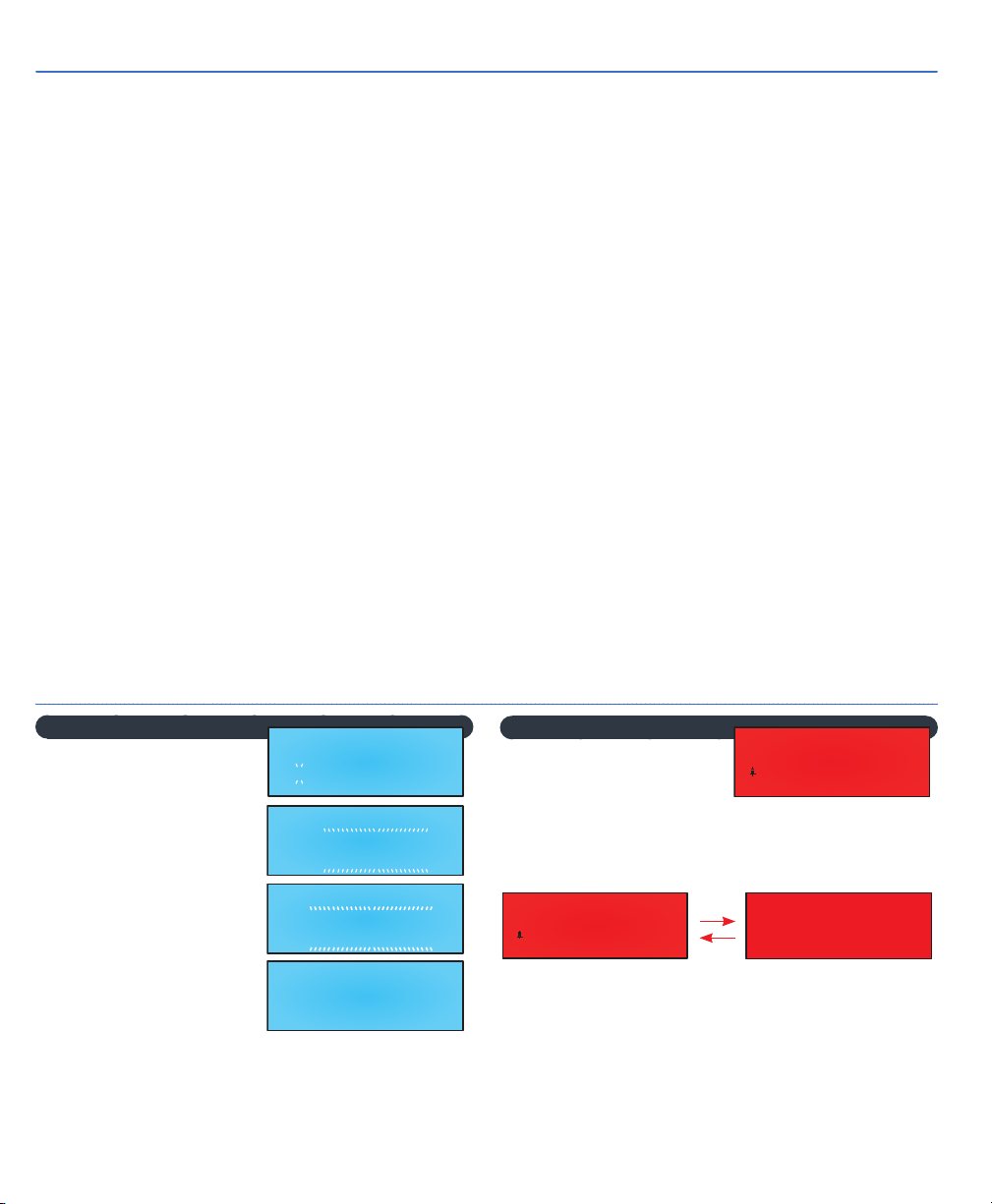

Button Operation and Function

Scrolls to the next display.

Pressing once and releasing will schedule

a regeneration at the preset delayed

regeneration time.

Pressing again and releasing will cancel the

regeneration.

Pressing and holding for 3 seconds will initiate an

immediate regeneration.

Pressing while in regeneration will advance to the

next cycle.

Pressing in the program levels will go backwards to

the previous screen.

Changes variable being displayed.

Holding NEXT and REGEN

simultaneously for 3 seconds initiates

a control reset. The software version is

displayed and the piston returns to the

home/service position re-synchronizing the valve.

Used with a twin valve, 1.0T, holding

for at least 3 seconds causes a switch in

the tank in Service without cycling the

regeneration valve. After tank switch, days remaining

and capacity remaining status is retained for each

tank until the next regeneration.

Holding pand qsimultaneously

for 3 seconds while in Control

Programming initiates a master reset.

Resets programming and diagnostic level. Displays

back to factory defaults. Retains current history level

displays.

Press any button to

activate display.

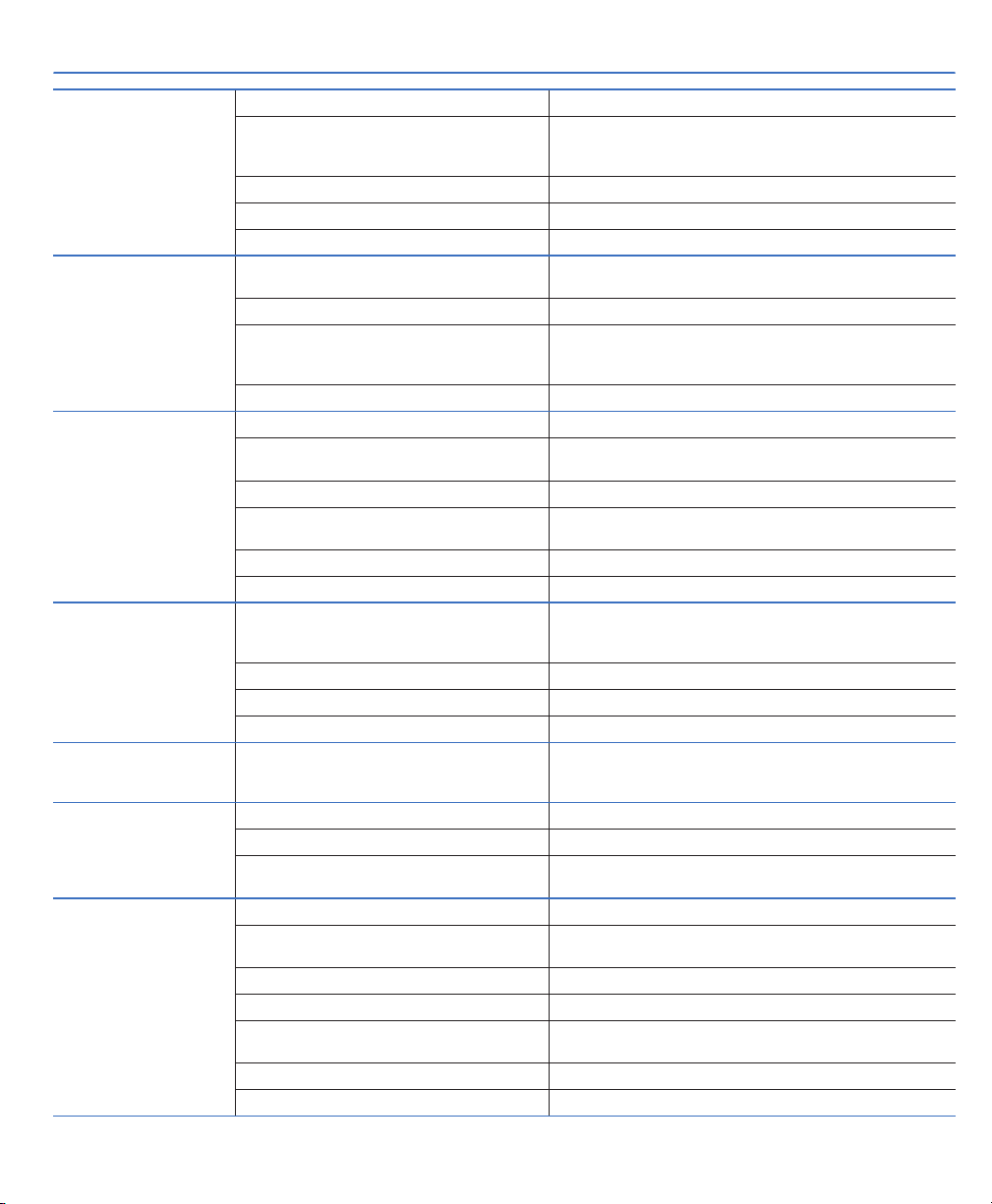

ByPass Operation

Normal Operation

Treated Out Untreated In

Bypass Operation

Untreated Out Untreated In

To shut off water to the system, position arrow

handles as shown in the bypass operation diagram to

the right.

Button Operation & Functions

Press and hold

CLOCK until TIME

HOUR is displayed and the

Hour and AM/PM flashes.

Press por quntil the

correct hour is displayed.

Then press NEXT. The

Minutes will flash. Press p

or quntil the correct minute

is displayed.

Setting Time of Day

TIME HOUR

12:00 PM

TIME MINUTES

12:01 PM

22Nelsen Water Solutions User Guide

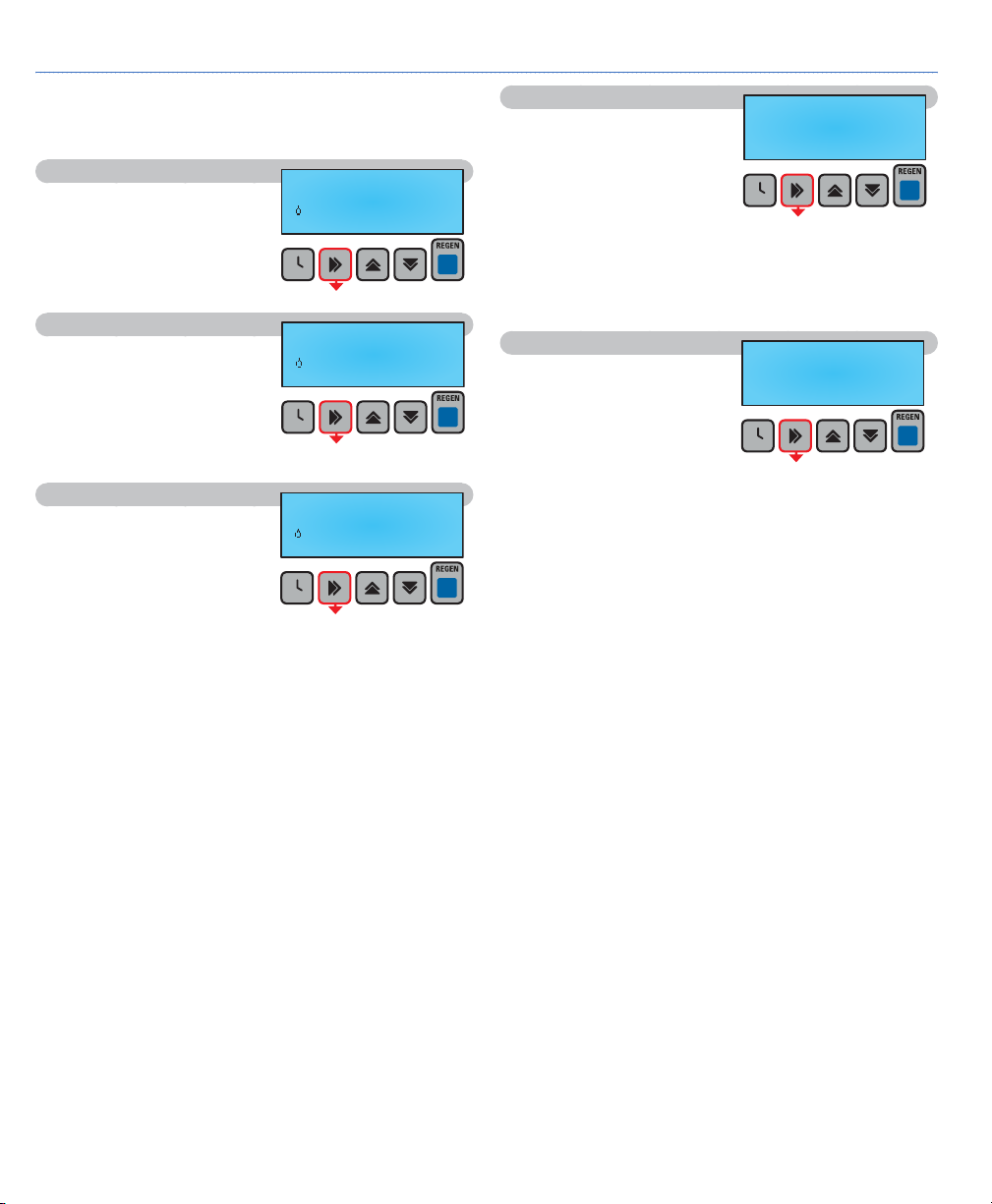

When the system is operating, one of five displays

may be shown. Pressing NEXT will alternate

between the displays shown below.

User 1

Typical user display shows

Time of Day and droplet of

water indicating water flow.

User 2

Shows volume remaining

to regeneration. This screen

will not be viewed if the

control is set for time-clock

operation.

User 3

Displays number of days

to next regeneration. Not

shown when day override

set to off.

User Displays

TIME OF DAY

12:01

PM

CAPACITY REMAINING

1200

GAL

REGENERATION IN

14 DAYS

User 4

Flow Rate displays the

current flow rate of treated

water through the valve. If

Configuration 3CS is set to

ALT A or B and the valve

is in Standby, this display

and the flashing Flow Indicator viewed in other User

Screens will not be viewed.

A Tank In Service Indicator (A or B) is active

whenever 1.0T Mode is set in Configuration 2CS.

User 5

Displays dealer contact

name and number when

programmed in the Installer

Level. Steps 7IL & 8IL.

FLOW RATE

A 0.0

GPM

PPPPPPPPPPPPPPPPPP

NNNNNNN

TEL

33

Nelsen Water Solutions 1", 1¼", 1½", 2" & Twin Control Valves

Nelsen Water Systems

Control Valve

Air Pocket

Filter Media

Distributor Tube

Brine

Tank

Control Valve

Softener Tank

Safety

Brine

Valve

Air Check

Ion Exchange Resin

Distributor

Riser Tube Distributor

Riser Tube

Distributor

Basket

Distributor

Basket

Single Tank Softener

Air Injection Oxidation (AIO) Filter System

Control Valve

Softener Tank

Safety

Brine Valve

Air Check

Distributor Basket

Brine

Tank

Twin Tank Softener

44Nelsen Water Solutions User Guide

Maintenance of Your Conditioner

Salt: Salt is vital to your system working correctly.

Not only must a softener have salt, but it should be

the proper type to ensure efficient unit recharging.

Ask your dealer what kind of salt may best suit your

needs. Always have an adequate supply of salt on

hand. Initially, check the salt level of your brine tank

every couple of weeks to determine how much salt

you use - this will depend on how much water you

use. As a rule of thumb, with 20 gpg of hard water,

about 1/2 lb. of salt per person per day is used. In

other words, a family of four uses 60 lbs. of salt a

month. Fill the tank approximately three-fourths full,

with a minimum of 12" of salt. If your household

does not use much water, do not fill your brine tank

over 1/2 full, salt bridging may occur in the brine

tank. This may result in hard water due to ineffective

regeneration. DO NOT USE Block Salt. Block salt

does not dissolve quickly enough to provide proper

regeneration.

Cleaning Brine Tank: The brine tank may require

periodic cleaning. Inspect the brine tank at least

once a year for buildup of insoluble materials. It is

recommended to periodically clean the brine tank no

matter what salt you use. REMEMBER: Salt is the fuel

to run your water conditioner. Buy the best clean

salt available.

Operating Conditions

Your water conditioner has been designed to

adequately handle up to 100 grains per gallon of

hardness and up to 2 ppm of ferrous bicarbonate

iron. This is iron dissolved in water and not visible

to the eye in a freshly drawn sample. After standing

in contact with air, the ferrous iron will oxidize to the

ferric state and start precipitating as a reddish-brown

floc. It can be seen and may cause discolored water.

For your softener to remove the iron, air (oxygen)

must be kept from coming in contact with water

until after it has been passed through the water

conditioner. In some cases, additional equipment

may be required to treat water supplies having

unique characteristics, such as ferric hydroxide iron,

iron bacteria, low pH, unpleasant taste, and odors,

etc. Contact your dealer if any questions should exist.

This water softener is not intended to be used to

treat microbiologically unsafe water or of unknown

quality without adequate disinfection before or after

treatment.

Water Softener Maintenance

55

Nelsen Water Solutions 1", 1¼", 1½", 2" & Twin Control Valves

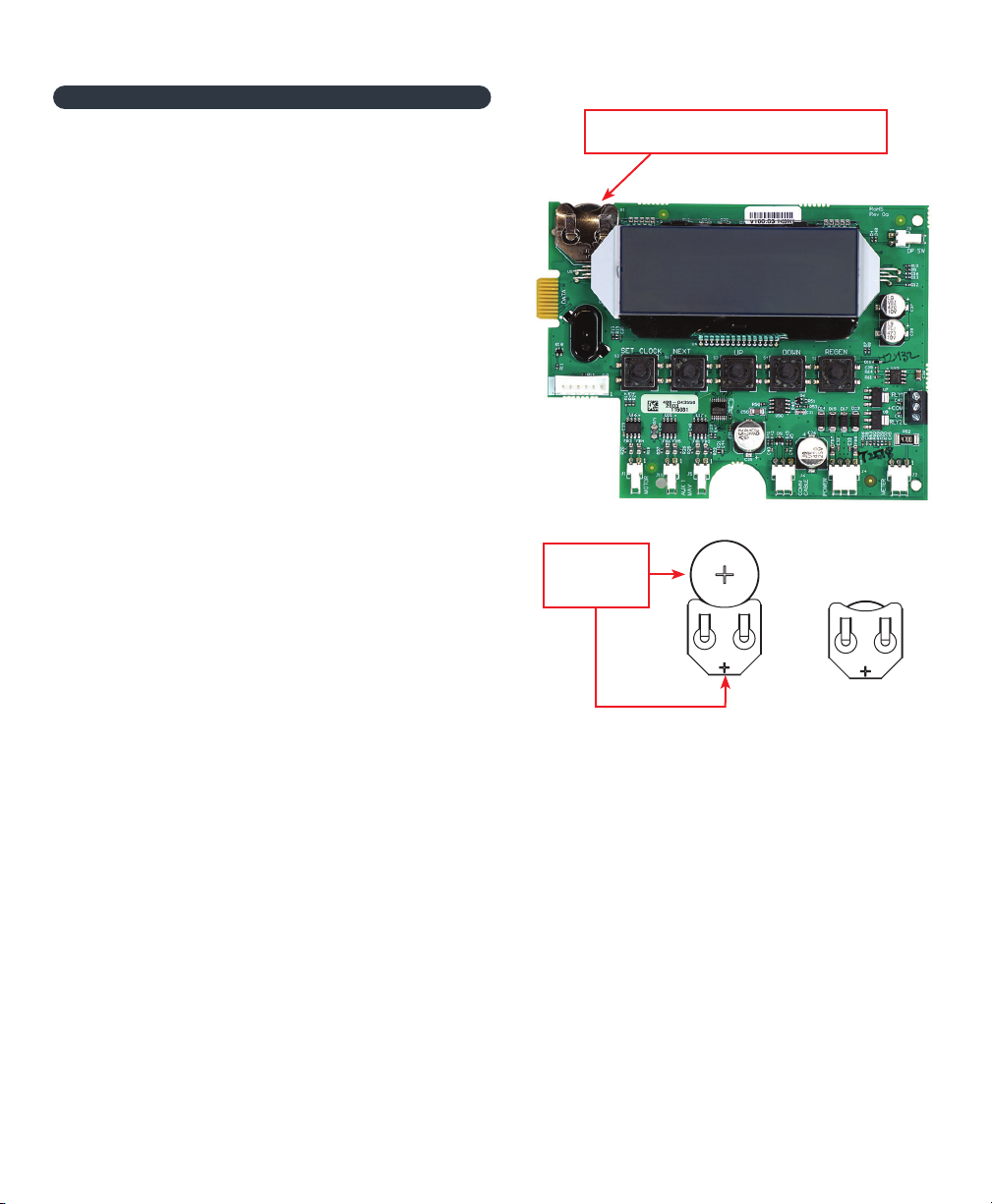

Power Loss and Battery Replacement

If an extended power outage occurs, the control

valve will retain the time-of-day settings until the

board’s battery is depleted. After the battery power

is depleted, the only item that needs to be reset is

the time of day.

Other values are permanently stored in the

nonvolatile memory. The control valve battery is

not rechargeable but is replaceable.

To determine if the battery is depleted:

1. Remove valve cover—disconnect power from PC

Board at the four-pin connector at the bottom of

the board.

2. Wait five minutes for the board to de-energize.

Remove the battery with a non-conductive/

nonmetallic material. Reference the Parts

Breakdown section of this manual for location.

3. Wait five minutes for the board to de-energize.

4. With the battery out, re-connect the power supply

to the board. The board’s display should begin to

show information. This indicates that the board is

operating correctly. If the display does not work,

call installing dealer for service.

5. To replace with a new battery, unplug the

transformer from the outlet. Install a 3-volt Lithium

Coin Cell type 2032 battery, available at most

stores.

Plug the unit back into the outlet.

It is essential to replace the battery with the valve

unplugged to avoid causing a short and potentially

ruining the board.

6. Reset the time of day (see programming

procedures) and initiate regeneration (see

operating displays and maintenance).

Please consult the installing dealer for service if these

procedures do not remedy the problem.

Battery replacement is

3 volt lithium coin cell type 2032.

When replacing

the battery, align

positives and push

down to fully seat.

Fully

Seated

Correct

Battery

Orientation

66Nelsen Water Solutions User Guide

Error Codes

101

UNABLE TO START Valve not sensing valve movement with motor output energized

102

MOTOR STALLED Valve unable to find next cycle position (stalled)

103

MOTOR RAN TOO LONG Valve unable to find next cycle position

104

VALVE HOMING Valve unable to find HOME position

106

ALT MAV RAN TOO LONG Alt MAV motor RAN TOO LONG - unable to find proper park position

107

ALT MAV STALLED Alt MAV motor RAN TOO SHORT, STALLED - unable to find proper park position

109

INVALID MOTOR STATE Control can no longer operate properly due to the detection of an invalid motor

state

116 AUX MAV RAN TOO LONG Aux MAV motor RAN TOO LONG - unable to find proper park position

117 AUX MAV STALLED Aux MAV motor RAN TOO SHORT, STALLED - unable to find proper park

position

201

INVALID REGEN STEP Control can no longer operate properly due to the detection of an invalid

regeneration cycle step - Internal Software Error

202

UNEXPECTED STALL Motor encountered an unexpected stall but was able to recover from and proceed

normally

402

POWER DOWN MEMORY Control can no longer operate properly due to a check sum error for the Operational

Data and Status Section of E

2

PROM memory

403

PROGRAM MEMORY Control can no longer operate properly due to a check sum error for the

Programming Section of E

2

PROM memory

404

DIAGNOSTIC MEMORY Control can no longer operate properly due to a check sum error for the Diagnostic

Section of E

2

PROM memory

405

HISTORY MEMORY Control continues to operate normally w/check sum error for the History Section of

E

2

PROM memory, however error is recorded in Error Log

406

CONTACT MEMORY Control can no longer operate properly due to a check sum error for the Contact

Screen Section of E

2

PROM memory

407

STATUS RAM

STATUS RAM MEMORY FAILURE - Error generated when the microcontroller can't

operate properly due to corrupted data contained in the Operational Data/Status

Section of RAM memory. When this error is generated, like a "405" or "408" Error,

a "407" is recorded in the Error Log, but the control does not enter Error Mode and

continues to operate normally using previously stored Status RAM data (that can be

up to 6 hrs. old). This portion of memory includes the state of motors, relays, flow,

regen, and more. Most things that are tracked on a moment-by-moment basis that

need to be able to recover in the event of a power loss or reset is saved here.

408

DIAGNOSTIC RAM

DIAGNOSTIC RAM MEMORY FAILURE - Error generated when the microcontroller

can't operate properly due to corrupted data contained in the Diagnostic Section

of RAM memory. When this error is generated, like a "405" or "407" Error, a "408" is

recorded in the Error Log, but the control does not enter Error Mode and continues

to operate normally using previously stored Diagnostic RAM data (that can be up to

6 hrs. old). This portion of memory includes parameters normally displayed in the

diagnostic branch of the menu map.

410

CONFIG DOWNLOAD Configurator file downloaded to the control was not originally uploaded from

another control with the identical software revision

Error Description of Error

77

Nelsen Water Solutions 1", 1¼", 1½", 2" & Twin Control Valves

Troubleshooting

No Display on PC Board

No power at electric outlet Repair outlet or use working outlet

Control valve power adapter is not plugged

into outlet or power cord end is not con-

nected to PC board connection

Plug Power Adapter into outlet or connect power cord

end to PC Board connection

Improper power supply Verify proper voltage is being delivered to PC Board

Improper power supply Replace power adapter

Defective PC Board Replace PC Board

PC Board does not dis-

play correct time of day

Power Adapter plugged into electric outlet

controlled by light switch Use uninterrupted outlet

Tripped breaker switch and/or tripped GFI Reset breaker switch and/or GFI

Power outage

Reset time of day. If PC Board has battery back up pres-

ent the battery may be depleted. See front cover and

drive assembly drawing for instructions

Defective PC Board Replace PC Board

Display does not

indicate that water is

flowing. (Refer to user

instructions for how the

display indicates water

is flowing)

Bypass valve is in bypass position Turn bypass handles to place bypass in service position

Meter is not connected to meter connec-

tion on PC Board

Connect meter to three pin connection labeled METER

on PC Board

Restricted/stalled meter turbine Remove meter and check for rotation or foreign material

Meter wire is not installed securely into

three pin connector

Verify meter cable wires are installed securely into three

pin connector labeled METER

Defective meter Replace meter

Defective PC Board Replace PC Board

Control valve

regenerates at wrong

time of day

Power outage

Reset time of day. If PC Board has battery back up

present the battery may be depleted. See front cover

and drive assembly drawing for instructions

Time of day is not set correctly Reset to correct time of day

Time of regeneration is set incorrectly Reset regeneration time

None of the Above Call Dealer for further troubleshooting

Time of day flashes on

and off Power outage

Reset time of day. If PC Board has battery back up pres-

ent the battery may be depleted. See front cover and

drive assembly drawing for instructions

Control valve does not

regenerate automati-

cally when the REGEN

button is pressed and

held

Broken drive gear or drive cap assembly Replace drive gear or drive cap assembly

Broken piston rod Replace piston rod

Defective PC Board Defective PC Board

Control valve does not

regenerate automati-

cally but does when

the REGEN button is

pressed and held

Bypass valve is in bypass position Turn bypass handles to place bypass in service position

Meter is not connected to meter connec-

tion on PC Board

Connected meter to three pin connection labeled METER

on PC Board

Restricted/stalled meter turbine Remove meter and check for rotation or foreign material

Incorrect programming Check for programming error

Meter wire is not installed securely into

three pin connector

Verify meter cable wires are installed securely into three

pin connector labeled METER

Defective meter Replace meter

Defective PC Board Replace PC Board

88Nelsen Water Solutions User Guide

Troubleshooting

Hard or untreated water

is being delivered

Bypass valve is open or faulty Fully close bypass valve or replace

Media is exhausted due to high water

usage Check diagnostics for abnormal water usage

Media is exhausted due to high water

usage Remove meter and check for rotation or foreign material

Meter not registering Test water and adjust program values accordingly

Water quality fluctuation Add proper salt to tank

No brine or low level of brine in brine tank Refer to Control valve fails to draw in brine below

Control fails to draw in brine Check refill setting in programming. Check refill flow

control for restrictions or debris and clean or replace

None of the above Call your Water Treatment Dealer

Control valve uses too

much brine

Improper refill setting Check refill setting

Improper program settings Check program setting to make sure they are specific to

the water quality and application needs

Control valve regenerates frequently Check for leaking fixtures that may be exhausting

capacity or system is undersized

Residual brine being

delivered to service

Low water pressure Check incoming water pressure - water pressure must

remain at minimum of 25 psi

Incorrect injector size Replace injector with correct size for the application

Restricted drain line Check drain line for restrictions or debris and clean

Excessive water in brine

tank

Improper program settings Check refill setting

Plugged injector Remove injector and clean or replace

Drive cap assembly not tightened in

properly Re-tighten the drive cap assembly

Damaged seal/stack assembly Replace seal/stack

Restricted or kinked drain line Check drain line for restrictions or debris and or un-kink

drain line

Plugged backwash flow controller Remove backwash flow controller and clean or replace

Missing refill flow controller Replace refill flow controller

Control valve fails to

draw in brine

Injector is plugged Remove injector and clean or replace

Faulty brine piston Replace brine piston

Brine line connection leak Inspect brine line for air leak

Drain line restriction or debris cause

excess back pressure Inspect drain line and clean to correct restriction

Drain line too long or too high Shorten length and or height

Low water pressure Check incoming water pressure - water pressure must

remain at minimum of 25 psi

Water running to drain

Power outage during regeneration Upon power being restored control will finish the re-

maining regeneration time. Reset time of day

Damaged seal/stack assembly Replace seal/stack assembly

Piston assembly failure Replace piston assembly

Drive cap assembly not tightened properly Re-tighten the drive cap assembly

99

Nelsen Water Solutions 1", 1¼", 1½", 2" & Twin Control Valves

Limited Warranty

NELSEN CORPORATION - NWS WATER CONDITIONER

Nelsen Corporation (“Nelsen”) provides this limited warranty as described below (the “Limited Warranty”).

Limited Warranty - Subject to the terms of this Limited Warranty, Nelsen warrants to the original buyer (“Buyer”) of this Water

Conditioner product (the “Product”) solely from a Nelsen authorized dealer that the Product will be free from defects in material or

workmanship for a period of one (1) year after the date of original installation. This Limited Warranty shall apply only if the Product is

installed, operated and maintained in strict accordance with Nelsen’s or the manufacturer’s guidelines and other legal requirements.

The Product is sold with the understanding that Buyer has independently determined the suitability and compatibility of such Product

for Buyer’s purposes. Any statements, technical information or recommendations concerning the Product or any parts therein by

Nelsen are based upon data provided to Nelsen by its suppliers and believed to be accurate, but do not constitute a guarantee or

warranty. This Limited Warranty shall not cover and shall be null and void if, in Nelsen’s discretion, the Product, or any parts therein,

are: (a) manufactured by a third party manufacturer; (b) modified after sale or use of replacement parts not specified by manufacturer

requirements; (c) improperly installed, stored, used, operated, handled or maintained; or (d) abused, misused or otherwise damaged

for any reason, including due to negligence, weather, fire, lightning, power surges or other acts of God or exposure to freezing or hot

water or the effects of normal wear and tear.

Third Party Warranties - In lieu of the above Limited Warranty, the Product, or any parts therein, may be covered by a third-party

manufacturer’s warranty. Nelsen’s authorized dealer will provide Buyer with a copy of any third-party manufacturer warranty prior

to purchase. Nelsen shall transfer and assign to Buyer any and all third-party manufacturer’s warranties on the Product, or any parts

therein, subject to the conditions and exclusions in the manufacturer’s warranty. Buyer’s exclusive remedy under such third-party

manufacturer’s warranty shall be against such third-party manufacturer and not Nelsen. Buyer may need to register the Product with a

third party manufacturer in order to obtain its warranty.

Additional Conditions -

• This Limited Warranty only covers the Product, and any parts therein, if used exclusively for residential purposes in a single-

family dwelling. This limited warranty shall be null and void if the Product is used for commercial, industrial or other non-residential

applications.

• This Limited Warranty will not cover any Product used for outdoor installations unless a weather cover that complies with

manufacturer requirements is utilized.

• This Limited Warranty shall not cover the Product if operated at water pressures or water temperatures or with water contaminants

that exceed manufacturer’s guidelines.

• The Product may include interconnecting piping that may have leaks, even if tested at the time of manufacture, due to pipe

vibrations and handling. For example, galvanized pipe threads are diligently assembled with recommended thread sealants but may

have leaks discovered at the time of installation or start-up. The installer of the goods is responsible for checking the system for leaks

upon start-up and making any repairs if necessary.

• This Limited Warranty does not cover damage or failure of the Product, or any part therein, caused by friction, wear, chemical

attack or debris build-up on wear parts. For purposes hereof, “wear parts” shall include, without limitation, pistons, piston rods, seals,

spacers, end cap quad rings, brine valves, valve disk flappers and parts requiring replacement under recommended maintenance

procedures, including, without limitation, o-rings and gaskets.

Warranty Claims - All claims under this Limited Warranty shall be submitted by Buyer to the authorized Nelsen dealer who sold the

Product in writing and shall include the Buyer’s name, address, telephone number, date of purchase of the Product, receipt evidencing

proof of purchase and a copy of this Limited Warranty. Nelsen or its authorized dealer will investigate the claim. Buyer must fully

cooperate in investigating and evaluating the claim, including, without limitation, providing additional information upon request. TO BE

ELIGIBLE FOR COVERAGE UNDER THIS LIMITED WARRANTY, BUYER MUST SUBMIT A CLAIM WITHIN SIXTY (60) DAYS OF THE DATE

THAT THE ALLEGEDLY DEFECTIVE PRODUCT OR PART IS FIRST DISCOVERED BY BUYER AND, IN NO EVENT, LATER THAN SIXTY (60)

DAYS AFTER THE WARRANTY PERIOD HEREIN.

Repair or Replacement/Credit - Subject to the conditions and limitations herein, if Nelsen determines that the Product, or any part

therein, does not conform to this Limited Warranty, Nelsen will repair or replace the defective Product or part therein. Non-conforming

Products or parts therein must be returned to Nelsen’s authorized dealer at Buyer’s cost. Any replaced Products, or any parts therein,

shall be retained by and become the property of Nelsen. If Nelsen determines that the repair or replacement of the Product or part

Continued Next Page

©Nelsen CorporationPart No: NWS USER GUIDE

therein is not commercially practicable, Nelsen will issue a credit in favor of Buyer in an amount not to exceed the purchase price of

the Product. Notwithstanding anything to the contrary herein, this Limited Warranty does not cover any cost or labor associated with

the removal or re-installation of the replacement Product or part therein or any shipping costs associated with the returned Product or

part therein, which remains the sole cost, risk and responsibility of Buyer, unless otherwise agreed in writing by Nelsen.

Eligibility/Non-Transferable - This Limited Warranty applies only to Buyer if the Product is purchased from a Nelsen authorized dealer.

This Limited Warranty is personal to Buyer and may not be assigned or otherwise transferred by Buyer. Any attempt to transfer this

Limited Warranty shall be null and void and not recognized by Nelsen.

Disclaimer of Other Warranties/Limitation on Liability

EXCEPT AS PROVIDED ABOVE AND TO THE EXTENT PERMITTED BY LAW, THERE ARE NO OTHER REPRESENTATIONS OR

WARRANTIES WITH RESPECT TO THE PRODUCT, EITHER EXPRESSED OR IMPLIED, WRITTEN OR ORAL, OR ARISING UNDER

CUSTOM OF TRADE, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. NO REPRESENTATIONS OR WARRANTIES AT ANY TIME MADE BY ANY EMPLOYEE, AGENT OR

REPRESENTATIVE OF NELSEN SHALL BE EFFECTIVE TO VARY OR EXPAND ANY WRITTEN WARRANTY OR THE TERMS HEREOF. TO

THE EXTENT A WAIVER OF IMPLIED WARRANTIES IS PROHIBITED BY LAW, ANY IMPLIED WARRANTIES SHALL BE LIMITED TO THE

DURATION OF ANY WRITTEN WARRANTY PROVIDED BY NELSEN.

IN NO EVENT SHALL NELSEN BE LIABLE TO BUYER OR TO ANY THIRD PARTY FOR CONSEQUENTIAL, INCIDENTAL, SPECIAL OR

PUNITIVE DAMAGES, OR FOR LOST PROFITS OR LOSS OF USE, RESULTING FROM OR IN ANY MANNER RELATED TO THE PRODUCT,

ITS DELIVERY, NON-DELIVERY, USE, OR INABILITY TO USE THE SAME, WHETHER SUCH DAMAGES BE CLAIMED UNDER CONTRACT,

TORT OR ANY OTHER LEGAL THEORY.

NELSEN’S TOTAL LIABILITY UNDER THIS OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED, IS LIMITED TO REPAIR OR

REPLACEMENT OF, OR CREDIT FOR, THE PRODUCT OR ANY PART, AS STATED HEREIN.

Waiver of Class Action

ANY AND ALL CLAIMS ASSERTED BY BUYER OR ANY OTHER PERSON OR ENTITY SHALL BE RAISED IN AN INDIVIDUAL CAPACITY

AND NOT AS A PLAINTIFF OR CLASS MEMBER IN ANY PURPORTED CLASS OR REPRESENTATIVE PROCEEDING, WHICH ARE HEREBY

WAIVED.

Applicable Law - This Limited Warranty shall be interpreted and governed under the laws of the State of Ohio without giving effect

to the choice of law rules thereof. Nelsen and Buyer irrevocably consent and submit to the exclusive jurisdiction and venue within the

courts of Summit County, Ohio and/or the United States District Court for the Northern District of Ohio in connection with any litigation

arising out of, or in any way relating to, this Limited Warranty or the Product, including, but not limited to, any and all claims for breach

of warranty or products liability, and Nelsen and Buyer expressly waive any objection to the jurisdiction and/or venue of such courts.

Limited Warranty

This manual suits for next models

3

Other NELSEN WATER Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Savillex

Savillex DST-1000 Upgrade instructions

Pure Company

Pure Company Carbon Filter Water Decanter instructions

Evolution Aqua

Evolution Aqua EAZYPOD AUTOMATIC Installation and instruction manual

SPX FLOW

SPX FLOW ME Series instruction manual

Puretec

Puretec Basic HD Series user guide

Bio-Tek

Bio-Tek Biolux HOS Series owner's manual

Waterco

Waterco HYDROCHLOR MK3 owner's manual

FLORABEST

FLORABEST FGPZ 12 A1 Operation and safety notes

Bluewater

Bluewater Pro Series owner's manual

Eco Pure

Eco Pure ECOP20 Installation and operation manual

Plasma Made

Plasma Made GUC 1214 Installation and user manual

Clear Water

Clear Water FS016 owner's manual