SPX FLOW ME Series User manual

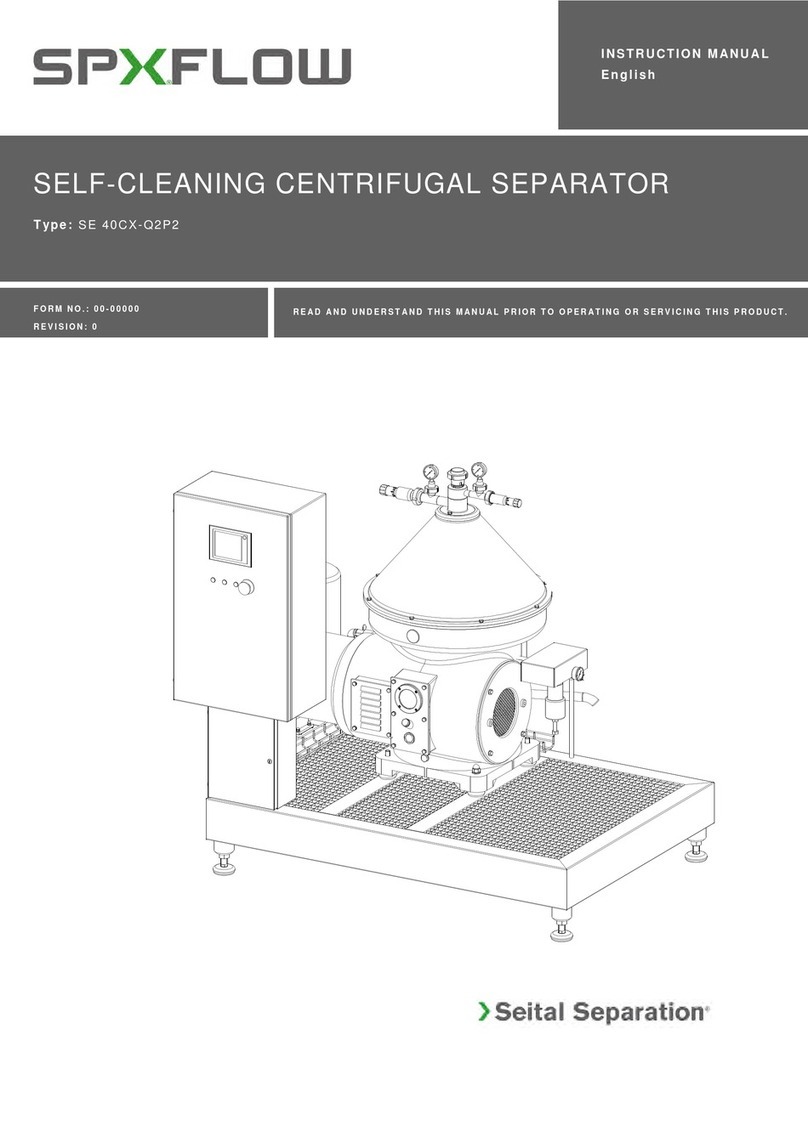

ME Series

Mist Eliminator

Models: ME125, ME250, ME500, ME1100, ME1500,

ME2100, ME2400, ME3000

FORM NO.: 3148671 REVISION: 12/2019 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

2

DESCRIPTION

The Mist Eliminator is a coalescing type oil removal lter designed to

remove oil and water aerosols from a compressed air system. It consists

of a highly engineered, loosely packed, glass ber lter cartridge housed

in a heavy duty ASME stamped pressure vessel.

Compressed air is directed into the vessel and through the lter cartridge

where entrained water and oil aerosols are captured by the bers. The

captured particles move along the bers and coalesce into larger droplets

which gravitate to the bottom of the cartridge. Here they fall into the vessel

sump and are discharged from the system.

CONTENTS

GENERAL SAFETY INFORMATION ....................... 2

RECEIVING INSTRUCTIONS ................................. 2

DESCRIPTION ........................................................ 2

1.0 INSTALLATION ................................................. 3

2.0 OPERATION ...................................................... 5

3.0 MAINTENANCE ................................................ 5

DIMENSIONS AND WEIGHTS ................................ 6

WARRANTY ............................................................ 7

GENERAL SAFETY INFORMATION

A. Pressurized devices

This equipment is a pressure containing device

• Do not exceed maximum operating pressure shown on the serial

number tag.

• Make sure equipment is depressurized before working on or

disassembling for service.

• A pressure relief device must be added to the equipment.

B. Breathing air

• Air treated by this equipment may not be suitable for breathing

without further purication.

Refer to OSHA standard 1910.134 for the requirements for breath-

ing quality air.

RECEIVING INSTRUCTIONS

A. Receiving

This shipment has been thoroughly checked, packed, and inspected

before leaving our plant. It was received in good condition by the carrier

and was so acknowledged.

1. Check for visible loss or damage

If this shipment shows evidence of loss or damage at the time of

delivery to you, insist that a notation of this loss or damage be made

on the delivery receipt by the carrier’s agent.

2. Check for concealed loss or damage

When a shipment has been delivered to you in apparent good

order, but concealed damage is found upon unpacking, notify the

carrier immediately and insist on his agent inspecting the shipment.

Fifteen days from receipt of shipment is the maximum time limit for

requesting such inspection. Concealed damage claims are not our

responsibility as our terms are F.O.B. point of shipment.

3

1.0 INSTALLATION

1.1 System cleaning

The compressed air system should be purged prior to the installation

of the Mist Eliminator.

• Solid particles should be removed from upstream lines in order to

prevent any loose dirt, rust, or scale from entering the lter and

causing a premature increase in pressure drop.

• Residual oil should be ushed from down-stream lines otherwise

considerable time will be necessary before the desired air quality

is available at the point-of-use.

1.2 Location in a compressed air system

Aftercooler/separator - It is strongly recommended that the Mist

Eliminator be installed at a point where the compressed air is as cool

as possible. In most cases the Mist Eliminator will have to be installed

downstream of an aftercooler to provide an inlet temperature below

the 150°F (65°C) maximum. While inlet temperatures as high as

150°F (65°C) are possible, this will allow some oil to remain a vapor

and pass through the lter. Lower inlet temperatures (preferably

below 120°F [49°C]) will have allowed more of the oil vapor present

to condense into liquid droplets which can then be removed by the

Mist Eliminator.

Refrigerated dryers - The Mist Eliminator should be installed down-

stream of a refrigerated dryer to remove any oil that may have

condensed inside the dryer.

Desiccant dryers - The Mist Eliminator should be installed upstream

of a desiccant dryer to prevent oil from contaminating the desiccant.

The distance between the Separator and Mist Eliminator must be

minimized to avoid over loading with water. A drop in temperature

from 110°F (43°C) to 105°F (41°C) will condense enough liquid water

to overload the Mist Eliminator.

1.3 Service clearance

Make certain that clearance exists above the lter to allow removal

and replacement of the lter cartridge.

1.4 Foundation

The Mist Eliminator can be installed on any at, level oor with suf-

cient strength to support the required weight. Mounting holes are

available for anchoring if desirable.

NOTE: Mount so that inlet and outlet connections are horizontal (vessel

is vertical). Separated and coalesced liquids drain by gravity downwards

through the cartridge and drop to and are collected in the lter sump. The

vessel must be mounted nearly plumb vertically so that drainage will not

be impeded and ltration eciency reduced.

A typical installation will also include:

Manual or Automatic Drains

Dierential Pressure Gauge

Isolation Valves and by-pass piping

1.5 Connections

Connect inlet and outlet piping to the compressed air system.

NOTE: Flow Direction - Check to ensure that the air ow is in the

proper direction as indicated on the vessel. Air ow direction through

the lter cartridge must be from the inside out.

4

1.6 Drain provisions

The bottom of the pressure vessel is provided with a drain plug for

shipping purposes. Provision for manual or automatic draining is

necessary for proper operation.

Do not attempt to remove drain plug if the unit is

pressurized.

A. Manual Drain - When draining is performed manually on a

regular, periodic basis, a simple (open/shut) valve piped to

the drain port may be used to drain the vessel. When draining

manually, the valve should be opened slowly to avoid rapid

depressurization and possible cartridge damage.

B. Automatic Drain - Where regular manual draining is not per-

formed, an automatic condensate drain should be used. A variety

of drains are available from the manufacturer. Pipe automatic

drains to the drain port.

An isolation valve is recommended if servicing drain is desired

while the system is pressurized.

1.7 Dierential pressure gauge

1. Maximum voltage switching 100 volts AC/DC

Maximum switching current 0.30 AMP

Maximum carrying current 1 AMP

Contact rating: 10 VA

A gauge and installation kit are shipped separately packaged

for eld installation. Gauge may be installed on vessel or on a

nearby wall using the wall mounting bracket supplied.

NOTE: Make certain O-rings are in place on the bottom of the

gauge body.

Connect the low pressure transmission bolt (bolt next to red band

on gauge) to the gauge port at the lter outlet (downstream side

of lter).

Connect the high pressure transmission bolt (bolt next to green

band on gauge) to the gauge port at the lter inlet (upstream

side of lter).

Torque bolts to 25 +/- 5 inch-oz. Do not over tighten.

1.8 Operating limitations

1. Maximum Working Pressure:

Standard ASME Coded Units 150 psig (10.3 bar)

NOTE: If using external drain, do not exceed pressure rating of

drain.

2. Maximum Pressure Dierential - 30 psi (2.1 bar)

IMPORTANT: Under normal circumstances the pressure dif-

ferential across the lter should not exceed 30 psi (2.1 bar);

excessive pressure drop may cause lter cartridge failure. Filter

cartridge change-out recommended at 3 psi (0.2 bar).

3. Maximum Operating Temperature - 150°F (65°C)

NOTE: Temperatures above 120°F (49°C) are not recommended

since ltration eciency may decrease.

4. Chemical Resistance - Compressed air does not normally contain

contaminants which will adversely aect the lter cartridge.

However, some hydrocarbons, acids, bases and certain

other chemicals can attack parts of the lter assembly. These

contaminants are usually introduced through the compressor

intake under certain environmental conditions.

Provision should be made to prevent this in order to protect the

entire compressed air system. On questionable applications

consult factory prior to installation.

5

2.0 OPERATION

2.1 After installation slowly pressurize Mist Eliminator and inspect for

leaks. Operation is continuous and automatic.

2.2 Periodic checks are recommended to insure continuous separation

and ltration eciency.

A.. Check pressure drop

1. Check for excessive pressure drop. Pressure drop in excess

of 3 psi (0.2 bar) indicates that the cartridge should be re-

placed.

IMPORTANT: Pressure drop should never exceed 30 psi

(2.1 bar).

2. Check for sudden reduction in pressure drop. This might

indicate a leak through the lter cartridge due to damage

from chemical attack or excessive pressure drop.

B. Check the flow, pressure, and temperature to make sure

that the lter is not being operated beyond its rated capacity.

See Section 1.8 for operating Limitations and Section 2.3 to

determine maximum ow capacity.

C. Check for proper drainage. See that manual drains are drained

periodically and that automatic drains are functioning.

2.3 Determining maximum ow capacity

Maximum air ow for the various lters at 100 psig (7 bar) is indicated

in Table 1. To determine maximum air ows at inlet pressures other

than 100 psig (7 bar), multiply ow from Table 1 by multiplier from

Table 2 that corresponds to the minimum operating pressure at the

inlet of the lter.

2.4 Maximum Operating Conditions

Maximum Working Pressure: 150 psig (10.3 bar)

ASME coded pressure vessels

Maximum Operating Temperature: 150°F (65°C)

TABLE 1

Model

Number

Flow scfm @

100 psig, 7 bar

ME125

ME250

ME500

ME1100

ME1500

ME2100

ME2400

ME3000

125

250

500

1100

1500

2100

2400

3000

TABLE 2

Minimum

Inlet Pressure

psig / bar

Multiplier

20 / 1.4

30 / 2.1

40 / 2.8

60 / 4.1

80 / 5.5

100 / 7.0

120 / 8.3

150 / 10.3

0.30

0.39

0.48

0.65

0.82

1.00

1.17

1.43

3.0 MAINTENANCE

3.1 When to replace lter cartridge

A. Initial (dry) pressure drop: 1 psi (0.07 bar) nominal.

B. Operating pressure drop: During operation the lter cartridge

becomes liquid loaded (wetted). At rated flow conditions,

operating pressure drop will normally be: 0.5 to 1 psi (0.035 to

0.07 bar). Further pressure drop will occur only as the cartridge

becomes loaded with solid particles.

C. Change out pressure drop: IT IS RECOMMENDED THAT THE

CARTRIDGE BE REPLACED FOR MAXIMUM FILTRATION

EFFICIENCY WHEN PRESSURE DROP REACHES 3 PSI

(0.2 BAR).

NOTE: Pressure drop after ow interruption.

When ow is interrupted for several hours, the pressure drop may tempo-

rarily increase upon the resumption of ow. Normally, within one hour, the

pressure drop should return to where it was prior to stopping the ow. This

phenomenon is not cause for lter cartridge replacement. It is due both

to residual liquids contained within the cartridge “pooling” and a change

in the viscosity of these liquids due to a temporary temperature change.

3.2. Procedure for lter cartridge replacement

THIS FILTER IS A PRESSURE CONTAINING DEVICE. DEPRESSURIZE

BEFORE SERVICING.

A. By-pass the lter assembly to permit servicing.

B. Depressurize the lter assembly slowly by opening blow down

valve.

C. Remove bolts securing the lter top to the vessel.

D. Remove the top ange of the lter complete with lter element.

E. Clean the inside of the vessel and inspect for any signs of cor-

rosion.

F. Unscrew the lter element from the top ange. Discard the ele-

ment in accordance with applicable regulations.

Used elements typically hold contaminants, such as compressor

lubricants and particulate matter.

G. Thread new element into top ange.

H. Replace top ange (complete with new lter element).

I. Reinstall bolts to secure lter top.

J. Slowly repressurize lter housing and check for any leaks.

6

NOTES: Dimensions and Weights are for reference only. Request certied drawings for construction purposes.

DIMENSIONS AND WEIGHTS

NOTES

1. All models meet the requirements of the A.S.M.E.

Boiler and Pressure Vessel Code and have the code

stamp applied.

2. Vessels with 4” or 6” nozzles have anges only. The

bolt holes straddle the vertical center line.

3. Maximum operating temperature for all vessels is

150°F (66°C).

Nominal Air Flow @ 100PSIG 125 SCFM 250 SCFM 500 SCFM 1100 SCFM 1500 SCFM 2100 SCFM 2400 SCFM 3000 SCFM

Vessel Type Type I Type I Type I Type Il Type Il Type Ill Type Ill Type Ill

Shell Size

(O.D.)

Inches

(mm)

14

(356)

14

(356)

14

(356)

16

(406)

18

(457)

24

(610)

24

(610)

24

(610)

Inlet Connection 2” FLG

150# CL

2” FLG

150# CL

2-1/2” FLG

150# CL

4” FLG

150# CL

4” FLG

150# CL

4” FLG

150# CL

4” FLG

150# CL

4” FLG

150# CL

Outlet Connection 2”

NPT (F)

2”

NPT (F)

2-1/2”

NPT (F)

4” FLG

150# CL

4” FLG

150# CL

4” FLG

150# CL

4” FLG

150# CL

4” FLG

150# CL

“A” INCHES

(mm)

17-3/4

(451)

17-3/4

(451)

17-15/16

(456)

25-13/16

(656)

26-13/16

(681)

32-13/16

(833)

32-13/16

(833)

32-13/16

(833)

“B” INCHES

(mm)

37-1/8

(943)

37-1/8

(943)

48-1/16

(1221)

72-3/4

(1848)

80-1/8

(2035)

89-3/8

(2270)

89-3/8

(2270)

89-3/8

(2270)

“C” INCHES

(mm)

27-1/8

(689)

27-1/8

(689)

36-1/2

(927)

55-1/8

(1400)

62-1/2

(1588)

71-1/2

(1816)

71-1/2

(1816)

71-1/2

(1816)

“D” INCHES

(mm)

11-1/2

(292)

11-1/2

(292)

11-1/2

(292)

11-1/2

(292)

11-1/2

(292)

11-1/2

(292)

11-1/2

(292)

11-1/2

(292)

“E” INCHES

(mm)

14

(356)

14

(356)

14

(356)

16

(406)

18

(457)

24

(610)

24

(610)

24

(610)

“F” INCHES

(mm)

12

(305)

15

(381)

27

(686)

46

(1168)

46

(1168)

36

(914)

50

(1270)

62

(1574)

Filter Assembly

Weight

POUNDS

(kg)

185

(84)

185

(84)

220

(100)

350

(159)

390

(177)

700

(318)

715

(324)

730

(331)

Replacement Crtg

Weight

POUNDS

(kg)

15

(7)

20

(9)

35

(16)

60

(28)

80

(37)

120

(55)

135

(62)

150

(68)

Drain Size Connection 1” NPT 1” NPT 1” NPT 1” NPT 1” NPT 1” NPT 1” NPT 1” NPT

Replacement Cartridge

Catalog Number 4001416 4001417 4001418 4001419 4001421 4001422 4001423 4001424

7

Mist Eliminator Warranty and Conditions of Sale

1. Mist Eliminator Coalescing Filter Cartridge 5 Year Guarantee Statement:

Seller guarantees that the coalescing lter cartridge shall not require replacement for ve (5) years after

shipment by Seller. This guarantee is based on the lter as delivered and is contingent upon the following:

a) the lter is installed and operated as specied in the Installation and Operating Manual supplied with the

lter and

b) operation of the lter is within the lter specication limits.

2. Mist Eliminator 5 Year Warranty Statement:

Seller warrants that the lter will be free from defects due to materials or workmanship for ve (5) years after

shipment by Seller. If within thirty (30) days after Buyer’s discovery of any such defects, Buyer noties Seller

thereof in writing, seller shall, at its options and as the exclusive remedy for this warranty, promptly repair or

replace the portion of the lter found to be defective. Failure by Buyer to give Seller such written notice within

the applicable time period specied above, shall be deemed a waiver of buyer’s claim for such defects.

The warranty covers parts only for the warranty period. Products repaired or replaced under warranty shall be

warranted for the unexpired portion of the warranty applying to the original product. This warranty is based on

the lter as delivered and is contingent upon the following:

a) the lter is installed and operated as specied in the Installation and Operating Manual supplied with the

lter and

b) operation of the lter is within the lter specication limits. The maximum damages liability of the

manufacturer or seller is the original purchase price of the product or part.

The foregoing warranty is exclusive and in lieu of all warranties, whether written, oral, or statutory, and is

expressed in lieu of the implied warranty of merchantability and the implied warranty of tness for a particular

purpose.

The manufacturer shall not be liable for loss or damage by reason of strict liability in tort or its negligence in

whatever manner including design, manufacture or inspection of the equipment or its failure to discover, report,

repair, or modify latent defects inherent therein.

The manufacturer, his representative or distributors shall not be liable for loss of use of the product or incidental

or consequential costs, expense, or damages incurred by the buyer, whether arising from breach of warranty,

negligence or strict liability in tort.

SERVICE DEPARTMENT: (724) 746-1100

ME SERIES

Mist Eliminator

Models: ME125, ME250, ME500,

ME1100, ME1500, ME2100,

ME2400, ME3000

SPX FLOW, INC.

4647 S.W. 40th Avenue

Ocala, Florida 34474-5788 U.S.A.

P: (724) 745-1555

E: ft.dehydration.order.entry@spxflow.com

www.spxflow.com/deltech

Improvements and research are continuous at SPX FLOW, Inc.

Specifications may change without notice.

ISSUED 12/2019 Form No. 3148671 Revision: E

COPYRIGHT ©2019 SPX FLOW, Inc.

This manual suits for next models

8

Table of contents

Other SPX FLOW Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Pentair Pool Products

Pentair Pool Products POSI-CLEAR PXC Series Installation and operating instructions

Bartscher

Bartscher K3600L Original instruction manual

Prozone Water Products

Prozone Water Products Complete Sanitation System 15 instructions

BRITISH BERKEFELD

BRITISH BERKEFELD SS Gravity Assembly, Operating and Maintenance Instruction

Aqua Free

Aqua Free Germlyser AM Instructions for use

Kinetico

Kinetico ERGO RO BLUE Instructions for use