2/01

PART CIRCLE S3000 AND D3000

DESIGNING WITH PART CIRCLE SPRINKLERS

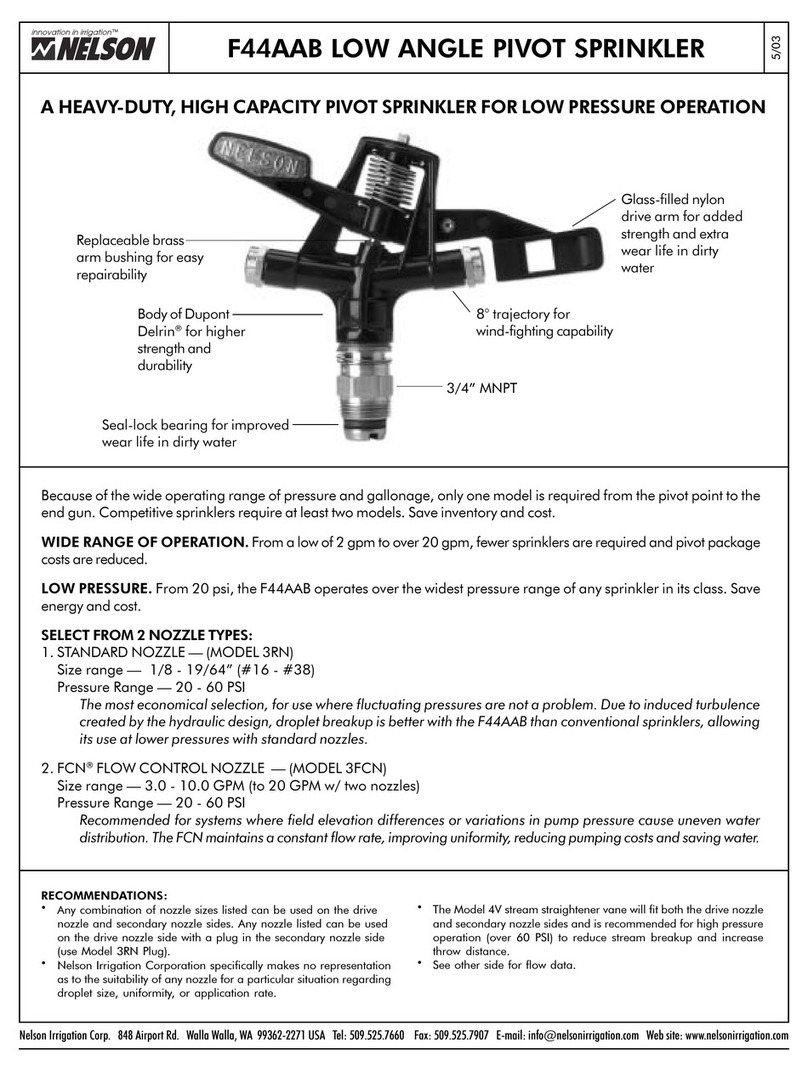

STEP 1: Plan the system with conventional full circle sprinklers.Plan the system with conventional full circle sprinklers.

Plan the system with conventional full circle sprinklers.Plan the system with conventional full circle sprinklers.

Plan the system with conventional full circle sprinklers.

For Linears/Laterals select sprinkler spacing and determine the

nozzle size to deliver your desired application rate. For pivot

systems, planning should include a Sprinkler Package Chart. The

Part Circle Spinner will fit best in packages with sprinkler spacing

of 15 feet (4.5m) or less. The Part Circle Spray should be in

sprinkler packages with spacings of 11 feet (3.3m) or less. If the

part circle devices are to be mounted on boombacks, maintain

uniform spacing between all sprinklers. If the devices will be

mounted on conventional drops, a distance of 1 to 3 feet (.3 to 1m)

between the wheel and the closest sprinkler on each side is optimal.

STEP 2:

Determine which outlets need modified sprinklers.Determine which outlets need modified sprinklers.

Determine which outlets need modified sprinklers.Determine which outlets need modified sprinklers.

Determine which outlets need modified sprinklers.

Use the preliminary design to compare the distance to the tower

with the radius for each sprinkler. If you are working from a Sprinkler

Package Chart, adjust the listed Tower location for the wheel offset.

An offset of 2 feet (.6m) is common. Coverage diameter information

on other 3000 Series Sprinklers is available in the SELECTOR

software program or by contacting Nelson Irrigation.

STEP 3: Plan the orientation angles for the PPlan the orientation angles for the P

Plan the orientation angles for the PPlan the orientation angles for the P

Plan the orientation angles for the Part Circle Sprinklers.art Circle Sprinklers.

art Circle Sprinklers.art Circle Sprinklers.

art Circle Sprinklers.

The semicircular pattern of the Part Circle Sprinklers adjacent

to the towers should be oriented as close to perpendicular to

the main pipe as possible. On boombacks, they should face

directly away from the main pipe as shown in the diagram. On

straight drops, they should be adjusted so the edge of the

semicircle falls immediately behind the rear tower wheel. If

possible, orient adjacent part circles at opposite directions from

the pipe. This reduces the application rate.

ADDITIONAL CAUTIONS

It is important to mount Part Circle Sprinklers on rigid drops. Side thrust will cause extreme movement of flexible drops.

Part Circle Sprinklers cannot provide the whole solution to traction, rutting, or runoff problems. If you are trying to utilize

mechanized irrigation systems on steep slopes or heavy soils you should carefully consider all aspects of system design

and management that can contribute to reduced soil loading and application rate minimization. The distribution profile

of the Part Circle Sprinklers provides good overlaps with conventional sprinklers in most configurations. However, it is

likely that a system intended to minimize application at the tower will not achieve the high uniformity possible with a well

designed conventional system. For best results keep the spacing within the limits described above. Part Circle Sprinklers

can be used to minimize, but they will not totally eliminate, application on the towers or wheel tracks.

WARRANTY AND DISCLAIMER

Nelson Part Circle Spinners & Sprays warranted for one year from date of original sale to be free of defective materials and workmanship when used within the working

specifications for which the products were designed and under normal use and service. The manufacturer assumes no responsibility for installation, removal or unautho-

rized repair of defective parts. The manufacturer’s liability under this warranty is limited solely to replacement or repair of defective parts and the manufacturer will not be

liable for any crop or other consequential damages resulting from defects or breach of warranty. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSES AND OF ALL OTHER OBLIGATIONS OR

LIABILITIES OF MANUFACTURER. No agent, employee or representative of the manufacturer has authority to waive, alter or add to the provisions of this warranty, nor to

make any representations or warranty not contained herein.

Part-Circle Sprinklers can be installed in a

variety of configurations

BOOMBACKS

STRAIGHT DROPS

Installations on boombacks minimize the compromise in

uniformity that occurs when part-circle devices are utilized.

Installations on straight drops require careful adjust-

ment of the orientation.

Nelson Irrigation Corporation 848 Airport Road Walla Walla, WA 99362-2271 USA Tel: 509.525.7660 Fax: 509.525.7907 info@nelsonirrigation.com www.nelsonirrigation.com

Nelson

Irrigation

Corp.

of

Australia

Pty

Ltd

35

Sudbury

Street

Darra

QLD

4074

T

el:

+61

7

3715

8555

Fax:

+61

7

3715 8666 [email protected] www.nelsonirrigation.com.au