SRNV100 BIG GUN® OPERATION AND ADJUSTMENT INSTRUCTIONS

Nelson Irrigation Corporation 848 Airport Road W

alla Walla, W

A

99362-2271 USA el: 509.525.7660 Fax: 509.525.7907 E-mail: [email protected] Web site: www.nelsonirrigation.comSET UP FOR OPERATION:

1. Install 100T taper bore nozzle or

100R ring nozzle. The SRNV100 is

not designed to operate with the

100TR taper ring nozzle. If using the

ring nozzle set, install desired ring size

in the ring nozzle cap. The ring nozzle

cap can be sufficiently tightened by

hand. NOTE: If the 100R is used, it is

supplied with the ring cap, part number

7872. If any other cap is used, the

nozzle al e will not completely close.

. To install the SRNV100, orient the

lower unit so the solenoid or hose

bracket will be located on the right

when viewed from the rear of the Big

Gun looking downstream.

3. Adjust location of stops to give desired

arc of coverage. Stops must be mounted

so that the arrows point toward each

other and the trip lever is located between

the arrows. If the stops are reversed on

the wrong end of the arc then the Big

Gun will fail to reverse.

4. The SRNV100 is factory set for normal

rotation speed. If a faster or slower

rotation speed is desired, move the arm

weight backward for faster operation

or forward for slower operation. The

SR100 low pressure drive vane kit,

part number 9857, is available to

enhance the drive when operating in

a nozzle range of .5-.65 100T and

pressure below 60 psi. NOTE: If the

SRNV100 is mounted on a tilted riser

of 10 degrees (or 17% slope) or more,

a 100CBK counter balance kit is

recommended to pre ent back-

sliding and impro e proper rotation

throughout the entire arc setting.

OA-SRNV100-2 8/01

SRNV100 BIG GUN®

WARRANTY AND DISCLAIMER

Nelson Big Gun® Sprinklers are warranted or one year rom date o original sale to be ree o de ective materials and workmanship when used within the working

speci ications or which the product was designed and under normal use and service. The manu acturer assumes no responsibility or installation, is limited solely to

replacement or repair o de ective parts, and the manu acturer will not be liable or any crop or other consequential damages resulting rom any de ects or breach o

warranty. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PARTICULAR PURPOSES AND OF ALL OTHER OBLIGATIONS OR LIABILITIES OF MANUFACTURER. No agent, employee or representative o the manu acturer

has authority to waive, alter or add to the provisions o the warranty, nor to make any representations or warranty not contained herein. This product may be covered

by one or more o the ollowing U.S. Patent Numbers 3,744,720 and 3,559,887 and other U.S. Patents pending or corresponding issued or pending oreign patents.

5. If installing the SRNV100E (with solenoid), connect the solenoid wires to the

proper voltage source. Energizing the solenoid with the proper voltage results

in the valve opening. If installing the SRNV100H hydraulically controlled

(without solenoid), connect the actuator feed hose to the appropriate control

pressure circuit. Application of hydraulic pressure (equal to or greater than

SRNV100 base water pressure) to the actuator causes the nozzle valve to

close. If actuator control pressure (line pressure) is approximately 0 psi or

below, low pressure SRNV closure kit, part number 99 4, is recommended to

provide reliable operation.

6. Be sure the entire control system is operating properly and that the hydraulic

fittings are securely installed. Failure to do so could prevent the nozzle valve

from closing, possibly causing personal injury or property damage. Observe

an entire opening-closing-opening cycle for proper operation.

WARNING!

1. Read operating instructions before operating sprinkler or making any

adjustments.

. Never make adjustments or perform service while sprinkler is in operation.

3. Stand clear of high velocity water stream.

4. Never direct water stream onto roadway or electrical transmission lines.

5. Stay clear of nozzle valve linkage during operation. High clamping forces exist.

6. Stand clear of sprinkler during operation. Abrupt water spray exists during

opening and closing of valve.

7. To avoid injury or damage, check for proper operation of control system

before using nozzle valve.

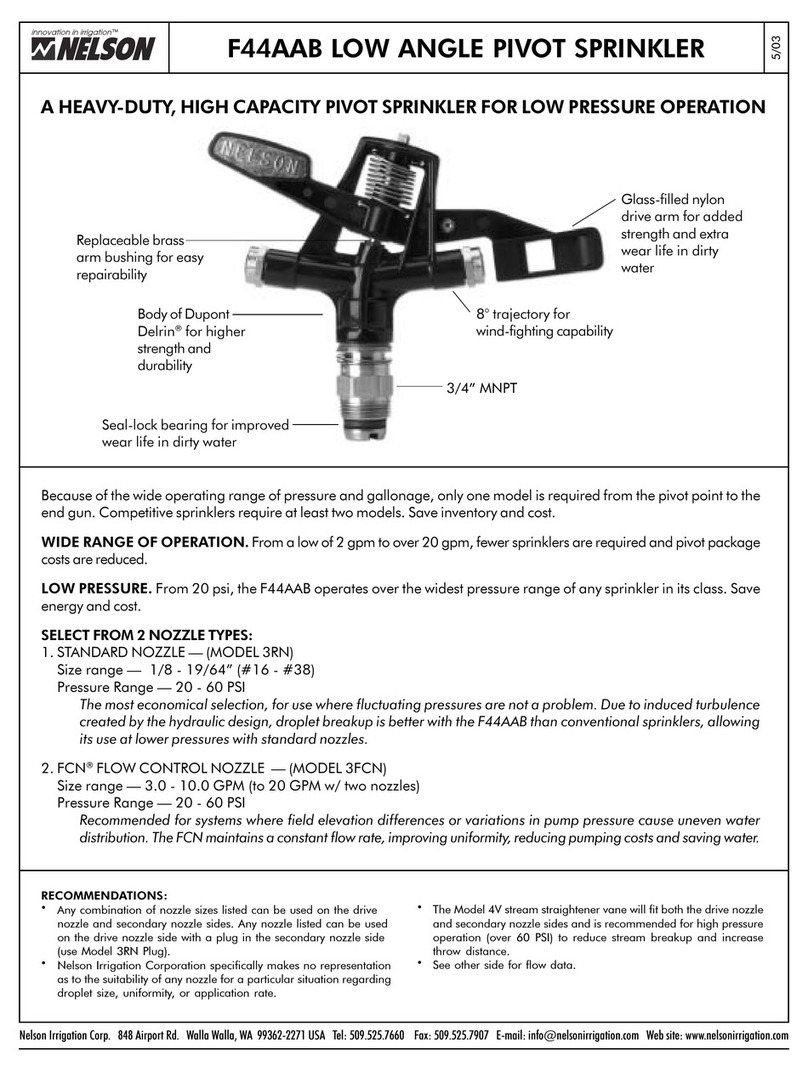

Trip Lever

Shift Lever

Arm Weight

Drive Arm

Nozzle

Actuator Feed Hose

Solenoid

Drive Vane

Nozzle Lever

Toggle Linkage

Actuator

Valve Seat