Neomeris Softwater RS Troubleshooting guide

Page 1 of 8

Gebr. Heyl Vertriebsgesellschaft für innovative Wasseraufbereitung mbH I Max-Planck-Straße 16 I D- 31135 Hildesheim

Phone: +49 (0) 5121 7609-0 I Fax: +49 (0)5121 7609-44 www.heylneomeris.de

NEOMERIS Softwater RS

Installation instruction and operation manual

Page 2 of 8

Gebr. Heyl Vertriebsgesellschaft für innovative Wasseraufbereitung mbH I Max-Planck-Straße 16 I D- 31135 Hildesheim

Phone: +49 (0) 5121 7609-0 I Fax: +49 (0)5121 7609-44 www.heylneomeris.de

Delivery comprises:

NEOMERIS Softwater RS

Note: Flow controller must be

ordered additionally. Size depends

on the pipe dimensions tubing for

connection (see selection table on

data sheet).

Intended use:

The device is used to monitor the water

hardness in pipes that contain fully

softened water.

Application limits:

Max. water temp.: 30°C (86°F)

Ambient temperature:

15°C (59°F) – 40° C (104° F)

Operating pressure: 2.5 – 6.0 bar

No water hammers.

Power supply and water pressure must be

constantly available. The feed water must

come from a softening system which is

operated in the sodium cycle. The pipes up

flow must be free of corrosion.

Installation

The NEOMERIS Softwater RS monitor

needs the following connections:

• Socket with 230V and 10W

• Connection to soft water

• Connection to drain

• brine supply

NEOMERIS Softwater RS

Flow Controller

The nominal size of the flow controller

needs to fit to the expected amounts of

flow. They may differ from the installed

nominal size of the existing pipes. A waste

water connection is required to re-

generate the (hardness) sensor. The

nominal width of the sewage pipe has to be

DN6. The amount of waste water per

regeneration is about 1.5—2 Liters (0.4—

0.5 gal). The maximum length of the hose is

5 meters (16.4 ft). The maximum level of

waste water transfer is 1m (3ft) above the

device. In case it is impossible to provide

these condition, you may use a longer

waste water hose or another height of the

device. But in this case, it is necessary to

check if the system and the device are

working under these conditions.

Page 3 of 8

Gebr. Heyl Vertriebsgesellschaft für innovative Wasseraufbereitung mbH I Max-Planck-Straße 16 I D- 31135 Hildesheim

Phone: +49 (0) 5121 7609-0 I Fax: +49 (0)5121 7609-44 www.heylneomeris.de

Installation and user manual:

The brine supply (10% NaCl) is needed to rege-

nerate the (hardness) sensor. It needs about

0.25 Liters (0.07 gal) or less to regenerate. The

pipe for the brine supply may not exceed 10 m

(33 ft). There are two possibilities available for

the brine supply:

• use of an existing brine tank (not

recommended)

• container with already 10% concentrate brine

If there is a brine tank available, install the suc-

tion lance in the tank. Do not block the brine

valves inside the tank. The best way is to install

a new brine pipe in the tank. The brine level has

to be at all times above the suction lance. In case

there is no brine tank available, you should use a

20 or 30 Liter container with already

concentrated brine (5-8 gal.). The brine should

last for 80-120 regenerations.

Electrical Connection:

The connection is made by inserting the

transformer into the wall socket.

Alarm Signal:

Contact Rating 24V 1A, you can connect the

alarm signal by using the 12 m connection plug.

Mounting:

The flow controller needs to installed in the soft

water pipe. Take care of the flow direction. It

doesn’t matter if mounted horizontal or vertical.

The NEOMERIS Softwater RS should be installed

as close as possible to the flow controller

because the testing hoses should be as short as

possible. Please mount the device with the holes

at the rear.

Connect the flow controller and the NEOMERIS

Softwater RS with the “yellow/6 mm” hoses. Be

careful that you don’t mix up the forward and

backward flow.

Connect the waste water with “red hose/8mm”

to the drain. No fixed connection (the drain exit

needs to be above the brine level).

Page 4 of 8

Gebr. Heyl Vertriebsgesellschaft für innovative Wasseraufbereitung mbH I Max-Planck-Straße 16 I D- 31135 Hildesheim

Phone: +49 (0) 5121 7609-0 I Fax: +49 (0)5121 7609-44 www.heylneomeris.de

Mounting of the device:

All tube has to be as short as possible and may

not be kinked. We recommend not to install any

shut-of-valves in the testing hoses.

Function:

The NEOMERIS Softwater monitor consists of a

hardness sensor, multi-way-valve with motor

and electrical control. The multi-way-valve is

connected to the hydraulics via hoses.

The flow controller creates a differential

pressure that pushes the test water through the

NEOMERIS Softwater device and then back to

the soft water pipe. As soon as hardwater is in

the pipe, the hardness sensor collects the

hardness and generates a signal which triggers

the corresponding alarm at the display “—>”

hardwater—continue with ENTER.

When that happens, it is necessary to reset the

system manually by triggering a regeneration.

(ENTER Button “✓"). Before doing that, the soft-

water supply needs to be checked and, if

necessary, recovered. As soon as soft water is

available, it‘s possible to regenerate the

NEOMERIS Softwater device.

The regeneration contains the following steps:

Brine injection

Time till effect

Test the sensor (hard or soft)

Brine washout

The sensor has to be “soft“ at the end of the re-

generation-process. Otherwise there is a prob-

lem in the system.

It is possible to adjust the parameters if

necessary see manual, settings and operations.

Commissioning:

Please proceed as follows:

Plug in the transformer and check for

voltage (the LED in the display should

shine)

Please wait while “startup run...“ is

displayed.

Page 5 of 8

Gebr. Heyl Vertriebsgesellschaft für innovative Wasseraufbereitung mbH I Max-Planck-Straße 16 I D- 31135 Hildesheim

Phone: +49 (0) 5121 7609-0 I Fax: +49 (0)5121 7609-44 www.heylneomeris.de

Structure of NEOMERIS Softwater RS

Put pressure on the soft-water pipe.

Start the regeneration manually.

Observe the process—brine should be

drawn into the brine pipe. It is possible to

see the brine flushing in the pipe.

In case the brine doesn’t reach the

sensor it will detect a problem and the

display gives the Information “no sensor

while regeneration“. That means the

sensor did not emit a signal while

regeneration.

The regeneration has to be repeated, till

the brine is drawn into the pipe and the

regeneration is finished without any

problem.

After the successful regeneration the

NEOMERIS Softwater RS switches to

regular hardness monitoring process and

display the remaining time till next

forced regeneration.

Operation:

As long as no error occurs is the operation of the

Softwater Monitor fully automatic.

Manual interaction is necessary in the following

cases:

• Alarm, lack of soft-water that means

“detection of hardness“.

Page 6 of 8

Gebr. Heyl Vertriebsgesellschaft für innovative Wasseraufbereitung mbH I Max-Planck-Straße 16 I D- 31135 Hildesheim

Phone: +49 (0) 5121 7609-0 I Fax: +49 (0)5121 7609-44 www.heylneomeris.de

Alarm, no signal of the sensor while rege-

neration.

The regeneration needs to be started manually.

Now open the case and observe whether the

sensor “switches“. It means that it is possible to

see the red “signal pen“ clearly.

Maintenance:

The NEOMERIS Softwater RS doesn’t need a

preventive maintenance but we recommend an

annual checkup and the exchange of the

hardness sensor every 2 Years.

Settings:

The following parameters can be changed:

• Time and date

• Time between 2 regenerations

The following parameter can be displayed:

• The last 30 alarms with time and date

Setting the time:

Enter the main menu by pressing the “ESC“

button. To change the time, scroll through the

menu by using the “↑“ or “↓“ ll “change time“

appears. Confirm with “✓ “. By using the “↑“ or

“↓“ buon the active part of the time changes,

confirm with “✓ “ than the active part should

flash: now it‘s possible to change its value by

using “↑“ or “↓“. The change needs to be

confirmed (“✓ “). If you want to change more

than one subject, proceed as described. After

entering the correct time and date it is necessary

to “save“ the settings by scrolling through the

menu till “MEM“ appears than press “✓“ to save

the new settings. To change back into the main

menu press “ESC“.

Setting the time between regenerations:

Enter the main menu by pressing the “ESC“

button. To change the time between regene-

ration, scroll through the menu by using the “↑“

“↓“ ll „regen. rep. me“ appears. Confirm with

“✓ “.

By using the “↑“ or “↓“ buon, the active part

of the time changes, confirm with “✓ “ than the

active part should flash: now it‘s possible to

change its value by using “↑“ or “↓“ . It is pos-

sible to change days (d), hours (h), minutes (m)

and seconds (s). The change needs to be confir-

med (“✓ “). If you want to change more than one

subject, proceed as described. To change back

into the main menu press “ESC“.

We recommend max. 7 days time between the

regenerations.

Start the regeneration manually:

In case the process display is not displayed ( Re-

generation in 6d 23h etc.), press “ESC“ to get to

main menu and then use “↑“ or “↓“ to display

the process and confirm with “✓ “ to open the

regeneration menu.

Page 7 of 8

Gebr. Heyl Vertriebsgesellschaft für innovative Wasseraufbereitung mbH I Max-Planck-Straße 16 I D- 31135 Hildesheim

Phone: +49 (0) 5121 7609-0 I Fax: +49 (0)5121 7609-44 www.heylneomeris.de

In case the process display is displayed (Regene-

ration in 6d 23h etc.), confirm with “✓ “ to open

the regeneration menu. Now select “start re-

gen.?“ by “ENTER“ or “ESC“ to cancel. Press “✓”

if you want to start the regeneration.

In case the regeneration was not successful it is

displayed:

“—> no sensor, proceed Enter“ or “regen. fai-

led, proceed with enter“ . Press “✓ “ to restart

the regeneration.

Troubleshooting

In case the green LED, right of the buttons does

not light, check the electricity.

In case a disorder occurs, the red LED, left of the

buttons is shining and the display back-ground

flashes.

There are 3 kinds of disorders

The sensor did not get “hard“ while regenera-

tion. Possible solutions see table on P. 8.

The sensor did not regenerate and is still „hard“.

Possible solutions see table on P. 8.

The sensor got “hard“ while monitoring which

means the soft water pipe contained hard water.

Page 8 of 8

Gebr. Heyl Vertriebsgesellschaft für innovative Wasseraufbereitung mbH I Max-Planck-Straße 16 I D- 31135 Hildesheim

Phone: +49 (0) 5121 7609-0 I Fax: +49 (0)5121 7609-44 www.heylneomeris.de

Troubleshooting

The table shows the most common problems. In case it is not possible to solve the problem with this

table, please contact the customer service.

Problem Reason Solution

“—> No sensor, proceed with

Enter”

No brine available

Check brine supply

Sensor malfunction Replace sensor

“—> Regen. Failed, proceed

with Enter“

No brine available

Check brine supply

Check brine sucking

Sensor malfunction Replace sensor

Brine is not drawn Clogged injector

Clean injector

Clean injector screen

Valve malfunction Replace valve

“Hardwater proceed with

Enter”

Hardwater in the soft

water pipe

Check soft water supply

Structure of the menu

Table of contents

Popular Water Filtration System manuals by other brands

Terra Universal

Terra Universal WhisperFlow 6601-24A-UR-220 product manual

WilTec

WilTec SUNSUN HW-302 Operation manual

Titon

Titon TP551 product manual

ELECTROSEA

ELECTROSEA ElectroStrainer ES-125 installation manual

Donaldson

Donaldson PowerCore CPC Series Installation, operation and maintenance manual

ARKA

ARKA Aquatics Core CFF1 Operation instructions

Donaldson

Donaldson Ultrafilter DF-T0050 Operation manual

Oase

Oase ProfiClear Premium Compact-L EGC operating instructions

Acuva

Acuva Arrow 5 Owner's Product Manual

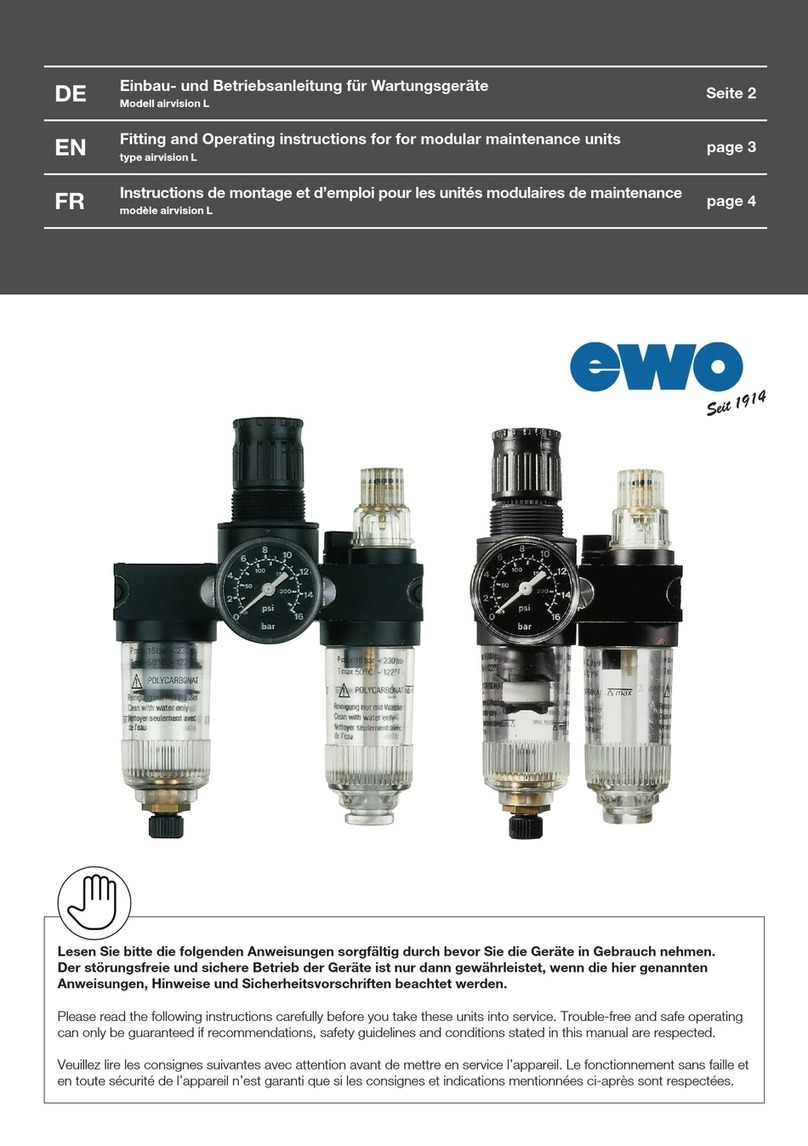

ewo

ewo Airvision L Series Fitting and operating instructions

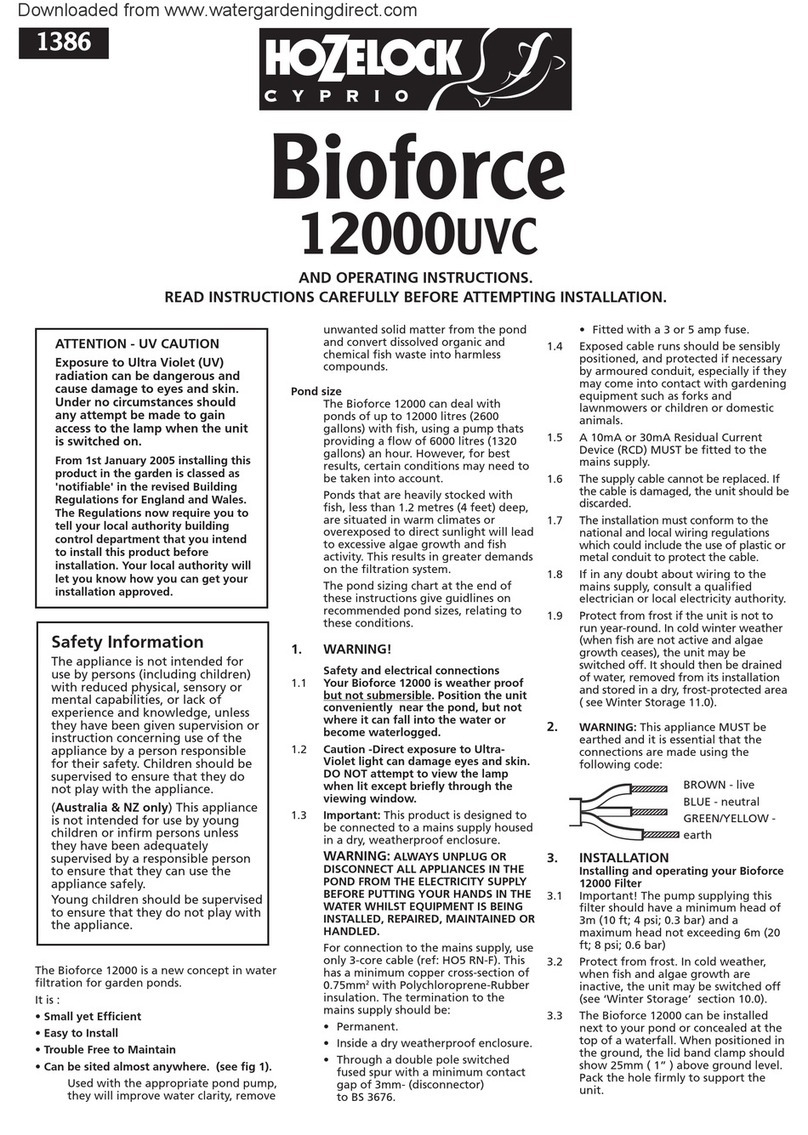

Hozelock

Hozelock bioforce 12000UVC operating instructions

Kessel

Kessel 99601.002B Installation and operating instructions