Terra Universal Product Manual

WhisperFlow® Fan Filter Units

© Copyright 2021 Terra Universal Inc. All rights reserved •Revised April 2021

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 6

3. Start-Up

3.1 Installation

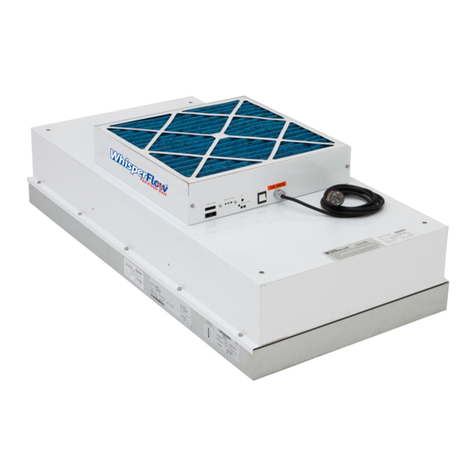

The fan filter unit is designed to fit on top of a Terra Laminar Flow Hood or standard clean room ceiling grid. It includes 1/4-

20 thread holes on corners for guy-wire suspension. Room-side replaceable filters are packaged separately for jobsite

installation by others.

1. Remove all packaging material from the shipping box

(Figure 1).

2. Perform a thorough visual inspection to ensure no

damage has occurred during shipping. Check that

there are no visible dents or penetrations on the filter

face and grille. If damage is discovered, contact the

freight company to file a damage claim immediately.

3. Remove the pre-filter and manually rotate the fan

wheel to make sure it does not come in contact with

any stationary parts and that there are no visible

loose screws or bolts obstructing the wheel’s

rotation.

4. Verify unit is sanitary for cleanroom placement.

5. Optional: fasten the eyebolts into each corner of the

lid assembly.

6. Lift the unit into the ceiling and position onto the

ceiling grid. If the grid is not secured, fasten to an

engineered support system with chain, s-hooks and

eyehooks (usually supported with wires).

7. Confirm fan dimensions are aligned with grid

dimensions.

8. Raise the unit and secure with support system

method suspended from a structural support bracing.

a. Minimum clearance of 1 foot (including

fixtures, ducts and pipes) on all sides and

at least 2 feet of vertical clearance between

the FFU inlet and ceiling for proper air

supply.

9. Connect the 4-pin power plug to the unit, set the

speed switch to the desired position (units are

shipped from the factory with the speed switch set to medium), and turn on the external power switch. With

power applied, the fan will rotate, and filtered air will exit the HEPA filter.

Note: After completing the Initial Setup, validation may be performed by a third-party testing service for HEPA filter integrity (leak-

testing), Air Changes per Hour and particle counter measurements to verify ISO 5 particle levels. Third-party testing should take

place within the intended cleanroom or another controlled environment to ensure an accurate evaluation of its performance.

To avoid thermal overload on FFU’s with Permanent Split Capacitor (PSC) motors, do not use LOW

speed switch when the FFU is connected to a PDM.

Figure 2: Hanger Supports