Table of Contents

Handling and Packaging ....................................................................................................................................................iv

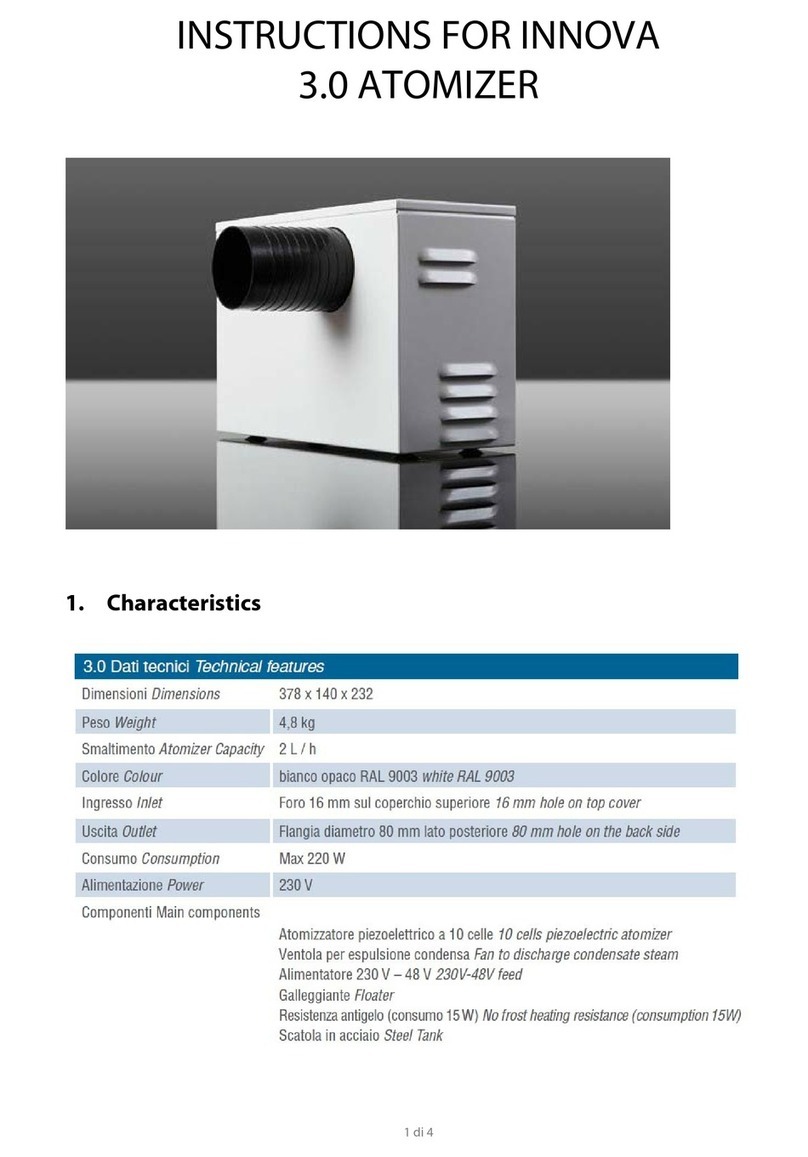

Overview.................................................................................................................................................................................................... 7

Benefits................................................................................................................................................................................7

Features ..............................................................................................................................................................................7

SKH4 System............................................................................................................................................................................................ 8

Principle of Operation..........................................................................................................................................................8

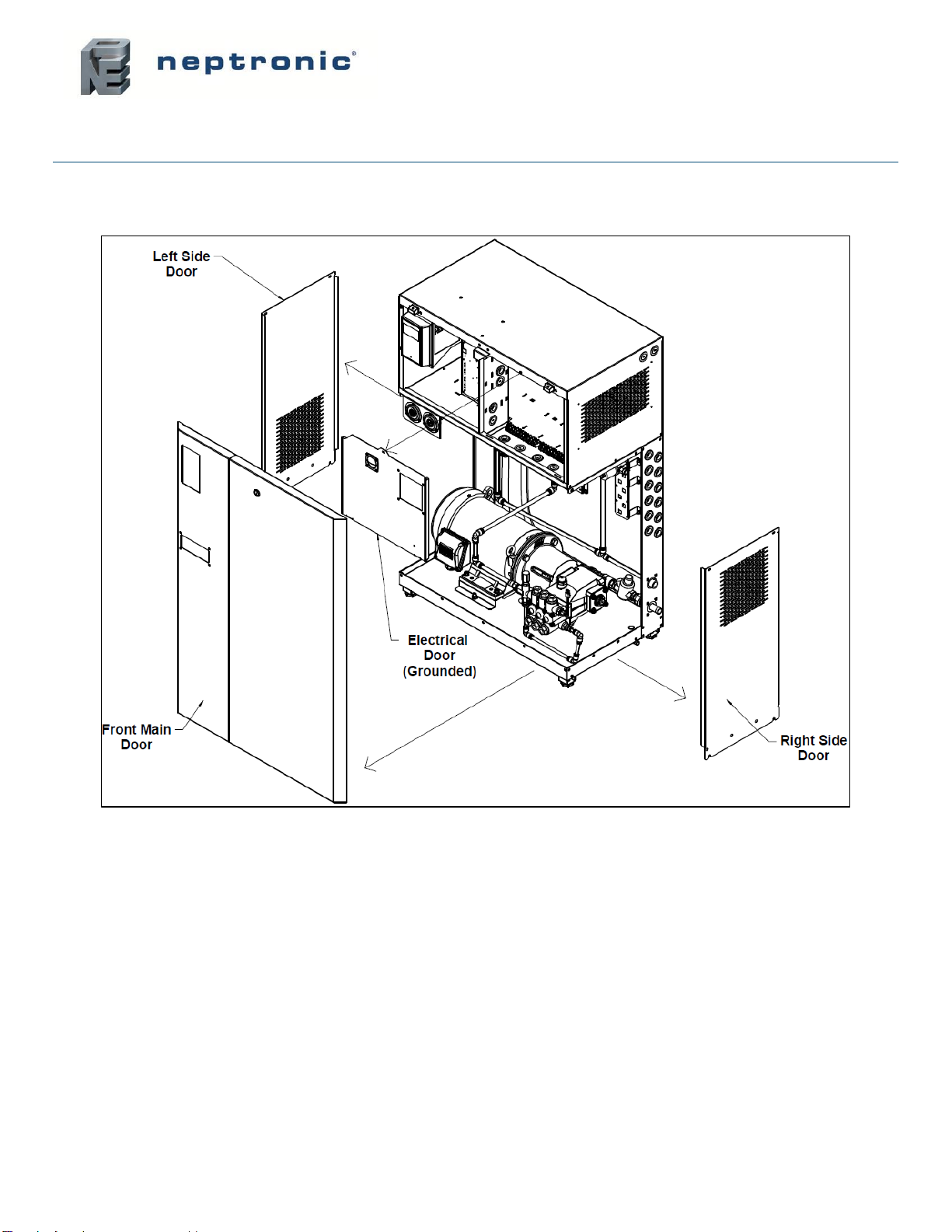

SKH4 Pump Station................................................................................................................................................................................... 9

Visual Overview ..................................................................................................................................................................9

Pump Unit Nomenclature................................................................................................................................................. 11

Capacities and Power Consumption of the Pump Unit (Brass) ....................................................................................... 12

Capacities and Power Consumption of the Pump Unit (SS)............................................................................................ 13

Dimensions and Weight ................................................................................................................................................... 14

Fan-Assisted Distributors......................................................................................................................................................................... 15

Fan-Assisted Distributors Nomenclature.......................................................................................................................... 15

Capacities and Power of the Fan-Assisted Distributors................................................................................................... 15

Fan-Assisted Distributors Dimensions and Weight.......................................................................................................... 16

In-Duct Distribution Rack......................................................................................................................................................................... 17

Basic Installation Overview...................................................................................................................................................................... 18

Pump Unit Installation.............................................................................................................................................................................. 19

Step 1 –SKH4 Pump Station Installation......................................................................................................................... 19

General Recommendations.................................................................................................................................................. 19

Step 2 –Water Connections for the SKH4 Pump Station................................................................................................ 21

Step 3 –Power Supply Connections................................................................................................................................ 23

Power Supply Connections on SKH4 Pump Station............................................................................................................ 23

Power Supply Knockout Holes Location on SKH4 Pump Station........................................................................................ 24

Step 4 –Electrical Control Connections........................................................................................................................... 25

Safety Contact Connections for Pump Unit.......................................................................................................................... 25

Safety Contact Connections Single Zone Without TRUB .................................................................................................... 25

Safety Contact Connections per Zone from TRUB .............................................................................................................. 25

Network Communication ...................................................................................................................................................... 26

Step 5 –Pump Controller Installation and Configuration................................................................................................. 27

Idle Screen .............................................................................................................................................................................................. 28

Menu Access.................................................................................................................................................................... 28

Configuration parameters..................................................................................................................................................... 29

Control function .................................................................................................................................................................... 29

Control Profile Selection....................................................................................................................................................... 29

Single Zone Operation ......................................................................................................................................................... 29

Multi-Zones Operation.......................................................................................................................................................... 30

Menu - General [Level 1 - No password required]............................................................................................................... 31

Menu - User Settings [Level 2 - Requires level 2 (or higher) password in order to access]................................................ 34

Menu - Service [Level 3 - Requires level 3 (or higher) password in order to access].......................................................... 36

Menu - Installation [Level 4 - Requires level 4 (or higher) password in order to access] .................................................... 37

Menu - Integration [Level 5 - Requires level 5 password in order to access] ...................................................................... 41

List of Alarms and Warnings ............................................................................................................................................ 44

Distribution Installation............................................................................................................................................................................. 45

Spraying in Space (Standard) .............................................................................................................................................. 45

Spraying in Space with Fan-Assisted Distributors ............................................................................................................... 47

Spraying in Duct................................................................................................................................................................... 50