Bentone B40 MF Technical specifications

Providing sustainable energy solutions worldwide

178 129 53-3 CR00505 2025-05-19

Installation- and maintenance instruction

B 40 MF

LMO24.255C2E

E4NC-1069

Translation of the original instructions.

2Bentone

example Beispielexempel

352011030141

Designation

Type

Model

Serial no.

Motor supply

Main supply

MADE IN SWEDEN BY

LIGHT OIL 35-90kW 1,25-6,0 cSt 7-14bar

BF 1 KS 76-24

BF 1

BF 1 KS 76-24

1234567

1~230V 1,0A 50Hz IP 20

Man.Year 2019

Cap. Min-Max

3

?

1

-sv

1. Manualer på övriga språk

2. www.bentone.com\

nedladdning

eller scanna QR-koden.

3. Skriv in brännarens

artikelnummer som nns på

din

typskylt (se bild) och välj ditt

språk.

Detaljerad ecodesign

information kan laddas ner

på:

www.bentone.com/

ecodesign.

-en

1. Manuals in other languages

2. www.bentone.com\

download

or scan QR-code.

3. Enter the burner`s article

number on your data plate

(see picture) and select

language.

Detailed ecodesign

information can be

downloaded at:

www.bentone.com/

ecodesign.

-da

1. Manualer på andre sprog

2. www.bentone.com\

download eller scan QR-

koden.

3. Indtast brænderens

artikelnummer, der ndes

på typeskiltet (se billede), og

vælg dit sprog.

Detaljerede oplysninger om

ecodesign kan downloades

på: www.bentone.com/

ecodesign.

-fr

1. Manuels dans d’autres

langues

2. www.bentone.com\

download

ou scannez le code QR.

3. Saisir le numéro d’article

du brûleur sur votre plaque

signalétique (consultez

l’illustration) et sélectionnez

la langue.

Des informations détaillées

sur l’écodesign peuvent être

téléchargées à l’adresse:

www.bentone.com/

ecodesign.

-de

1. Gebrauchsanweisungen in

anderen Sprachen

2. www.bentone.com\

download

oder scannen Sie den QR-

Code.

3. Geben Sie die

Artikelnummer des Brenners

auf Ihrem Typenschild ein,

(siehe Bild) und wählen Sie

die Sprache aus.

Detaillierte Informationen

zum Ecodesign können unter

www.bentone.com/ecodesign

heruntergeladen werden.

2

3Bentone

General

Table of contents

1. Safety Information...............................................................4

2. Technical data.......................................................................7

2.1 Dimensions B 40 MF..................................................................... 7

2.2 ElectricSpecication..................................................................... 8

2.3 Settingofbrakeplateandairow ............................................ 9

2.4 Recommendednozzleandpressure ........................................ 9

2.5 Burnerinstallation ........................................................................ 9

2.6 Oilgrades......................................................................................10

2.7 Nozzleforbiooils,20-28bar....................................................11

2.8 Nozzleforfossiloils,22-28bar ................................................12

2.9 Description B 40 MF ..................................................................13

3. Installation..........................................................................15

3.1 Acceptanceinspection............................................................... 15

3.2 Preparationsforinstallation .....................................................15

3.3 Distributionofoil.........................................................................15

3.4 Electricalconnection ..................................................................16

3.5 Nozzleselection...........................................................................17

3.6 Settingofbrakeplateandairow ..........................................17

3.7 Burnerinstallation ......................................................................18

3.8 Checkoillineseals......................................................................18

4. Function description..........................................................19

4.1 B40MF1-stageburner............................................................. 19

5. Basic settings......................................................................20

5.1 ExamplesofbasicsettingB40MF..........................................20

5.2 Settingvaluesfornozzleandairdamper.............................. 20

5.3 Nozzleassemblycontrol,brakeplate .....................................21

5.4 Air setting B 40 MF......................................................................21

6. Burner servicing.................................................................22

6.1 Servicingthecombustionassembly ......................................22

6.2 Servicingairdampers ...............................................................23

6.3 Replacementofoilpump ..........................................................24

6.4 Replacementofpreheaters ......................................................25

6.5 Replacementofelectricalcomponents.................................. 26

6.6 Replacementofpreheateroverheatingprotector............... 26

6.7 Checkoillineseals......................................................................27

6.8 Checkpressurepistonnozzleholderseals ...........................27

6.9 Replacementofpressurepistonandseat.............................28

6.10 Immersionheatersforextrapreheating ............................... 29

6.11 Check/serviceoilpre-lter.........................................................31

7. Preheater ............................................................................32

7.1 Technicaldata ..............................................................................32

7.2 Adjustmentofpreheateroperatingthermostat ..................33

7.3 ReturnOilPressureSwitch........................................................ 34

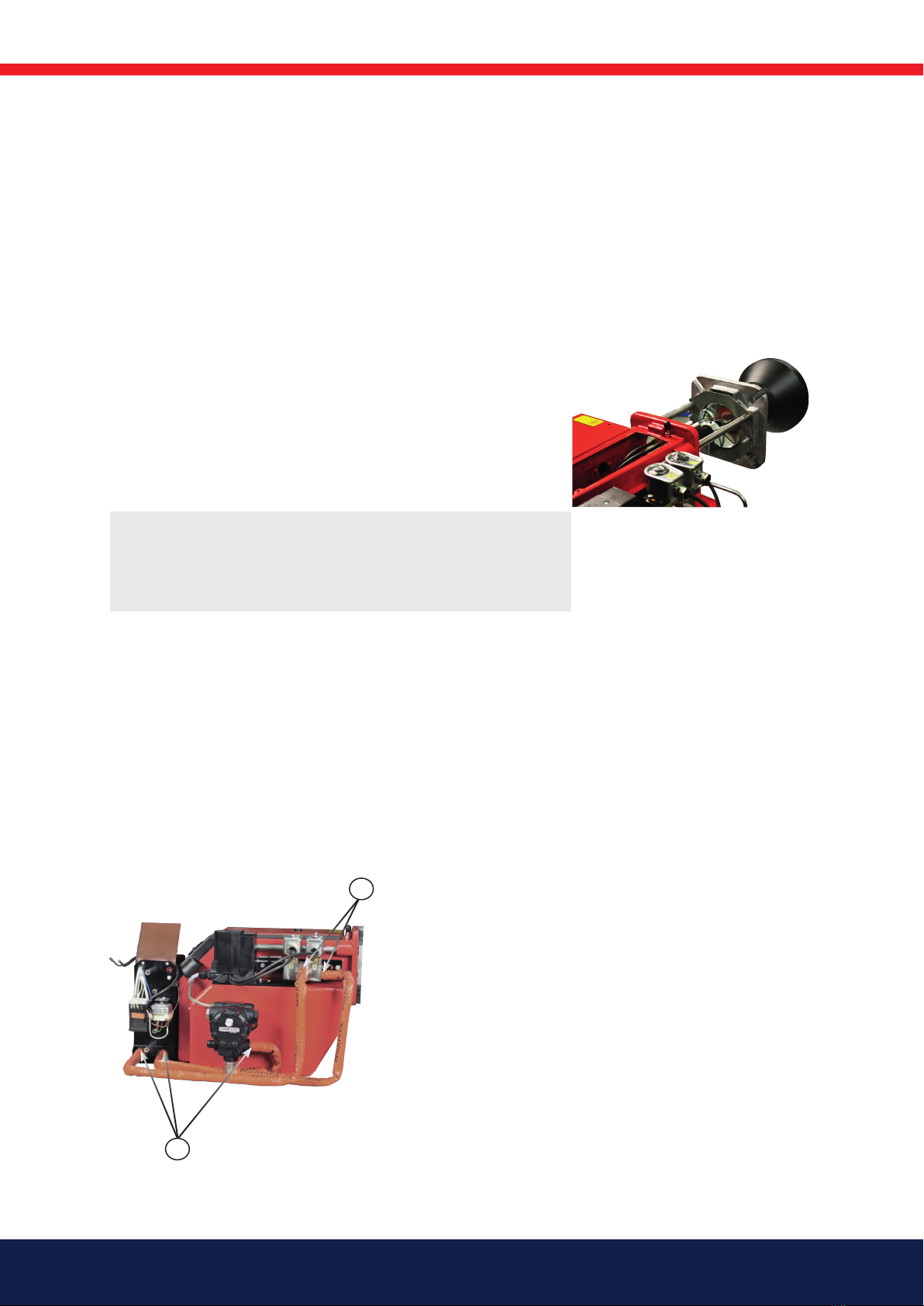

8. Pump instruction E4NC-1069............................................35

8.1 Technicaldata ..............................................................................35

8.2 Components.................................................................................35

8.3 Oil connection..............................................................................35

8.4 Changingthelter......................................................................35

8.5 Function ........................................................................................36

8.6 Preheatingpump ........................................................................36

9. Electrical equipment .........................................................37

9.1 WiringdiagramLMO24.255... ................................................37

9.2 ComponentlistLMO24.255....................................................38

9.3 ColourcodesLMO14/24............................................................39

9.4 FaultcodesLMO14/24............................................................... 39

10. Fault Location.....................................................................40

10.1 Burnerwillnotstart....................................................................40

10.2 Burnerwillnotstartafternormaluse ....................................40

10.3 Delayedignition ..........................................................................41

10.4 Noiseinpump .............................................................................41

10.5 Pumppressure ............................................................................ 42

.....................................................43

4Bentone

1. Safety Information

This Installation and Maintenance manual:

• is to be regarded as part of the burner and must always be kept near

the installation site

• is intended for use by authorised personnel

• must be read prior to installation

• must be observed by all who work with the burner and associated

system components

• work with the burner may only be carried out by certied installers/

personnel

• Enertech AB is not liable for any typographical errors and reserves the

right to make design changes without prior notice.

• The burner may only be used for its intended purpose in accordance

with the product’s technical data.

• The burner may only be installed and operated by authorised

personnel.

• The product is packaged to prevent damage from occurring during

handling. Handle the product with care. Lifting equipment must be

used to lift larger packages.

• The products must be transported/stored on a level surface in a dry

environment, max. 80% relative humidity, no condensation.

Temperature -20 to +60 °C.

• Check that the burner is compatible with the boiler’s output range.

• The label information on the rating plate refers to the burner’s

minimum and maximum power.

• The power data on the type sign refers to the burner’s min. and max.

power.

• All components must be installed without being bent, twisted or

subjected to mechanical or thermal forces which can affect the

components.

• The burner must be installed so that it complies with local regulations

for re safety, electrical safety, and fuel distribution.

• Make sure when installing the equipment that there is enough space

to service the burner.

• Permitted ambient temperature during operation -0 to +60 °C. Max

80% relative humidity, no condensation.

• The installer must ensure that the room has adequate air supply.

• The room must comply with local regulations pertaining to its

intended use.

• The installation site must be free of chemicals.

• Burner pipes, fan wheels and air dampers may contain sharp edges.

• The surface temperature of the burner’s components can exceed 60

°C.

• Caution: The burner has moving parts, and there is risk of crushing

injuries.

• The electrical installation must be professionally carried out in

accordance with applicable high voltage regulations, as per Enertech’s

recommendations.

• Before servicing, shut off the fuel supply and turn off the power to the

165 105 60

5Bentone

burner.

• Leak checks must be performed during installation and servicing to

prevent fuel leakage.

• Care should be taken by the installer to ensure that no electrical

cables or fuel lines are crushed or otherwise damaged during

installation or servicing.

• If the boiler is equipped with an access hatch, this must be equipped

with a hatch opening switch connected to the burner's safety system.

• When in operation, the burner’s noise level can exceed 85 dBA.

Use hearing protection.

• The burner must not be put into operation without proper safety and

protection devices.

• A Class BE re extinguisher is recommended.

• It is forbidden to alter thedesign or use accessories which have not

been approved by Enertech in writing.

• Prior to operation, the following points must be checked:

-fitting and installation work has been completed and approved

-electrical installation has been correctly performed

-flue gas ducts and combustion air ducts are not blocked

-all actuators and control and safety devices are in working order and

correctly set

6Bentone

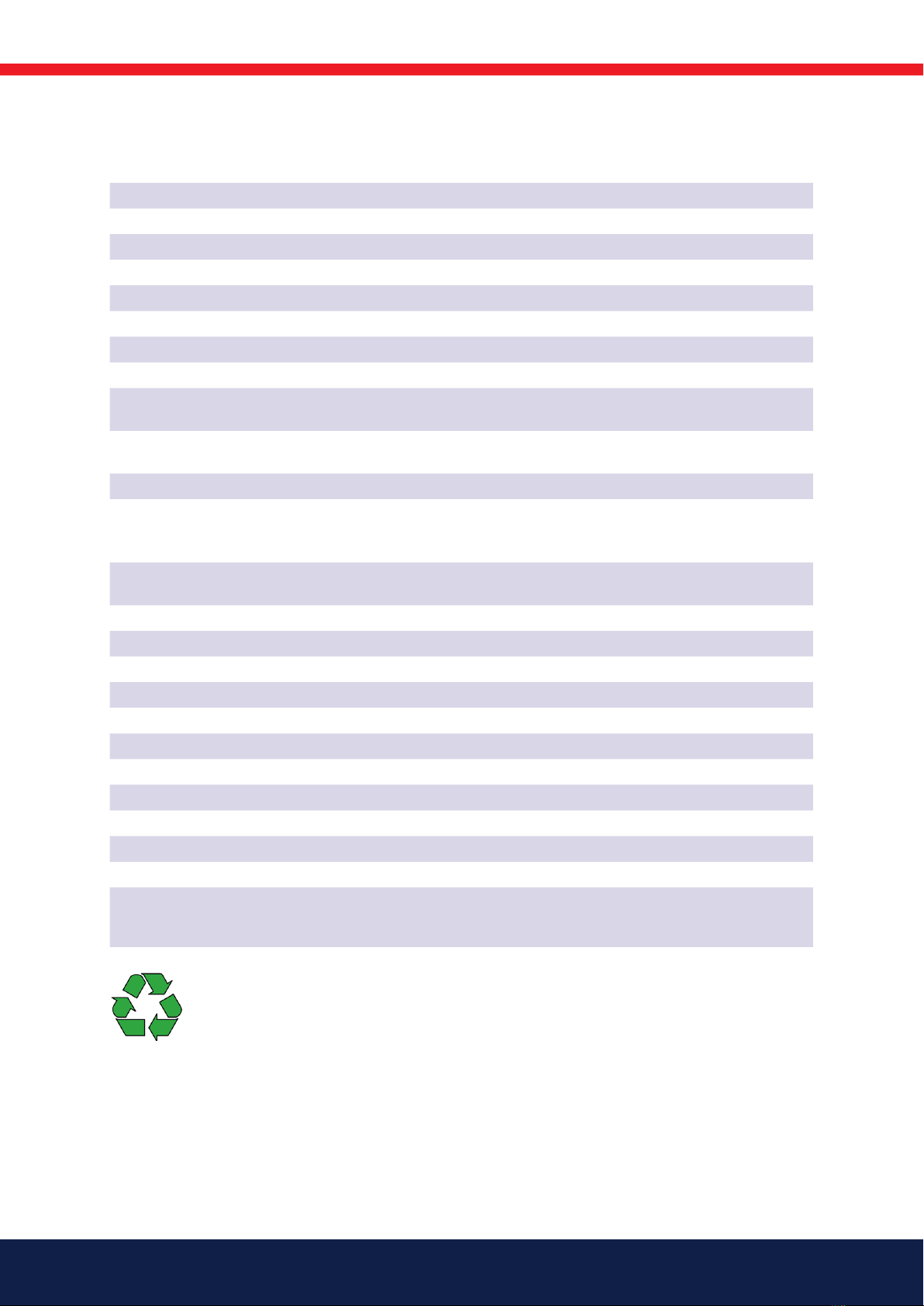

Components Service life – Recommended

replacement

Service life – Recommended

replacement Operating starts

Control system 10 years 250 000 starts

Pressure switch 10 years 250 000 starts

Flame guard 10 years 250 000 starts

UV ame sensor 10 000 hrs N/A

Damper motor 500 000 starts

Contaktor 10 years 500 000 starts

Gas valve with seal testing Replacement upon fault detection N/A

Gas pressure switch 10 years 250 000 starts

Safety blow-off system 10 years N/A

Damper motor N/A 500 000 starts

Contactor 10 years 500 000 starts

Pressure piston max. load,

Pressure piston min. load

+ O-ring, Valve seat

10 years 80 000 starts

Burner 1 year 3 000 hrs

Filter 1 year 3 000 hrs change

Oilhose 1 year control/change

Nozzle 1 year change 3 000 hrs change

Electrods 1 year change /cleaning 3 000 hrs change /cleaning

Brake plate 1 year change /cleaning 3 000 hrs change /cleaning

Motor 1 year 3 000 hrs

Cuppling chaft 1 year control/change 3 000 hrs control/change

Fan wheel “1 year change when dirty /

unbalance”

“3 000 hrs change when dirty /

unbalance”

Pressure piston max. load

Pressure piston min. load

Regular checks of seal and function

every 3 month. Change at leakage.

Control 2 000 hrs

Oil lter 2 year 3 000 hrs change

Oil valve Tightness check 2 year Replacement in case of leakage

The burner and its components must be recycled according to applicable regulations.

Burner servicing schedule

Servicing must be carried out once a year or after 3000 hours of operation

Component replacement intervals

Delivery check

• Make sure everything is delivered and the goods have not been

damaged during transit.

• If something is wrong with a delivery, report it to the supplier.

• Transport damage must be reported to the shipping company.

7Bentone

165 205 77-2

2. Technical data

The burner is intended for:

• Light oil, B10 heating oil/biofuel blend, FAME, B-100 (RME) (as dened in DIN V51603-6)

rapeseed DIN 51605:2010-10.

and is used for:

• Water heating generators.

• Hot air generators (these require LMO 24 255 C2E).

2.1 Dimensions B 40 MF

* Min. recommended distance to oor.

A Ø B Ø C D E F G H I * J

B 40 MF 202 160 114 527 262 316 362 202 451 200

I

H

A

D

E

F

G

B

C

8Bentone

Type Motor Complete burner Sound

B 40 MF 450W 230V 50/60Hz

10µF 230V 3,5A 400V 8,5A 50Hz 84 dBA ± 0,5 dBA

Max operating current, see data plate.

Working eld B 40 MF

2.2 Electric Specication

* Used lower caloric value of 10.00 kWh/kg for

rapeseed oil in accordance with DIN 51605:2010-10

-

1,0

0,0

1,0

2,0

3,0

4,0

50 100 150 200 250 300

mbar

kW

6.5-29.5 kg/h

65-300 kW

160303-224

9Bentone

2.4 Recommended nozzle and pressure

Nozzle: 45° Solid/semisolid

60° Solid/semisolid

80° Solid/semisolid

Pump pressure 10 bar (8-25 bar) depending on pump model

2.5 Burner installation

2.5.1 Hole patten

Make sure the hole pattern on the boiler is designed for burner ange.

Because of the various boiler types with varying furnace geometries and

furnace loads, it is impossible to commit to a certain scattering angle or a

specic distribution pattern.

It should be noted that the scattering angle and distribution pattern changes

with pump pressure.

d1

d2

d3

Combustion device d1d2d3

B 40 MF ø (115) 165 M14 ø 200-250

Burner correspond to IP 20

2.3 Setting of brake plate and air ow

a

b

e

c

d

a b c d e

B 40 MF 2,5-3,0 2,0 6,5-7,0 2,0 5,0

!*NB It is important

that the spark does

not strike against the

brake plate or nozzle

!

10 Bentone

!Altered structure of the oil can give rise to altered viscosity, pumpabilty and ignitability. This can

cause the pump, valves and nozzles to get blocked

2.6 Oil grades

The burner is tested and approved for pure rapeseed oil that complies with

standard DIN 51605:2010-10.

The burner is designed to be able to burn oils with a higher viscosity, both

of biological and fossil origin. The maximum viscosity with which the burner

is tested is 75 mm²/s, 0–130°c. Another way of dening which kind of oil

the burner can handle is that the oil must be of such a nature that it can be

pumped by the burner pump at the temperature the oil has at the point of

access to the pump.

The burner, without the pump, is designed to withstand the more corrosive

environment often created by oils of biological origin.

The Suntec E1069 pump is NOT designed for aggressive oils.

The burner pump has a service life of approx. 3–5 years if the oil is of a grade

that complies with standard DIN 51605:2010-10. If oil of a different grade

is used, especially if the oil contains contaminants such as particles, press

residue, metal swarf etc., or has chemical aggression, the pump may be

expected to have a signicantly shorter service life.

The pump is considered to be a wearing part and is not covered by the

warranty.

Pressure at the pump inlet must be -0.30 to max 2.0 bar. If there is a noise

from the pump, the oil is not pumpable at the current temperature or ow.

A transport oil pump combined with preheater is then needed to supply the

burner’s pump with oil for trouble-free operation.

The oil distribution system must be designed with the required equipment

such as lters, transport oil pump, preheater and reduction valve to provide

trouble -free operation. Max lter size is 120 µm and the oil may need to be

ltered in several steps.

In the case of a standstill in which the oil can be expected to change structure,

for example aging or phase transitions due to temperature and storage, the

burner must be ushed with fuel oil after the standstill. This procedure ensures

a good start after standstill.

11Bentone

2.7 Nozzle for bio oils, 20-28 bar

Pump pressure bar

Rapeseed oil compliant with DIN 51605:2010-10 Viscosity: 36.0 mm2/ s, at 40 °C preheater 160 °C

Gph 20 22 24 26 28

kg/h kW kg/h kW kg/h kW kg/h kW kg/h kW

1,00 4,9 49 5,2 51 5,4 53 5,6 56 5,8 58

1,50 7,4 73 7,7 77 8,1 80 8,4 84 8,7 87

2,00 9,8 98 10,3 103 10,8 107 11,2 112 11,6 116

2,50 12,3 122 12,9 128 13,5 134 14,0 140 14,5 145

3,00 14,8 147 15,5 154 16,2 161 16,8 168 17,5 174

3,50 17,2 172 18,0 180 18,9 188 19,6 196 20,4 203

4,00 19,7 196 20,6 206 21,5 215 22,4 224 23,3 232

4,50 22,1 221 23,2 232 24,2 242 25,2 252 26,2 261

5,00 24,6 245 25,8 257 26,9 269 28,0 280 29,1 290

5,50 27,0 270 28,4 283 29,6 296 30,8 308 32,0 320

6,00 29,5 295 30,9 309 32,3 323 33,6 336 34,9 349

6,50 32,0 319 33,5 335 35,0 350 36,4 364 37,8 378

7,00 34,4 344 36,1 361 37,7 377 39,2 392 40,7 407

7,50 36,9 368 38,7 386 40,4 404 42,0 420 43,6 436

8,00 39,3 393 41,3 412 43,1 430 44,9 448 46,5 465

8,50 41,8 418 43,8 438 45,8 457 47,7 476 49,5 494

9,00 44,3 442 46,4 464 48,5 484 50,5 504 52,4 523

9,50 46,7 467 49,0 489 51,2 511 53,3 532 55,3 552

10,00 49,2 491 51,6 515 53,9 538 56,1 560 58,2 581

10,50 51,6 516 54,1 541 56,6 565 58,9 588 61,1 610

11,00 54,1 540 56,7 567 59,3 592 61,7 616 64,0 640

11,50 56,5 565 59,3 593 61,9 619 64,5 644 66,9 669

12,00 59,0 590 61,9 618 64,6 646 67,3 672 69,8 698

12 Bentone

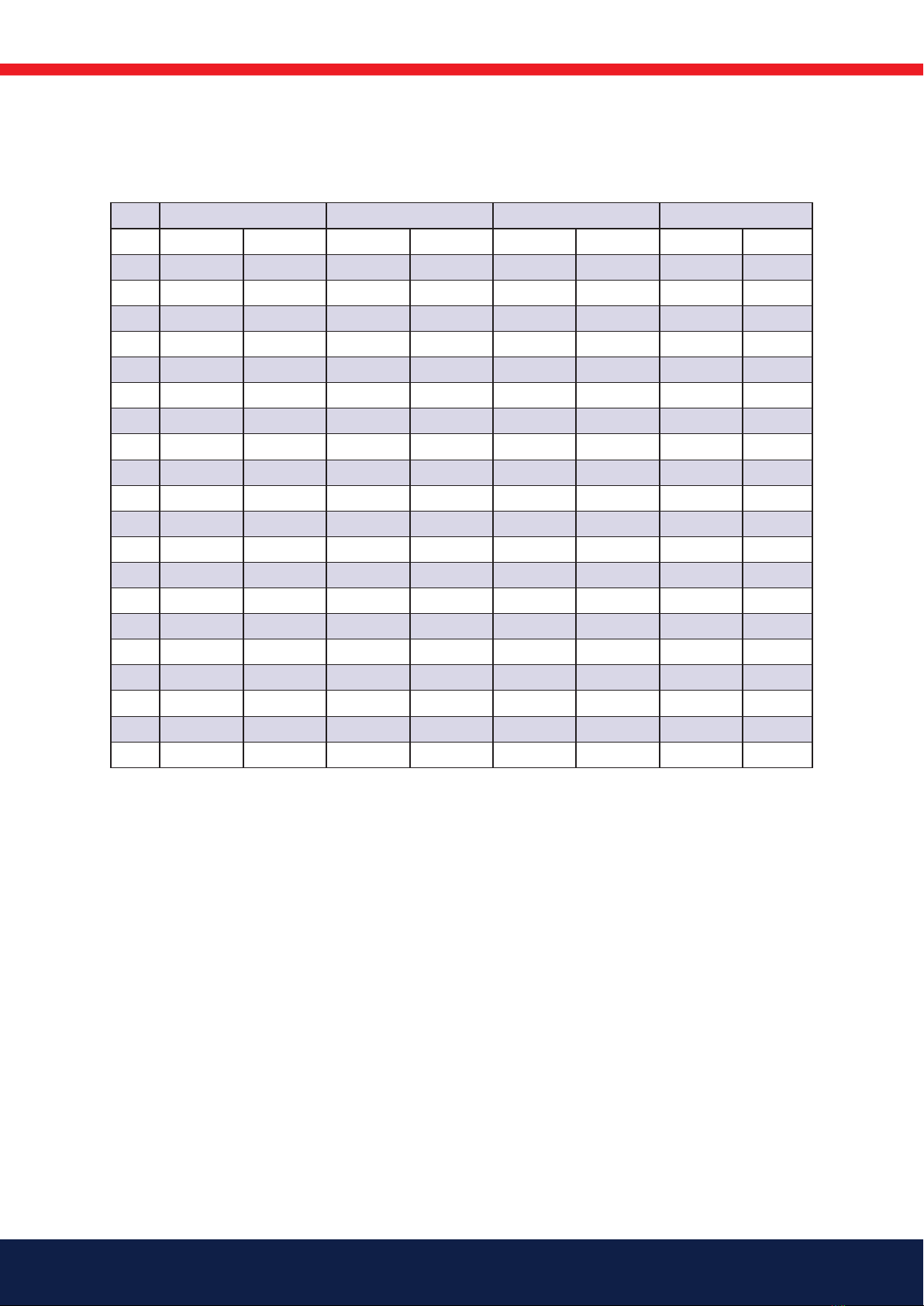

2.8 Nozzle for fossil oils, 22-28 bar

Pump pressure bar

The table applies to oil with a viscosity of 4.4 mm 2/s at a density of 830 kg/m 3.

Gph 22 24 26 28

kg/h kW kg/h kW kg/h kW kg/h kW

1,00 5,52 65,44 5,76 68,35 6 71,14 6,22 73,83

1,50 8,66 102,73 9,05 107,3 9,42 111,68 9,77 115,9

2,00 11,01 130,53 11,5 136,33 11,96 141,9 12,42 147,25

2,50 13,78 163,42 14,39 170,69 14,98 117,66 15,55 184,37

3,00 17,21 204,06 17,97 213,13 18,7 221,83 19,41 230,21

3,50 19,13 226,93 19,89 237,02 20,8 246,7 21,59 256,01

4,00 21,06 249,8 22 260,9 22,9 271,56 23,76 281,81

4,50 23,88 283,22 24,94 295,81 25,96 307,89 26,94 319,51

5,00 27,44 325,44 28,66 339,91 29,83 353,79 30,96 367,14

5,50 31 367,66 32,38 384 33,7 399,68 34,97 414,77

6,00 34,71 411,63 36,25 429,94 37,73 447,49 39,16 464,39

6,50 38,71 459,13 40,43 479,55 42,08 499,13 43,67 517,97

7,00 41,38 490,8 43,22 512,62 44,99 533,55 46,69 553,69

7,50 44,2 524,22 46,17 547,53 48,05 569,89 49,86 591,4

8,00 46,72 554,12 48,8 578,76 50,79 602,4 52,71 625,14

8,50 49,1 582,27 51,28 608,16 53,37 632,99 55,39 656,89

9,00 52,51 622,73 54,84 650,42 57,08 676,98 59,24 702,53

10,00 55,92 663,19 58,4 692,68 60,79 720,96 63,08 748,18

11,00 63,04 747,63 65,84 780,87 68,53 812,76 71,12 843,44

12,00 70,75 839,1 73,9 876,41 76,91 912,2 79,82 946,63

13Bentone

21

23

27

24

26 25

22

13

4

9

6

587

3

10

2

15 12 1114

1

17

18

19

16

20

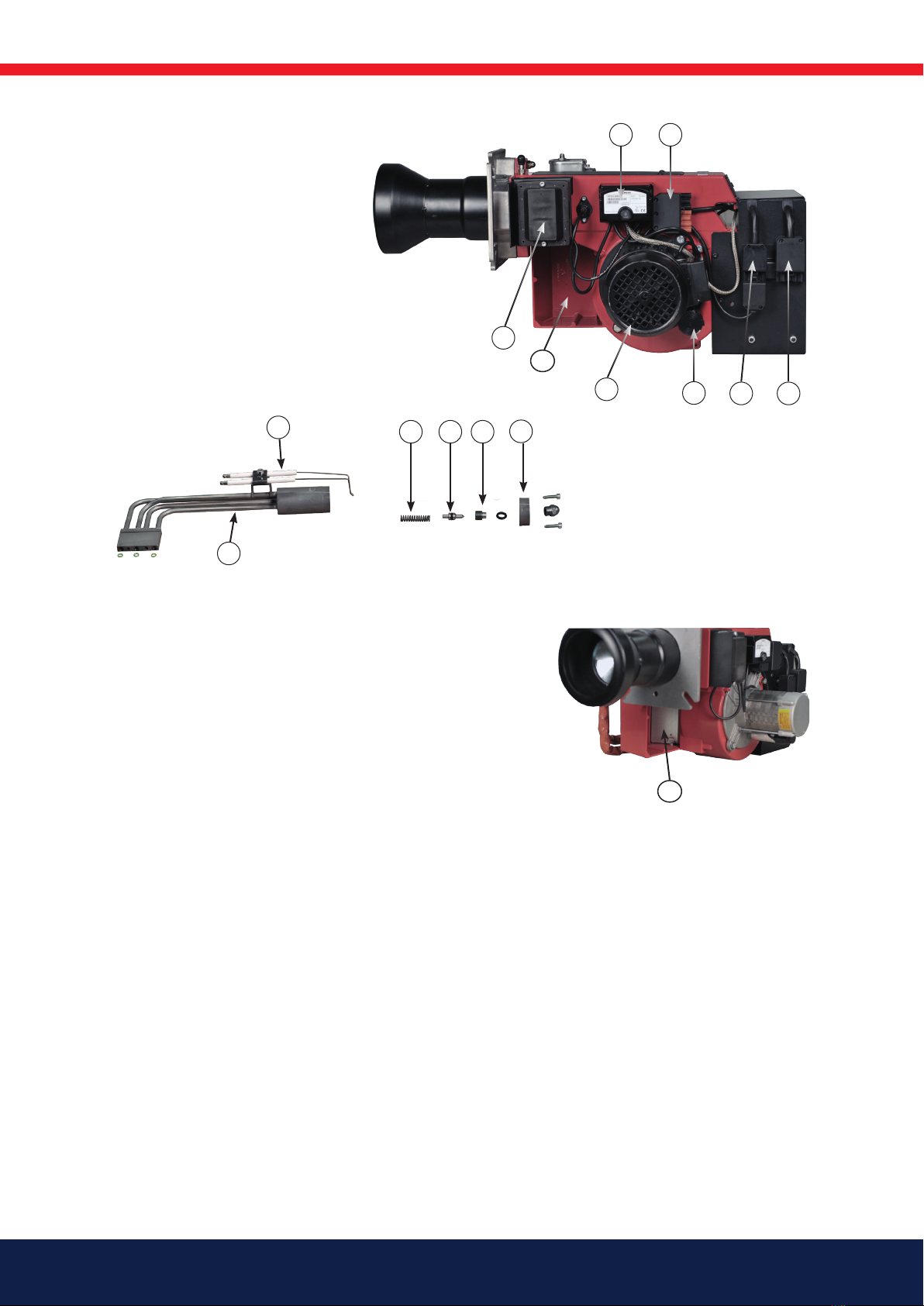

2.9 Description B 40 MF

2.9.1 Components B 40 MF

1. Indicator lamp, preheater ON

2. Inspection glass

3. Immersion heater, pump

4. Fan housing

5. Nozzle assembly control

6. Scale, nozzle assembly control

7. Solenoid valve NO

8. Valve block

9. Burner tube

10. Cavity immersion heater valve block

11. Pressure outlet pump

12. Return pump

13. Pump

14. Pressure control pump

15. Inlet pump

16. Nozzle assembly

17. Brake plate

18. Nozzle

19. Cavity immersion heater nozzle holder

20. Preheater

14 Bentone

41

16

28 29 30 31

39

38

40

37 3536

33 34

32

1. Fan wheel

2. Measuring nipple, fan pressure

3. Burner ange

4. Connecting pipe, valve block return

5. Damper motor

6. Connecting pipe, preheater valve block

7. Connecting pipe, pump preheater

8. Ignition electrodes

9. Spring pressure piston

10. Preheater

11. Valve seat

12. Front nozzle holder

13. Relay box

14. 7-pole Europlug (feed)

15. 5-pole Euro plug (feed preheater)

16. 4-pole Euro plug (control signal preheater)

17. Capacitor

18. Motor

19. Air intake

20. Ignition transformer

21. Air damper

15Bentone

165 205 78

1

3. Installation

3.1 Acceptance inspection

Make sure everything is delivered and the goods have not been damaged

during transit. If something is wrong with the delivery, report it to the supplier.

Transport damage must be reported to the shipping company.

3.2 Preparations for installation

Check that the burner's dimensions and capacity range are suitable for the

boiler in question. The power data on the type sign refers to the burner's min.

and max. power.

3.3 Distribution of oil

In order to achieve good reliability, it is important that the oil distribution

system is designed correctly.

Take the following into account:

• Selection of pipe diameter, pipe length and height difference; see

Pump instruction.

• Pipelines are to be laid with a minimal number of glands.

• The pipes are to be laid so that the oil supply hoses are not subjected

to tensile stresses or are excessively bent when the burner is swung

out or removed for service.

• The ½ " oil lter should be installed so that the lter cartridge can

easily be replaced or cleaned. Self-cleaning lters are recommended

for oils of a higher viscosity or oils that contain signicant impurities.

• Oil-affected parts shall be selected in materials that are capable of

withstanding the medium's physical properties.

• When installing oil hoses, check that the inlet and return hoses are

tted to the appropriate connection on the oil pump. The hoses shall

be located so that they do not bend or become subject to tensile load.

To the suction line on the pump (see paragraph 7.2 pos. 3) should the

supplied oil hose with 90° bend be connected.

• Bleed the oil system. The oil pump/oil preheater may be damaged

if run dry. The vacuum should not fall below 0 bar in the suction line

during start-up.

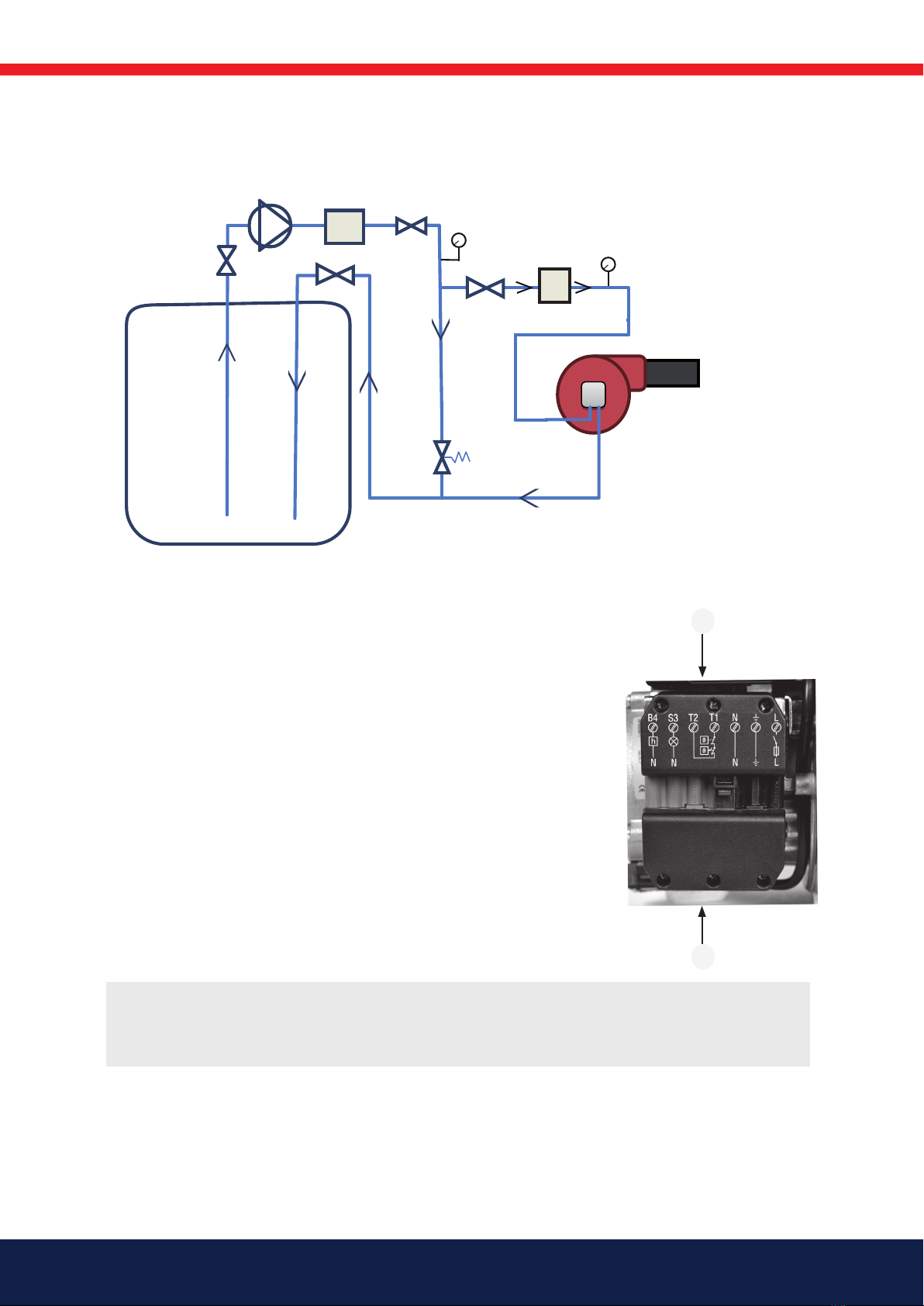

3.3.1 Proposed pipe routing for oil distribution systems

without transport pump

This type of connection should be used only when the oil has a viscosity less

than 30 mm²/s.

1. Self-cleaning lter

!

burner oil system

before starting it for the

16 Bentone

X3

X4

1. Transport oil lter

2. Basket lter

3. Overow valve 0.5 – 2.0 bar

4. Seal lter

5. Pressure gauge 1

6. Pressure gauge 2

3

2

1 Transport oil pump / Transportoljepump

4

5

6

1

!If any electrical connection is used other than that recommended by Bentone, there may be a

danger of damage to property and personal injury.

3.3.2 Proposed pipe routing for oil distribution systems with transport pump,

basket lter and seal lter

3.4 Electrical connection

Before electrical installation begins, the main power switch must be turned off.

If the boiler has a 7-pole and a 4-pole Euro plug connector, they will usually

connect directly to the burner. Otherwise, use the supplied connectors. The

5-pole connector supplies the burner preheater with a separate 3-phase

supply. See connection under Electrical equipment.

1. Switch off the main switch.

2. Connect the Euro plugs. (See Electrical equipment)

3. Make sure the burner operations switch (S1) is off.

4. Turn on the main switch.

17Bentone

3.5 Nozzle selection

See under Technical data: Recommended nozzle and Nozzle table.

If, after selecting the nozzle, burner type B45-2 MF has diculty starting, this

may in some cases be due to the selection of nozzle made for the rst stage.

Selecting a nozzle with a smaller effect in the rst stage may solve the problem.

3.6 Setting of brake plate and air ow

Prior to commissioning, the basic settings of the burner can be set in

accordance with the diagram. See under Basic settings. Note that it is simply

a matter of a basic setting that should be adjusted retrospectively once the

burner has started. You should then conduct a ue gas analysis and soot

quantity measurement.

18 Bentone

A

A

3.7 Burner installation

1. Separate the burner body and the ange.

2. Remove the brake plate from the oil pipe.

3. Install the selected nozzle. (See Technical data)

4. Install the brake plate on the oil pipe

5. Remove the burner tube from the ange.

6. Install the ange with gasket on the boiler.

7. Install the burner tube on the ange. Make sure that the hole in the

front of the burner tube pipe is pointing down. This allows any drops

of oil to ow out.

8. Insulate between the burner and boiler door to reduce radiated heat.

9. Fit the burner body on the ange.

10. Lock the burner body using with the nut/nuts.

11. Connect the oil hoses to the pump, see paragraph 2.3

12. Connect burner electrically, see paragraph 2.4

3.8 Check oil line seals

Once the burner has been installed and commissioned, the seals of the various

coupling elements should be checked (A). These may, due to temperature

uctuations or transportation, start to leak.

Temperature uctuations arise from the process of heating oil used in these

burners.

When a leak is detected, it is usually sucient to tighten the coupling element

that is leaking.

!Because the burner tube must be installed from the inside the

boiler, it must be possible to open the boiler or have a hinged

ange that is designed so that it can be reconnected with the

burner tube installed.

19Bentone

165 205 79

E1P

Y1

I

N

Y1

1

L

V1

4. Function description

4.1 B 40 MF 1-stage burner

When the installation calls for heat, the burner's preheater starts to heat the

oil. Once the oil reaches the set temperature, the burner receives the signal to

start. Hot oil is ushed throughout the burner's oil system.

After the end of the blow period, the solenoid valve (Y1) receives voltage and

closes. The oil pressure builds up in the nozzle holder and the cut valve (V1)

opens. The oil is atomised in the nozzle and ignited. A small amount of oil and

the nozzle assembly compressed air ow is channelled back to the return side

of the pump through the leak oil line (L).

Once the installation has reached the desired temperature, a solenoid valve

(Y1) is rendered without power and then opened; cut valve (V1) is then closed.

This process extinguishes the burner ame. In the same process, oil heating is

also interrupted.

P Oil pump

E1 Preheater

I Nozzle assembly

L Leak pipe

N1 Nozzle 1

Y1 Solenoid valve 1 NO

V1 Cut valve

20 Bentone

165 205 80-2

5. Basic settings

5.1 Examples of basic setting B 40 MF

Burner output 200 kW

Estimated nozzle output 200 kW/10 kWh/kg*= 20 kg/h

Nozzle selection in accordance with the table. (See technical data) Nozzle

selection is based on the selected pump pressure and the desired effect.

According to the nozzle table, this provides the following nozzle.

Selected pump

pressure

25 bar

Nozzle 3.50 gph

Power in 20.61 kg/h => 20.61 kg/h x 10 kWh/kg* = 206 kW

* Taken from the fuel in accordance with standard DIN 51605:2010-10

Effects and nozzle selection from example

Nozzle assembly 14

Damper 7

Basic settings should only be seen as setting values to get burner to start and

establish a ame. Once the burner has started and established a ame, it will

be necessary to adjust the settings so that they are adapted to the installation

in question and the fuel used at the time.

Basic settings

The setting value for 200 kW in accordance with basic setting tables. For the

correct procedure when implementing settings, see 4.7 Nozzle assembly

control, brake plate B40 MF and 4.8 Air setting B40 MF (See technical data )

5.2 Setting values for nozzle and air damper

0

10

20

30

50 100 150 200 250 300

160303-225

kW

Air settings

Nozzle assembly

Scale

Burner output

Other manuals for B40 MF

2

Table of contents

Other Bentone Industrial Equipment manuals