Neptune ProCoder User manual

ProCoder™

Quick Install Guide

1: Product Description

The ProCoder™ is an electronic absolute encoder

register designed for use with the Neptune®

Automatic Reading and Billing (ARB®) System. This

register operates with the Neptune R900®and R450™

Meter Interface Units (MIUs), providing advanced

features such as leak, tamper, and backflow detection.

With the ProCoder register, both the homeowner and

the utility can use the following features:

lMechanical wheel bank for an absolute visual

reading

lEight digits for billing

lSweep hand for extreme low flow detection and

directional water flow indication

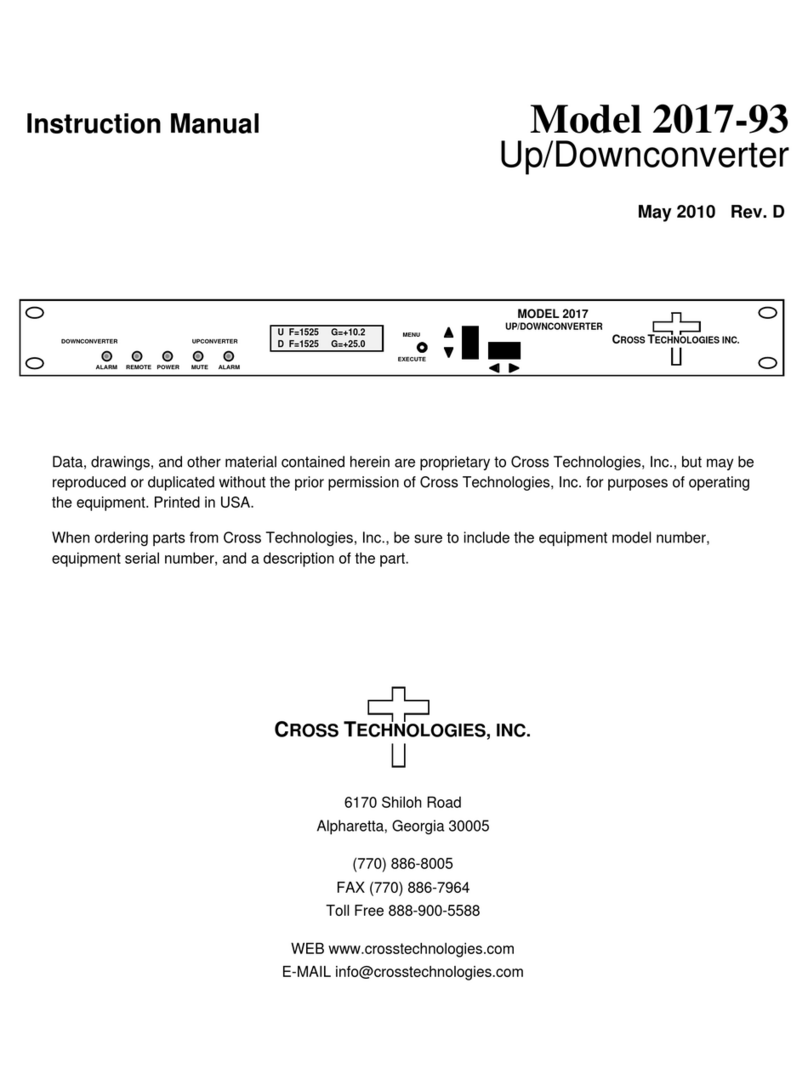

Figure 1: ProCoder™ Dial Face with Sweep Hand

This guide helps you identify and read information

displayed on the ProCoder register. It also helps you

recognize the common causes of leaks and instructs

what to do if you find one. This guide contains steps to

determine whether a leak is fixed after repairs.

- 1 -

2: Wiring Inside Set Version

To run a three-conductor cable from the ProCoder™

register to the MIU, complete the following steps.

1. Connect the three-conductor wire to the encoder

register’s terminals as described in the

manufacturer’s instructions, using this color code:

lBlack / B

lGreen / G

lRed / R

2. Remove the terminal cover with a flat-head screw

driver.

Figure 2: Removing the Terminal Cover

Figure 3: Wiring with

Proper Color Wire

3. Wire the encoder

register with the

proper colors.

4. Test the wiring to

verify the read.

- 2 -

5. Route the wire as

shown.

Figure 4: Routing the

Wire

Figure 5: Applying

Compound

6. Apply Novagard

G661 or Down

Corning #4 to the

terminal screws and

exposed bare wires.

Neptune recommends Novagard G661

or Dow Corning Compound #4.

Novagard may cause irritation to eyes

and skin. If swallowed, do not induce

vomiting; dilute with one to two glasses

of water or milk and seek medical

attention. Please refer to:

lMSDS Novagard Silicone Compounds

& Grease Inc. 5109 Hamilton Ave.

Cleveland, OH 44114

216-881-3890.

- 3 -

lFor copies of MSDS sheets, call

Neptune Customer Support at

(800) 647-4832.

3. Place the terminal cover

on register, ensuring the

wire is routed through

the strain relief.

Figure 6: Placing the

Cover on the Register

Figure 7: Snapping the

Cover in Place

4. Snap the terminal

cover in place by

pressing on the

molded arrow.

- 4 -

3: Wiring the Pit Set Version

To wire the pit set version, complete the steps. Figure 5

shows the components required for installation.

Figure 8: Installation Components

Figure 9: Scotchlok

Connector

1. Hold the Scotchlok™

between the index

finger and thumb

with the red cap

facing down.

2. Take one non-stripped

black wire from the

pigtail and one from

the receptacle / MIU

and insert the wires

into the Scotchlok

connector until fully

seated.

Figure 10: Seating the

Connector Wires

- 5 -

Do not strip the colored insulation from

the wires or strip and twist the bare

wires prior to inserting in the connector.

Insert the insulated colored wires

directly into the Scotchlok connector.

Figure 11: Crimping Tool

3. Place the connector

red cap side down

between the jaws of

the crimping tool.

Refer to Table 2 on

page 12 for part

numbers.

4. Check to ensure that

the wires are still fully

seated in the connector

before crimping the

connector. Figure 12

illustrates improper

connections due to

wires not being fully

seated.

Figure 12: Improper

Connections

5. Squeeze the connector firmly with the proper

crimping tool until you hear a pop and gel oozes

out the end of the connector.

6. Repeat steps 1 through 5 for each color wire. See

Table 1 on page 7 for the wiring configuration to

connect MIUs to the ProCoder.

- 6 -

MIU Wire Color/

Encoder Terminal

MIU Type

Black / B Green / G Red / R lR900

lR450

Black / G Green / R Red / B Sensus

Black / B White / G Red / R Itron

Black / G White / R Red / B Aclara

Black / G Green / B Red / R Elster

Black / G Green / R Red / B Badger

Table 1: Color Codes for Wires

7. After you connect all

three color wires, read

the encoder register to

ensure proper

connections, and the

receptacle / MIU is

functioning properly.

Figure 13: Three Color

Wires Connected

Figure 14: Splice Tube

8. Take all three

connected Scotchloks

and push them into

the splice tube until

fully covered by the

silicone grease.

- 7 -

9. Separate the gray

wires, and place in the

slots on each side of

the splice tube.

Figure 15: Gray Wires

in Slot

Figure 16: Cover in Place

10. Snap the cover closed

to finish the

installation.

4: Installation Instructions for

Networked Receptacle / Dual Port

MIUs

Enhanced R900 v4 MIUs are not dual

port capable. These instructions only

apply to v3 MIUs.

The Dual Port R900 and R450 MIUs work with

Neptune ProRead™, E-CODER®, and ProCoder

registers. Each register must be programmed in RF

Network mode prior to installation.

- 8 -

lE-CODER and ProCoder registers

cannot be programmed while

connected together in a network.

Each register must be programmed

separately prior to making the

network connection.

lThe designations HI and LO are

Neptune designations for the high

(HI) flow or turbine side of the

compound, and the low (LO) flow or

disc side of the compound.

lThe settings can also be used to

designate the primary (HI) and

secondary (LO) meters in a dual set

application.

Programming the HI Register

To complete the following steps, use the Neptune

Field Programmer to select the ProRead Program tab

for programming.

1. Select RF

Compound HI

format.

2. Match the

Connectivity 2W.

3. Match the Dial Code

65.

4. Type the

appropriate register

ID. Figure 17: HI Register

- 9 -

5. Program the register.

6. Read or query the register to confirm correct

programming. See Figure 17.

Programming the LO Register

Use the Neptune Field Programmer to select the

ProRead Program tab for programming.

Figure 18: LO Register

1. Select RF Compound

LO format.

2. Match the

Connectivity 2W.

3. Match the Dial Code

65.

4. Type the appropriate

register ID.

5. Program the register.

6. Read or query the

register to confirm

correct programming.

- 10 -

5: Wiring Networked Registers

Complete the following steps to wire networked

registers.

1. Connect each color wire with the appropriate color

wire from the pigtail and both registers, until all

three colors have been successfully connected. See

Figure 19.

Figure 19: Interconnection of Like Terminals

lRemove any bare or non-insulated

wire. Make sure that you only insert

insulated wires into the splice

connector.

lObserve proper polarity when wiring

the registers so that all terminals are

interconnected with wires of the

same color: red, black, or green.

2. Proceed to "How to Read" on page13.

- 11 -

6: Crimping Tool Manufacturers

To apply the Scotchlok™ connectors, Neptune requires

the use of a proper crimping tool. Table 2 shows a list

of various manufacturers and model numbers.

To reduce fatigue, use a tool within each

splicing group with the highest

mechanical advantage indicated within

the parentheses ( ).

Manufacturer Manufacturer’s Model

Number

3M E-9R (10:1) — To reduce

fatigue, use a tool within each

splicing group with the

highest mechanical advantage

indicated within the

parentheses ( ).

E-9BM (10:1)

E-9C/CW (7:1)

E-9E (4:1)

E-9Y (3:1)

Eclipse Tools 100-008

Table 2: Proper Crimping Tools

Use of normal pliers or channel locks is

highly discouraged because they do not

apply even pressure and can result in an

improper connection.

- 12 -

7: How to Read

It is important to become familiar with the information

available from the register.

Figure 20: Reading the ProCoder™

Figure 21: ProCoder™ Sweep Hand

The sensitive sweep hand provides a visual

representation of extreme low flows as well as reverse

flow. Depending on the size and type of ProCoder™

register, a specific multiplier is present. This multiplier,

along with the current position of the sweep hand,

provides additional digits of resolution that are

especially useful for testing.

- 13 -

For further information on reading the

ProCoder sweep hand, see the Product

Support Document entitled How to Read

the Neptune ProCoder Register.

8: Common Causes of Leaks

Leaks can result from various circumstances. To better

help you identify a possible leak, Table 3 contains

some common causes of leaks.

Possible Cause of

Leak

Intermittent

Leak

Continuous

Leak

Outside faucet,

garden or sprinkler

system leaking

Toilet valve not

sealed properly

Toilet running

Faucet in kitchen or

bathrooms leaking

Ice maker leaking

Soaker hose in use

Leak between the

water meter and the

house

Table 3: Possible Leaks

- 14 -

Possible Cause of

Leak

Intermittent

Leak

Continuous

Leak

Washing machine

leaking

Dishwasher leaking

Hot water heater

leaking

Watering yard for

more than eight

hours

Continuous pet

feeder

Water-cooled air

conditioner or heat

pump

Filling a swimming

pool

Any continuous use

of water for 24

hours

Table 3: Possible Leaks (continued)

- 15 -

9: How to Tell if Water is in Use

To determine if water is in use, complete the following

steps.

1. Look at the mechanical sweep hand.

2. Determine which of the following conditions exist.

If... Then...

The sweep hand is

moving slowly in a

clockwise direction

Water is running very

slowly

The sweep hand is

moving quickly

Water is running

The sweep hand is not

moving

Water is not running

The sweep hand is

moving counter-

clockwise

Backflow is occurring

Table 4: Determining if Water in Use

- 16 -

10: What to Do if There is a Leak

Refer to the following checklist if there is a leak.

Check all faucets for possible leaks.

Check all toilets and toilet valves.

Check the ice maker and water

dispenser.

Check the yard and surrounding

grounds for a wet spot or indication of

a pipe leaking.

Table 5: Checklist for Leaks

11: If a Continuous Leak is Repaired

If a continuous leak is found and repaired, complete

the following steps.

1. Use no water for at least 15 minutes.

2. Check the sweep hand.

If the sweep hand is not moving, then a continuous

leak is no longer occurring.

- 17 -

12: If an Intermittent Leak is Repaired

If an intermittent leak is found and repaired, complete

the following steps.

1. Check the sweep hand after at least 24 hours.

If the leak has been correctly repaired, the sweep

hand does not move.

2. Refer to the following table which describes the

standard functions of the ProCoder™ flags.

(When connected to an R900®MIU)

Backflow Flag (Resets After 35 Days)

Based on reverse movement of the eighth digit, the

eighth digit is variable based on the meter size.

No backflow event Eighth digit reversed less than

one digit

Minor backflow

event

Eighth digit reversed more

than one digit up to 100

times the eighth digit

Major backflow

event

Eighth digit reversed greater

than 100 times the eighth

digit

Leak Status Flag

Based on total amount of 15-minute periods

recorded in the previous 24-hour period.

No leak Eighth digit incremented less

than 50 of the 96 15-minute

intervals

Table 6: ProCoder™ Flags

- 18 -

Table of contents

Other Neptune Media Converter manuals