NetSafetyMonitoringInc.

9

MAN-0047 Rev 12 MLP-A/AR/AD-SC1100 & MLP- LP-A/AR/ARS-SC1100

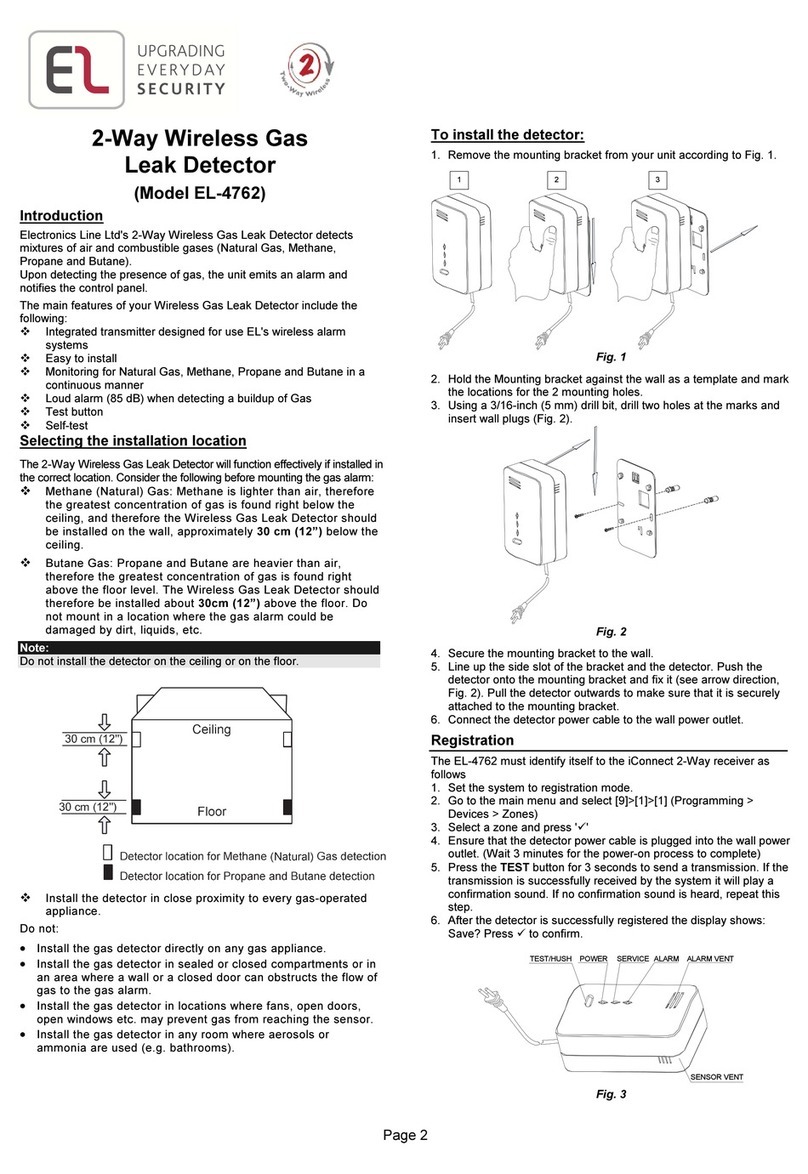

Mount

The controller should be mounted near eye-level and be easily

accessible for calibration and maintenance purposes. The sensor

should be placed where gas is likely to accumulate.

Ensure all devices are securely mounted, taking into consideration all

requirements.

SECTION 3: Wire

Field Installation

Warning Wiring codes and regulations may vary. Wiring

must comply with applicable regulations relating to the installation

of electrical equipment in a hazardous area and is the responsibility

of the installer. If in doubt, consult a qualified official before wiring

the system. See some wiring considerations below.

•If the 4-20 mA signal is not used, connect a jumper between

the 4-20 mA terminal and the Common terminal.

•The use of shielded cable is highly recommended for signal,

input, output and power wires to protect against interference

caused by extraneous electrical or electromagnetic 'noise'.

•In applications where the wiring cable is installed in conduit,

the conduit must not be used for wiring to other electrical

equipment.

•The maximum distance between sensor and controller is

limited by the resistance of the connecting wiring, which is a

function of the gauge wire being used. See Appendix B.

•When developing a RS-485 chain of devices, the last device

in the chain requires end of line termination.

•RS-485 connection 2-wire, multipoint serial line.

Seal

The use of seals is recommended to further protect the system

against any unwanted water ingression, and equipment should be

installed according to applicable local electrical codes. Seals are

especially recommended for installations that use high-pressure or

steam cleaning devices in proximity to the transmitter and/or sensor.

•Water-proof and explosion-proof conduit seals are

recommended to prevent water accumulation within the

enclosure.

•Seals should be located as close to the device as possible and

not more than 18 inches (46 cm) away.

•Explosion-proof installations may require an additional seal

where conduit enters a non-hazardous area. Ensure

conformity with local wiring codes.

•When pouring a seal, use a fibre dam to ensure proper

formation of the seal. Seals should never be poured at

temperatures below freezing.

•The jacket and shielding of the cable should be stripped back

to permit the seal to form around the individual wires. This

will prevent air, gas and water leakage through the inside of

the shield and into the enclosure.

•It is recommended that explosion-proof drains and conduit

breathers be used. In some applications, alternate changes in

temperature and barometric pressure can cause 'breathing'

which allows moist air to enter and circulate inside the

If necessary use the Face Rotation Option to mount the

Millennium Controller at a different orientation. Refer to “Face

Rotation Option” for detailed instructions.