3

■

How to connect

・

Use clean air filtered through air dryer and air filter.

If not,dirty air can cause painting failure.

・

Before using the spray gun for the first time, clean fluid passages with thinner to removerust preventive oil.

If not cleaned, the rust preventive oil can cause paint failure,such as fish eyes

・

Firmly connect hose or cup to spray gun.

If not, disconnection of hose or dropof cup can cause bodily injury

..

Step1. Connect an air hose to air nipple tightly.

Step2. Connect a fluid hose or a container to fluid nipple tightly.

Step3. Flush the spray gun fluid passage with a compatible solvent..

Step4. Pour paint into container, testspray and adjust fluid output as well as pattern width.

■

Maintenance and inspection

・

Firstrelease air and pressure fully according to item No. 3 of “Improperuseof equipment” ofWARNING on page 2.

・

Only an experienced person who is fully knowledgeable of the equipment should perform maintenance and inspection.

・

pH valueshall be 6 to 8, otherwise could cause corrosion.

・

Only usegenuineANEST IWATA parts for any maintenance or repairs.

Step-by-step procedure

Pour remaining paint to another container. Clean fluidpassages and

Spray a smallamount of thinner into fluid passages to clean them.

Incomplete cleaningcanresult in poorspray pattern andcontaminated paint.

It is especially important clean the gun fully and promptly after using two-component paint.

Clean each section withbrush soaked with thinner and wipe out with waste cloth.

Soaking whole spray gun in solvent may cause spray gun malfunction.

cap assy. itself forextended period may cause a defective spray pattern.

When cleaning, never scratch the air cap assy., fluid nozzle, or fluid needle.

Avoid touching or damaging the tip of the fluid nozzle or needle.

3. Before disassembly,fully clean fluidpassages.

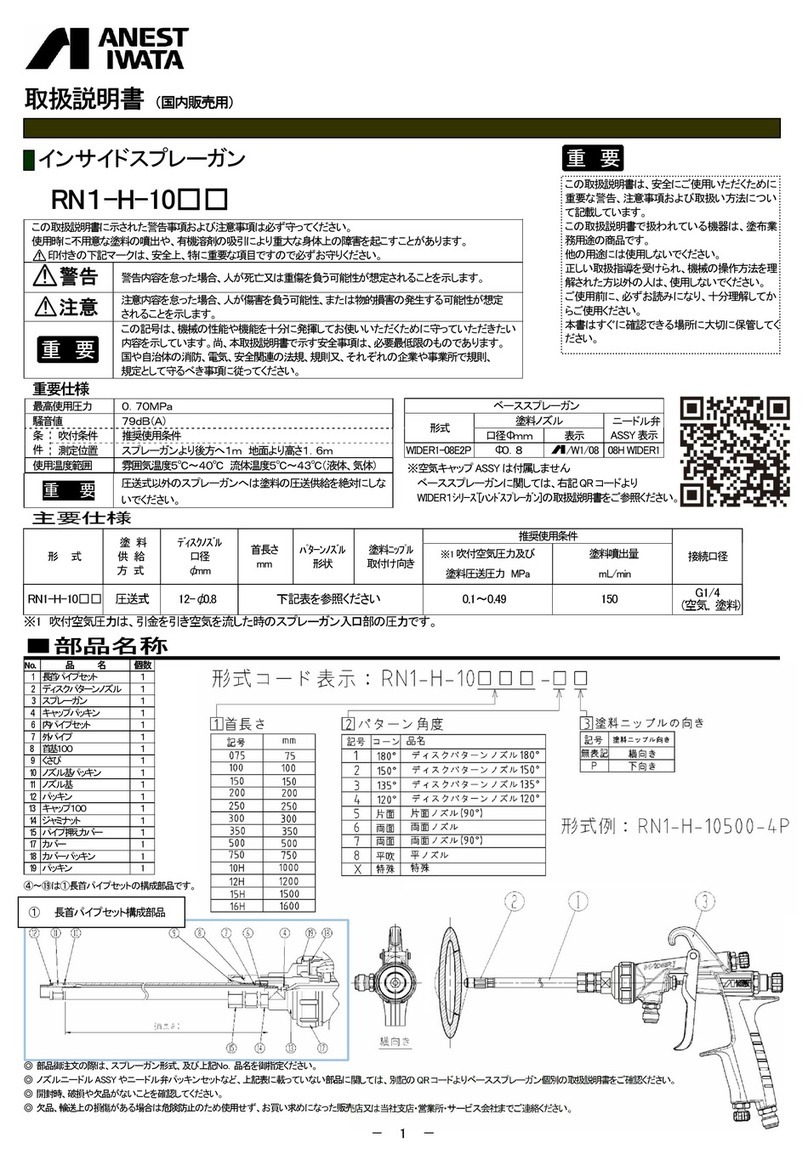

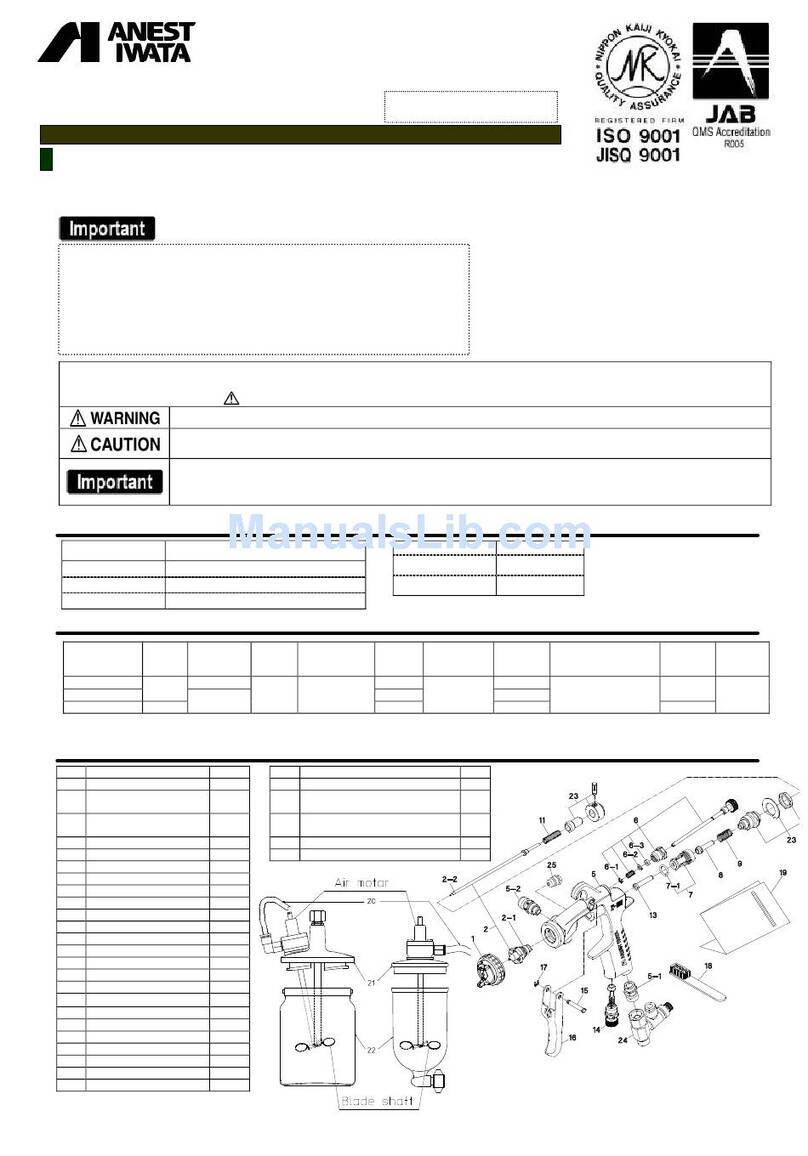

Remove fluid nozzle, using a ring spanner, box wrench or optional accessory spanner

(code 93538601)

3. Duringdisassembly,avoid scratchingtheneedleseating surface.

Either first remove the fluid needle or hold the trigger backwhile removing the fluid nozzle,

to protect the seating surface.

If you need to adjust fluid needle packing set, first tighten it by hand (with fluid needle in

place). Then tighten it further about 1/6turn (60-degree) by spanner.

When you remove needle packing set, do not leave the plastic tip of the packing in the

spray gunbody.

If you tighten the fluid needle packing set too much, fluid needle will not move smoothly,

resulting in paint leakage from tip of the fluid nozzle. Try to adjust it carefully while pulling

thetrigger and confirming smooth movement of the fluidneedle.

If you tighten it too much, first fully loosen it and then retighten again carefully.

5. To assemble the air valve, first assemble the air valve, air valve spring, and fluid adj. guide

assy. together. Next, insert fluid needle into fluid adj. guide assy., then fit it to spray gun

body and screwfluid adj. guide assy. in.

If you try to fit air valve spring and air valve to the spray gun body without the fluid

needle, the air valve may not be fitted correctly and the packing inside fluid adj. guide

assy. can be damaged.

6. Before assembling the pattern adj. assy. or air adj. assy. back on to the gunbody, fully turn

the adjustment knobs counterclockwise to open. Once in the gun body the pattern adj.

knoband airadj. knob can be tightened.

6. If pattern adj. knob or air adj.knobis not fully opened when tightening into gun body, thetip

of it can contact and damage the seating surface.

7. When you assemble the needle spring on the fluid needle, the plastic tip should be on the

opposite sideasthefluid needletip.

7. If plastic tip is on the wrong side, it may not operate normally.Incorrectinstallation of the

needle spring may cause a heavy trigger pull.

Parts replacement standard

1. Each holepassage of air cap assyand fluid nozzle Replaceif it is crushed or deformed.

2. Packing and O ring Replaceif it is deformed or worn out.

3. Leakage from seating surface between fluid nozzle and fluid needle Replacethemif leakage does not stop after fully cleaning the fluid nozzle and needle.

If you replace the fluid nozzle or fluid needle only, ensure they fully match and confirm that

there isno leakage.

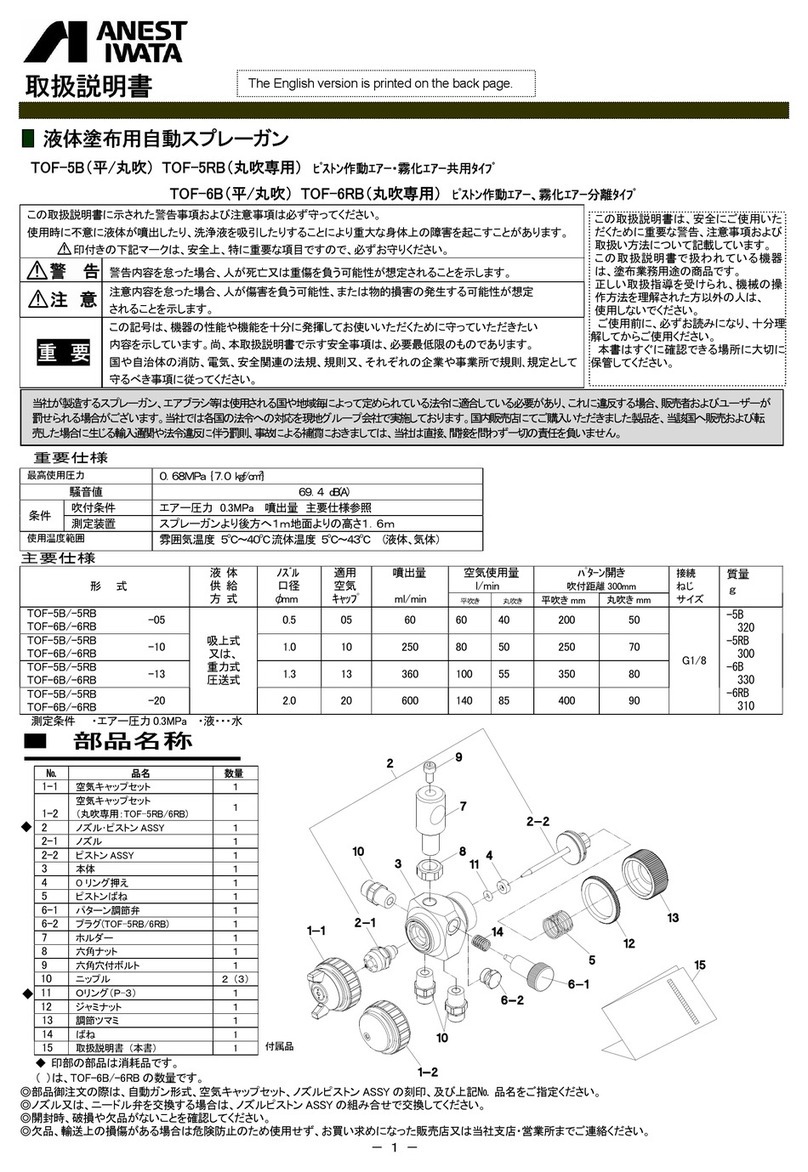

Fluidnipple

(Suction/Pressure)

Air

Fluidneedle

Needlespringassy

Plastictip