New Cosmos Electric KS-7O User manual

Oxygen Detector

KS-7O

Instruction Manual

Keep this manual for easy reference.

Carefully read this manual prior to use.

This manual describes the standard model. If your unit has end-user-specific

options, this manual will be superseded by your delivery specifications.

Instruction Manual No.

GAE-052-06

June 2023

Table of Contents

1. Introduction ................................................................................................................................ 1

2. General Precautions .................................................................................................................. 2

3. Package Contents ..................................................................................................................... 3

4. Unit Dimensions and Components ............................................................................................ 4

4-1. Outer Appearance .................................................................................................................. 4

4-2. Inner Components .................................................................................................................. 5

5. Installation ................................................................................................................................. 6

6. Wiring ........................................................................................................................................ 9

6-1. Pin Terminal/Insulating Sleeve Installation ...........................................................................10

6-2. Wire Connection/Disconnection to/from Terminal Block ...................................................... 11

6-2-1. Power Terminal Block ....................................................................................................... 11

6-2-2. External Output Terminal Block ......................................................................................... 11

6-3. Cable Tie Installation ............................................................................................................ 11

6-4. AC Power Cable (PC0125) Wiring Procedure .....................................................................12

7. Operation .................................................................................................................................13

7-1. Precautions before Use ........................................................................................................13

7-2. Operating Procedure ............................................................................................................13

7-3. LCD Operation .....................................................................................................................15

7-3-1. LCD ...................................................................................................................................15

7-3-2. Normal Operation Status ...................................................................................................15

7-3-3. Full Scale and Alarm Set Values Display ..........................................................................16

7-3-4. Peak Value Display and Reset ..........................................................................................16

7-3-5. Operation during Gas Alarm .............................................................................................16

7-4. User Mode ............................................................................................................................17

7-4-1. User Mode Operation ........................................................................................................17

7-4-2. Switching Maintenance Mode On/Off [Mode1] .................................................................18

7-4-3. Zero Adjustment [Mode 2] .................................................................................................19

7-4-4. Span Adjustment (21.0vol% Adjustment) [Mode 3] ...........................................................19

7-4-5. Alarm Test [Mode 4] ..........................................................................................................20

7-4-6. Alarm History [Mode 5] ......................................................................................................21

7-4-7. Clock Setting [Mode 6] ......................................................................................................22

7-5. Maker Mode .........................................................................................................................23

7-5-1. Maker Mode Activation ......................................................................................................23

7-5-2. Operating Time Refresh ....................................................................................................23

7-5-3. Alarm Set Value Change ...................................................................................................24

8. Maintenance ............................................................................................................................26

8-1. Inspection Contents and Frequency ....................................................................................26

8-2. Sensor/Backup Battery/Clock Battery Replacement............................................................28

9. Troubleshooting .......................................................................................................................31

10. Specifications.........................................................................................................................33

11. Warranty ................................................................................................................................34

12. Expected Sensor Life ............................................................................................................34

13. Detection Principle ................................................................................................................35

14. Glossary ................................................................................................................................36

15. Proper Product Disposal at End of Life .................................................................................37

- 1 -

1. Introduction

Thank you for purchasing the New Cosmos KS-7O oxygen detector.

To ensure safe and reliable operation, please read this instruction manual prior to use.

This unit detects oxygen leakage/deficiency in working environments, e.g., semiconductor

manufacturing plants and laboratories, and relays the oxygen concentration value as an analog

signal (4-20mADC) to external devices while simultaneously displaying the concentration value on

its display.

Oxygen levels are monitored, and if the concentration reaches a preset level, the unit will produce

audio/visual alarms and activate relay contacts.

This manual uses Danger, Warning, Caution and Note symbols to draw attention to

procedures, materials, methods, and processes, which require particular attention.

: Indicates an imminently hazardous situation that can result in

death or serious injury.

: Indicates a potentially hazardous situation that may result in death

or serious injury.

: Indicates a hazardous situation that may result in minor injury or

property damage.

: Provides information on product handling.

DANGER

CAUTION

WARNING

NOTE

- 2 -

2. General Precautions

Carefully read this manual prior to use.

Follow the precautions below to ensure safe operation.

Only use this product in accordance with the applicable laws and regulations.

Only a qualified electrician with knowledge of wiring and installation procedures should perform

wiring and installation.

In the event of a gas alarm, follow the safety procedures in accordance with your

company's regulations.

This product is not explosion-proof and should not be installed in a hazardous area.

Secure the cover by tightening the two fastening screws. Proper gas detection is not

possible if the cover is not tightly closed.

WARNING

Operation during power outage

In the event of a power outage during operation, the detector will cease operation if the

backup battery is not installed. The detector will automatically resume operation once

power is restored, as long as the main power switch, under the cover, is in the on (up)

position. A backup battery is included in the package (not pre-installed) when delivered.

Install it into the detector if the detector needs to continue running during a power outage.

If the backup battery level becomes very low while the detector operates on the backup

- LCD. If the detector

continues operating while "E-B" is displayed, it will cease operation automatically to

prevent over-discharge. In this case, the detector will not automatically resume operation

even if power is restored.

Remove the backup battery from the detector before a planned power outage etc., if the

detector is expected to operate on the backup battery for an extended period of time.

Refer to 8- removal/

ill not be affected

whether the backup battery installed or removed.

NOTE

Do not disassemble, modify, or alter the structure of this unit or its electrical circuits.

Doing so may compromise the performance of the product.

This product is not drip-proof and should be kept away from water.

-layer

monitoring software, perform a 21% suppression setting using the high-layer monitoring

software.

ranges from 250 to 500 (contingent on full scale

setting). Because of the difference in resolution or number of displayed gas

concentration digits between this product and high-layer monitoring software, or

connected impedance, some errors in displayed gas concentration value may be

observed.

If the fault threshold needs to be set via analog output, set it to 1.0 mA.

To comply with JIS T 8201:2010 (Japanese Industrial Standard), your unit should be

configured for manual-resetting. Specify manual-resetting type at time of order. If a

self-resetting type is chosen and manual-resetting is maintained using a high-layer

system, a self-resetting type of detector can be used to comply with this standard.

CAUTION

- 3 -

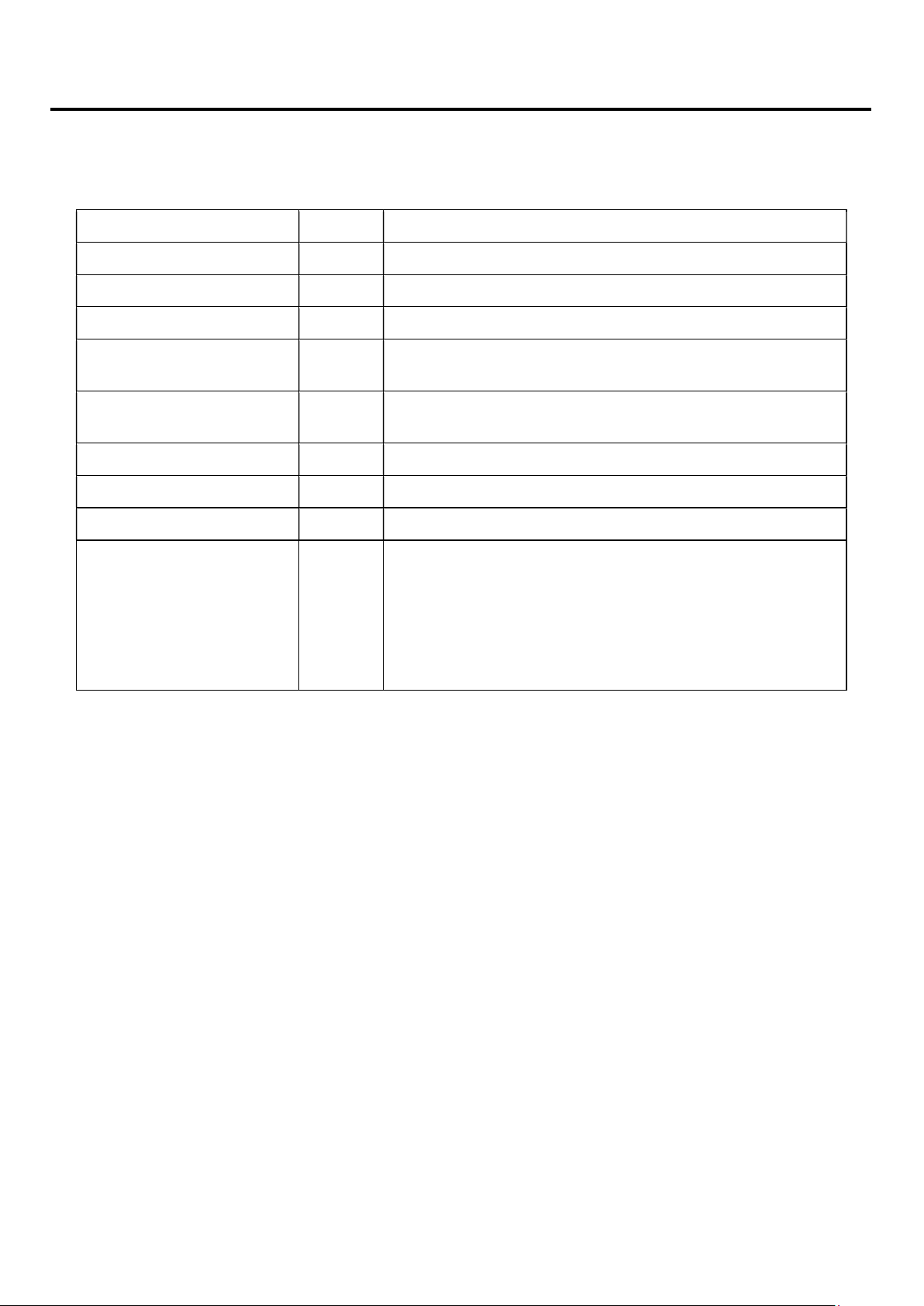

3. Package Contents

The following items are included in a standard package. If any items are missing or damaged,

please contact New Cosmos or its authorized representative for replacement.

Item Quantity

Description

Oxygen detector 1 KS-7O

Mounting screw 2 M5x12 with spring washer (wall mounting)

Cable tie 1 To be used to bundle electric cables

Pin terminal 9 To be crimped to cables and inserted into the terminal

block

Insulating sleeve 9 To be installed in a crimped pin terminal to provide

insulation

Instruction manual 1 This manual

Inspection certificate 1

Backup battery 1 CR2 lithium battery

AC power cable

(Optional) 1

100 VAC power cable with 2-pin power plug at one end

and two pin terminals at the other end

Length: 2.5 m

Note: AC power cable is not included unless specified at

the time of order, even though your unit has AC power

option.

- 4 -

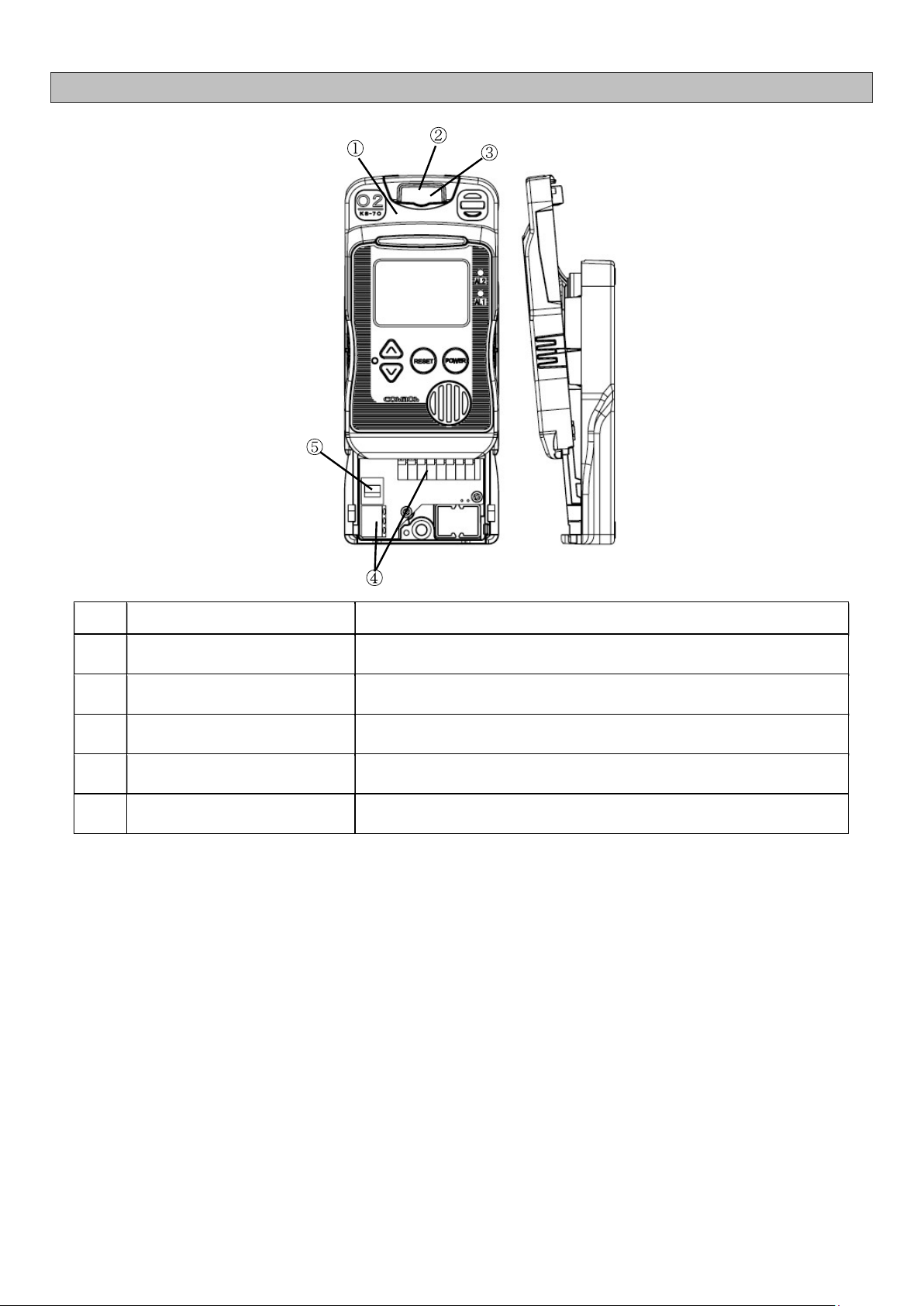

4. Unit Dimensions and Components

4-1. Outer Appearance

Item Component Description/Function

1 Cover

Slide up and lift the cover to access to the main power switch and to

wire external cables. This cover is normally closed.

2 Screw cover Houses one mounting screw, and two fastening screws

that attach the

cover to the unit. This cover is normally closed.

3 Gas detection port Gas inlet to the oxygen sensor.

4 Status indicator

(red/amber/green)

During normal operation all three green internal LEDs are lit.

In the

event of an 1st/2nd stage gas alarm, four internal amber

/red LEDs

light sequentially.

5 LCD Displays oxygen concentration, parameter values, error code,

and

status icons.

6 AL2 alarm LED (red) Flashes red in the event of a 2nd stage gas alarm. The LED

will

become solid if reset by pressing the RESET button.

7 AL1 alarm LED (amber) Flashes amber in the event of a 1st stage gas alarm. The LED

will

become solid if reset by pressing the RESET button.

8 (Up) button

During normal operation, press to display the highest

peak value of

oxygen concentration after powering-up on the LCD.

Used for making settings in combination with other button operation.

9 (Down) button

During normal operation, press to display the lowest

peak value of

oxygen concentration after powering-up on the LCD.

Used for making settings in combination with other button operation.

10 RESET button During normal operation, press to display the full scale and alarm set

values. Used for muting an on-going audio alarm.

11 POWER button Press and hold for 3 seconds to turn on/off the detector.

12 Speaker opening Opening for audio.

13 Cable entry (3 places)

Make a cutout (cable entry) with a nipper to connect external cables to

the terminals.

14 Maintenance button Recessed button used for making settings.

Dimensions are in mm.

- 5 -

4-2. Inner Components

Item Component Description/Function

1 Cover Slide up and lift the cover to access to the main power switch and

to wire external cables. This cover is normally closed.

2 Screw cover Houses one mounting screw, and two fastening screw

s that attach

the cover to the unit. This cover is normally closed.

3 Fastening screw (2 places) Located under the screw cover.

Screws that attach the screw cover to the unit.

4 Terminal block Connect to external wiring.

5 Main power switch Turns on/off the main power.

- 6 -

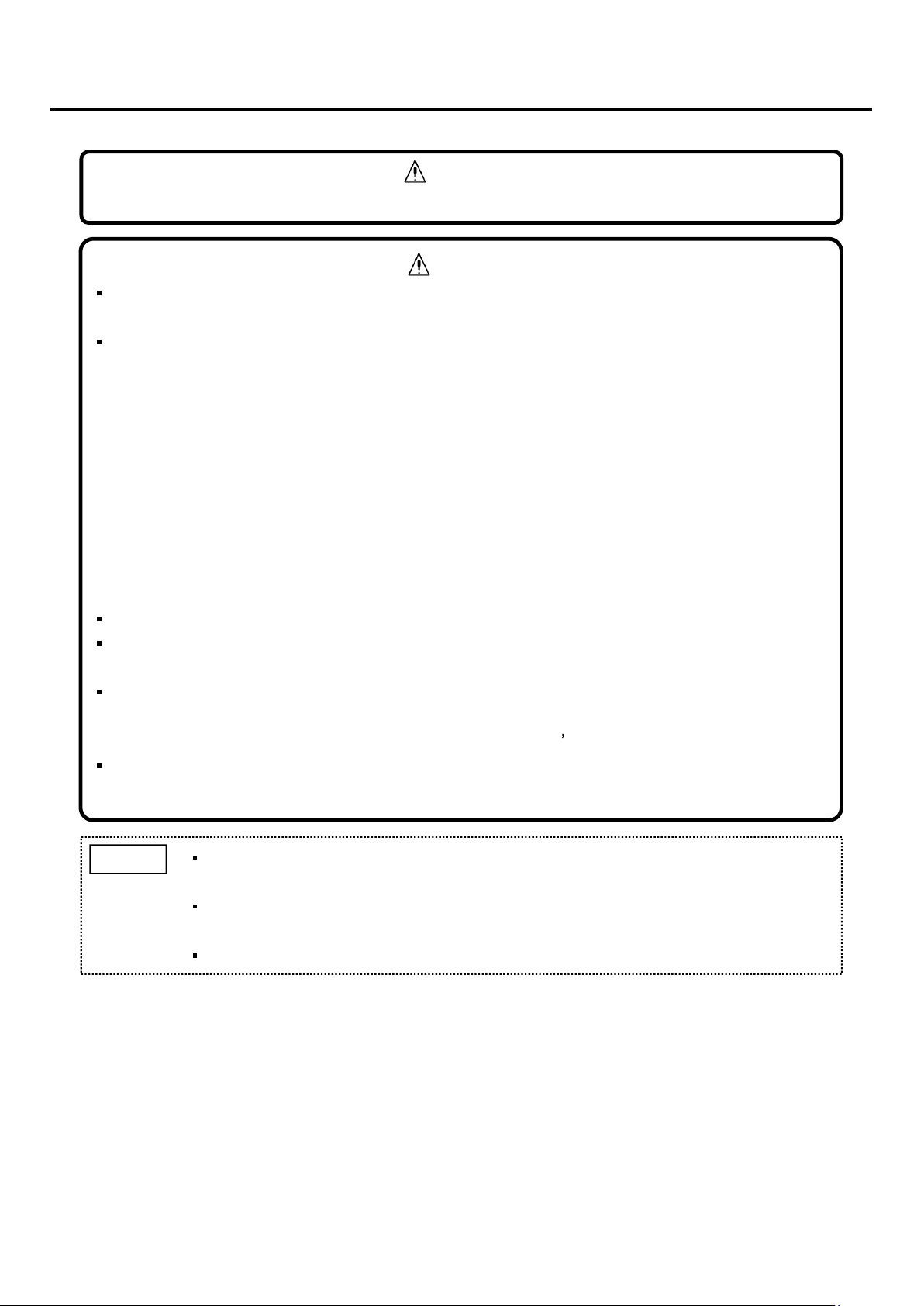

5. Installation

This product is not explosion-proof and should not be installed in a hazardous area.

WARNING

Leave a distance of more than 30mm from each side of the detector for

removal purpose.

Leave a distance of more than 50mm from the top of the detector to allow the

cover to slide open.

Leave enough space for cable wiring below the detector.

NOTE

Avoid strong mechanical shock, impact or vibration to the detector by dropping or bumping.

Failure to do so may impair the performance of the detector.

Do not install the detector in the following conditions.

- Outdoors

- Exposure to water spray

- Outside the following operating temperature/humidity

-10 to +40 °C (no rapid temperature change)

30 to 85% RH (no condensation)

- Presence of corrosive gas

- Exposure to impact or vibration

- Presence of high frequencies or a magnetic field

- Exposure to electrical noise

Install the detector in a location that ensures easy access for maintenance.

For detecting oxygen deficiency, the detector should be installed at head height in a place

free from obstruction to the gas detection port.

When used in a measurement environment where the atmospheric pressure is different

from the standard atmospheric pressure, e.g., at a high altitude, the measurement value

should be adjusted to compensate for the oxygen sensor s pressure dependence.

Secure the cover by tightening the two fastening screws. Proper gas detection is not

possible if the cover is not tightly closed.

CAUTION

- 7 -

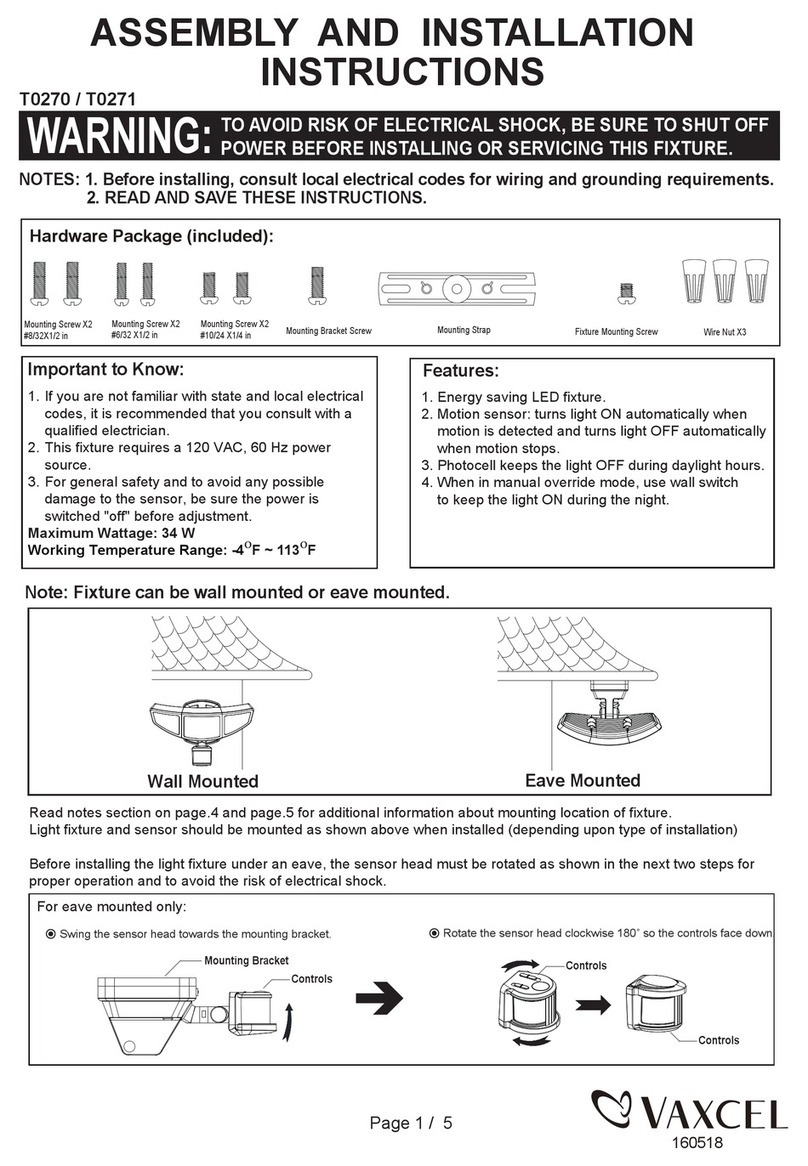

Wall-mount the detector using two M5 mounting screws (pitch: 134) according to the following

procedure.

1. Open the screw cover.

2. Loosely install the mounting screw (top).

3. Loosen the two fastening screws.

4. Slightly pull the cover forward.

2. Loosely install the

mounting screw (top)

3. Loosen the two fastening screws

4. Pull the cover forward

Cover

1. Open the screw cover

Screw cover

Mounting hole

50

Sensor

Space for

cover to slide

Cable entry

Mounting hole

Dimensions are in mm.

50

Mounting hole

- 8 -

5. Slide the cover up (cover is open).

6. Firmly tighten the mounting screw (bottom) to secure the detector to the wall.

7. Slide the cover down (cover is closed).

8. While pressing down the cover toward the case,

9. tighten the mounting screw (top).

10. Secure the screw cover to the case with the two fastening screws.

11. Close the screw cover.

5. Slide the cover up

6. Tighten the mounting screw (bottom)

7. Slide the cover down

CAUTION

Secure the cover by tightening the

two fastening screws. Proper gas

detection is not possible if the cover

is not tightly closed.

10. Tighten the two fastening screws

Case

9. Tighten the mounting screw

8. Press down the cover

- 9 -

6. Wiring

The knockout holes for cable entry are provided

on the back and bottom of the unit, and can be

removed using a nipper.

Use a shielded cable (with 0.5 to 1.25 mm2 wires)

up to 500 m in length with an outside diameter of

10.5 mm or less.

NO: Normally Open NC: Normally Closed

Remove any power source during wiring work to prevent electric shocks.

After wiring is completed, close the detector s cover to prevent electric shocks.

WARNING

Knockout hole on the bottom

Knockout hole on the back

AC

DC

Power supply

24 VDC or 100 VAC

R P +

S N

E Earth terminal for grounding the detector

Signal + Analog output

4-20mADC

ZA1 1st stage alarm relay contact

(Dry NO or NC)

ZA2 2nd stage alarm relay contact

(Dry NO or NC)

TA Fault alarm relay contact (Dry NO or NC)

COM Common

D Not used

C

New Cosmos is not responsible for the cost or any damage resulting from controlling

external equipment (e.g., interlock) by using the oxygen concentration outputs (e.g.,

analog output, alarm relay contact output) from this product.

Connect wires to their corresponding terminals by referring to the marking on the terminal

block.

Keep the connection cable away from the electrical power line.

When using with external devices, isolate the product s 4-20mA analog output from power

lines of external devices in order to prevent inflow current and noise.

CAUTION

Ex. NO contacts

-

+

R

S

C

D

COM

Signal

E

N S

P R

+

ZA2

ZA1

TA

Refer to page 12 for the wiring procedure

for the optional AC power cable.

Refer to 7-3-2

on page 15 for the operation of the backup

battery.

NOTE

- 10 -

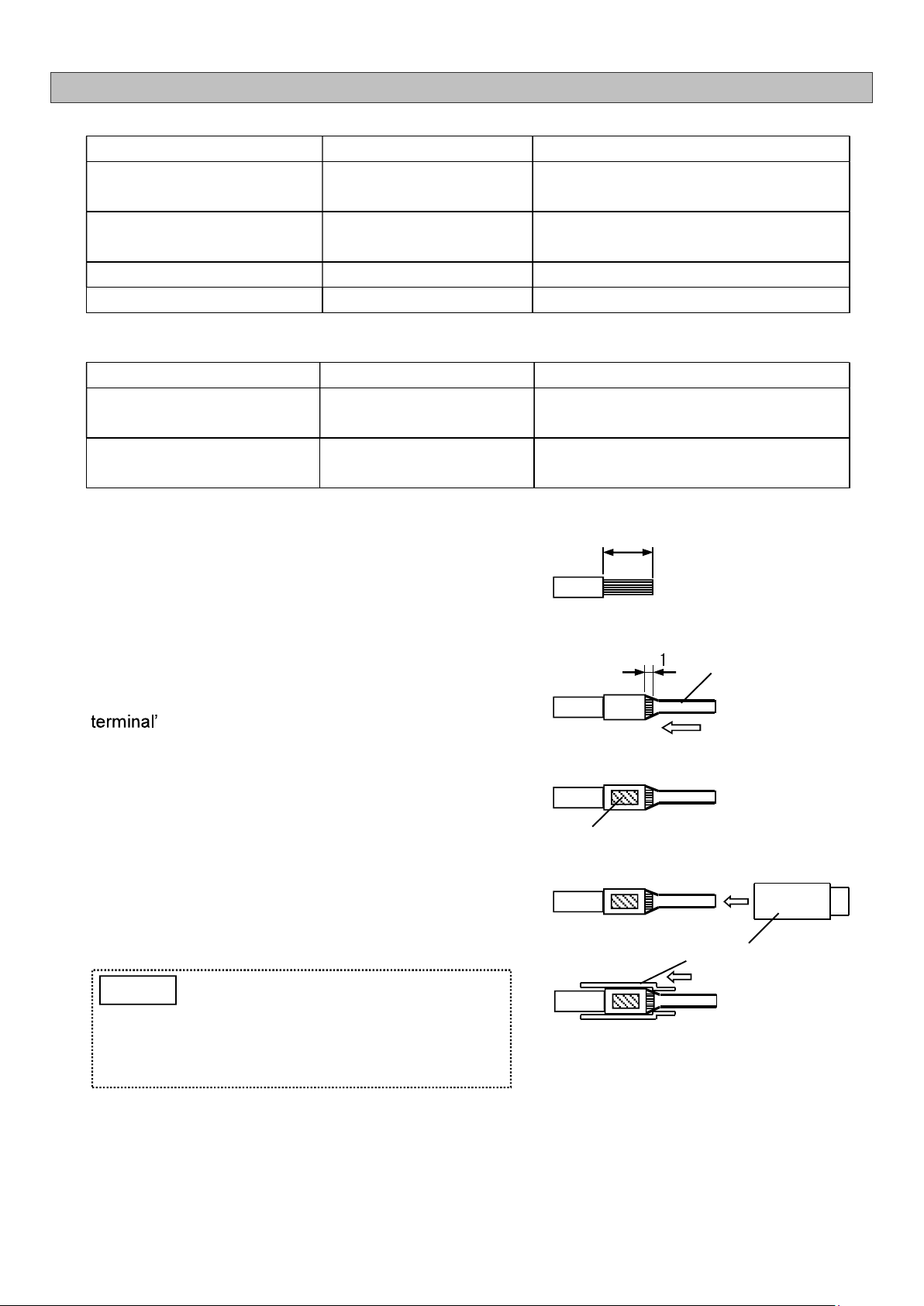

6-1. Pin Terminal/Insulating Sleeve Installation

Recommended parts/tools

Part Model (Manufacturer) Description

Electric cable

Shielded cable (with 0.5-1.25 mm2 wires)

Outer diameter: 10.5 mm or less

Pin terminal TC1.25-16 (Nichifu) (Included in package)

Used for 0.25-1.65 mm2 twisted wire

Insulating sleeve VC1.25 (Nichifu) (Included in package)

Crimping tool NH1 (Nichifu) 1.25

Terminal block (reference)

Part Model (Manufacturer) Description

Power terminal block ML-1400-S1L-3P

(Sato Parts) Dia. 0.65-1.6 mm

External output terminal block

FFKDSA1/H1-5, 08-8

(Phoenix Contact) Dia. 0.2-1.5 mm

1. Wire stripping

Strip the wire.

Recommended stripped wire length: 5.5 mm

2. Pin terminal installation

Insert the stripped wire into a pin terminal until 1 mm

of stripped wire can be seen from the end of the pin

s barrel.

3. Terminal crimping

Crimp the center of the barrel.

4. Insulating sleeve installation

Attach an Insulating sleeve to the crimped pin

terminal.

Completely insert the pin terminal into

the insulating sleeve. Not doing so may

cause an insufficient pin length when

wired to the terminal block, which may

result in a poor connection.

NOTE

Pin Terminal

Barrel

Insulating sleeve

Completely insert

5.5 mm

- 11 -

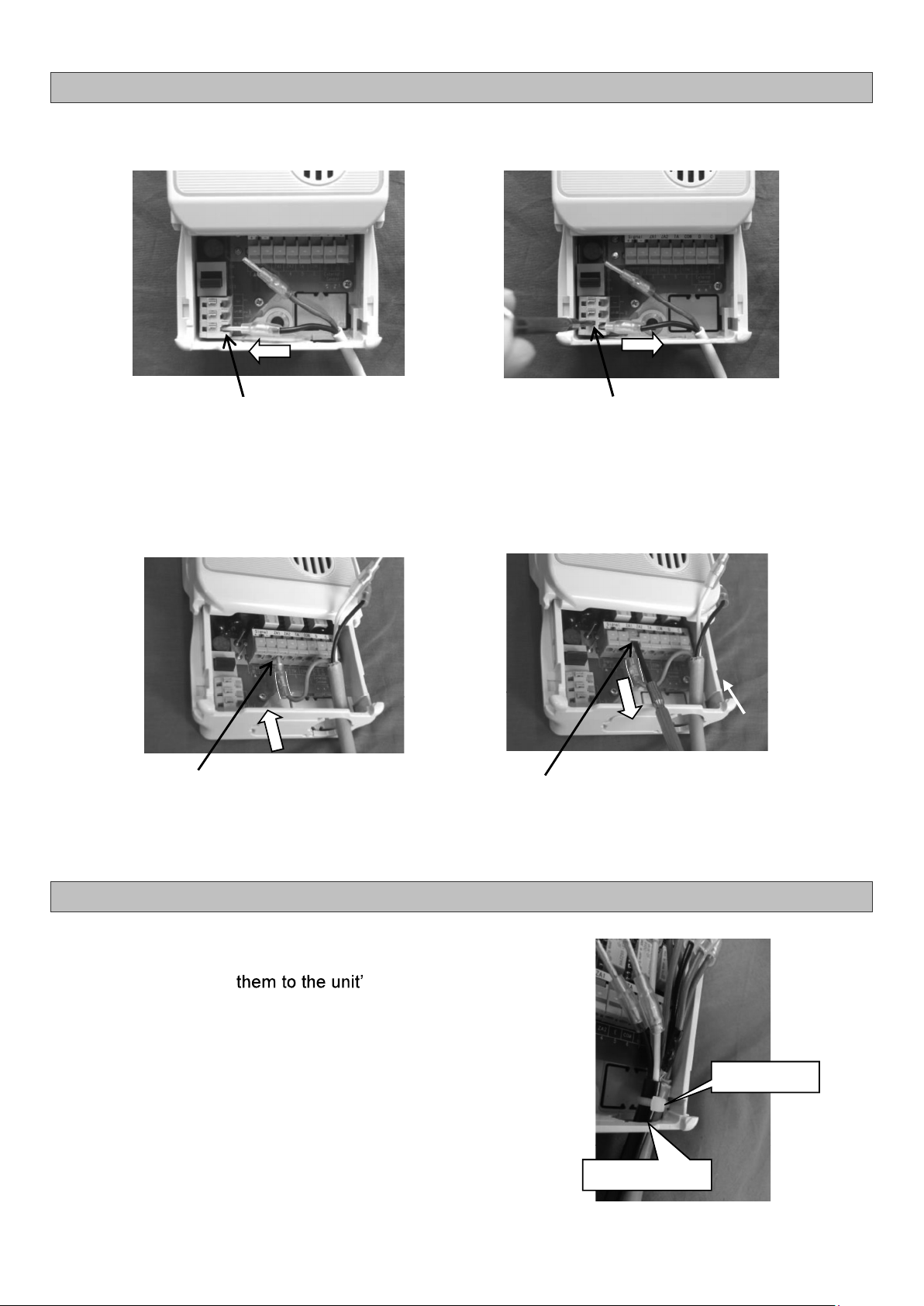

6-2. Wire Connection/Disconnection to/from Terminal Block

6-2-1. Power Terminal Block

6-2-2. External Output Terminal Block

6-3. Cable Tie Installation

Use a cable tie for bundling the in-coming cables through the

cable entry and secure s wall.

The unit has a cable tie holder inside its case near the bottom.

Pre-install a cable tie by feeding it through the tie holder and

make a loop. To easily bundle the wiring of in-coming cables to

the terminal block, feed these cables through this loop and

secure to the case wall.

Cable tie

Cable entry

Insert each pin terminal to its

corresponding slot on the terminal block.

(Connection) (Disconnection)

While pressing the release button with a

precision screwdriver (recommended tip

thickness: 2.6 mm), lift the pin terminal.

(Disconnection)

(Connection)

Insert each pin terminal to its

corresponding slot on the terminal block.

While pressing the release button with a

precision screwdriver (recommended tip

thickness: 3.0 mm), lift the pin terminal.

- 12 -

6-4. AC Power Cable (PC0125) Wiring Procedure

1. Make a cutout (cable entry) on the bottom of

the unit with a nipper.

Note: The knockout holes for cable entry are

provided on the back and bottom of the unit,

and either can be used as cable entry.

Cut here (2 places)

2. Install a cable tie by feeding it through the

tie holder and make a loop.

3. Ensure that the insulating sleeves are

completely installed to the pin terminals of

the AC power cable.

4. Feed the AC power cable through the cable

entry and the loop of the cable tie.

5. Insert the pin terminals into the slots

(Nos. R and S) on the terminal block.

Note: Either pin terminal can be connected to

either slot.

6. Pull the cable tie to secure the AC power

cable to the case wall. Cut off the excess

strap with a nipper.

- 13 -

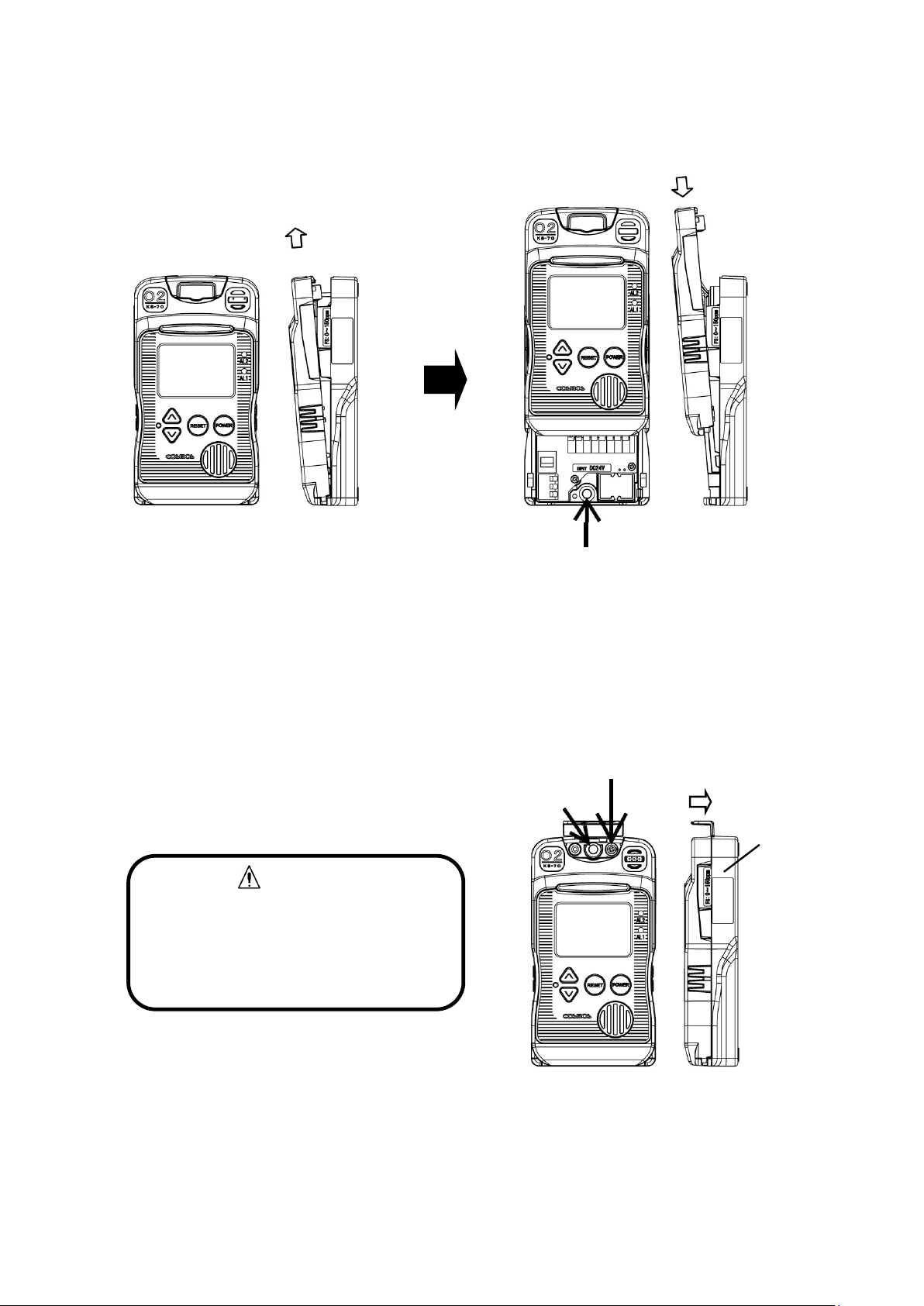

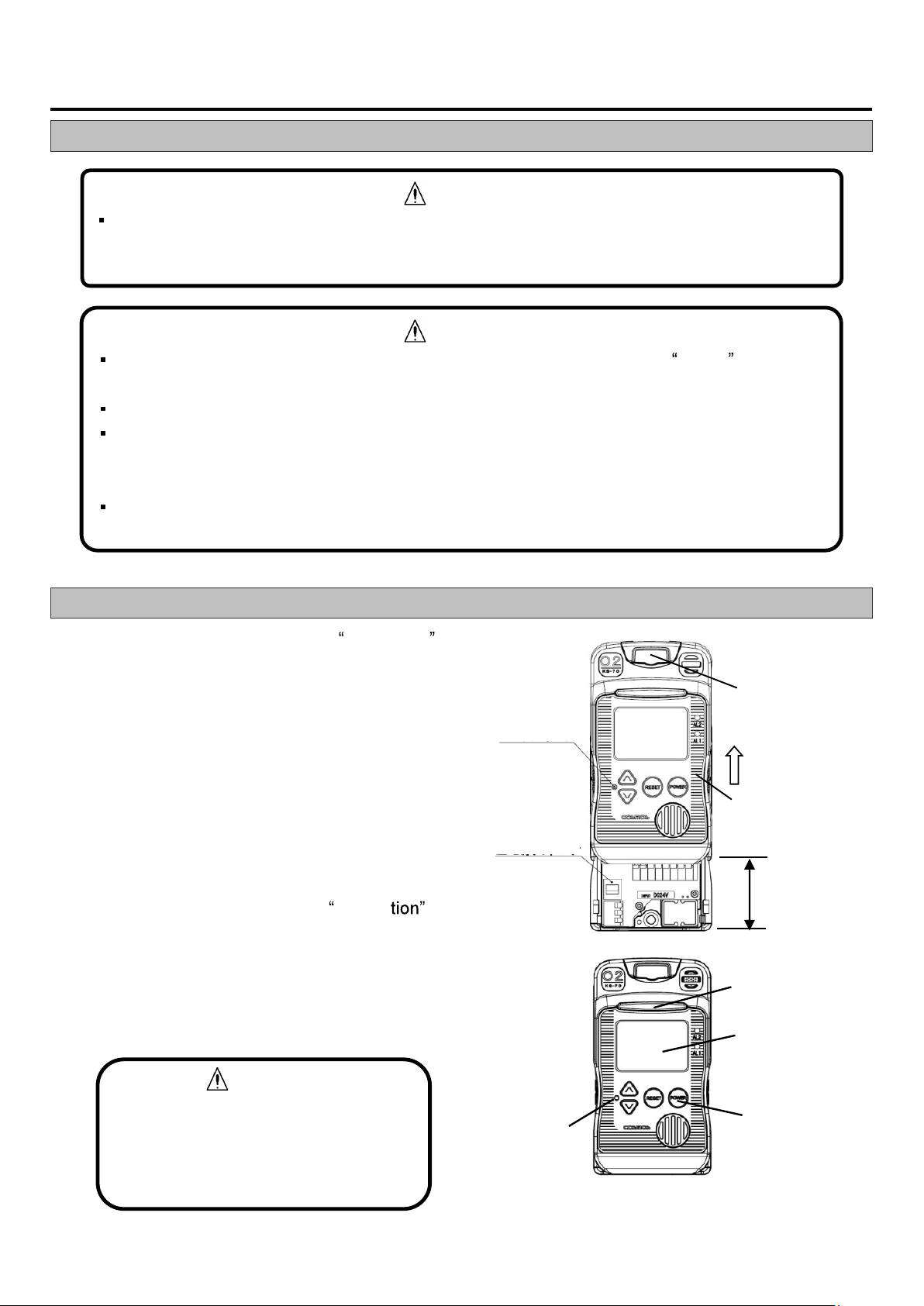

7. Operation

7-1. Precautions before Use

7-2. Operating Procedure

1) Follow Steps 1, 3, 4, and 5 of 5. Installation

to slide up and open the cover (cover is not

fully opened).

1. Open the screw cover.

3. Loosen the two fastening screws.

4. Slightly pull the cover forward.

5. Slide the cover up (cover is open).

2) Set the main power switch to the on (up)

position.

3) Follow Steps 7, 8, and 10 of 5. Installa

to close the cover and tighten the screws.

7. Slide the cover down (cover is closed).

8. While pressing down the cover toward the case,

10. secure the screw cover to the case with the

two fastening screws.

CAUTION

Secure the cover by tightening the

two fastening screws. Proper gas

detection is not possible if the cover

is not tightly closed.

Status indicator

LCD

POWER button

Maintenance

button

Screw cover

Cover

Open

Maintenance

button

Main power

switch

Before tuning on the unit, confirm that the power supply is:

24 VDC±10% when DC power is used.

100 VAC±10% and 50/60Hz±10% when AC power is used.

WARNING

Before turning on the unit, check that all wiring is correct. (Refer to 6. Wiring or delivery

specifications if provided.)

Turn on the unit in clean air.

When the sensor output is not stable, the external relay contact may possibly activate

after the warm-up. To prevent possible activation of the external relay contact after the

warm-up is completed, release the interlocks of the external devices, as needed.

During the warm-up, the analog signal is output and the external relay contacts are

disabled.

CAUTION

- 14 -

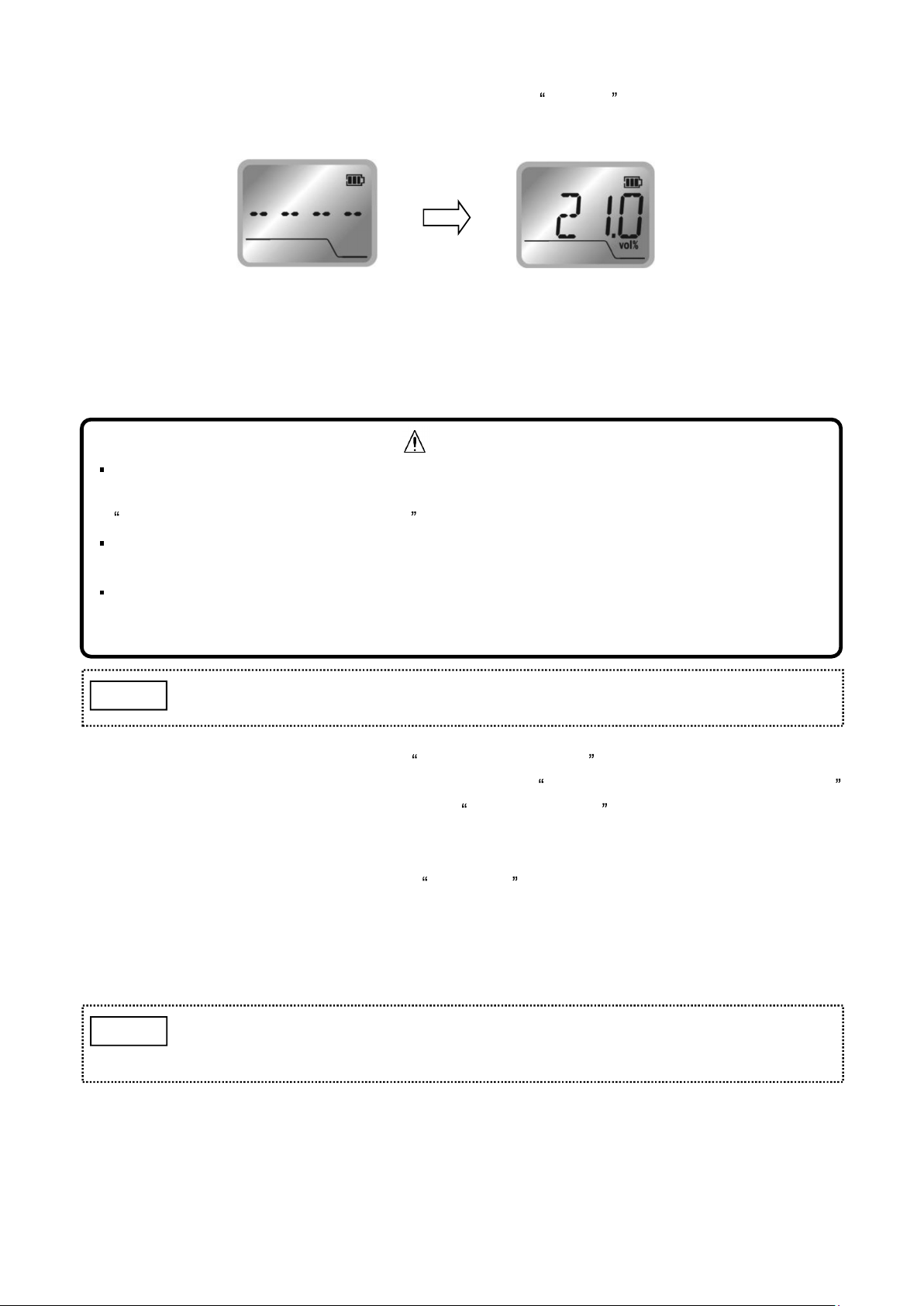

4) Press and hold the POWER button for 3 seconds to turn on the detector (two beeps). The three

green LEDs inside the status indicator start flashing and -- -- -- -- is displayed on the LCD. The

warm-up cycle lasts 30 seconds.

5) When the warm-up cycle is completed, the three green flashing LEDs inside the status indicator

become solid, the gas concentration is displayed on the LCD, and normal operation starts.

6) Perform a span adjustment (21.0 vol%).

1. Enter the User mode. (Refer to 7-4-1. User Mode Operation )

2. Switch the Maintenance mode to ON. (Refer to 7-4-2. Switching Maintenance Mode On/Off )

3. Perform a span adjustment. (Refer to 7-4-4. Span Adjustment )

4. Switch the Maintenance mode to OFF.

7) Perform an alarm test by referring to7-4-5. Alarm Test .

Confirm that an alarm activates.

8) To turn off the detector, press and hold the POWER button for 3 seconds to stop the operation,

then set the main power switch to the off (down) position.

Once the POWER button is turned off, the backup power is not available.

The backup power is activated if the main power switch is turned off, as long as

the POWER button is in the on position.

NOTE

To prevent a possible activation of alarm or external alarm relay contact, switch to the

Maintenance mode to ON before performing a span adjustment. (Refer to 7-4-2.

Switching Maintenance Mode On/Off .)

Check that there is no gas present before span adjustment. Proper gas detection is not

possible if a span adjustment is performed in a gas atmosphere.

When a span adjustment is completed, switch the Maintenance mode to OFF. External

alarm relay contacts or audio alarm are not active while the unit is in the Maintenance

mode.

CAUTION

Use a rounded pin (e.g., precision screwdriver) for pressing the maintenance

button.

NOTE

Warm-up cycle Normal operation

- 15 -

7-3. LCD Operation

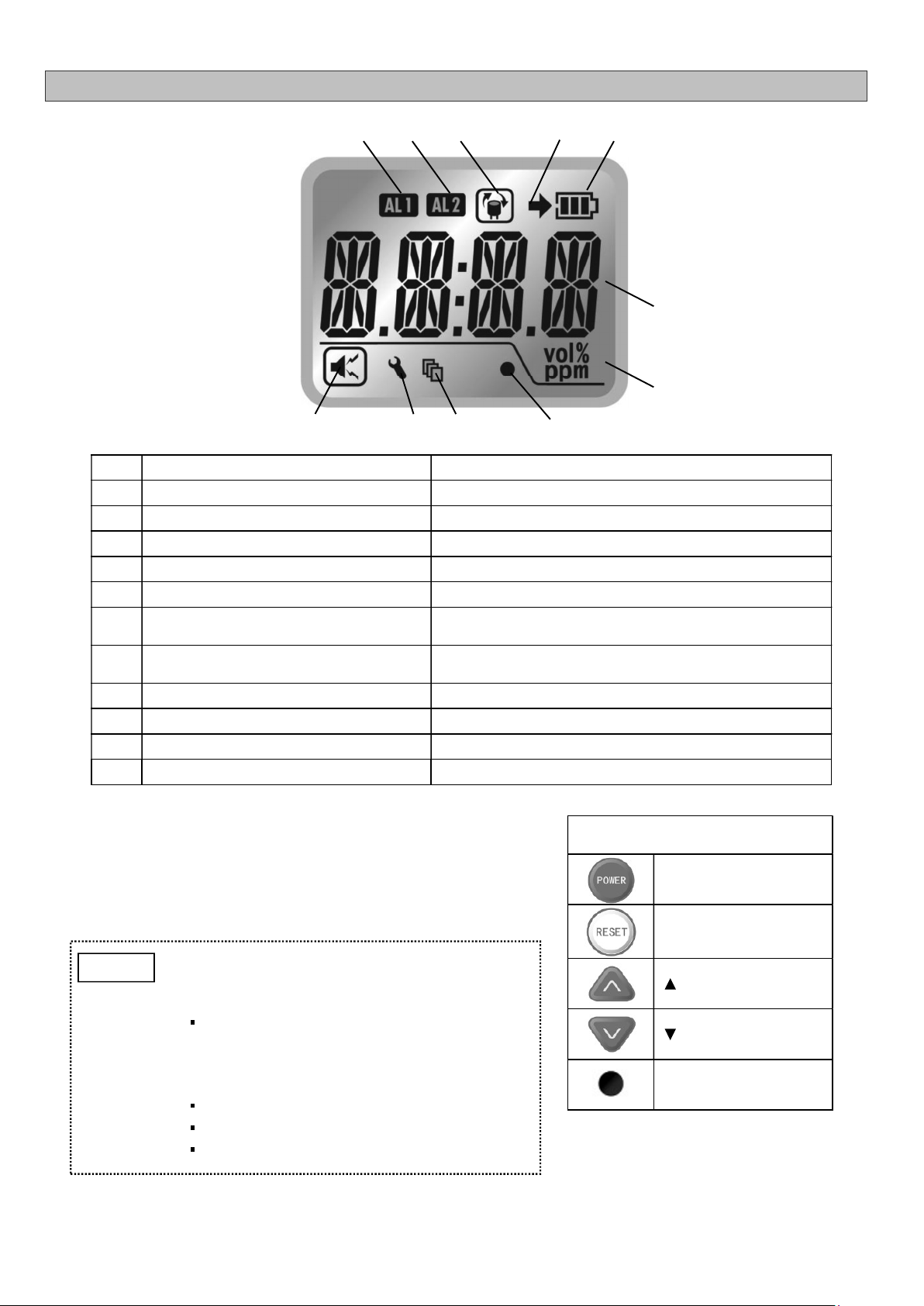

7-3-1. LCD

Item Icon/Display Description/Function

1 Audio alarm icon Always present

2 AL1 icon 1st stage gas alarm notification

3 AL2 icon 2nd stage gas alarm notification

4 Sensor replacement icon Sensor needs to be replaced

5 Backup battery icon Unit is operating on the backup battery

6 Backup battery level indicator Battery level of the backup battery used during power

outage

7 Concentration value and information Oxygen concentration value, parameter values, error

code, etc.

8 Unit of measurement A unit of gas concentration

9 Clock battery level indicator Clock battery level is low

10 Alarm history icon Alarm history is being accessed

11 Maintenance mode icon Maintenance mode is active

7-3-2. Normal Operation Status

During normal operation the green status indicator is fully lit,

the gas concentration value is displayed on the LCD, and

the AL1 and AL2 alarm LEDs are off.

Operation buttons

POWER button

RESET button

(UP )button

(DOWN) button

Maintenance button

1

2

3

4

5

6

7

8

9

10

11

When the detector operates on the backup

battery, unlike when it is driven by 24 VDC

or 100 VAC power supply,

The status indicator is not lit during

normal operation and it sequentially

flashes In the event of a 1st/2nd stage

gas alarm.

The analog output is 0 mA (no output).

The external relay contacts are disabled.

The audio volume is lower.

NOTE

- 16 -

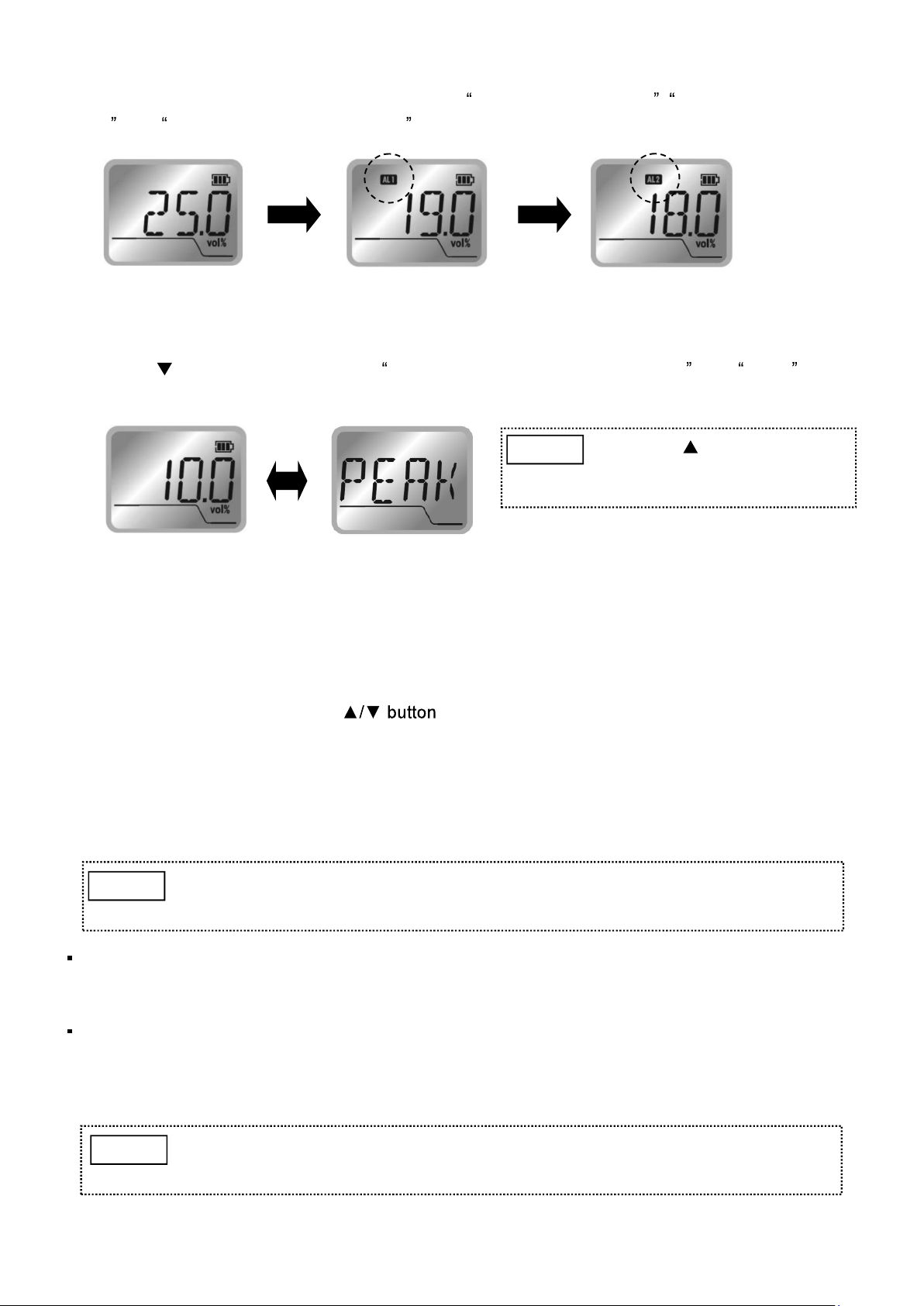

7-3-3. Full Scale and Alarm Set Values Display

Press the RESET button (one beep) to display the full scale concentration , 1st stage gas alarm set

value , and 2nd stage gas alarm set value in sequence.

7-3-4. Peak Value Display and Reset

Press the button (one beep). The lowest peak value after powering-up and PEAK will be

displayed alternately.

(Ex. lowest peak value is 10vol%)

To return to the normal gas concentration display, press the RESET button (one beep).

The display will show the full scale value and alarm set value, then return to the normal gas

concentration display.

To reset the peak value, press the at the same time (two beeps).

The peak value is reset then the display returns to the normal gas concentration display.

7-3-5. Operation during Gas Alarm

When the oxygen concentration reaches the alarm set value, the alarm LED flashes, the status

indicator sequentially-flashes and an audio alarm sounds.

There are two options to clear a gas alarm, manual-resetting and self-resetting. By default, the

detector is set to manual-resetting mode. Please specify the alarm clearance option at the time of

order, if necessary.

The alarm hysteresis range is 0.2vol%. The alarm will not be cleared until the oxygen

concentration exceeds the alarm set value by more than the hysteresis value. E.g., when the alarm

set value is 18.0vol% and an alarm is activated, the alarm will not be cleared until the

concentration reaches 18.3vol% or higher.

Full scale: 25.0 vol% 1st stage gas alarm set value: 19.0 vol%

2nd stage gas alarm set value: 18.0 vol%

Press the button to display

the highest peak value after

powering-up.

NOTE

Alarm relay contact reset: If the RESET button is pressed while the

concentration is outside the alarm set value, the alarm relay contact will return to

its normal position and the alarm LED will turn off.

NOTE

Audio alarm mute: If the RESET button is pressed during a gas alarm, the audio

alarm will be muted and the flashing alarm LED(s) will become solid. If the

RESET button is pressed and held, the alarm will not be muted.

NOTE

- 17 -

7-4. User Mode

7-4-1. User Mode Operation

To enter the User mode, press the maintenance button

while the unit is on. After one beep, 1 and its abbreviated

mode name MT will be alternately displayed.

To select the mode options, use the and buttons.

To confirm your selection, press the maintenance button. To return to the previous step, press the

RESET button.

To execute the selected mode, press and hold the maintenance button for 3 seconds.

To return to the normal operation mode, press and hold the RESET button for 5 seconds.

Mode Mode name Abbreviated mode name

1 Switching maintenance mode on/off MT

2 Zero adjustment 0.0 vol%

3 Span adjustment 21.0 vol%

4 Alarm test AL T

5 Alarm history AL H

6 Clock setting DATE

During the User mode, gas detection, alarm operation, analog output, and

contact output activation are active as during normal operation mode.

However, audio alarm mute and alarm clearance are not active and cannot be

used.

Return to normal operation mode after using the User mode.

NOTE

Use a rounded pin (e.g., precision screwdriver) for pressing the maintenance

button.

NOTE

< 1st stage alarm >

Amber AL1 alarm LED flashes and the status indicator sequentially-flashes amber.

Audio alarm beep: Fast, high and low beep tones.

ZA1 alarm relay contact is closed. (When normally open contacts are used)

< 2nd stage alarm >

Red AL2 and A1 alarm LEDs flash and the status indicator sequentially-flashes red.

Audio alarm beep pattern: Very fast high and low beep tones.

ZA2 alarm relay contact closes and ZA1 alarm remains closed. (When normally open

contacts are used)

- 18 -

7-4-2. Switching Maintenance Mode On/Off [Mode1]

1) Enter the User mode. Press the / button to

select 1 . MT and 1 will be alternately

displayed.

2) Press the maintenance button (one beep).

OFF will flash.

3) Press the button (one beep).

ON will flash.

4) Press and hold the maintenance button for 3

seconds (beep pattern: short long short short) to

confirm the selection.

The maintenance icon is displayed, and 1 and

MT will be alternately displayed, indicating that

the unit is in the Maintenance mode.

5) To exit the Maintenance mode, take Steps 1) to 4)

above to switch the mode from N to "OFF".

Confirm the maintenance icon has turned off.

During the Maintenance mode, the external relay contacts and audio alarm are disabled.

Turn off the Maintenance mode during normal operation.

WARNING

Maintenance icon

If the unit is returned to normal operation mode

while in the Maintenance mode, the

_ _ _ _ will be

alternately displayed and the maintenance icon

will remain displayed.

NOTE

Table of contents

Other New Cosmos Electric Security Sensor manuals

Popular Security Sensor manuals by other brands

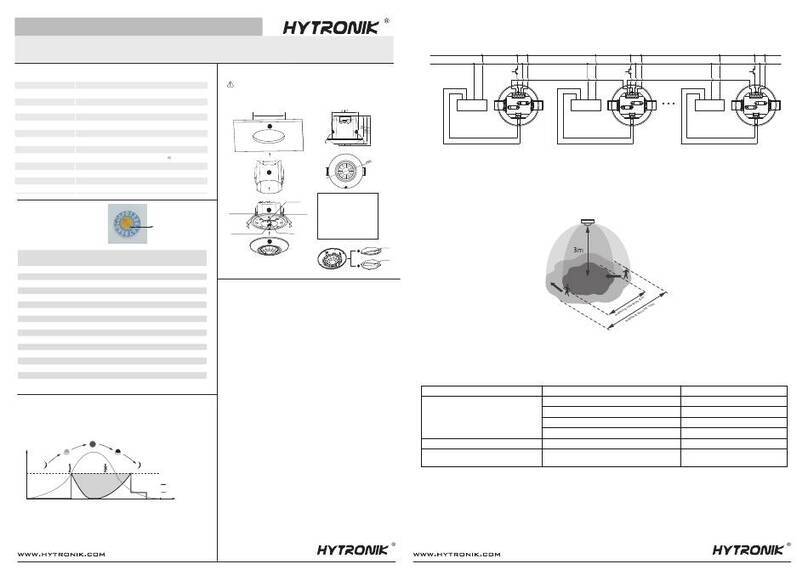

Hytronik

Hytronik HIR24 Installation and instruction manual

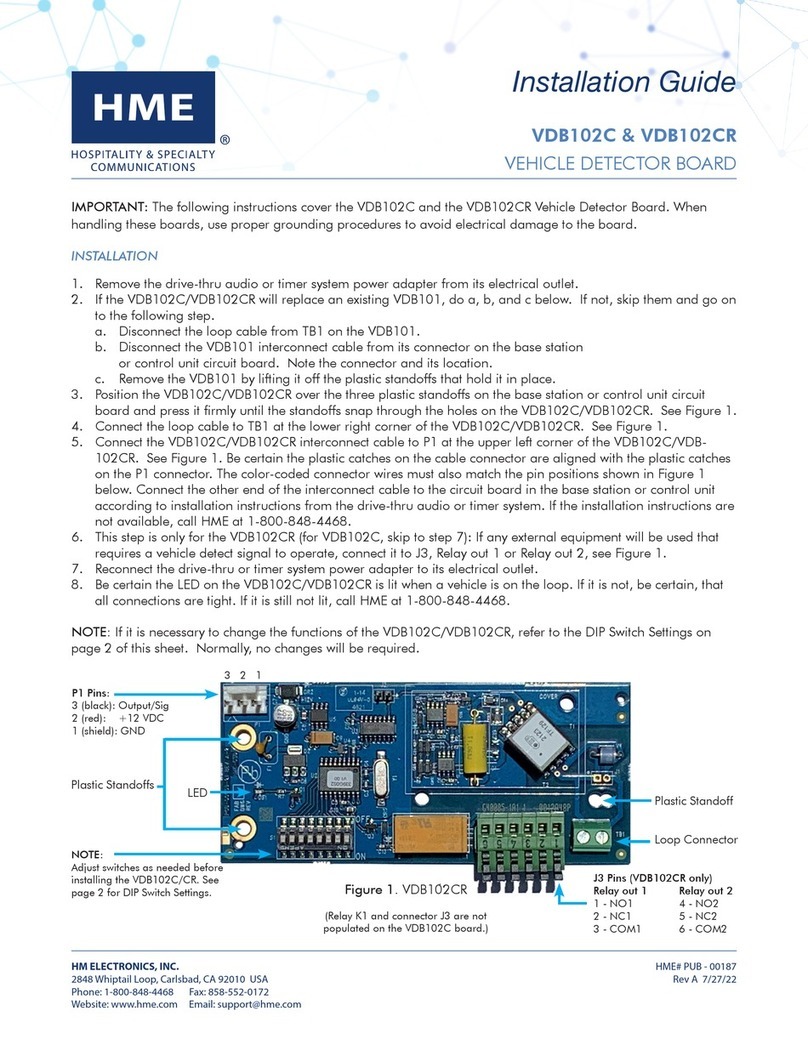

HME

HME VDB102C installation guide

SMART

SMART TL-2100CP Change Pad Indicator Installation and use instructions

brennenstuhl

brennenstuhl PIR 240 Directions for use

ESYLUX

ESYLUX RC 130i Installation and operating instructions

Master

Master Vega BT quick start guide