New H3C Technologies WX5860X User manual

H3C WX5860X Access Controller

Installation Guide

New H3C Technologies Co., Ltd.

http://www.h3c.com

Document version: 5W100-20220812

Copyright © 2022, New H3C Technologies Co., Ltd. and its licensors

All rights reserved

No part of this manual may be reproduced or transmitted in any form or by any means without prior written

consent of New H3C Technologies Co., Ltd.

Trademarks

Except for the trademarks of New H3C Technologies Co., Ltd., any trademarks that may be mentioned in this

document are the property of their respective owners.

Notice

The information in this document is subject to change without notice. All contents in this document, including

statements, information, and recommendations, are believed to be accurate, but they are presented without

warranty of any kind, express or implied. H3C shall not be liable for technical or editorial errors or omissions

contained herein.

Environmental protection

This product has been designed to comply with the environmental protection requirements. The storage, use,

and disposal of this product must meet the applicable national laws and regulations.

Preface

This installation guide describes the installation procedures for the H3C WX5860X access controller,

including preparing for installing the controller, installing and accessing the controller,

troubleshooting the controller, and maintaining the controller.

This preface includes the following topics about the documentation:

•

Audience.

•

Conventions

•

Documentation feedback

Audience

This documentation is intended for:

•

Network planners.

•

Field technical support and servicing engineers.

•

Network administrators working with the H3C WX5860X access controller.

Conventions

The following information describes the conventions used in the documentation.

Command conventions

Convention

Description

Boldface Bold text represents commands and keywords that you enter literally as shown.

Italic Italic text represents arguments that you replace with actual values.

[ ] Square brackets enclose syntax choices (keywords or arguments) that are optional.

{ x | y | ... }

Braces enclose a set of required syntax choices separated by vertical bars, from which

you select one.

[ x | y | ... ]

Square brackets enclose a set of optional syntax choices separated by vertical bars,

from which you select one or none.

{ x | y | ... } *

Asterisk marked braces enclose a set of required syntax choices separated by vertical

bars, from which you select a minimum of one.

[ x | y | ... ] *

Asterisk marked square brackets enclose optionalsyntaxchoices separated by vertical

bars, from which you select one choice, multiple choices, or none.

&<1-n> The argument or keyword and argument combination before the ampersand (&) sign

can be entered 1 to n times.

# A line that starts with a pound (#) sign is comments.

GUI conventions

Convention

Description

Boldface Window names, button names, field names, and menu items are in Boldface. For

example, the New User window opens; click OK.

>

Multi-level menus are separated by angle brackets. For example, File > Create >

Convention

Description

Folder.

Symbols

Convention

Description

WARNING!

An alert that calls attention to important information that if not understood or followed

can result in personal injury.

CAUTION:

An alert that calls attention to important information that if not understood or followed

can result in data loss, data corruption, or damage to hardware or software.

IMPORTANT:

An alert that calls attention to essential information.

NOTE:

An alert that contains additional or supplementary information.

TIP:

An alert that provides helpful information.

Network topology icons

Convention

Description

Represents a generic network device, such as a router, switch, or firewall.

Represents a routing-capable device, such as a router or Layer 3 switch.

Represents a generic switch, such as a Layer 2 or Layer 3 switch, or a router that

supports Layer 2 forwarding and other Layer 2 features.

Represents an access controller, a unified wired-WLAN module, or the access

controller engine on a unified wired-WLAN switch.

Represents an access point.

Represents omnidirectional signals.

Represents directional signals.

Examples provided in this document

Examples in this document might use devices that differ from your device in hardware model,

configuration, or software version. It is normal that the port numbers, sample output, screenshots,

and other information in the examples differ from what you have on your device.

Documentation feedback

For any comments or suggestions about product documentation, you can share with us by sending

Your comments or suggestions would be highly appreciated.

i

Contents

1 Preparing for installation·············································································1

Safety recommendations ···································································································································1

Safety symbols···········································································································································1

General safety recommendations··············································································································1

Electrical safety··········································································································································1

Laser safety················································································································································2

Examining the installation site····························································································································2

Temperature and humidity·························································································································2

Cleanliness·················································································································································2

Cooling·······················································································································································3

ESD prevention··········································································································································3

EMI·····························································································································································4

Lightning protection····································································································································5

Installation accessories······································································································································5

Installation tools ·················································································································································5

Pre-installation checklist·····································································································································6

1

1 Preparing for installation

Safety recommendations

To avoid any equipment damage or bodily injury, read the following safety recommendations before

installation. Note that the recommendations do not cover every possible hazardous condition.

Safety symbols

When reading this document, note the following symbols:

WARNING means an alert that calls attention to important information that if not understood or

followed can result in personal injury.

CAUTION means an alert that calls attention to important information that if not understood or

followed can result in data loss, data corruption, or damage to hardware or software.

General safety recommendations

•

Make sure the installation site is flat, vibration-free, and away from electromagnetic

interferences. Make sure ESD and anti-slip measures are in place.

•

Do not place the device on an unstable case or desk. The device might be severely damaged in

case of a fall.

•

Keep the chassis and installation tools away from walk areas.

•

Keep the chassis clean and dust-free.

•

Do not place the device near water or in a damp environment. Prevent water or moisture from

entering the device chassis.

•

Ensure good ventilation of the equipment room and keep the air inlet and outlet vents of the

device free of obstruction.

•

Make sure the operating voltage is in the required range.

•

Use a screwdriver to fasten screws.

•

After you move the device from a location below0°C (32°F) to the equipment room, follow these

guidelines to prevent condensation:

Wait a minimum of 30 minutes before unpacking the device.

Wait a minimum of 2 hours before powering on the device.

•

Wear an ESD wrist strap when you replace a removable power supply, removable fan tray, or

expansion module.

Electrical safety

•

Carefully examine your work area for possible hazards, such as moist floors, ungrounded

power extension cables, or missing safety grounds.

•

Locate the emergency power-off switch in the room before installation. Shut off the power

immediately if an accident occurs.

•

Unplug all the external cables (including power cords) before moving the chassis.

•

Do not work alone when you operate the device with the device powered on.

2

•

Always verify that the power has been disconnected when you perform operations that require

the device to be powered off.

Laser safety

WARNING!

Do not stare into any

open apertures of operating transceiver modules or optical fiber connectors.

The laser light emitted from these apertures might hurt your eyes.

CAUTION:

•

Before you remove the optical fiber connector from a fiber port, execute the shutdown

command in interface view to shut down the port.

•

Insert a dust cap into any open optical fiber connector and a dust plug into any open fiber port or

transceiver module port to protect them from contamination and ESD damage.

Examining the installation site

The device can only be used indoors. To ensure correct operation and a long lifespan for your device,

the installation site must meet the requirements in this section.

Temperature and humidity

Maintain the temperature and humidity in the equipment room at acceptable levels.

•

Lasting high relative humidity can cause poor insulation, electricity leakage, mechanical

property change of materials, and metal corrosion.

•

Lasting low relative humidity can cause washer contraction and ESD and bring problems

including loose captive screws and circuit failure.

•

High temperature can accelerate the aging of insulation materials and significantly lower the

reliability and lifespan of the device.

To ensure correct operation of the device, the equipment room must meet the temperature and

humidity requirements listed in Table1-1.

Table1-1 Temperature/humidity requirements in the equipment room

Temperature

Humidity

0°C to 45°C (32°F to 113°F) 5% RH to 95% RH, noncondensing

Cleanliness

Dust buildup on the chassis can result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor relative humidity is low. In the worst case,

electrostatic adsorption can cause communication failure. To ensure correct operation, the

equipment room must meet the dust concentration requirements listed in Table1-2.

Table1-2 Dust concentration limit in the equipment room

Substance

Particle diameter

Concentration limit

Dust particles ≥ 5 µm ≤ 3 × 104particles/m3

Dust (suspension) ≤75 µm ≤0.2 mg/m3

3

Substance

Particle diameter

Concentration limit

Dust (sedimentation) 75 µm to 150 µm ≤1.5 mg/m3

Sand ≥ 150 µm ≤30 mg/m3

To eliminate corrosion and premature aging of components, the equipment room must also meet

limits on salts, acids, and sulfides, as shown in Table1-3.

Table1-3 Harmful gas limits in an equipment room

Gas

Max. (mg/m

3

)

SO20.2

H2S 0.006

NH30.05

Cl20.01

NO20.04

Cooling

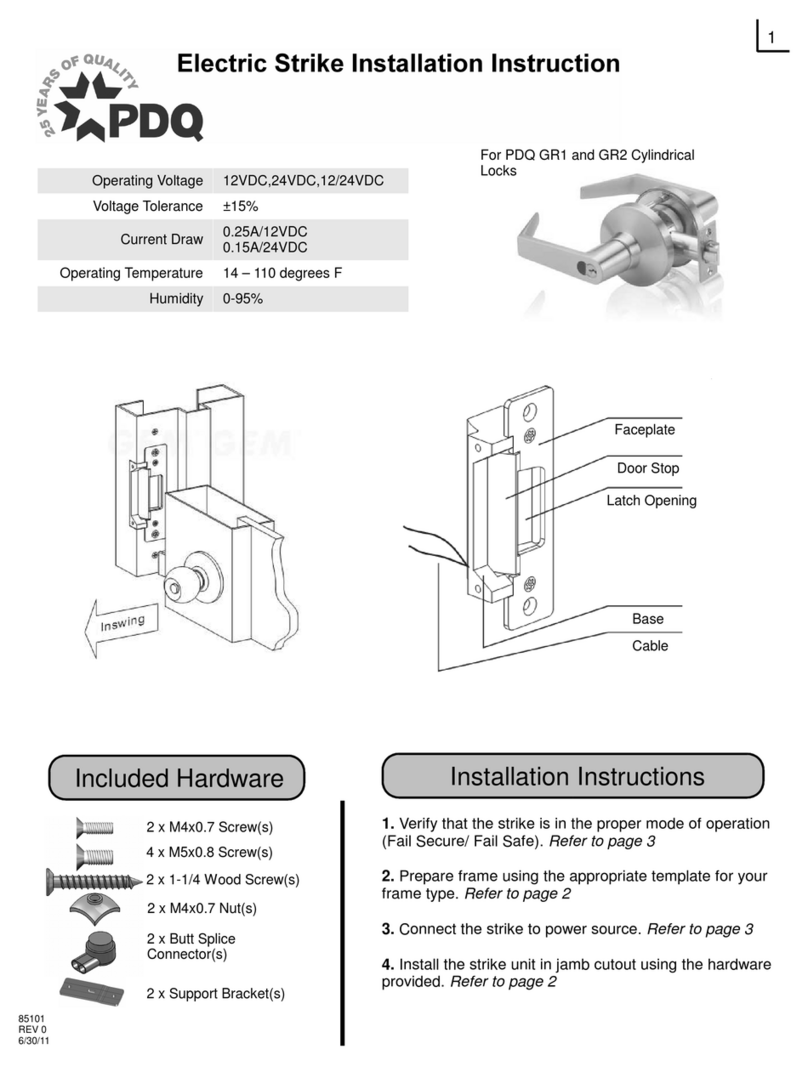

The device uses front-to-rear airflow to draw in air from the port side and exhaust air from the power

supply side. For adequate heat dissipation of the device, follow these guidelines:

•

Plan the installation site for the device based on the airflow direction

•

Reserve a minimum clearance of 100 mm (3.94 in) around the air vents.

•

Make sure the rack or workbench has a good ventilation system.

Figure1-1 Heat dissipation

ESD prevention

To prevent electrostatic discharge (ESD), follow these guidelines:

•

Ground the device and rack or workbench reliably.

•

Take dust-proof measures for the equipment room. For more information, see "Cleanliness."

•

Maintain the humidity and temperature at acceptable levels. For more information, see

"Temperature and humidity."

4

•

Before working with the device, wear an ESD wrist strap or gloves and ESD garment, and

remove conductive objects such as jewelry or watch. Make sure the wrist strap makes good

skin contact and is reliably grounded.

•

Always remember to wear an ESD wrist strap when working with a transceiver module.

No ESD wrist strap is provided with the device. Prepare one yourself.

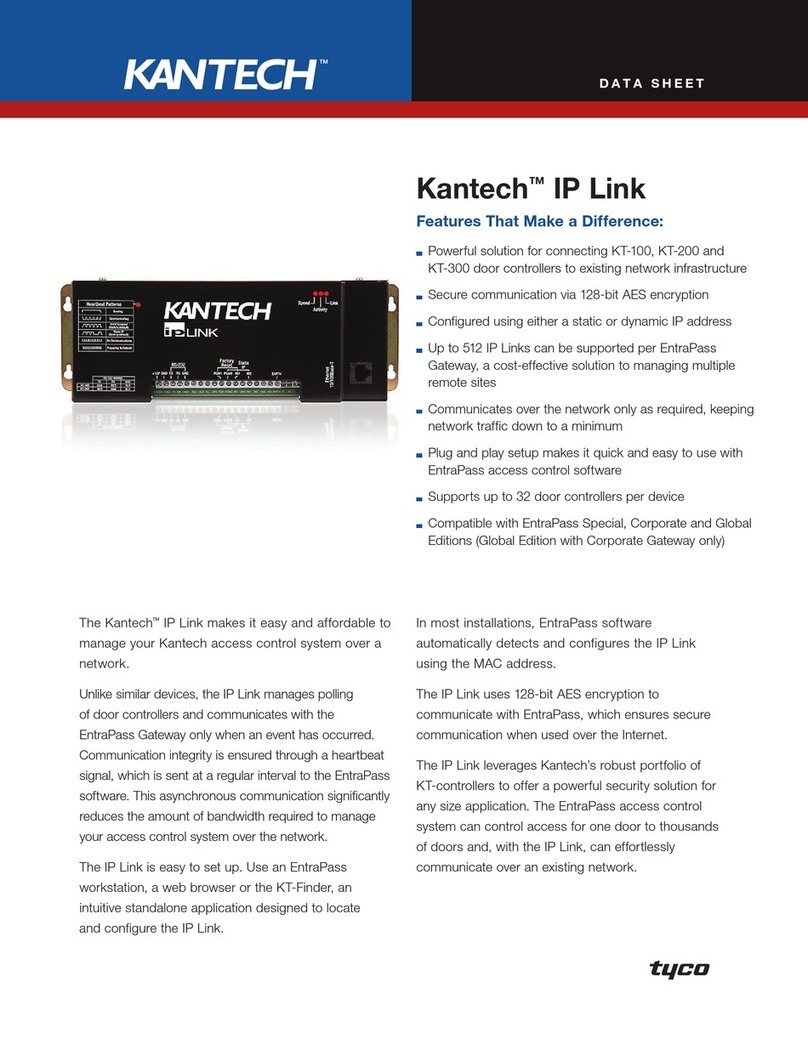

To attach an ESD wrist strap:

1. Wear the wrist strap on your wrist.

2. Lock the wrist strap tight around your wrist to maintain good contact with the skin.

3. Secure the wrist strap lock and the alligator clip lock together.

4. Attach the alligator clip to the rack.

5. Make sure the rack is reliably grounded.

Figure1-2 Attaching an ESD wrist strap

(1) Alligator clip

(2) ESD wrist strap

(3) Lock

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the device and application

system, adversely affect the device in the following ways:

•

A conduction pattern of capacitance coupling.

•

Inductance coupling.

•

Electromagnetic wave radiation.

•

Common impedance (including the grounding system) coupling.

To prevent EMI, perform the following tasks:

•

If AC power is used, use a single-phase three-wire power receptacle with protection earth (PE)

to filter interference from the power grid.

5

•

Keep the device far away from radio transmitting stations, radar stations, and high-frequency

devices.

•

Use electromagnetic shielding, for example, shielded interface cables, when necessary.

•

To prevent signal ports from getting damaged by overvoltage or overcurrent caused by lightning

strikes, route interface cables only indoors. If you must route interface cables outdoors, install

network port lightning protectors.

Lightning protection

To better protect the device from lightning, follow these guidelines:

•

Make sure the grounding cable of the chassis is reliably grounded.

•

Make sure the grounding terminal of the AC power receptacle is reliably grounded.

•

Install a lightning protector at the input end of the power supply to enhance the lightning

protection capability of the power supply.

Installation accessories

Figure1-3 Installation accessories for the device

Installation tools

No installation tools are provided with the device. Prepare installation tools as required.

6

Figure1-4 Installation tools

Pre-installation checklist

Table1-4 Pre-installation checklist

Item

Requirements

Result

Installation

site

Ventilation

•There is a minimum clearance of 100 mm (3.94 in))

around the inlet and outlet vents for heat dissipation

of the device chassis.

•A good ventilation system is available at the

installation site.

Temperature •0°C to 45°C (32°F to 113°F)

Humidity •5% RH to 95% RH, noncondensing

Cleanliness •Dust concentration ≤ 3 × 104particles/m3

•No dust on desk within three days

ESD prevention

•The equipment and rack or workbench are reliably

grounded.

•The equipment room is dust-proof.

•The humidity and temperature are at acceptable

levels.

•An ESD wrist strap is available.

EMI prevention

•Effective measures are taken for filtering interference

from the power grid.

•The protection ground of the device is away from the

grounding facility of power equipment or lightning

protection grounding facility.

•The device is far away from radio transmitting

stations, radar stations, and high-frequency devices.

•Electromagnetic shielding, for example, shielded

interface cables, is used as required.

Lightning

protection

•The device is reliably grounded.

•The AC power source is reliably grounded.

•(Optional.) Network port lightning protectors are

available.

•(Optional.) A surge protected power strip is available.

Electricity safety

•A UPS is available.

•The power-off switch in the equipment room is

identified and accessible so that the power can be

7

Item

Requirements

Result

immediately shut off when an accident occurs.

Rack-mounting

requirements

•The rack has a good ventilation system.

•The rack is sturdy enough to support the weight of the

device and installation accessories.

•The size of the rack is appropriate for the device.

•The front and rearof the rack are a minimum of 0.8 m

(31.50 in) away from walls or other devices.

Safety

precautions

•The device is far away from any moist area and heat source.

•You have located the emergency power switch in the equipment room.

Accessories Accessories provided with the device are available.

Reference •Documents shipped with the device are available.

•Online documents are available.

i

Contents

1 Installing the device····················································································1

Confirming installation preparations···················································································································1

Installation workflow···········································································································································2

Mounting the device on a workbench ················································································································2

Installing the device in a 19-inch rack················································································································3

Rack-mounting procedures at a glance·····································································································3

Chassis dimensions and rack requirements ······························································································4

Mounting brackets, chassis rails, and grounding cable installation positions ············································5

Attaching the mounting brackets and chassis rails to the chassis·····························································6

Connecting the grounding cable to the chassis ·························································································7

Attaching the slide rails to the rack ············································································································8

Mounting the device in the rack ·················································································································9

Grounding the device·······································································································································11

Grounding the device through a grounding strip······················································································11

Grounding the device through the rack····································································································12

Grounding the device with a grounding conductor buried in the earth·····················································13

Installing/removing fan trays ····························································································································14

Installing a fan tray···································································································································14

Removing a fan tray·································································································································15

Installing/removing power supplies··················································································································16

Installing a power supply··························································································································16

Removing a power supply························································································································17

Connecting the power cords ····························································································································18

Connecting an AC power cord·················································································································18

Connecting a DC power cord···················································································································19

Installing and removing expansion modules····································································································20

Installing an expansion module················································································································20

Removing an expansion module··············································································································21

(Optional) Installing network port lightning protectors······················································································22

(Optional) Installing a surge protected power strip···························································································23

Verifying the installation···································································································································23

Accessing the device for the first time··············································································································24

Connecting the device to a configuration terminal···················································································24

Setting terminal parameters·····················································································································24

Powering on the device····························································································································24

1

1 Installing the device

WARNING!

Keep the tamper

-

proof seal on a mounting screw on the chassis cover intact, and if you want to open

the chassis, contact

Technical Support for permission. Otherwise, H3C will not be liable for any

consequence caused thereby.

Confirming installation preparations

Before you install the device, verify that you have read "Preparing for installation" carefully and the

installation site meets all the requirements.

2

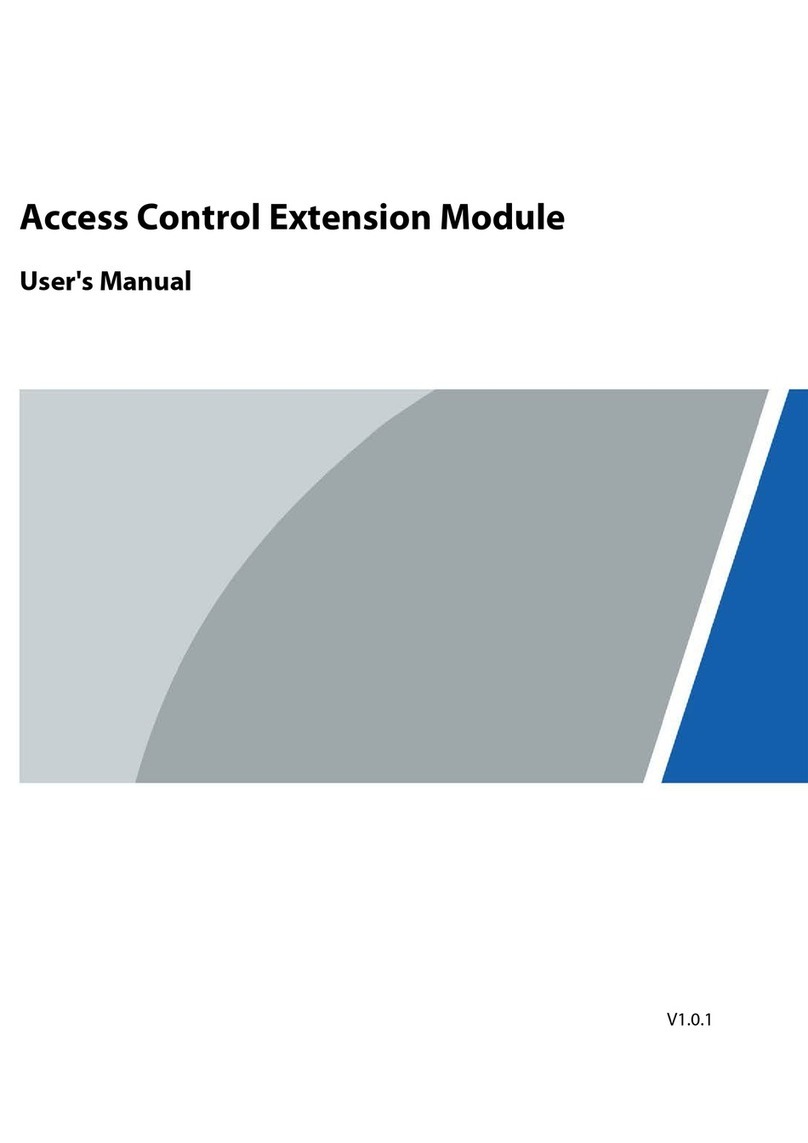

Installation workflow

Figure1-1 Installation workflow

Mounting the device on a workbench

CAUTION:

Do not place heavy objects on the device.

If a standard 19-inch rack is not available, you can mount the device on a clean, flat workbench.

To mount the device on a workbench:

1. Place the device upside down. Clean the recessed areas on the chassis bottom.

2. Attach the six rubber feet to the recessed areas on the chassis bottom.

3. Place the device on the workbench with the upside up. Make sure the six rubber feet stand

firmly on the workbench.

Determine installation

position

Installthedevice ina

19-inch rack

Mountthe device ona

workbench

Ground the device

Install and remove fan

trays

Start

Connect power cords

Install and remove power

supplies

(Optional) Installing a

surgeprotected power

strip

No

Power on the device

Operatingcorrectly?

Yes

End

Power off the device

Troubleshoot

Install and remove

expansion modules

(Optional) Installing

network port lightning

protectors

3

Figure1-2 Mounting the device on a workbench

Installing the device in a 19-inch rack

IMPORTANT:

Keep

a minimum distance of 1 U (44.45 mm, or 1.75 in) between devices in a rack for good heat

dissipation.

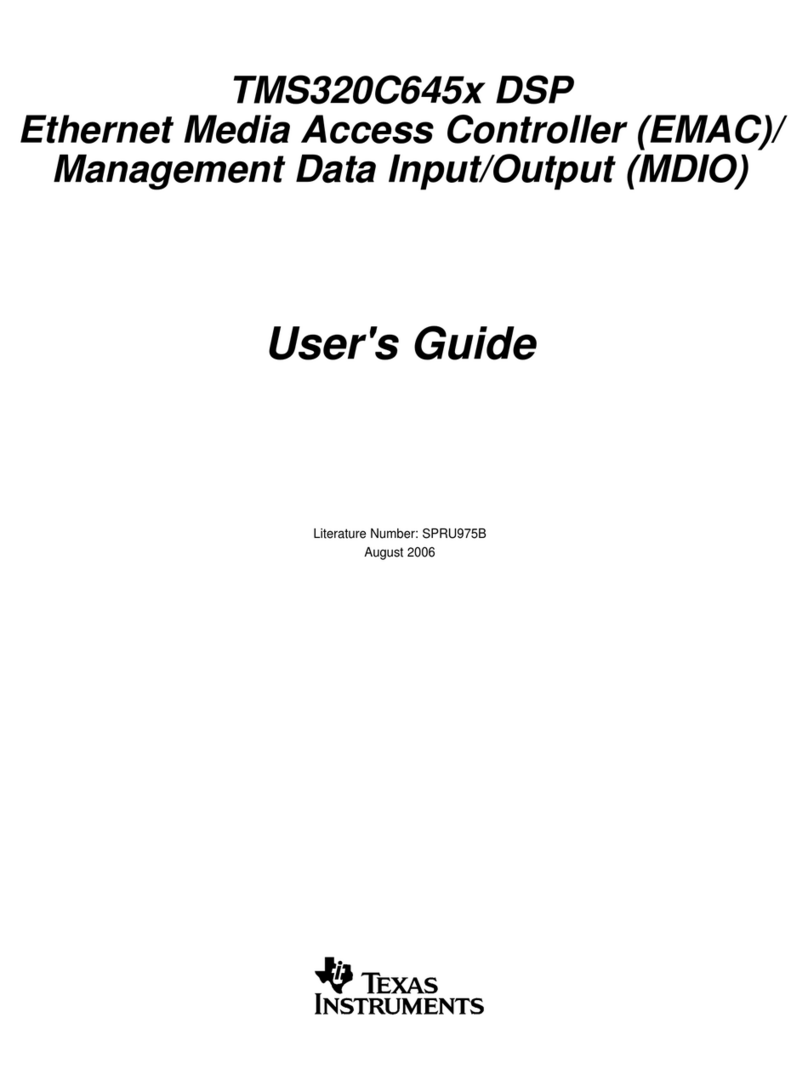

Rack-mounting procedures at a glance

Figure1-3 Rack-mounting procedure

NOTE:

If a rack shelf is available, you can put the

device on the rack shelf and slide the device to a

position

so that the mounting brackets make close contact with the front rack posts. Then use screws to

secure the mounting brackets to the rack.

Select an installation

position for the mounting

brackets (near the port

side or power supply side)

Attach the

mounting

brackets to the

device

Attach the chassis rails

to thedevice

Connectthegrounding

cable to a grounding

point

Attach the slide

rails to the rack

Mount the

device in the

rack

4

Chassis dimensions and rack requirements

Figure1-4 Chassis dimensions (mounting brackets installed at the port side)

(1) Power supply handle (2) Mounting bracket

Figure1-5 Chassis dimensions (mounting brackets installed at the power supply side)

(1) Power supply handle

(2) Mounting bracket

Table1-1 Chassis dimensions and installation requirements for the rack

Installation

method Chassis dimensions

Requirements

for the

distance

between the

front and rear

rack posts

Rack requirements

Mounting brackets

installed at the port

side

•Height—88.1 mm

(3.47 in)/2 RU

•Width—440 mm

(17.32 in)

•Depth—776 mm

(30.55 in)

660 mm (25.98

in) for the

chassis

26 mm (1.02 in)

for the power

supply/fan tray

handle

90 mm (3.54 in)

for the mounting

bracket

518 to 923 mm

(20.39 to 36.34

in)

To close the rack door easily after

cabling the device, make sure the

rack meets the following

requirements for depth:

•Aminimum of 1000 mm (39.37

in) in depth (recommended)

•A minimum of 130 mm (5.12

in) between the front rack post

and the front door.

•A minimum of 750 mm (29.53

in) between the front rack post

and the rear door.

5

Installation

method Chassis dimensions

Requirements

for the

distance

between the

front and rear

rack posts

Rack requirements

Mounting brackets

installed at the power

supply side

•Height—88.1 mm

(3.47 in)/2 RU

•Width—440 mm

(17.32 in)

•Depth—750 mm

(29.53 in)

660 mm (25.98

in) for the

chassis

90 mm (3.54 in)

for the mounting

bracket

518 to 858 mm

(20.39 to 33.78

in)

Mounting brackets, chassis rails, and grounding cable

installation positions

The device has one mounting position near the network ports and one mounting position near the

power supplies for mounting brackets.

The device provides a primary grounding point and two auxiliary grounding points. The primary

grounding point has a grounding sign.

Figure1-6 Mounting brackets and grounding cable installation positions on the device

(1) Auxiliary grounding point 2

(2) Power supply-side installation position for the mounting bracket

(3) Primary grounding point

(4) Port-side installation position for the mounting bracket

(5) Auxiliary grounding point 1

6

Attaching the mounting brackets and chassis rails to the

chassis

1. Place the wide flange of the mounting bracket against the chassis side panel. Align the

mounting bracket installation holes with the screw holes in the chassis. Use the provided M4 ×

8 screws to attach the mounting bracket to the chassis.

As a best practice, use a torque of 12 kgf-cm (1.18 Nm) to fasten M4 screws.

To install the mounting brackets at the port-side mounting position, use the four front

mounting holes in the mounting brackets. See Figure1-7.

To install the mounting brackets at the power supply-side mounting position, use the four

rear mounting holes in the mounting brackets. See Figure1-8.

2. Determine the installation position of the chassis rails based on the position of mounting

brackets and the distance between the front and rear rack posts.

Table1-2 Chassis rail installation position

Installation

method Mounting bracket

position Distance between the front

and rear rack posts

Chassis rail

installation

position

Port-side mounting position, as shown in

Figure1-7.

675 to 923 mm (26.58 to 36.34 in) Position a

611 to 858 mm (24.06 to 33.78 in) Position b

546 to 793 mm (21.50 to 31.22 in) Position c

518 to 728 mm (20.39 to 28.66 in) Position d

Power supply-side mounting position, as

shown in Figure1-8.

518 to 728 mm (20.39 to 28.66 in) Position e

546 to 793 mm (21.50 to 31.22 in) Position f

611 to 858 mm (24.06 to 33.78 in) Position g

3. Place the chassis rail against the chassis side panel. Align the chassis rail installation holes with

the screw holes. Use the provided M4 × 6 screws to attach the chassis rail to the chassis. See

Figure1-7 and Figure1-8.

Figure1-7 Attaching the mounting brackets and chassis rails to the device (port-side

mounting position for the mounting brackets)

7

Figure1-8 Attaching the mounting brackets and chassis rails to the device (power

supply-side mounting position for the mounting brackets)

NOTE:

Use the same procedure to

attach the mounting brackets and chassis rails to the two sides of the

chassis.

Connecting the grounding cable to the chassis

CAUTION:

If you use

a grounding point to ground the device, you must connect the grounding cable to the

grounding point before you mount the device in the rack.

The device provides a primary grounding point and two auxiliary grounding points. The primary

grounding point and auxiliary grounding point 1 are at the right panel and auxiliary grounding point 2

is at the front panel. The primary grounding point has a grounding sign and the auxiliary grounding

points do not. If you use a grounding cable that has a dual-hole lug, connect it to the primary

grounding point or auxiliary grounding point 1. If you use a grounding cable that has a single-hole lug,

connect it to auxiliary grounding point 2. Choose the grounding point according to the mounting

bracket installation positions.

The grounding cable connection procedure is the same for the primary and auxiliary grounding

points. The following procedure connects the grounding cable to the primary grounding point.

To connect the grounding cable to the primary grounding point:

1. Choose a grounding point as required.

When you install the mounting brackets at the port-side mounting position, choose the auxiliary

grounding points. When you install the mounting brackets at the power supply-side mounting

position, choose the primary grounding point.

2. Unpack the grounding cable and grounding screws.

3. Use the two grounding screws to attach the two-hole grounding lug of the grounding cable to

the grounding holes at the grounding point. Use a screwdriver to fasten the screws. See

Figure1-9.

As a best practice, use a torque of 20 kgf-cm (1.96 Nm) to fasten the grounding screws.

Table of contents