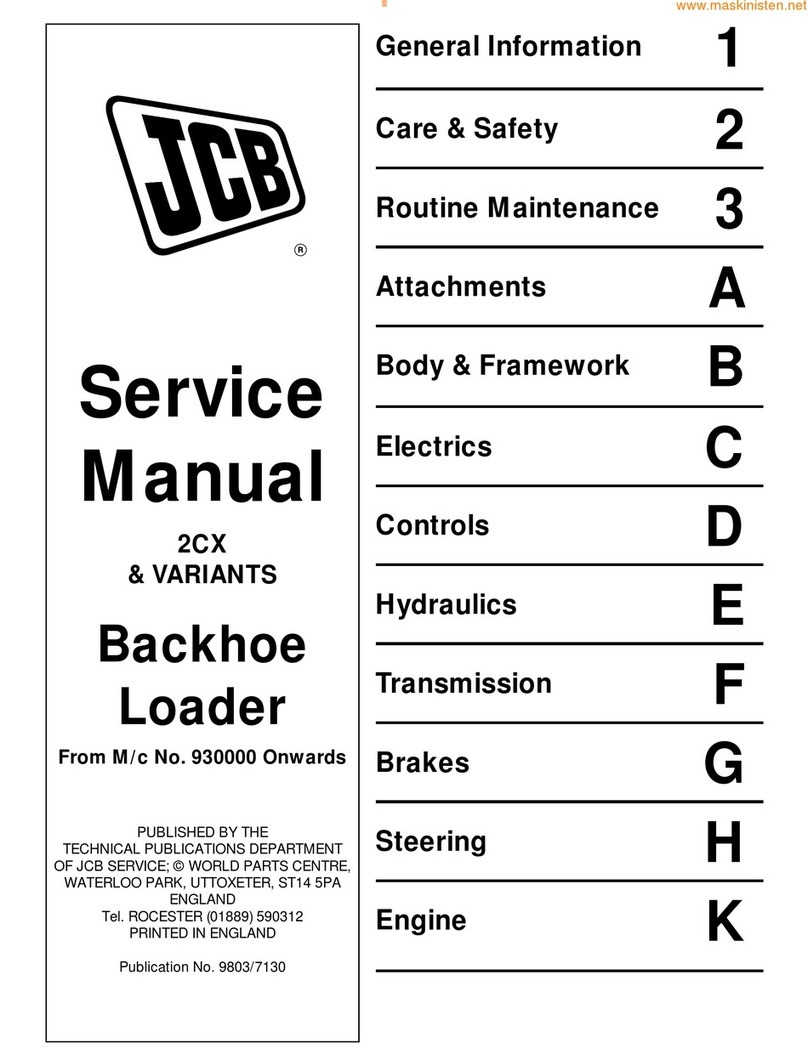

4 CONTENTS

CHAPTER 3 - Hydraulic Circuits and Components for REXROTH

Description Page

General Specifications

......................................................................

1

Description and Operation

...................................................................

5

Hydraulic Circuits

...........................................................................

10

CHAPTER 4 - Fault Finding, Pressure and Flow Testing for REXROTH Only

Description Page

Specifications

..............................................................................

1

Preliminary Checks

.........................................................................

2

Fault Finding Charts

........................................................................

3

Pressure Testing

...........................................................................

7

Steering Stndby

............................................................................

7

Steering Circuit Relief Valve

.................................................................

7

System Pressure Relief Valve

................................................................

8

Loader Bucket Relief Valve (Piston End)

.......................................................

9

Extendible Dipper Relief Valve (Piston End)

....................................................

8

Swing System Relief Valve

..................................................................

9

Dipperstick Bucket and Boom Relief Valves

....................................................

9

Flow Testing (Pump Performance Test)

........................................................

10

CHAPTER 5 - Control Valves for REXROTH with Mechanical or Hydraulic Control

Description Page

General Specifications

......................................................................

1

Loader Control Valve Overhaul

...............................................................

2

Backhoe Control Valve Overhaul

.............................................................

3

Control Valve Disassembly

..................................................................

4

Control Valve Section Disassembly

...........................................................

8

CHAPTER 6 - Swing System and Hydraulic Cylinders

Description Page

General Specifications

......................................................................

1

Swing System Description and Operation

......................................................

3

Hydraulic Cylinders Description and Operation

.................................................

6

Backhoe and Loader Cylinders -Removal and Installation

......................................

9

Backhoe and Loader Cylinder Overhaul

.......................................................

18

Swing Cylinder Removal and Overhaul

........................................................

22

03/2004

Find manuals at https://best-manuals.com