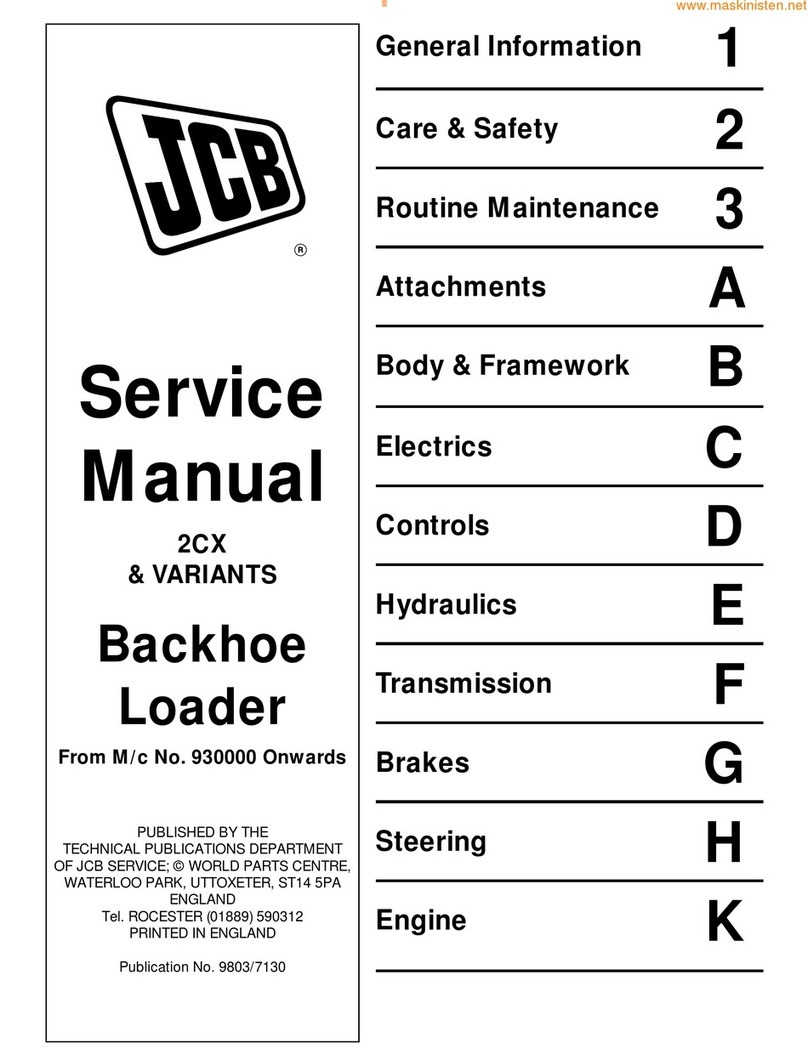

INTRODUCTION

Manualcontent

ThismanualisdividedintoSections.EachSectionisthendividedintoChapters.Contentspagesareincludedatthe

beginningofthemanual,theninsideeverySectionandinsideeveryChapter.AnalphabeticalIndexisincludedat

theendofeachChapter.Pagenumberreferencesareincludedforeverypieceoftechnicalinformationlistedinthe

ChapterContentsorChapterIndex.

EachChapterisdividedintofourInformationtypes:

•T echnicalData(specications)forallthemechanical,electricalorhydraulicdevices,components,assembliesor

sub-assemblies.

•FunctionalData(howitworks)forallthemechanical,electricalorhydraulicdevices,components,assembliesor

sub-assemblies.

•DiagnosticData(faultcodes,electricalandhydraulictroubleshooting)forallthemechanical,electricalorhydraulic

devices,components,assembliesorsub-assemblies.

•ServiceData(removedisassemble,assemble,install)forallthemechanical,electricalorhydraulicdevices,com-

ponents,assembliesorsub-assemblies.

Sections

Sectionsaregroupedaccordingtothemainfunctionsorasystemsonthemachine.EachSectionisidentiedbya

number(00,35,55,etc.).TheSectionsincludedinthemanualwilldependonthetypeandfunctionofthemachinethat

themanualiswrittenfor.EachSectionhasaContentspagelistedinalphabetic/numericorder.Thistableillustrates

whichSectionscouldbeincludedinamanualforaparticularproduct.

PRODUCT

Tractors

Vehicleswithworkingarms:backhoes,excavators,

skidsteers,….

Combines,forageharvesters,balers,….

Seeding,planting,oating,spraying

equipment,….

SECTIONMountedequipmentandtools,….

00-MaintenanceXXXXX

05-MachinecompletionandequipmentXXXXX

10-EngineXXXX

14-MaingearboxanddriveXXXX

18-ClutchXXX

21-TransmissionXXXX

23-Fourwheeldrive(4WD)systemXXXX

25-FrontaxlesystemXXXX

27-RearaxlesystemXXXX

29-HydrostaticdriveXXXX

31-PowerTake-Off(PTO)XX

33-BrakesandcontrolsXXXX

35-HydraulicsystemsXXXX

36-PneumaticsystemXXXX

37-Hitches,drawbarsandimplementcouplingsXXX

39-FramesandballastingXXXXX

41-SteeringXXXX

44-WheelsXXXX

46-Steeringclutches

48-TracksandtracksuspensionXXX

50-CabclimatecontrolXXXX

55-ElectricalsystemsXXXXX

56-Grapeharvestershaking

58-Attachments/headersX

60-ProductfeedingX

4774304819/02/2015

5

Find manuals at https://best-manuals.com