SECTION 00 - SAFETY RULES 5

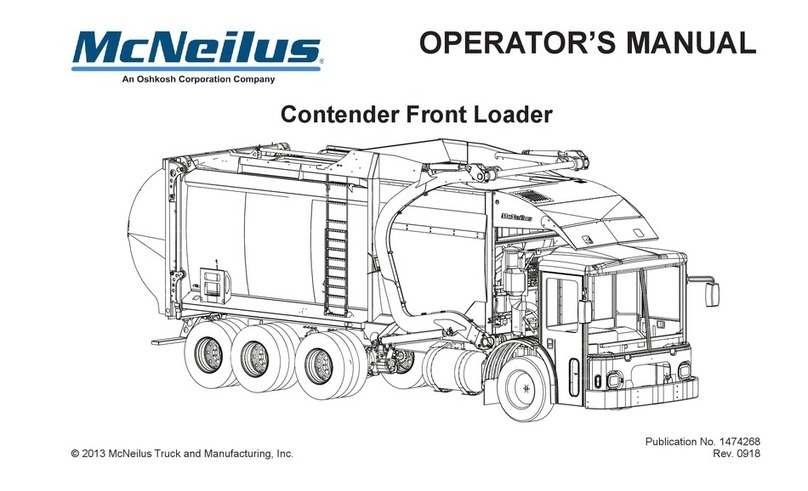

The current Operator’s Manual is the user’s guide

for correct run-in, use and maintenance of the

machine.

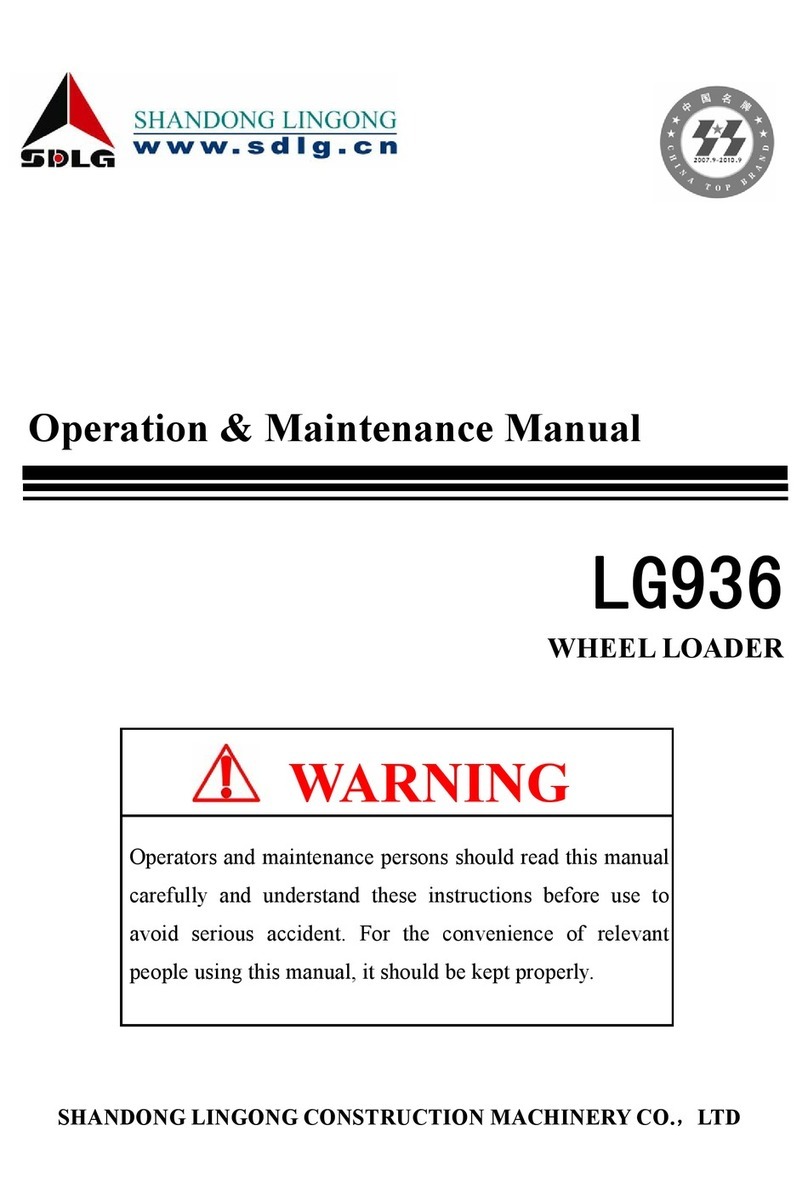

Carefully read this Operator’s Manual and store it in

the cab for quick location and reference.

Instructions concerning safety, operation and main-

tenance have been developed to permit safe serv-

ice and operation of this machine.

In the event of queries or suggestions relevant to

your machine do not hesitate to address to your

Dealer. Dealers have qualified and trained person-

nel at disposal as well as Original Spares, means

and equipment suitable to carry out all necessary

maintenance.

Do not use this machine for any applications or pur-

poses other than those described in this manual. If

you use this machine for duties involving the use of

attachments, accessories, or special tools, consult

your Dealer to make sure that the adaptations or

modifications carried out are in conformity with the

machine’s technical specifications and with current

regulations on safety.

Any modifications or adaptations which are not

approved by the manufacturer may invalidate the

machine’s original conformity with safety require-

ments.

IMPORTANT: the engine and fuel system on your

machine are designed and built to government

emissions standards. Tampering by dealers, cus-

tomers, operators and users is strictly prohibited by

law. Failure to comply with this prohibition could

result in government fines, rework charges, invalid

warranty, legal action and possible confiscation of

the machine until rework to original condition is

completed. Engine service and/or repairs must be

carried out by a certified technician only.

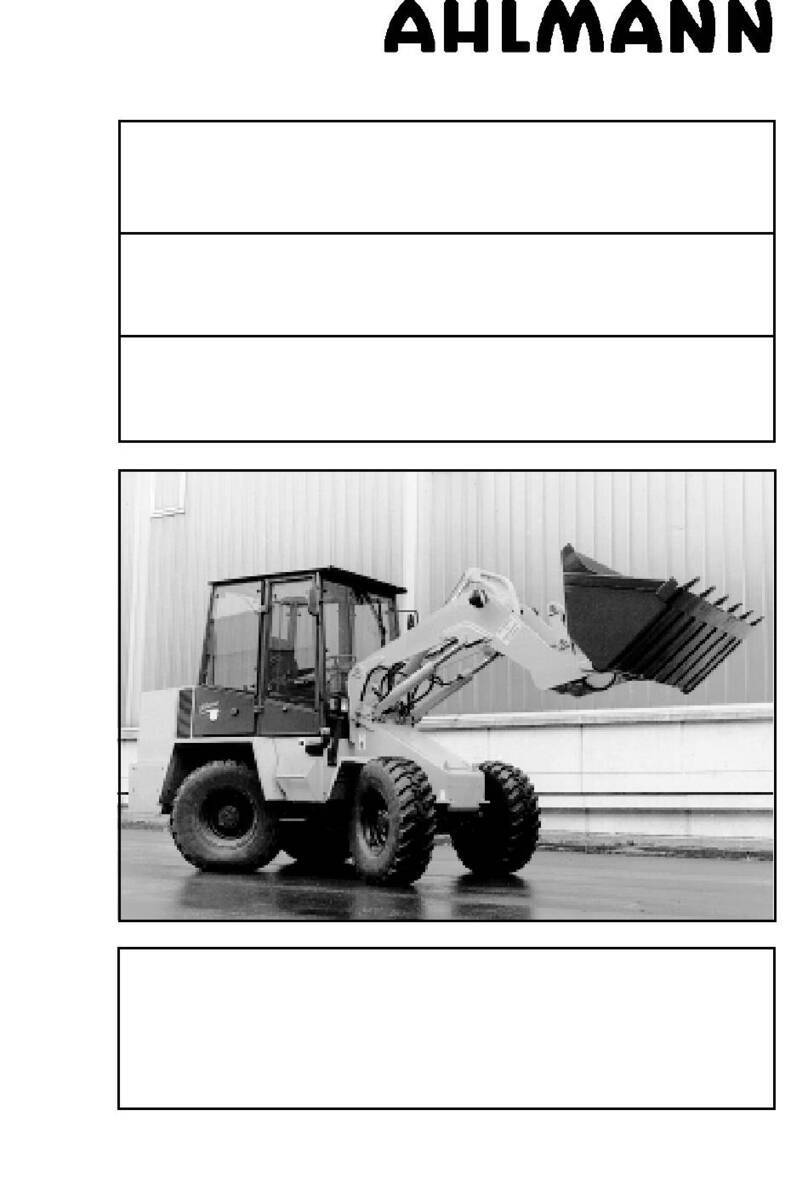

NOTA: each machine is supplied complete with a

copy of this Manual. Descriptions and illustrations

provided herein are not binding. The Manufacturer,

provided that the basic characteristics of machine

types described and shown in this Manual remain

the same, reserves the right to change compo-

nents, parts and accessories supplied without any

commitment to timely update this publication; and

this any time it deems it convenient for improve-

ment purposes or due to commercial or manufac-

turing requirements. For exact information, please

consult your Dealer or contact the Manufacturer’s

Branch Offices, who remain at your disposal for fur-

ther help.

SPARE PARTS

The “non-genuine” spare parts have not been

checked and authorized by the Manufacturer. The

assembly and/or use of such products may have

negative effects on the machine design features

and could impair its operation safety. The Manufac-

turer is not liable for any damage caused by “non-

genuine” spare parts or accessories.

WARRANTY

This machine is under warranty according to the

regulations in force in Your Country and in compli-

ance with the sales agreement drawn up with the

Dealer. The warranty, however, expires if the opera-

tion and maintenance instruction for this machine

and contained in this manual, have not been fol-

lowed.

Find manuals at https://best-manuals.com