Bray Series 70 User manual

Series 70

24V On/Off Electric Actuator

Operation and Maintenance Manual

1

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

For information on this product and other Bray products please visit us at our web page - www.bray.com

TABLE OF CONTENTS

1. Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4. Operating your Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.1. Operating by Hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.2. Operating Electrically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Mounting the Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6. Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.1. Wiring Your Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.2. Setting Travel Limit Switches Cams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.3. Setting Mechanical Travel Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.4 Configuring your 24V On/Off Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.5 DIP Switch Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7. Field or Factory Installable Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.1. Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.2. Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.3. Auxiliary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.4. Torque Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.5. Battery Backup Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.6. Spinner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.7. Receptacles (Quick Connectors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

A.1. Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

A.2. Actuator Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

A.3. Troubleshooting Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

B.1. Basic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

1. DEFINITION OF TERMS

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

NOTICE Used without the safety alert symbol indicates a potential situation which, if not avoided,

may result in an undesirable result or state, including property damage.

2. SAFETY

This device left the factory in proper condition to be safely

installed and operated in a hazard-free manner. The notes

and warnings in this document must be observed by the

user to ensure hazard-free operation of this device.

All necessary precautions need to be taken to prevent

damage due to rough handling, impact, or improper

storage. Do not use abrasive compounds to clean the

device, or scrape its surfaces with any objects.

Configuration and setup procedures for this device are

described in this manual. Proper configuration and setup

are required for the safe operation of this device.

The control system in which this device is installed must

have proper safeguards to prevent injury to personnel,

or damage to equipment, should a failure of system

components occur.

Installation, commissioning, operation and maintenance

of the unit must be performed under strict observation

of all applicable codes, standards and safety regulations.

The actuator must only be installed, commissioned,

operated and repaired by qualified personnel.

As per this document, a qualified person is one who is

trained in:

1. The operation and maintenance of electrical equipment

and systems in accordance with established safety

practices.

2. Procedures to energize, de-energize, ground, tag and

lockout electrical circuits and equipment in accordance

with established safety practices.

3. The proper use and care of personal protective

equipment (PPE) in accordance with established safety

practices.

This document does not cover every detail about every

version of the product described. It does not take into

account every potential occurrence concerning the

installation, operation, maintenance and use of this device.

If situations transpire that are not documented in sufficient

detail, please request the required information from the

Bray Distributor or Representative responsible for your area.

3. STORAGE

Store units on a shelf or wooden pallet in order to protect

against floor dampness.

Cover the units to protect against dust and dirt.

To prevent condensation inside these units, maintain a

near constant external temperature and store in a well-

ventilated, clean, dry room away from vibration. For units

with an internal heater, power should be supplied to the

heater via conduit entry with an appropriate sealing gland.

Actuators are not weatherproof unless they are properly

installed on the valve or prepared for storage. Bray will

not accept responsibility for deterioration caused on-site.

Read and Follow These Instructions

Save These Instructions

3

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

4. OPERATING YOUR ACTUATOR

4.1. Operating by Hand

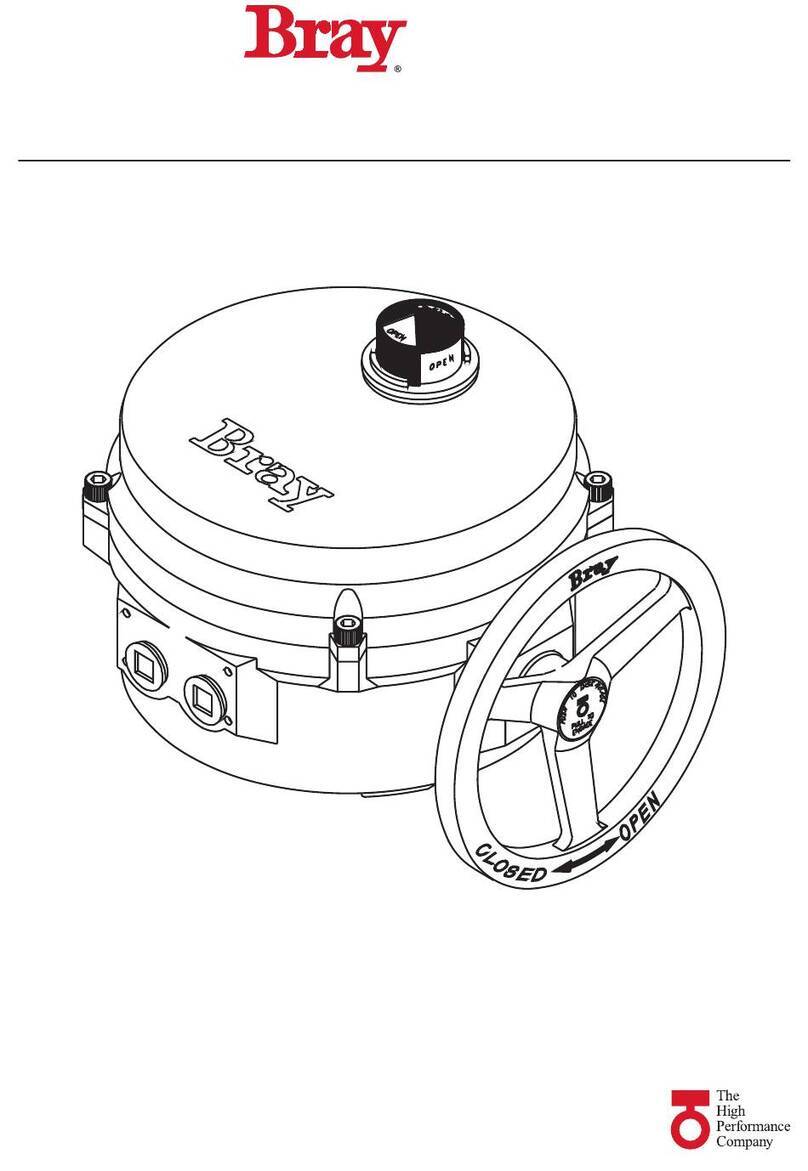

To engage the manual override, simply pull the handwheel

to its outermost position. A yellow stripe is revealed to

visually indicate manual override engagement as shown in

Figure 1.

Figure 1.

Yellow Stripe

Handwheel is engaged, revealing the yellow stripe.

Once the manual override is engaged, rotating the

handwheel in the clockwise direction will rotate the output

shaft in the clockwise (close) direction and vice-versa.

To disengage the manual override, the handhwheel needs

to be pushed towards the actuator until the ‘yellow stripe’

is hidden.

A label on the handwheel hub warns users not to exceed

a specific ‘rim pull’ force, for each size of actuator.

If the ‘rim pull’ force is exceeded, the roll pin securing the

handwheel onto the manual override shaft is designed to

shear, thus preventing serious internal gearing damage.

4.2. Operating Electrically

To control the actuator remotely from a process controller,

user must apply 24 VAC or 24 VDC to the actuator. This

control signal voltage can be applied locally or remotely

from a process controller.

Verify that the main electric power supplied to the

actuator is in compliance with the specifications on the

actuator label

Engaging the handwheel before or during the application

of a control signal voltage will prevent the actuator motor

from operating.

If torque switches are installed in the actuator, an

overtorque condition will also prevent the actuator motor

from operating.

5. MOUNTING THE ACTUATOR

All Bray Series 70 electric actuators are suitable for direct

mounting on Bray butterfly valves. With proper mounting

hardware, the S70 actuator can be installed onto other

quarter-turn valves or devices as well.

NOTICE

The standard mounting position for the actuator is to

orient the base of the actuator parallel to the pipeline.

If the actuator is to be mounted on a vertical pipe, it

is recommended that the unit be positioned with the

conduit entries on the bottom to prevent condensation

entering the actuator through its conduits.

Follow the steps below to mount the actuator onto the

valve.

1. Manually operate the actuator until the output shaft of

the actuator is in line with the valve stem. If possible,

select an intermediate position for both the valve and

actuator.

2. If required, place the proper adapter onto the valve

stem. It is recommended that a small amount of ‘anti-

seize’ lubricant be applied to the adapter to ease

assembly.

3. Mount the actuator onto the valve stem. It may be

necessary to operate the actuator manually to align the

valve and actuator bolt patterns.

4. Install the furnished mounting studs by threading them

all the way into the actuator base.

5. Fasten the mounting studs in place with furnished hex

nuts and lock washers.

4

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

6. COMMISSIONING

6.1. Wiring Your Actuator

Turn off all power and lockout/tagout service panel

before installing or modifying any electrical wiring.

1. Take the actuator cover off and place it in a safe

location.

2. Each actuator is provided with two conduit entries. Use

one for power and the other for control wiring.

3. Wire the actuator as per the wiring diagram attached

to the inside of the actuator cover.

a. A minimum of 18 AWG wire is recommended for all

field wiring.

b. The terminals on the actuator switch plate, On/Off

Controller or Servo NXT accepts wire sizes ranging

from 14 to 22 AWG.

c. The conduit connections must be properly sealed to

maintain the weatherproof integrity of the actuator

enclosure.

Figure 2. Sample field wiring diagram for Series 70 24V

On/Off Actuator with auxiliary switches.

6.2. Setting Travel Limit Switches Cams

Bray uses its patented cam design along with 2 SPDT

mechanical switches to set the ‘Open’ and ‘Close’ position

of the valve.

The green cam actuates the ‘open’ switch when the

actuator reaches the ‘open’ position. Similarly, the red cam

actuates the ‘close’ switch when the actuator reaches the

‘close’ position.

Standard factory setting of the travel limit switches allows

90° travel between open and close positions. Cams for

each switch are adjustable for applications where less than

90° degree travel is desired between the open and closed

positions.

Figure 3. Two SPDT Travel Limit Switches.

5

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

Follow the steps below to adjust the travel limit cams.

1. Remove the indicator rotor by pulling it away from the

indicator shaft as shown in Figure 4.

Figure 4.

Indicator Rotor

Indicator rotor pulled up from the indicator shaft.

2. Manually operate the actuator clockwise until the valve

reaches the desired ‘close’ position.

3. Loosen the cam locking screw shown in Figure 5.

Figure 5.

UPPER GREEN

“OPEN” CAM

LOWER RED

“CLOSE” CAM

POT DRIVE GEAR

“BLACK” NOT SHOWN

FOR CLARITY REASONS

CAM ADJUSTMENT KNOB

(ONLY ADJUST IF LOCKING

SCREW IS SLACKENED)

CAM

LOCKING

SCREW

Top view of the indicator cam shaft.

NOTE: It is possible that the rotation of one cam will move

the other cam. If this occurs, hold the other knobs or cams

during adjustment.

4. Rotate the red cam adjustment knob by hand or with

a flat head screwdriver until the red cam lobe activates

(depresses) the ‘close’ switch from a clockwise

direction.

5. Manually operate the actuator counterclockwise until

the valve reaches the desired ‘open’ position.

6. Rotate the green cam adjustment knob until the green

cam lobe activates (depresses) the ‘open’ switch from a

counterclockwise direction.

7. After both travel switch adjustments have been

completed, tighten the cam locking screw and place

the indicator rotor back on the indicator shaft.

6.3. Setting Mechanical Travel Stops

Mechanical travel stops are designed to prevent overtravel

while manually operating the actuator. They are not

designed to stop the electric motor.

Mechanical travel stops are located outside the actuator

base for easy readjustment. Stainless steel lock nuts with

O-ring seals hold the travel stops securely in place as shown

in Figure 6

Figure 6. Mechanical Travel Stops (CW Close).

Follow the steps below to set the mechanical travels stops.

1. Manually drive the actuator to the closed position.

2. Once the actuator is in the closed position, rotate the

handwheel clockwise:

• ½ turn for Housing Size 6.

• 1 turn for Housing Size 12.

• ½ turn for Housing Size 30.

NOTE:

Maximum Actuator Torque Housing Size

600 Lb-In 6

2000 Lb-In 12

5000 Lb-In 30

3. Adjust the closed travel stop bolt until it contacts the

output segment gear and lock it in position with the

locknut.

4. Manually drive the actuator to the open position.

5. Once the actuator is in the open posiiton, rotate the

handwheel counterclockwise:

• ½ turn for Housing Size 6.

• 1 turn for Housing Size 12.

• ½ turn for Housing Size 30.

6. Adjust the open travel stop bolt until it contacts the

output segment gear and lock it in position with the

locknut.

Close

Travel

Stop

Open

Travel

Stop

6

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

6.4 Configuring your 24V On/Off Controller

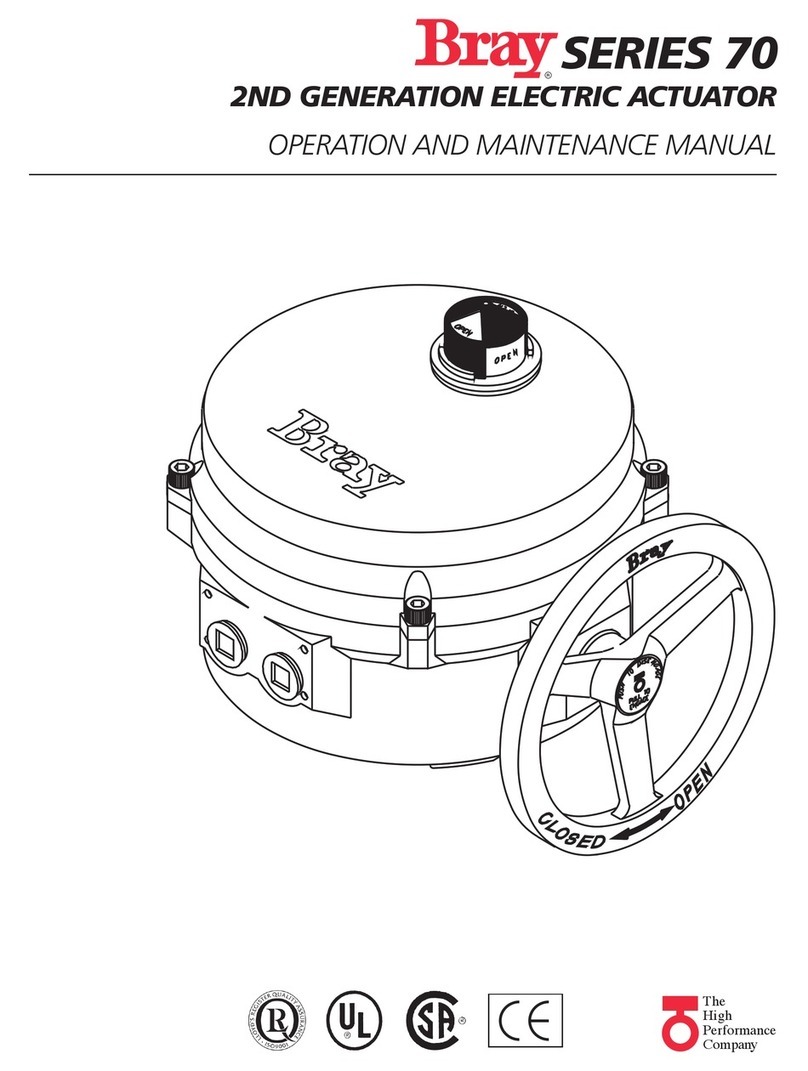

Every Series 70 24V On/Off Actuator is fitted with a 24V

On/Off Controller as shown in Figure 7.

Figure 7. S70 24V On/Off Actuator.

The 24V On/Off Controller offers 3-wire control for the

actuator.

To drive the actuator in the open direction, 24 VDC or

24 VAC power must be applied between the ‘Open’ and

‘Common’ terminals of the controller.

Similarly, to drive the actuator in the close direction, 24VDC

or 24VAC power must be applied to the ‘Close’ and

‘Common’ terminals of the controller.

When the command signal is first applied, the Controller

will wait for 1 second before powering the actuator motor.

This delay is necessary to prevent a simultaneous reversal of

the motor if an abrupt change in command signal direction

occurs (instant reverse delay).

Once the actuator has reached the ‘Open’ or ‘Close’

position, the travel limit switch is activated and the

controller turns off power to the motor.

NOTICE

Verify that the main electric power supplied to the

actuator is in compliance with the specifications on the

product label

6.5 DIP Switch Setting

The DIP switches on the 24V On/Off Controller are

dependent on the installation of mechanical torque

switches in the actuator. Table 1 shows the DIP switch

settings for the 24V On/Off Controller.

Table 1

Mechanical Torque

Switches installed

DIP Switch 1 DIP Switch 2

YES OFF ON

NO OFF OFF

Figure 8. DIP switch settings when mechanical torque

switches are installed in an actuator.

NOTICE

An engaged torque switch will prevent the actuator

motor from operating in the over torque direction.

The 24V On/Off Controller has four LED’s for status and

fault indication as shown in Figure 9.

On/Off

Controller

7

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

FAULT

POWER

OPEN

CLOSE

Figure 9. 24V On/Off Controller LEDs.

The LED flash codes for the 24V On/Off Controller are

described in Table 2 below.

Table 2

LED Behavior Meaning

‘Pwr’ LED flashes green

every ½ second

The actuator has power and is

operational.

‘Fault’ LED glows red

Hand-wheel is engaged/pulled

out

The Open or Close Torque

switch is engaged

Both the travel limit switches

are engaged at the same time

‘Open’ LED glows green Actuator is being driven in the

open direction.

‘Close’ LED glows red Actuator is being driven in the

close direction

7. FIELD OR FACTORY INSTALLABLE OPTIONS

7.1. Heater

To prevent condensation from forming inside the actuator,

Bray offers an optional heater as a field or a factory

installable option.

The heater is thermostatically controlled. It self-regulates by

increasing or decreasing its electrical resistance relative to

its temperature.

Figure 10. Heater installed on an S70 switch plate.

NOTICE

a. The heater must have a constant power supply to be

effective.

b. The heater surface can reach temperatures in excess

of 200° Celsius.

The heater surface can reach temperatures in excess of

200° Celsius

8

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

7.2. Control Station

Bray’s Control Station gives the operator the ability to

locally drive the actuator with electrical power; overriding

the control signal from the process controller.

The control station has a red (close) and green (open)

light to provide end of travel indication. It also has two

3-position switches as shown in Figure 11.

Figure 11.

Switch 2

Green

Light

Switch 1

Red

Light

S70 with the Control Station.

Switch 1 lets the operator choose between the following

three modes of operation:

1. Local: In this mode, using switch 2 the operator can

drive the actuator to open or close position, or stop the

actuator; overriding any control signal from the process

controller.

2. Off: In this mode, the actuator can only be operated

manually.

3. Remote: In this mode, the Actuator is controlled

remotely from a process controller using a 24 VDC or

24 VAC signal.

NOTE:

a. Control Station can also be ordered with key lockable

switches.

b. Control Station requires a dedicated set of auxiliary

switches. These switches are required for turning on or

off the lights on the control station to locally indicate

actuator position.

c. Control Station does not contain terminal strips. All

wiring is done directly to the switches and lights via 2

x 3/4” NPT holes in the bottom of the control station

housing. Wire the process controller to the control

station in accordance to the wiring diagram provided.

d. Ordering the Control Station with optional pin

connector receptacles will eliminate the necessity of

field wiring.

7.3. Auxiliary Switches

Auxiliary switches are a pair of dry-contact (voltage free)

SPDT mechanical switches used to indicate travel position

to remote customer control systems.

Figure 12. Fixed auxiliary switches installed in an actuator.

NOTE:

a. Fixed Auxiliary switches activate 3° before the travel

limit switches. They are available as a factory and field

installable option.

b. Adjustable auxiliary switches can be set to any position.

They are available as a factory or field installable option.

7.4. Torque Switches

Mechanical Torque switches are designed to interrupt

power to the motor windings when the actuator torque

exceeds the calibrated factory setting.

Mechanical Torque switches are a factory installed and

calibrated option available for all Series 70 units.

7.5. Battery Backup Unit

To meet customer needs, Bray offers a Battery Backup Unit

(BBU) for the 24 V Series 70 Electric Actuator.

In the event of power failure, the BBU will switch the

actuator to battery power to reach its fail position. After

the actuator has reached its fail position, the BBU goes to

‘Standby Mode’ until external power is restored.

Once external power has been restored, the actuator

returns to the position corresponding to the control signal

present.

9

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

Figure 13. S70 with Battery Backup Unit.

Battery Backup Unit is available as a factory installable

option. For more information, please refer to the ‘S70 24V

Actuator with BBU’ Manual. This manual is available on the

company website (www.bray.com).

7.6. Spinner

A spinner is available as an attachment to the actuator

handwheel to ease and speed the manual operation of the

actuator.

Figure 14. S70 with Handwheel Spinner Attached.

NOTE:

a. Care should be exercised in the use of spinner equipped

handwheels.

b. Rapid operation of the handwheel to close the valve

may cause water hammer.

c. Rapid travel into a travel stop may also cause damage.

7.7. Receptacles (Quick Connectors)

For quick and easy field wiring, Bray offers plug-in recep-

tacles. Cordsets to fit these connectors can also be ordered

in several lengths.

Figure 15. S70 with a 5-pin receptacle and the corres-

ponding cordset.

10

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

APPENDIX A

A.1. Troubleshooting Guide

The Series 70 24V On/Off actuator is easy to configure and operate, but if problems do occur, the following guide can assist

in troubleshooting.

The first step is to observe the ‘Pwr’ LED on the 24V On/Off Controller to verify that proper electrical power has been

connected. If the ‘Pwr’ LED is flashing green, it means that the actuator has been powered correctly.

Next, observe the Fault LED. If the ‘Fault’ LED on the 24V On/Off Controller is turned on red, refer to Table 2 on page 7 of

the manual to determine the root cause of the fault. After the root cause of the fault has been addressed, the ‘Fault’ LED

should turn off.

If the problem still persists refer to the Actuator Troubleshooting Chart below.

A.2. Actuator Troubleshooting Chart

Problem Possible Cause Solutions

Actuator motor does not run in either

direction and the ‘Pwr’ LED on the

24V On/Off Controller is flashing

green

Manual override/handwheel is engaged. Push handwheel in all the way

Wiring is incorrect Check wiring and power supply

Actuator operates in reverse directions Field wiring is reversed Rewire field wiring per wiring

diagram

Actuator does not fully close valve (or

open valve)

Limit switches are set incorrectly Readjust travel limit switches

Mechanical travel stops are set

incorrectly Adjust mechanical travel stops

Valve torque requirement is higher than

actuator output

Manually override out of seat, try

angle seating or larger actuator

Optional torque switches are activating Valve torque exceeds actuator torque

rating - consult factory

Voltage power supply is low Check power source

Corrosion inside unit Water leaking in Check all seals and possible water

entry through conduit

Actuation only runs in one direction Wiring is incorrect Correct field wiring

Incorrect control signal Check/correct the control signal wire

11

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

A.3. Troubleshooting Example

The following example demonstrates a typical troubleshooting process.

Assume these starting conditions:

1. The handwheel is engaged (pulled away from the actuator).

2. The 24V On/Off Controller has been configured to enable torque switches but torque switches are not physically

installed on the actuator.

3. 24VAC signal has been properly applied between the ‘Open’ and ‘Close’ terminals of the 24V On/Off Controller. The

‘Pwr’ LED is flashing indicating the control signal has been properly applied.

The ‘Fault’ LED on the 24V On/Off Controller is turned on red. Evaluate all possible reasons for the ‘Fault’ LED to be turned

on as per Table 2 on page 7 of this manual.

1. Observe if the handwheel is engaged. In this case, the handwheel is engaged. Disengage the handwheel by pushing it

in to eliminate a possible reason for the ‘Fault’ LED to be turned on red.

2. Evaluate if the limit switches have been correctly wired.

3. Check if the 24V On/Off Controller has been configured correctly to enable or disable the torque switches. In this case,

torque switches have not been installed in the actuator but the 24V On/Off Controller has been configured to enable

the torque switches. Correctly configure the 24V On/Off controller correctly to disable the toque switches as per Table

1 (on page 6).

4. The ‘Fault’ LED on the 24V On/Off Controller turns off and the actuator is now ready for service.

12

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

APPENDIX B

B.1. Basic Tools

Common To All Units

Terminal connections, cam adjustment Screwdriver, 1⁄4" tip flat tip blade

All switches, terminal strip, torque switch plate Screwdriver, No.1 Phillips

Switchplate screws Screwdriver, No. 2 Phillips

Housing Size 6

Mounting nuts Wrench, 1⁄2"

Cover captivated capscrews Hex key, 1⁄4"

Travel stop adjusting bolts Wrench, 7⁄16"

Travel stop jam nuts Wrench, 7⁄16"

Conduit Entry Plug (1⁄2” NPT) Hex key, 3⁄8"

Housing Size 12

Mounting nuts (small pattern) Wrench, 1⁄2"

Mounting nuts (large pattern) Wrench, 3⁄4"

Cover captivated capscrews Hex key, 5⁄16"

Travel stop adjusting bolts Wrench, 9⁄16"

Travel stop jam nuts Wrench, 9⁄16"

Conduit Entry Plug (3⁄4” NPT) Hex key, 9⁄16"

Housing Size 30

Mounting nuts (small pattern) Wrench, 3⁄4"

Mounting nuts (large pattern) Wrench, 11⁄8"

Cover captivated capscrews Hex Key, 3⁄8”

Travel stop adjusting bolts Wrench, 3⁄4"

Travel stop jam nuts Wrench, 3⁄4”

Conduit Entry Plug (3⁄4” NPT) Hex key, 9⁄16"

13

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

14

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

Bray Series 70

24V On/Off Electric Actuator

Operations and Maintenance Manual

All statements, technical information, and recommendations

in this bulletin are for general use only. Consult Bray

representatives or factory for the specic requirements and

material selection for your intended application. The right

to change or modify product design or product without prior

notice is reserved. Patents issued and applied for worldwide.

Bray®is a registered trademark of

Bray International, Inc.

© 2015 Bray International, Inc. All rights reserved.

OM_70_24VOnOff_11-2015

Bray Controls

A Division of Bray International, Inc.

13333 Westland East Blvd.

Houston, Texas 77041

Tel: 281.894.5454 • www.bray.com

Other manuals for Series 70

9

Table of contents

Other Bray Controllers manuals

Bray

Bray GAS Series User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray 75 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray SERVO PRO 70 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray 98 Series User manual