NewAE CHIPSHOUTER CW520 User manual

CHIPSHOUTER®

USER MANUAL

Last Update: Sept 3/2019

© 2018-2019 NewAE Technology Inc. All rights reserved. Specifications are subject to change without

notice. All product names are trademarks of their respective companies. ChipSHOUTER is a registered

trademark of NewAE Technology Inc.

NewAE Technology Inc. makes no representations or warranties with respect to the accuracy or completeness

of the contents of this document and reserves the right to make changes to specifications and product

descriptions at any time without notice. NewAE Technology does not make any commitment to update the

information contained herein. NewAE Technology products are not intended, authorized, or warranted for

use as components in applications intended to support or sustain life. NewAE Technology products are

designed solely for teaching purposes.

ii

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each NewAE Technology Inc product is warranted to be free from defects in mate-

rial and workmanship under normal use and service. The warranty period is one

year and begins on the date of shipment. This warranty extends only to the

original buyer or end-user customer of a NewAE Technology Inc authorized re-

seller, and does not apply to probes (including EMFI injection tips), exposed

circuit boards, fault injection targets, or to any product which, in NewAE

Technology Inc's opinion, has been misused, altered, neglected, contaminated,

or damaged by accident or abnormal conditions of operation or handling (includ-

ing failing to observe required ESD handling procedures).

Authorized resellers shall extend this warranty on new and unused products to

end-user customers only but have no authority to extend a greater or different

warranty on behalf of NewAE Technology Inc. NewAE Technology Inc.'s warranty

obligation is limited, at NewAE Technology Inc.'s option, to refund of the

purchase price, free of charge repair, or replacement of a defective product

which is returned to a NewAE Technology Inc. within the warranty period. To

obtain warranty service, contact NewAE Technology Inc.

If NewAE Technology Inc. determines that failure was caused by neglect, misuse,

contamination, alteration, accident, or abnormal condition of operation or

handling, including failures caused by use outside the product’s specified

rating, or normal wear and tear of mechanical components, NewAE Technology Inc

will provide an estimate of repair costs and obtain authorization before com-

mencing the work.

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEWAE

TECHNOLOGY INC SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE

OR THEORY.

Since some countries or states do not allow limitation of the term of an im-

plied warranty, or exclusion or limitation of incidental or consequential

damages, the limitations and exclusions of this warranty may not apply to every

buyer. If any provision of this Warranty is held invalid or unenforceable by a

court or other decision-maker of competent jurisdiction, such holding will not

affect the validity or enforceability of any other provision.

NewAE Technology Inc.

1083 Queen St., Suite 196

Halifax, NS. Canada

iii

Table of Contents

Introduction.................................................... 5

Safety Information ............................................. 6

High Voltage Warnings .......................................... 9

Packing Information ........................................... 11

Background and Quick Start Guide .............................. 14

Device Architecture ........................................... 15

Specifications................................................. 17

General Specifications ...................................... 17

I/O Characteristics ......................................... 18

High Voltage Characteristics ................................ 18

Pulse Source Characteristics ................................ 19

Inserted Pulse Characteristics .............................. 19

External Connections .......................................... 22

SMA High Voltage Output ..................................... 22

Attaching/Removing SMA Connectors ......................... 23

SMB Trigger Input ........................................... 23

DC Power Jack ............................................... 26

RJ12 Expansion Connector .................................... 25

Oscilloscope Probe Connectors ............................... 26

Pulse Generation .............................................. 27

Generated Pulse vs. Inserted ................................ 27

Active-High vs. Active-Low Inputs ........................... 27

Basic Pulse Generator ....................................... 28

Programmable Pulse Generator ................................ 28

Simple EMFI Target (CW322) .................................... 30

Ballistic Gel EMFI Target (CW522) ............................. 33

Injection Tip Usage ........................................... 36

Avoiding Spark Discharge .................................... 38

Oscilloscope Pulse Shape Monitoring ........................... 39

Adjusting for Oscilloscope Setting .......................... 41

Forced-Air Cooling ............................................ 43

Fault Modes.................................................... 46

Probe Disconnected Fault .................................... 47

Over-Temperature Fault ...................................... 48

Triggered when Disarmed ..................................... 49

Trigger Length Invalid ...................................... 49

Internal Faults ............................................. 50

Serial Interface .............................................. 51

Command List ................................................ 52

USB Interface ............................................... 59

Python API Interface .......................................... 61

iv

XY(Z) Table Connection ........................................ 62

Troubleshooting ............................................... 63

Table of Figures

Figure 1: Overview of ChipSHOUTER device architecture. ........ 15

Figure 2: 4mm tip pulse width ................................. 20

Figure 3: 1mm tip pulse width ................................. 21

Figure 4: External connectors on the ChipSHOUTER. ............. 22

Figure 5: RJ12 Connector on ChipSHOUTER Panel. ................ 25

Figure 6: CW322 Simple Target ................................. 30

Figure 7: CW522 Ballistic Gel ................................. 33

Figure 8: Detail of the 4MM/CCW tip construction. ............. 36

Figure 9: Detail of included probes. .......................... 37

Figure 8: Inserted pulse viewed on oscilloscope screen. ....... 39

Figure 11: Tuning oscilloscope probe. ......................... 41

Figure 10: Example calibration waveform. ...................... 42

Figure 11: Removing blanking plug. ............................ 44

Figure 14: Adding air inlet adapter. .......................... 44

Figure 15: USB Interface for ChipSHOUTER ...................... 59

Revision

Release Date

Changes

1.1

9-SEPT-2019

•Fix RJ12 pinout, small clarifica-

tions throughout, add more detail of

external hardware trigger, add more

detail of probe construction.

1.0

20-JULY-2018

•Initial release, minor fixes.

0.2

16-JULY-2018

•Add troubleshooting section.

0.1

13-JULY-2018

•Pre-Pre-Release.

ChipSHOUTER Users Manual: Introduction

5

Introduction

The CW520 (ChipSHOUTER) is a fully-featured Electromagnetic

Fault Injection platform that can be used to discover and

characterize vulnerabilities in embedded systems. ChipSHOUT-

ER makes EMFI available to test labs, engineering

development firms, educators, and embedded enthusiasts. With

a flexible API and bundled practice targets the system is a

platform for experimentation and education right out of the

box. Paired with an X-Y table and some basic python script-

ing the ChipSHOUTER becomes a fully automatable EMFI

platform capable of precision testing and fault characteri-

zation. This manual will give a basic background for the

principles behind the device, using it safely, and example

injections on included targets. Users will also be directed

to further reading on advanced uses, where professionals and

researchers can take advantage of the modular design to fur-

ther fine tune their processes and experiments.

ChipSHOUTER Users Manual: Safety Information

6

Safety Information

CAREFULLY READ BOTH THE FOLLOWING GENERAL SAFTEY

INFORMATION, AND SAFTEY INFORMATION IN THE SECTION ENTITLED

“HIGH VOLTAGE WARNINGS”:

•This product generates strong electronic and mag-

netic fields:

oDO NOT use around persons with implanted

or attached medical devices such as pace-

makers, implanted defibrillators, or

medication pumps.

oDO NOT use around safety-critical devices,

or anything were interruption of device

function would be undesirable.

•DO NOT touch the injection tip or high voltage

connector when device is armed or discharging.

•DO NOT aim or position the injection tip onto a

person or other living tissue.

•This product is capable of PERMANENTLY DESTORYING

devices under test.

•This product is capable of PERMANENTLY DAMAGING

devices under test. NEVER return a tested device

to service, even if it appears operational, as

the functionality of this device could be affect-

ed.

•DO NOT operate the product with covers removed or

the case open. Hazardous voltage exposure is pos-

sible.

•IF you hear or notice electrical discharge, imme-

diately discontinue operation and remove power

ChipSHOUTER Users Manual: Safety Information

7

from the ChipSHOUTER by unplugging the power

source. Check connections are secure and for dam-

age to the probe. If probe is damaged destroy and

discard it, and replace with an undamaged probe.

•IF you notice smoke or unusual odors emitted from

the ChipSHOUTER, immediately discontinue opera-

tion and remove power from the ChipSHOUTER by

unplugging the power source. Store the device

where it cannot accidently be used, and contact

us for repair or replacement information.

•DO NOT operate the product with the air inlet

cover removed without connecting an air hose. If

an air hose is removed immediately replace the

air inlet cover.

•Repairs must only be performed by an approved

technician.

•DO NOT expose the ChipSHOUTER to water or other

liquids, DO NOT submerge the ChipSHOUTER in water

or any liquid, and do not use ChipSHOUTER as a

bath toy under ANY circumstances.

•Keep ChipSHOUTER away from children and especial-

ly smart dogs.

•DO NOT use ChipSHOUTER or any accessories if they

appear damaged in any way, paying careful atten-

tion to the insulation on the injection tips.

•CAREFULLY READ the high voltage warnings section.

•Familiarize yourself with the warning and label

pictures from the table below.

ChipSHOUTER Users Manual: Safety Information

8

Symbol

Description

Symbol

Description

WARNING. RISK OF DANGER.

WARNING. HAZARDOUS

VOLTAGE. Risk of electric

shock.

Consult user documenta-

tion. DC (Direct Current)

Conforms to European

Union directives. AC (Alternating Current)

For indoor use only.

Do not disassemble unit.

This product complies with the WEEE directive marking require-

ments. The affixed label indicates that you must not discard

this electronic product in domestic household waste. Product

Category: With reference to the equipment types in the WEEE

Directive Annex I, this product is classed as category 9 “Moni-

toring and Control Instrumentation” product. Do not dispose of

this product as unsorted municipal waste. Please contact us to

dispose/recycle this product.

ChipSHOUTER Users Manual: High Voltage Warnings

9

High Voltage Warnings

In addition to the safety warnings regarding the ChipSHOUTER

operation, there are some specific additional warnings re-

lated to the high voltage circuitry. Please carefully read

both the “Safety Information” in addition to these “High

Voltage Warnings”. All users of the ChipSHOUTER must be

aware of these warnings.

•ChipSHOUTER can generate strong magnetic and

electrical fields. DO NOT use around safety-

critical equipment. DO NOT allow a person with an

implanted or on-body medical device near the

ChipSHOUTER.

•The SMA center pin has hazardous voltage present.

DO NOT touch or otherwise expose this connection.

•DO NOT touch the injection probe or high voltage

connector when device is armed or discharging.

•DO NOT attempt to arm the ChipSHOUTER without a

EMFI injection probe attached.

•DO NOT use the ChipSHOUTER to generate a spark-

gap discharge. In addition to exposing hazardous

ChipSHOUTER can generate hazardous voltages. It

is very important that everyone who will be operat-

ing the ChipSHOUTER carefully reads and

understands this manual and the warning instruc-

tions. If you have questions about these warnings

please contact NewAE immediately.

ChipSHOUTER Users Manual: High Voltage Warnings

10

voltages, this may generate U.V. light and other

dangerous radiation. ChipSHOUTER will also be se-

verely damaged during the discharge process, as

the spark-gap discharge exceeds allowed dv/dt

ratings of the driver circuit.

•The insulation on the injection probes must be

unbroken for your protection. Carefully inspect

the probes for damage to the insulation, and de-

stroy (to prevent accidental reuse) and discard

any damaged probes.

•DO NOT position the injection probes in such a

manner they will scrape conductive areas of the

device under test.

•The SMA connector shell is NOT connected to the

enclosure (chassis). Do not short the SMA con-

nector shell to the enclosure or ground, as

otherwise high voltages and currents could pass

through this connection.

•Do not connect anything besides a EMFI injection

probe or included accessory to the ChipSHOUTER

output.

ChipSHOUTER Users Manual: Packing Information

11

Packing Information

①

ChipSHOUTER CW520 Main Unit ⑧SMB to SMA adapter

②

19V / 3.4A Power Adapter ⑨SMB to BNC adapter

③

Injection probe/tips (1mm, 4mm) ⑩SMB Cable

④

Isolated USB Adapter +

RJ12 Cable

+ Micro USB Cable ⑪CW521

Ballistic Gel SRAM

Target + USB Cable

⑤

SMA Saver (Installed) ⑫CW322 Simple EMFI

Target

+ CR2032 Battery

⑥

SMA Right angle adapter ⑬Cooling air adapter

and

4mm wrench

⑦

Oscilloscope Probe Adapter (x2)

ChipSHOUTER Users Manual: Packing Information

12

1. The ChipSHOUTER CW520 main unit is the EMFI fault in-

jection platform itself.

2. The 19V power supply provides DC power to the Chip-

SHOUTER.

3. The injection probe tips must be added onto the end of

the ChipSHOUTER before using the device. Do not touch

the probes during operation.

4. The Isolated USB adapter provides a computer interface

to the ChipSHOUTER.

5. The SMA Saver is a sacrificial SMA male to female

adapter. It is added onto the ChipSHOUTER to save wear

and tear on the ChipSHOUTER SMA connector. The SMA

Saver can easily be replaced in case it is damaged.

6. The SMA right angle adapter is used in combination

with a horizontal mount XY table.

7. The oscilloscope probe adapter allows monitoring of

the pulse inserted at the tip of the ChipSHOUTER it-

self.

8. The SMB to SMA adapter allows interfacing the external

trigger input with the ChipWhisperer trigger outputs,

or other equipment with logic-level SMA outputs.

9. The SMB to BNC adapter allows interfacing the external

trigger input with regular lab equipment.

10.The SMB cable is used to connect the external trigger.

11.The Ballistic Gel SRAM target provides detailed infor-

mation about the effectiveness of a fault injection

pattern.

12.The Simple EMFI target allows quick validation that a

fault injection probe is working.

ChipSHOUTER Users Manual: Packing Information

13

13.The cooling air adapter allows you to insert dry high-

pressure air into the ChipSHOUTER for cooling. The

adapter may look different or be of different material

thank shown here.

We are continuously improving our products. Some of the ac-

cessories or the device may look different than the photos

used for this manual, but this is part of our continuous re-

finement of the product. If you have questions about the

parts received please contact us.

ChipSHOUTER Users Manual: Background and Quick Start

Guide

14

Background and Quick Start Guide

Electromagnetic Fault Injection (EMFI) is a way of injecting

transient faults into electronic systems without direct

electrical contact. This is accomplished by generating a

rapidly changing magnetic field directed at the Device under

Test (DuT). Changing magnetic fields cause induced currents

in the DuT, resulting in changing voltage levels on internal

signals. These changing voltage levels can cause incorrect

read (or write) operations, affecting results of latches,

registers, and more. Corrupting memory, resetting lock bits,

skipping instructions, and inserting faults into crypto-

graphic operations are all applications of EMFI. This can be

used for embedded security research, validating fault-

tolerance of algorithms, and validating fault-tolerance of

entire systems.

To use the ChipSHOUTER in its simplest configuration you

need only three things: the ChipSHOUTER itself, the included

19V power adapter, and one of the included injection tips.

Attach the tip to the high voltage output of the device, and

the power adapter to the DC input. Holding the ARM button

arms the device and pressing pulse generates a fault. Press-

ing ARM again will disarm the device. Application of the

device and more detail on performing injections is included

in the sections pertaining to the included targets.

ChipSHOUTER Users Manual: Device Architecture

15

Device Architecture

Figure 1: Overview of ChipSHOUTER device architecture.

Fundamentally, the ChipSHOUTER provides a high voltage

charge that is discharged through an inductor (the “injec-

tion tip”). This injection tip generates a powerful magnetic

field that can be used to induce faults in a target device.

To make using the device easier, the ChipSHOUTER in-

cludes a microcontroller that controls device operation.

This includes detection of fault conditions such as over-

temperature or invalid operational requests. Once a fault is

ChipSHOUTER Users Manual: Device Architecture

16

active, the device will prevent “arming” (turning on the

high-voltage circuit) until the condition is cleared, and

possibly acknowledged by the user.

This microcontroller can also generate pulse waveforms.

These waveforms can either be basic pulses of a specified

lengths, or more complicated patterns involving switching

the high voltage on/off in 21nS time-steps.

To reduce the delay between a trigger event and the

pulse injection, a special hardware trigger is also present

that directly drives the high-voltage switch. This hardware

trigger allows entirely arbitrary on/off pulses to be sent

into the injection tip. This hardware trigger can be used

with general-purpose test equipment or specific power analy-

sis equipment such as the ChipWhisperer.

The output connector is a SMA connector jack. For safety

reasons the device uses “high-side” switching, which means

the high voltage is present ONLY during the pulse operation

itself. The output includes two current-limiting resistors

to prevent device destruction even when discharging into a

direct short, and two catch diodes to absorb the reverse

voltage spike generated by the collapsing magnetic field.

ChipSHOUTER Users Manual: Specifications

17

Specifications

General Specifications

Power supply (ChipSHOUTER DC Input)... 19V DC ±10%, 3.4A

Power consumption (standby)........... 0.4W Typical

Power consumption (armed)............. 5W Typical

Power consumption (charging/pulsing).. 5W to 50W Typical

Power supply (AC-DC adapter).......... 100–240VAC, 50/60Hz, 1.5A

Size (ChipSHOUTER main unit).......... 130 x 55 x 25 mm

Weight (ChipSHOUTER main unit)........ 180 g

Altitude

Operating......................... 2000 m

Storage........................... 12 000 m

Storage Temperature................... -40°C to 60°C

Operating Temperature................. 5°C to 40°C

Relative Humidity..................... Noncondensing

0 % to 80 % @ 5°C to 30°C

Decreasing linearly to 50 % @ 40°C

Safety

EN 61010-1:2010.................. Pollution Degree 2

Electromagnetic Compatibility

International.................... EN 61326-1: Portable Electromagnetic

Environment; EN 61326-2-2 CISPR 11: Group 2, Class A

Group 2: This equipment intentionally generates RF

energy that is used in electromagnetic coupling, in-

ductive coupling, and capacitive coupling for

material analysis or inspection.

Class A: This equipment is suitable for use in all

establishments other than domestic and those directly

connected to the public low voltage power supply net-

work that supplies buildings used for domestic

purposes.

There may be potential difficulties in ensuring elec-

tromagnetic compatibility in other environments due

to conducted and radiated disturbances.

Emissions that exceed the levels required by CISPR 11

can occur when the equipment is connected to a test

object. The equipment may not meet the immunity re-

quirements of this standard when test leads and/or

test probes are connected.

ChipSHOUTER Users Manual: Specifications

18

USA (FCC)........................ 47 CFR 15 subpart B. This product is

considered and exempt device per clause

15.103.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference

and (2) this device must accept any interference re-

ceived, including interference that may cause

undesired operations. You must discontinue use of

this device if it causes interference to another us-

er, and remedy the interference before continuing

operation of this device.

I/O Characteristics

Serial command interface.............. 3.3V CMOS Serial, 115200 baud, 8N1

Protocol ............................. (1) ASCII command prompt

(2) Binary

Serial connection..................... RJ12 connector with GND, TX/RX,

3.3V output, and switchable pulse/arm

pin.

Hardware trigger connector type ...... SMB connector, center-positive

Hardware trigger threshold ........... 2V

Hardware trigger absolute max ratings -0.5V to 6.5V

Hardware trigger impedance............ 50Ω/ 1.8KΩ(Switchable)

Hardware trigger level................ Active-high / Active-Low (Switchable)

Injected waveform monitor............. BNC connector for mating with standard

1MΩ|| 10-25pF oscilloscope input. Ad-

justable compensation trimmer for fine-

tuning match.

Voltage monitor attenuation........... 20x attenuation

Voltage monitor output range.......... ±25V into properly matched oscilloscope

input

High Voltage Characteristics

Characteristic

Min

Typ

Max

Units

Programmable voltage range

150

500

V

Charge rate

30

40

V/ms

Charge energy

625

mJ

Measured voltage accuracy via digital

interface

±(5% + 10V)

ChipSHOUTER Users Manual: Specifications

19

Pulse Source Characteristics

Pulse generator source................ (1) Internal pulse generator, basic

(2) Internal pulse generator,

programmable pattern

(3) External hardware trigger

Characteristic

Min

Typ

Max

Units

Basic pulse generator

Pulse width range

80

960

nS

Pulse width resolution

80

nS

Pulse width jitter

350

pS std-dev

Pulse dead-time (between repeats)

1

1000

mS

Pulse repetition count (per

Trigger event)

1

10000

Programmable pattern generator

Pulse width resolution (time-steps)

20.83

nS

Time-steps per pulse

1

5000

Time-steps

Total pulse width

0.0208

100

uS

Pulse output state per time-steps

1/0

Pulse width jitter

tested pulse width of 80nS

350

pS std-dev

Hardware Input Trigger

Delay

Tested high voltage 150V to 500V

75

nS

Delay jitter

Tested high voltage 150V to 500V

150

pS std-dev

Width jitter

Tested high voltage 150V to 300V

800

pS std-dev

Width jitter

Tested high voltage 300V to 500V

220

pS std-dev

Inserted Pulse Characteristics

Characteristic

Min

Typ

Max

Units

Pulse width into 1mm injection tip

15

80

TYPICAL nS

Pulse width into 4mm injection tip

24

480

TYPICAL nS

Minimum consecutive pulse spacing

Tested with 4mm injection tip at

voltage setting of 500V

2 Pulses

100

ns

3 Pulses

175

ns

For details of the pulse insertion see following text.

ChipSHOUTER Users Manual: Specifications

20

While the pulse generator characteristics show that a

wide variety of pulses can be applied to the injection tip,

the actual resulting pulse characteristics will depend con-

siderably on the tip properties itself. It is not possible

to achieve every injection result on every tip.

Insertion of multiple pulses may require adjusting the

driven pulses, which is achieved with the “monitor” port

output. As an example, achieving (approximately) the same

pulses multiple times is shown with the following pattern

trigger waveform setting for 1, 2, and 3 pulses. Note the

spacing between pulses varies as well:

s w 1110

s w 111011110

s w 111000011110000111110

The following figures (Figure 2 and Figure 3) show exam-

ples of possible range of pulses that can be achieved on one

test of the provided 1mm and 4mm tips.

10

100

1000

100 150 200 250 300 350 400 450

Pulse Width (ns)

Peak Output Voltage (Measured)

4mm Tip Pulse Width Limits

Maximum Minimum

Figure 2: 4mm tip pulse width

Table of contents

Popular Test Equipment manuals by other brands

agratronix

agratronix WCT-2 Operator's manual

Teledyne Lecroy

Teledyne Lecroy WaveSurfer 10 Operator's manual

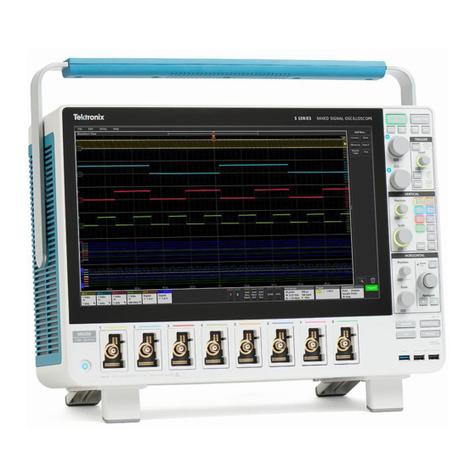

Tektronix

Tektronix 5 Series Printable help

Agilent Technologies

Agilent Technologies InfiniiVision 4000 X-Series user guide

Unitest

Unitest CHB 5 instruction manual

Ponovo

Ponovo PDC15k instruction manual