Newall DP500 User manual

DP500

Digital Readout

User Manual

2

Contents

Specification Page 3

Electrical Page 3

Physical Page 3

Environment Page 3

Accreditation Page 3

Disposal Page 3

Input and Resolution Page 3

Mounting ptions Page 4

Mill Mount Page 4

Lathe Mount Page 4

Connection Details Page 5

Important Information Page 5

Connections Page 5

Display and Keypad Page 6

Understanding the Display Page 6

Understanding the Keypad Page 6

Setting up the Unit Page 7

Navigating Complete Setup Page 7

Navigating Complete Setup (Continued) Page 8

Language Setup Page 9

Type Setup Page 9

Encoder Type Setup Page 9

Encoder Resolution Setup Page 9

Direction of Travel Setup Page 10

Radius / Diameter (Measure Setup) Page 10

Error Compensation Page 11

Linear Error Compensation Page 12

Linear Error Compensation Setup Page 13

Segmented Error Compensation Setup Page 14/15

Using Segmented Error Compensation Page 15

Plane Setup Page 15

Functions Setup Page 16

Beep Setup Page 16

Sleep Setup Page 16

Reset Setup Page 17

Standard Functions Page 18

Absolute / Incremental Page 18

Inch / mm Page 18

Zero and Preset an Axis Page 19

Undo Function Page 19

1/2 Function / Centre Find Page 20

Reference Page 20

Mill Functions Page 21

Pitch Circle Diameter (PCD) / Bolt ole Page 21

Lathe Functions Page 22

Tool Offsets Page 22/23

Multiple Tool Datums Page 24

Trouble Shooting Page 25

3

EU Directive 73/23/EEC (Low Voltage Directive)

BS EN 55022:1998 Class B

BS EN 55024:1998

Input to Power Supply Unit (Supplied)

100-240V (47-63 z)

External switch-mode - Output voltage 15VDC

Input Voltage to DP500 15-24VDC ±10%

Conforms to Low Voltage Directive

eight 170mm (6.69") Depth 48mm (1.89") Mounting Bolt: M10

Width 260mm (10.23") Weight 1.5kg (3.3lb)

Climatic Range Storage Temperature -20°C to 70°C

Working Temperature -10°C to 50°C

Working umidity 95% R. . at 31°C

IP-Ingress Protection IP40 Stand Alone

CE

At the end of its life, you should dispose of the DP500 system in a safe manner applicable to electrical

goods

Do not burn

The casework is suitable for recycling. Please consult local regulations on disposal of electrical equip-

ment

Only Spherosyn LT or Microsyn LT encoders can be used with the DP500 DRO

Resolutions

Spherosyn LT or Microsyn LT (10µm)

5µm (0.0002")

10µm (0.0005")

20µm (0.001")

50µm (0.002")

Newall Measurement Systems Limited reserves the right to make changes to this specification without

notice

Specification

Electrical

Physical

Environmental

Accreditation

Disposal

Input & Resolutions

Lathe Mount (Non Adjustable)

This chapter details the various mounting options for the DP500, both the standard version and the

panel mount version.

Mounting Options

Mill Mount (Non Adjustable)

4

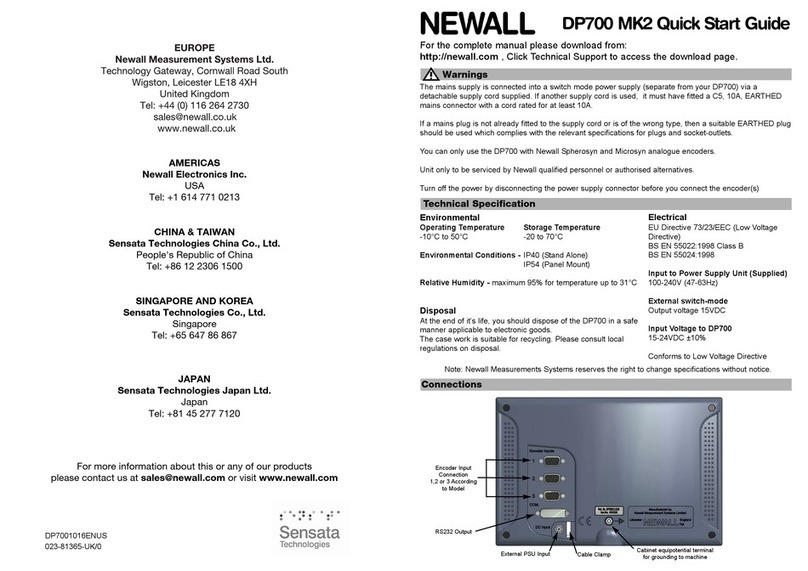

This chapter details the cable connections for the DP500.

Connection Details

Important Details

Connections

You can only use the DP500 with Newall Spherosyn LT and Microsyn LT analogue encoders.

You need to ensure that:

You secure all the cables to prevent the connectors from dropping into hazardous

positions (for example the floor or coolant tray) when you unplug them.

You route all cables to prevent them from being caught on moving parts.

The DP500 is grounded to the machine, using the braided grounding lead provided,

before you turn on the machine supply.

The power has been disconnected, before you connect the encoder(s).

Do not connect this unit directly to the mains supply.

If an encoder connected to the DP500 travels over 2.2m an error code (2.1) will be displayed in the X

axis and the other axes will go blank. See the trouble shooting guide for further details on page 25.

Encoder input connection

2 or 3 according to model

Cabinet equipotential terminal

for grounding to machine

External PSU input

Cable clamp

5

This chapter explains how to interpret the display and use the keypad.

Display and Keypad

Understanding The Display

Understanding The Keypad

Axis Selection Key

Numeric Keys

Enter Key

Clear Numeric Entry

Centre Find

Undo Key

Digifind / Reference

Switches between Zero

and Axis Preset modes

Switches between Absolute

and Incremental modes

Information selection (scrolls through

options on Message display)

Function Menu Key

Function Navigation Keys

Switches between Inch and

mm display

Axis 1

Axis 2

Axis 3

Message

Display

Power LED

6

Sleep Key

T0 0 l 01

156.2 5 5

100.2 5 0

950.355

Setting Up The Unit

Navigating Complete Setup

How to enter setup

setup

Encoder nn26-lt

S26-lt

Until display shows uncs

Setup

Unit then

displays

setup

code?

setup

res 0.005

0.02

0.01

0.05

setup

dir ---i

setup

measure dia

rad

setup

err comp none

linear

select

segments

I---

Spherosyn LT

Microsyn LT (10µm)

setup

Language Eng us

Eng gb

rancais

pol

a r.

turkce

setup

type

lathe

nnill

generic

Note: Other languages may be available

italiano

dansk deutsch

portugue

setup

plane (----)

(----)

(----)

(----)

(----)

(----)

nly applicable

to 3 axes units

cesky

espanol

nederlan

russian

7

Setting Up The Unit

Navigating Complete Setup (continued)

setup

uncs on o

set unc

tools

set unc

PCD on o

setup

reset

reset

as generic

lathe

nnill

To exit setup

setup

beep o

setup

sleep 0user defined, use numeric keypad to

enter value (value is in whole minutes)

(Default is inactive)

8

on

Display Spherosyn™ LT Microsyn™ LT (10µm)

µm mm in

5 0.005 0.0002

10 0.01 0.0005

20 0.02 0.001

50 0.05 0.002

Setting Up The Unit

Encoder Type Setup

The encoder settings must match the actual encoder in use, or the DP500 will not measure

correctly.

Newall encoders that work with DP500:

Nnm26-LT

s26-LT

Spherosyn LT

Microsyn LT (10µm)

Press the axis select key next to the ‘X’, ‘Y’ or ‘Z’ axis to cycle through options

Encoder Resolution Setup

The resolution settings available for each axis depend on the inch/mm setting.

Press the axis select key next to the ‘X’, ‘Y’ or ‘Z’ axis to cycle through options

Language Setup

This setting enables the user to choose the language that is required to be displayed in the DP500 display.

Eng us

rancais

deutsch

italiano

dansk

turkce

portugue

russian

Eng gb (Default)

Press the axis select key next to the ‘X’ axis to cycle through options

English UK

English US

French

German

Italian

Russian

Danish

Czech

Spanish

Turkish

Portuguese

Type Setup

This setting enables the user to choose the machine type that the DP500 operates in.

lathe

nnill

Generic

There are 3 settings:

Press the axis select key next to the ‘X’ axis to cycle through options

Note: When set to lathe the x axis changes to diameter measurement

There are 14 language settings:

Note: When set to lathe or mill some functions are automatically turned off

Note: Other languages may be available

espanol

9

cesky

a r.

nederlan

pol

Afrikaans

ollandic

Polish

You use the direction setting to match the DP500 to the actual direction of travel of any axis.

There are two settings for each axis and

Example

If the current setting is and the travel is positive from right to left, changing

the setting to will reverse the direction to measure positive from left to right.

Setting Up The Unit

Radius / Diameter (measure Setup)

The radius/diameter function allows the operator to display actual (radius) or twice-actual (diameter)

measurements for each axis.

This function is generally used in turning applications, such as the cross travel on a lathe where you

want to display the diameter reading rather than the radius.

There are two settings for each axis:

dia

rad

Radius

Diameter

Press the axis select key next to the ‘X’, ‘Y’ or ‘Z’ axis to cycle through options

Press the axis select key next to the ‘X’, ‘Y’ or ‘Z’ axis to cycle through options

Direction of Travel Setup

---i i---

---i

i---

10

Other manuals for DP500

2

Table of contents

Other Newall Digital Readout manuals