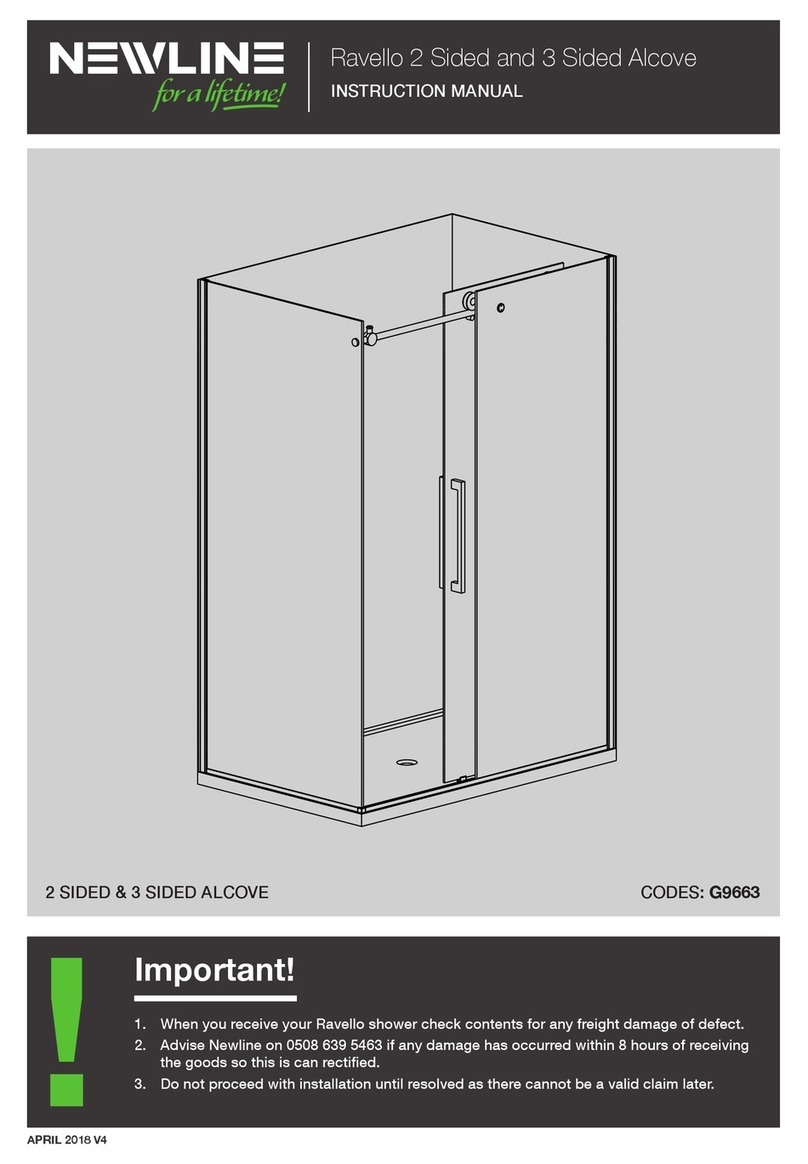

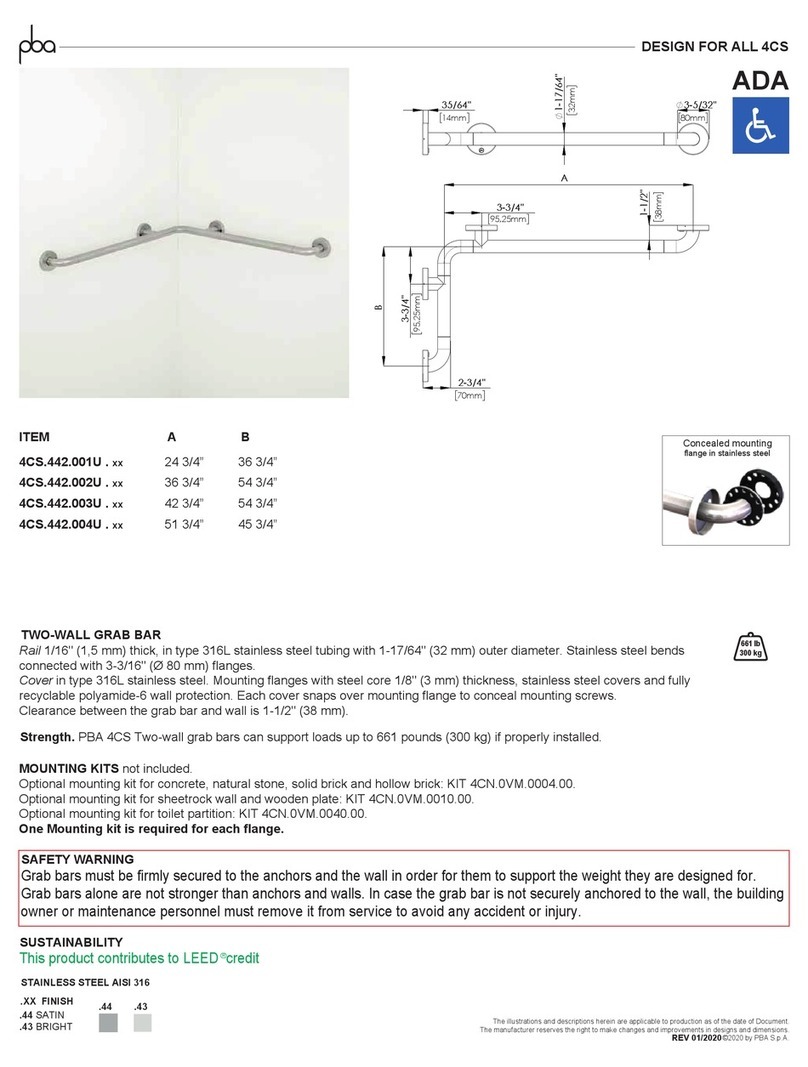

NewLine Ravello User manual

Ravello 2-Sided and 3-Sided Alcove

1. When you receive your Ravello shower check contents for any freight damage or defect.

2. Advise Newline on 0508 639 5463 if any damage has occurred within 8 hours of receiving

the goods so this can be rectied.

3. Do not proceed with installation until resolved as there cannot be a valid claim later.

Important!

INSTRUCTION MANUAL

2-SIDED & 3-SIDED ALCOVE CODES: G9663

JULY 2020

2

WARRANTY

• Faulty goods are covered under warranty. Visit www.newline.nz for warranty information.

• Breakages incurred during installation are not covered under warranty.

• Installations must conform to the instructions to be covered by the warranty.

HEALTH AND SAFETY

Toughened Glass:

• Do not rework pre-cut glass panels. Cutting or altering a glass panel will cause it to explode without warning.

• Unpack all glass assemblies. Stand glass on soft packaging when it is on the oor and against a wall. Care

must be taken not to strike any edge or corner against a hard surface as this will chip and destroy the glass

panel.

Installation:

• Glass panels and assemblies are heavy. Two man lifting is recommended for handling and installation.

• Determine positioning of wiring and piping within wall cavities before shower installation. Mark their positions

to ensure electrical and piping areas are avoided.

• Wear appropriate protective clothing and eye protection during installation.

TOOLS REQUIRED

NEWLINE RECOMMENDS A SKILLED TRADESMAN ACQUAINTED WITH

SHOWER INSTALLATIONS TO ENSURE THE VERY BEST OUTCOME.

IMPORTANT INFORMATION

SUPPLIED MATERIALS

• NG Silicone (Acrylic)

• Bostik V60 (Tile)

• Self Adhesive Blocks

• Nylon Packers

AFTERCARE

• The shower must be squeegeed down after each shower. Thoroughly clean weekly with a microber cloth,

mild detergent and water. Rinse with clean water and squeegee and wiped dry.

Self Adhesive Blocks

Nylon Packers

3

ENSURE YOU TICK THE SPECIFIC BOXES THAT APPLY AS YOU PROGRESS

Floor & Walls: Floor must level with no deection and walls plumb and at.

Ensure tray is level. IMPORTANT! The door rail needs slight fall to close and will be easily attainable if level.

Tray and Liner: Instructions for Tile trays or Acrylic Trays & Liner are supplied with the specic tray ordered.

Frame:

1. Wall Prole Options

Acr yl ic Tray: Centred 20mm off outside of tray edge

Hob Tile Tray: Centred 45mm off nished tile edge (this will allow 32mm off tray before tiling)

Level Entry: Centred at the transition line (where slope begins)

2. Solid xing for Wall Rail Bracket

A 2-Sided is only on the door side adjacent to wall and a 3-sided Alcove is both walls.

Attach a 300mm vertical length of framing on the inside of the wall prole stud starting at the lowest

point of 1780mm off the oor to 2080mm at the top.

3. Solid xings for Wall Mounted Plumbing Fittings

Consult with the plumber.

Wet Grade Lining: Aqualine Gib. or equivalent “must be used behind all shower installations for compliance”

Plumbing: All plumbing ttings/connections must be completed by a registered plumber.

Waterproong “ProFinish Tile Trays”: This must comply with AS/NZS 4858:2004 and be undertaken by

certied applicator and a Producer Statement provided. There is a list of proven systems on our website

www.newline.co.nz

Tiling:

1. A complete system must be used. i.e. Waterproong - Tile Adhesive - Grouting - Silicone. This is for full

accountability and performance requirements.

2. Tiles must conform to gradients of the “ProFinish Tile Tray”. Compliance to NZ Building Code.

3. There must be isolation of the shower enclosure from moisture migration under the tiles. This must align

with AS374 standard using a “Water Stop”.

4. The tile base where the shower is positioned must be level for a satisfactory installation.

PREPARATION CHECKLIST

INDEX

Page 4 Exploded View Diagram & Component List for Part Numbers - 2-Sided Chrome + Black

Page 5 Exploded View Diagram & Component List for Part Numbers - 3-Sided Alcove Chrome + Black

Page 6 Step 1 Layout Pages - Acrylic 2-Sided

Page 7 Step 1 Layout Pages - Tile 2-Sided

Page 8 Step 1 Layout Pages - Tile 3-Sided Alcove

Page 9 Step 2 Assembly of Fixed Front Glass to Floor Prole

Page 10 Steps 3 to 7

4

A

V

B

GH

P

O

C

K

M

U

X

W

QT

S

R

L

D

E

F

N

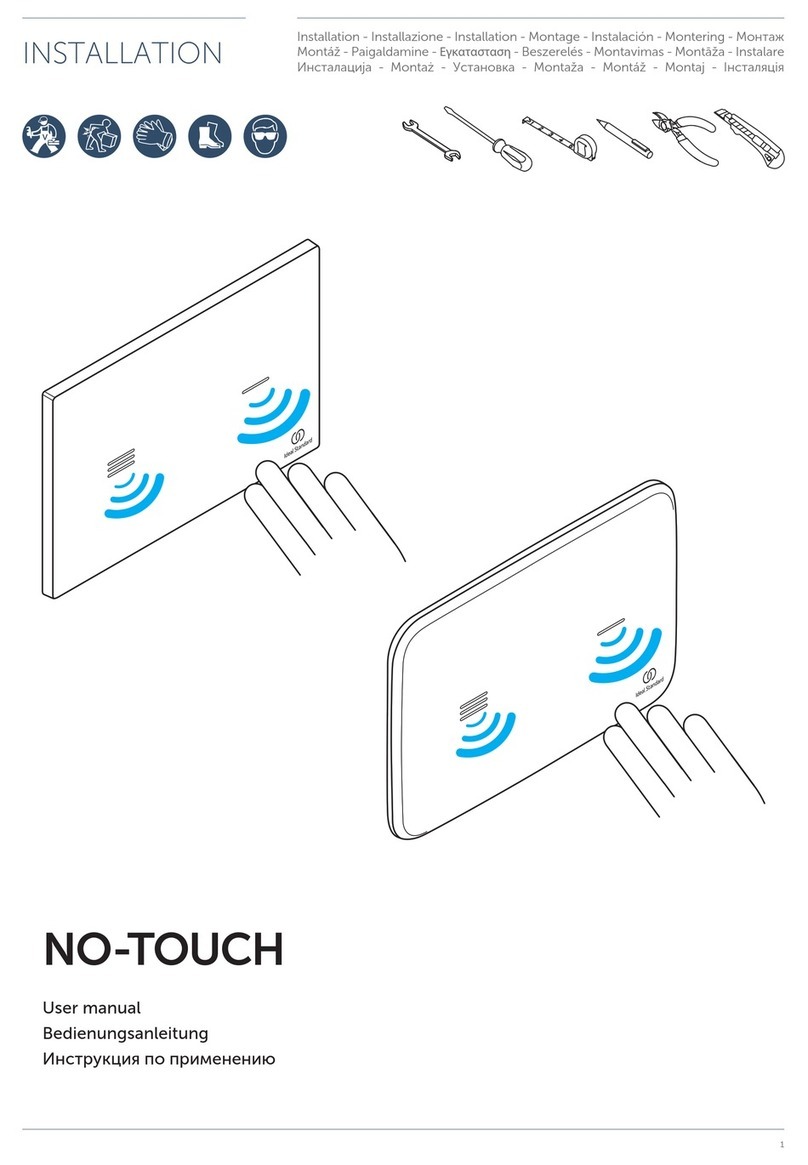

EXPLODED VIEW DIAGRAM & COMPONENT LIST 2-SIDED CHROME + BLACK

EXPLODED VIEW

COMPONENT LIST - CHROME + BLACK

CODE PART CHROME BLACK QTY CODE PART CHROME BLACK QTY CODE PART CHROME BLACK QTY

A Door Handle H5542 H5504 1 I 1 Q Top Door

Rail

1

B Return 1 J Wall Plugs 6 R Door Stops H5634 H5641 2

C Fixed Front

Panel

1 K 6 Gauge x 7 S Door Rollers H5658 H5665 2

D Door Panel E3845 E3845 1 L 6 Gauge x 7 T Door Lock

Knobs

H5610 H5627 2

EFloor Prole

Door Set

1 M Screw

Cover Caps

7 U Deector

Seals

I6112 I6112 2

FFloor Prole

Seal

1 N Lower Door

Guide

H5252 H9953 1 V Buffer Seal I6105 I6105 1

GFloor Prole

Corner Clip

Set

H6294 H6300 2 O Fixed Glass

Rail Bracket

H7239 H7246 2 W Rail Mount

(Wall End)

H7253 H7260 1

HProle

Cover Strip

A1542 A1573 1 P Rail End

Cap

1 X Wall Proles A6751 A6799 2

Fastening Kit

F4163

F4230

5

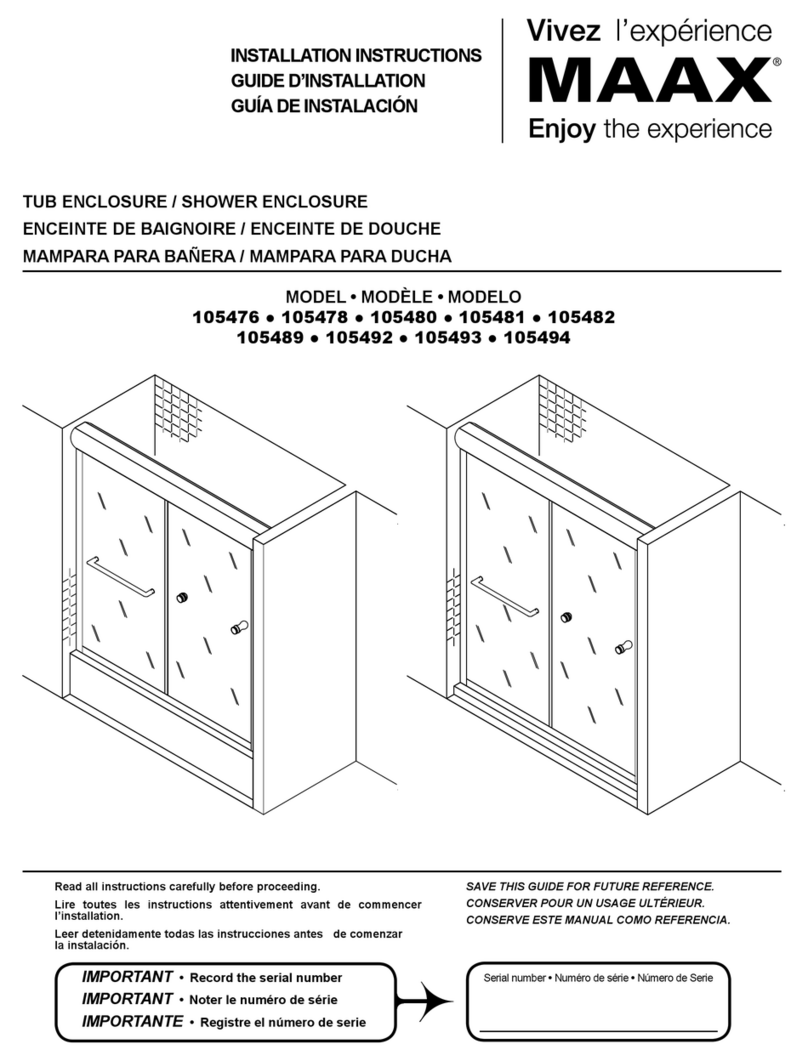

EXPLODED VIEW DIAGRAM & COMPONENT LIST 3-SIDED CHROME + BLACK

EXPLODED VIEW

A

V

H

O

C

K

M

U

X

QT

S

R

W

W

L

D

E

F

N

COMPONENT LIST - CHROME + BLACK

CODE PART CHROME BLACK QTY CODE PART CHROME BLACK QTY CODE PART CHROME BLACK QTY

A Door Handle H5542 H5504 1 I 1 Q Top Door

Rail

1

J Wall Plugs

x 4

6 R Door Stops H5634 H5641 2

C Fixed Front

Panel

1 K 6 Gauge x

Drive

7 S Door Rollers H5658 H5665 2

D Door Panel E3845 E3845 1 L 6 Gauge x

Drive

7 T Door Lock

Knobs

H5610 H5627 2

EFloor Prole

Door Set

1 M 7 U Deector

Seals

I6112 I6112 2

FFloor Prole N Lower Door

Guide Set

H5252 H9953 1 V Buffer Seal I6105 I6105 1

G O Fixed Glass

Rail Bracket

H7239 H7246 2 W Rail Mount

(Wall End)

H7253 H7260 1

H X Wall Proles A6751 A6799 2

Fastening Kit

F4163

F4230

6

INSTALLATION ACRYLIC 2-SIDED LAYOUT

STEP 1 ACRYLIC

• Mark the two wall proles 19mm back from the outside edge of the tray.

• Use the minimum to maximum table to check this lay-out and adjust if required .

• Predrill the wall proles, align to wall markings and drill a 2mm lead hole in the liner.

• Silicone the back of wall prole and screw in place.

• All details of component assembly can be followed from Step 2, Page 9.

19mm in from

outside edge

Door Rail Mounting

Wall Position

Minimum to Maximum

Door Return

1160 to1172mm 879 to 891mm

92mm

1. Drill a 3mm lead hole in liner ll

with silicone.

2. IMPORTANT! The slot in the

base plate provides adjustment

for slight fall of the top rail to

closing. Up to increase and down

to reduce fall.

3. Fasten mounting plate in position.

7

INSTALLATION TILE 2-SIDED LAYOUT

STEP 1 TILE

• Identify your installation measurement from the table below. Mark outside line of wall proles.

The base proles being 2mm inside this (dotted lines).

• Bond wall proles as outlined in the “Penetration of Waterproong” below.

• Component assembly follows from Step 2, Page 9.

MINIMUM TO MAXIMUM TABLE - WALL TO OUTSIDE OF WALL CHANNEL

ProFinish Tray Size (Before Tiling) Door Set Return Panel

1200x915 1160 to 1172 879 to 891

1200x1000 1160 to 1172 964 to 976

PENETRATION OF WATERPROOFING UNDER TILES

Waterproong warranties are potentially void with penetrations of membrane. Bond wall proles with Bostik V60.

Minimum curing 24 hours (2mm to 3mm). Curing is by atmospheric moisture absorption (approx. 7mm in 7 days).

92mm

Door Rail Mounting

Wall Position

1. Drill a clearance hole in tile, clean

out and ll with silicone.

2. IMPORTANT! The slot in the

base plate provides adjustment

for slight fall of the top rail to

closing. Up to increase and down

to reduce fall.

3. Fasten mounting plate in position.

8

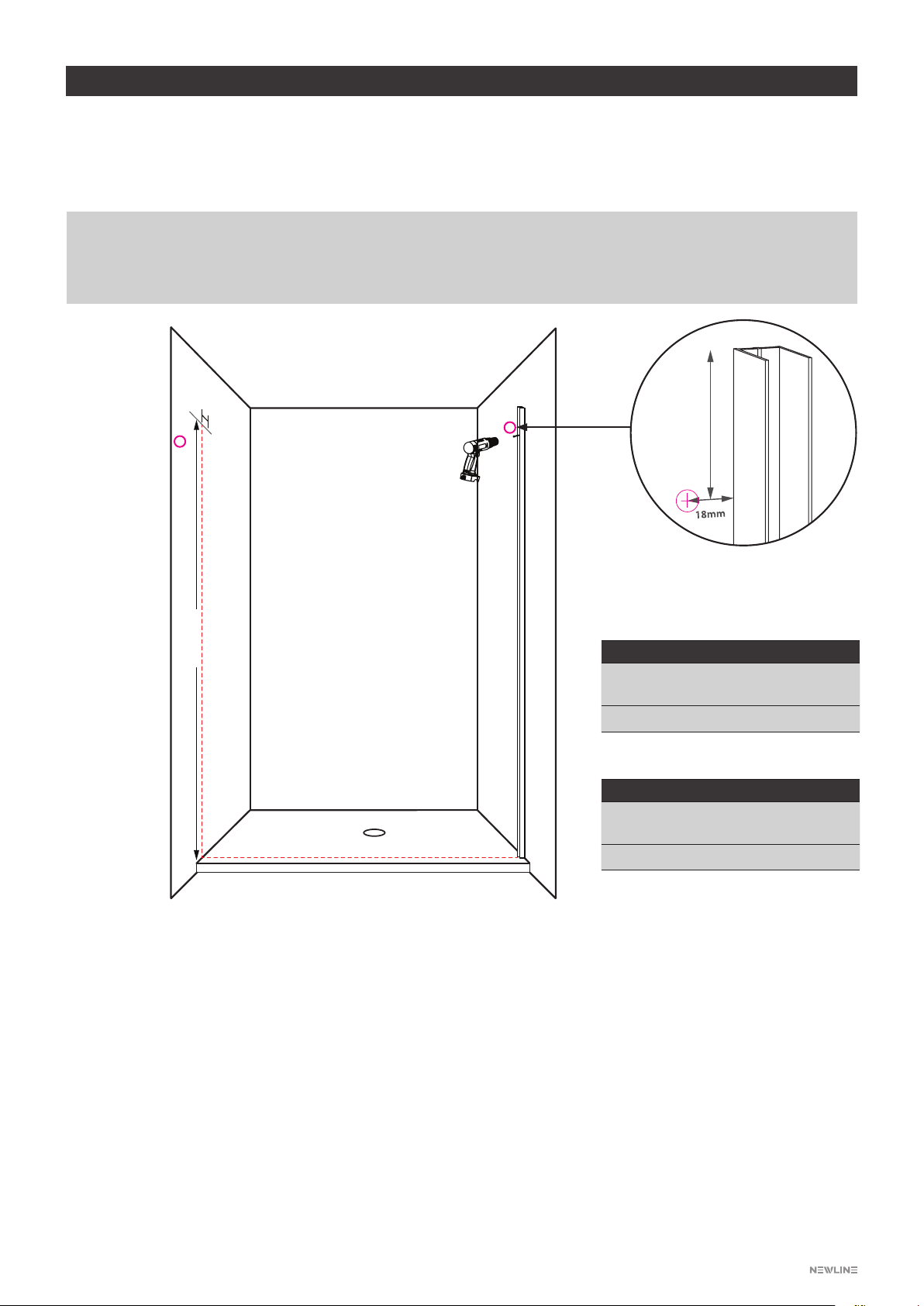

INSTALLATION 3-SIDED ALCOVE LAYOUT

This Diagram covers Acrylic and Tile installations and guidance.

• Acrylic Tray: Positioning the wall prole 20mm off edge of the tray.

• Tile Tray Level Entry: Locate at transition centreline where the slope starts.

• Tray with Hob: Position the boundary line 35mm back from outside of nished hob.

1906mm

37mm

All other installation steps can be now be followed in the instruction steps eliminating the return panel details.

Steps below are distinct to 3-Sided Alcove applications:

Steps run in Conjuction with the 2-Sided instructions.

1. Mark outer boundary line (dotted) across the base and up each wall and the positioning of top rail mounting base

plates on both walls as diagram.

2. Fit wall prole to boundary line (xed glass side only). Fasten as acrylic or tile details on page 6 or 7.

3. Door Rail Mounting: Refer to page 6 for acrylic and page 7 for tile details. IMPORTANT! In the 3-sided alcove

adjustment of rail height requires a slight fall to door shut position.

4. Assemble the rail with stops and rail mount tubes both sides. Attach mounting tubes to base plates on wall. Don’t

fully tighten allen screws onto rail until step 8.

5. Place the xed glass in wall channel.

6. Line up xed glass hole to rail and and install bracket.

7. Plumb up the glass, t to wall prole and screw in place.

8. Finally tighten up the allen key screws in mounting tubes to lock the top rail in place.

These are condensed steps. All other installation steps can now be followed in the instructions eliminating the

return panel details.

MINIMUM TO MAXIMUM TABLE

ProFinish Tray Size

(Before Tiling)

Door Set

1200W x 1000D 1168 to 1180

MINIMUM TO MAXIMUM TABLE

Acrylic Tray Size Door Set

1200W x 915D 1168 to 1180

PENETRATION OF WATERPROOFING UNDER TILES

Waterproong warranties are potentially void with penetrations of membrane. Bond wall proles with Bostik V60.

Minimum curing 24 hours (2mm to 3mm). Curing is by atmospheric moisture absorption (approx. 7mm in 7 days).

92mm

Top Door Rail Mounting

Position

Tile Tray & Walls

Acrylic Tray & Liner

9

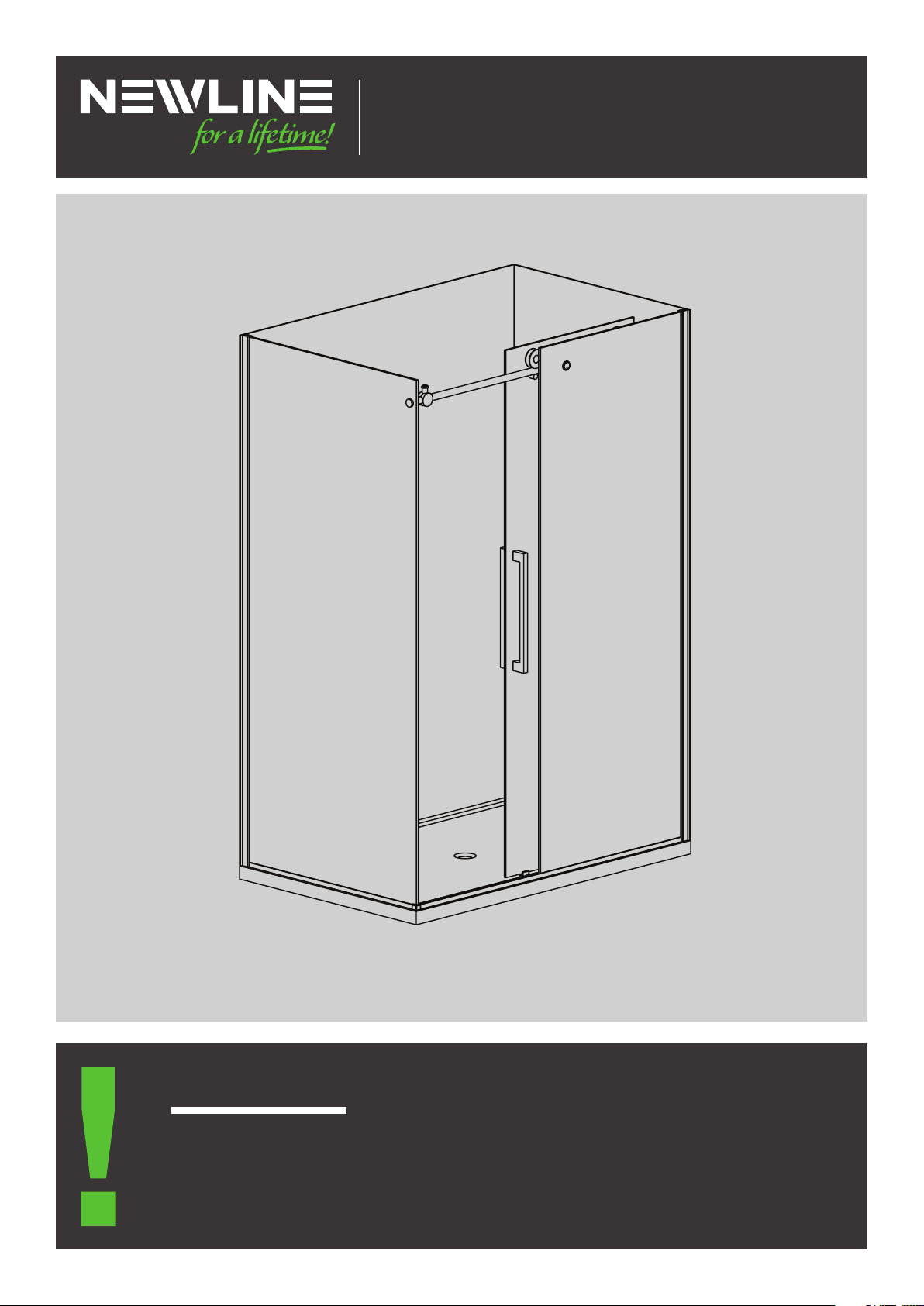

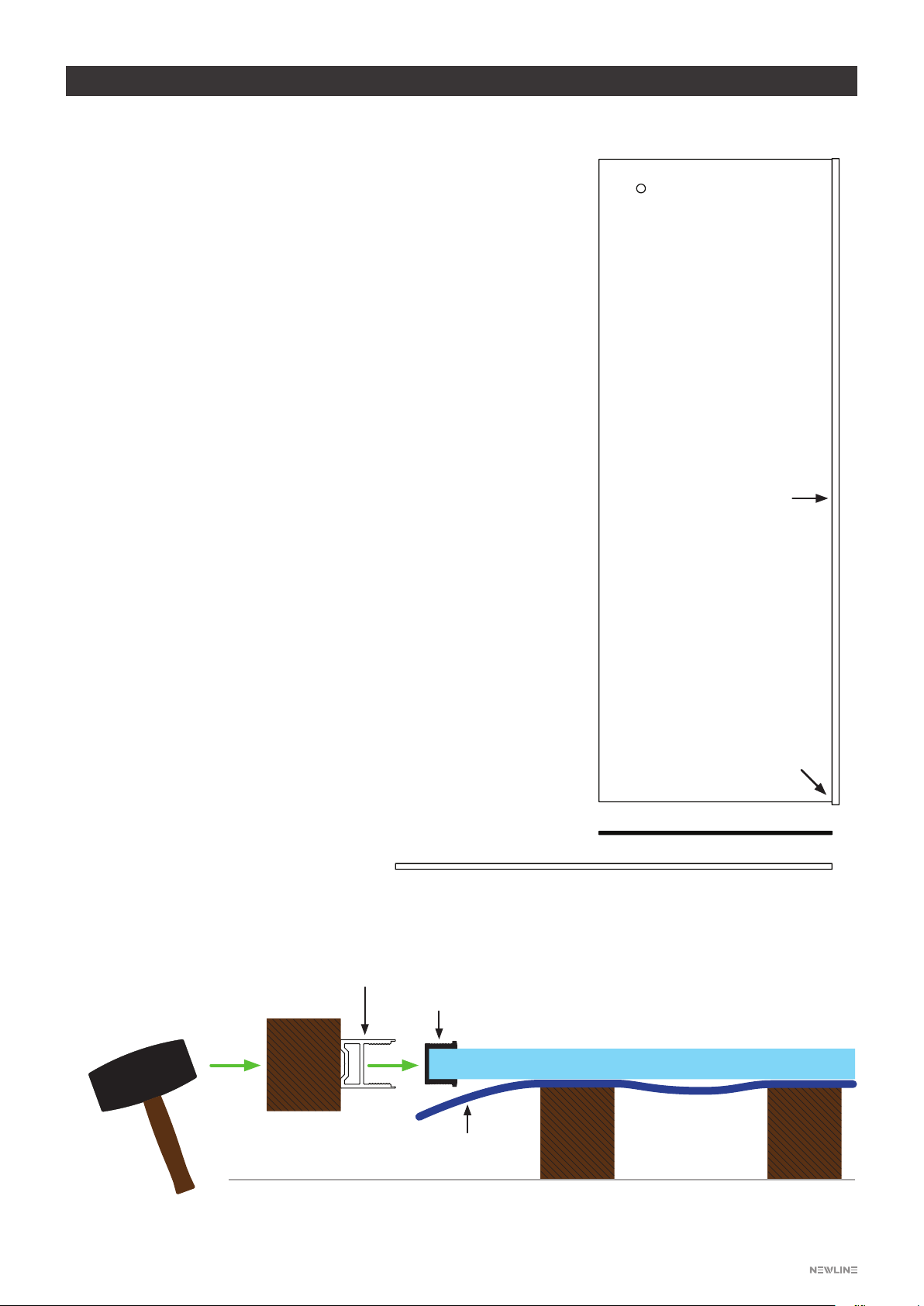

INSTALLATION TILE & ACRYLIC

Diagram A

Wood

Block

Support Support

Rubber Mallet

Floor prole

Seal

Soft protection layer

Fixed Glass Panel

Fixed Front Glass

Knock-on Seal

Floor Profile

Vertical prole

Joint oor to

vertical proles

STEP 2

The fixed glass requires the floor profile with knock-on

seal attached.

Find the three components as drawing

1. Fixed front glass

2. Knock-on seal

3. Floor prole

Assembly Steps:

• Place xed glass onto suitable support with protection

layer as Diagram A.

• Trim the “Knock-on Seal” to length, apply small bead of

NG silicone to leading end and position on glass and join

to vertical prole.

• Ensure there is also a small amount of silicone at join to

seal behind prole in next step.

• Place the oor prole onto seal and push in place

making sure, it is tight against the vertical prole.

• Firmly knock on the oor prole using a short length of

wood working across until fully seated.

• Finish by placing two small beads of silicone underneath

each side of prole join. Clean up excess silicone.

10

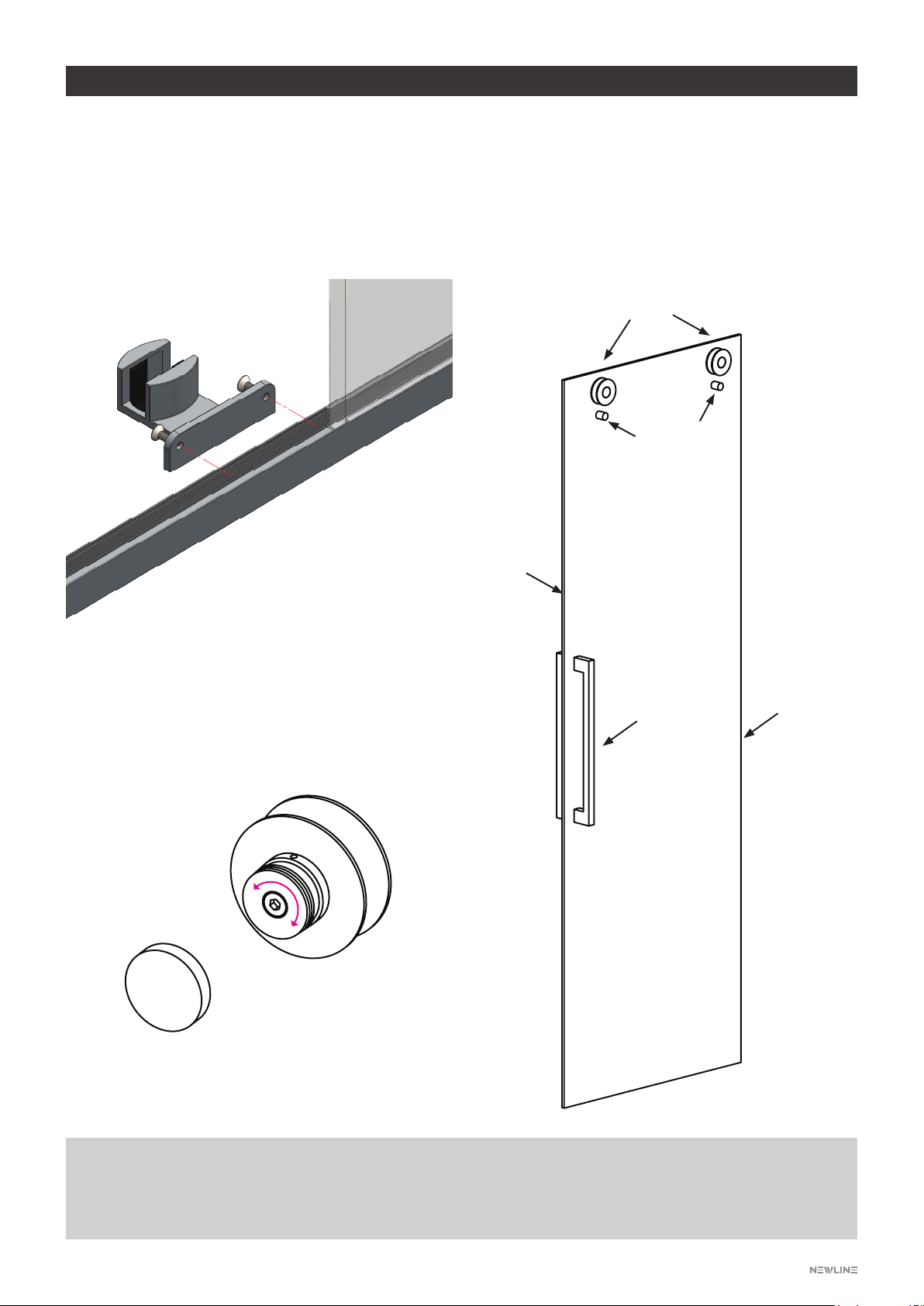

INSTALLATION TILE & ACRYLIC

D1

D2

• IMPORTANT! Check the rail has a slight fall down

towards the outside of door. D2 (there is adjustment

in the base plate slot of the rail mounting).

STEP 4

Diagram C1

Diagram D1

• Assemble the door top rail complete with stops

each end and wall mount tube.

• Mounting top rail to return panel, xed front panel

and wall mounting.

STEP 3

Rail mounting

attached to wall

(Align as layout

page 7)

Diagram C2 Corner Clip

• Assemble both xed glass panels and install corner clip to bottom rail.

• Align to wall proles and tray edge.

• Tape position of inside and out of corner.

• Lift corner, support with 5mm packer, apply silicone under oor proles at corner.

• Lower to tape position, clean excess silicone, remove tape and hold with self-adhesive blocks.

CAUTION:

Fit return glass and xed front glass progressively into the wall proles. Horizontal scratches will show on the

glass prole if tting requires shifting out.

DOOR LINE

RETURN

RETURN

DOOR LINE

Cut-out is only

on return panel

Be sure you select the right clip for your corner.

Of the two options provided only one will work.

CORNER CLIPS

IMPORTANT!

11

INSTALLATION TILE & ACRYLIC

Diagram E

• Note: Rubber insert in the guide must be removed

and turned to 8mm glass adjustment. Insert tightly

back in place.

• Secure door guide to oor prole.

• Caution: The screw closest to the glass needs a

5mm clearance.

Diagram G

• Rotate cam door adjustment from inside (take

weight of door when adjusting).

Diagram F

• Assembly all parts to door.

• Fit door on top rail and into lower guide.

• Adjust cams to height and alignment.

• Fit lock knobs to door panel.

Rollers

Front Buffer Seal

Handle

Deector Seal

Cut 1860mm high

Lock Knobs

(Fit after door is in

place)

STEP 5

PLEASE NOTE:

If the door line is not parallel to the tray the wall mounted rail bracket can offer some adjustment in or out to

correct this.

12

INSTALLATION TILE & ACRYLIC

Diagram H

• Fasten the shower to wall proles with three 3.5 x 12mm screws and check all ttings are tight (Diagram H).

• Adjust door stops. Ensure the door has a clearance of 25mm at wall and closing to return glass is also

restrained by stop (Diagram I).

Diagram J

• Apply silicone seal to dotted line as indicated.

• Leave for 24 Hrs to cure.

STEP 6

STEP 7

150MM

150MM

Diagram H Diagram I

150MM

150MM

CONTACT

Freephone: 0508 639 5463 Phone: 09 444 2053

Adjust back of

door no closer than

25mm to wall

25mm

Other manuals for Ravello

1

Table of contents

Other NewLine Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

Signature Hardware

Signature Hardware BERWYN 953657 quick start guide

Samo

Samo B7980 Assembly instruction

Luxier

Luxier SP25-CEC quick start guide

Caroma

Caroma ELVIRE installation instructions

IB RUBINETTI

IB RUBINETTI Industria 394 Fitting instructions

Triton

Triton DENE HI-FLO Installation and operating instructions