Newport ZVR Series User manual

In egra ed

Ver ical and Ro a ion S ages

for Wafer Posi ioning

ZVR Series

USER’SMANUAL

G

U

A

R

A

N

T

E

E

D

S

P

E

C

I

F

I

C

A

T

I

O

N

S

EDH0316En1031 — 11/18 ii

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

Warranty

Newpor Corpora ion warran s his produc o be free from defec s in

ma erial and workmanship for a period of 1 year from he da e of

shipmen . If found o be defec ive during he warran y period, he produc

will ei her be repaired or replaced a Newpor ’s discre ion.

To exercise his warran y, wri e or call your local Newpor represen a ive,

or con ac Newpor headquar ers in Irvine, California. You will be given

promp assis ance and re urn ins ruc ions. Send he ins rumen ,

ranspor a ion prepaid, o he indica ed service facili y. Repairs will be

made and he ins rumen re urned, ranspor a ion prepaid. Repaired

produc s are warran ed for he balance of he original warran y period, or

a leas 90 days.

Limitation of Warranty

This warran y does no apply o defec s resul ing from modifica ion or

misuse of any produc or par .

This warrant is in lieu of all other warranties, expressed or implied,

including an implied warrant of merchantabilit or fitness for a

particular use. Newport Corporation shall not be liable for an indirect,

special, or consequential damages.

b Newport Corporation, Irvine, CA. All rights reserved.

Original instructions.

No part of this document ma be reproduced or copied without the prior

written approval of Newport Corporation. This document is provided for

information onl , and product specifications are subject to change without

notice. An change will be reflected in future publishings.

CAUTION

Warran y does no apply o damages resul ing from:

• Incorrec usage:

– Load on he s age grea er han maximum specified load.

– Carriage speed higher han specified speed.

–Improper grounding.

¬ Connec ors mus be properly secured.

¬ When he load on he s age represen s an elec rical risk, i mus

be connec ed o ground.

– Excessive or improper can ilever loads.

• Modifica ion of he s age or any par hereof.

CAUTION

Please ret rn eq ipment in

the original (or eq ivalent)

packing.

Yo will be responsible for

damage inc rred from

inadeq ate packaging if the

original packaging is not

sed.

© 2018

iii EDH0316En1031 — 11/18

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

able of Contents

Warranty .................................................................................................................ii

EC Declaration of Conformity...............................................................................v

Definitions and Symbols.......................................................................................vi

Warnings ...............................................................................................................vii

Caution .................................................................................................................viii

1.0 — Introduction.................................................................................1

2.0 — Description ...................................................................................2

2.1 Design Details ............................................................................................2

3.0 — Characteristics............................................................................3

3.1 Definitions..................................................................................................3

3.2 echanical Specifications .......................................................................4

3.3 Load Specification Definitions.................................................................4

3.4 Load Characteristics and Stiffness .........................................................5

3.5 Stage Weights ............................................................................................5

4.0 — Drives and Motors ....................................................................5

4.1 Stepper Drive Axes ...................................................................................5

4.2 DC-Servo Drive Axis ..................................................................................6

4.3 Sensor Position..........................................................................................6

4.4 Feedback Signal Position .........................................................................7

4.5 Pinouts........................................................................................................7

4.6 CAB-3 Cable ............................................................................................8

5.0 — Connection to Newport Controllers................................9

5.1 Warnings on Controllers ..........................................................................9

5.2 Connection...............................................................................................10

5.3 Cables .......................................................................................................10

5.4 SCABLE-3 Cable....................................................................................10

6.0 — Connection to Non-Newport Electronics ....................11

6.1 Connections.............................................................................................11

7.0 — Disabling Limit Switches of the Rotation Axis.........12

EDH0316En1031 — 11/18 iv

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

8.0 — Dimensions.................................................................................13

8.1 ZVR-PP Stage............................................................................................13

8.2 ZVR-PC Stage ...........................................................................................14

9.0 — Maintenance ..............................................................................15

9.1 aintenance ............................................................................................15

9.2 Repair .......................................................................................................15

9.3 Calibration ...............................................................................................15

Service Form .........................................................................................................17

v EDH0316En1031 — 11/18

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

ZVR Series

EU Declaration of Conformity

following Annex II-1A

of Directive 2006/42/EC on machinery

The manufacturer:

MICRO-CONTROLE Spectra-Physics,

9, rue du Bois Sauvage

91055 Évry CEDEX, FRANCE

Hereby declares that the machinery:

yDescription: " ZVR"

yFunction: Integrated Vertical and Rotation Stage for Wafer Positioning

yModels: ZVR-PC/-PP

– the technical file of which was compiled by:

Mr Hervé LE COINTE , Quality Director,

MICRO-CONTROLE Spectra-Physics, Zone Industrielle - B.P.29

F-45340 Beaune La Rolande France

– complies with all the relevant provisions of the Directive 2006/42/EC on machinery.

– complies with all the relevant provisions of the Directive 2014/30/EU relating to electro-

magnetic compatibility.

– complies with all the relevant provisions of the Directive 2011/65/EU relating to RoHS2.

– was designed and built in accordance with the following harmonised standards:

yNF EN 61326-1:2013 « Electrical equipment for measurement, control and

laboratory use – EMC requirements – Part 1: General requirements »

yNF EN 55011:2010/A1:2011 Class A

– was designed and built in accordance with the following other standards:

yNF EN 61000-4-2

yNF EN 61000-4-3

yNF EN 61000-4-4

yNF EN 61000-4-5

yNF EN 61000-4-6

ORIGINAL DECLARATION

Done in Beaune La Rolande on 16 May 2017

Hervé LE COINTE

Quality Director

DC1-EN rev:A

EC Declaration of Conformity

EDH0316En1031 — 11/18 vi

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

Definitions and Symbols

The following erms and symbols are used in his documen a ion and also

appear on he produc where safe y-rela ed issues occur.

General Warning or Caution

The exclama ion symbol may appear in warning and cau ion ables in his

documen . This symbol designa es an area where personal injury or

damage o he equipmen is possible.

The following are defini ions of he Warnings, Cau ions and No es ha may

be used in his manual o call a en ion o impor an informa ion regarding

personal safe y, safe y and preserva ion of he equipmen , or impor an

ips.

WAR N IN G

Warning indicate a potentially dangerou ituation which can re ult in

bodily harm or death.

CAUTION

Caution indicate a potentially hazardou ituation which can re ult in

damage to product or equipment.

NOTE

Note indicate additional information that mu t be con idered by the

u er or operator.

European Union CE Mark

The presence of he CE Mark on Newpor Corpora ion equipmen means

ha i has been designed, es ed and cer ified as complying wi h all

applicable European Union (CE) regula ions and recommenda ions.

Warning and Caution

ATTENTION

Thi tage i a Cla A device. In a re idential environment, thi device

can cau e electromagnetic interference. In thi ca e, uitable mea ure

mu t be taken by the u er.

vii EDH0316En1031 — 11/18

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

Warnings

WARNING

The motion of objects of all types carries potential risks for operators.

Ensure the protection of operators by prohibiting access to the dangerous

area and by informing the personnel of the potential risks involved.

WAR N IN G

D n t use this stage when its m t r is emitting sm ke r is unusually

h t t the t uch r is emitting any unusual d r r n ise r is in any

ther abn rmal state.

St p using the stage immediately, switch ff the m t r p wer and then

disc nnect the electr nics p wer supply.

After checking that sm ke is n l nger being emitted c ntact y ur

Newp rt service facility and request repairs. Never attempt t repair the

stage y urself as this can be danger us.

WAR N IN G

Make sure that this stage is n t exp sed t m isture and that liquid d es

n t get int the stage.

Nevertheless, if any liquid has entered the stage, switch ff the m t r

p wer and then disc nnect the electr nics fr m p wer supply.

C ntact y ur Newp rt service facility and request repairs.

WAR N IN G

D n t insert r dr p bjects int this stage, this may cause an electric

sh ck, r l ck the drive.

D n t use this stage if any f reign bjects have entered the stage.

Switch ff the m t r p wer and then disc nnect the electr nics p wer

supply.

C ntact y ur Newp rt service facility f r repairs.

WAR N IN G

D n t place this stage in unstable l cati ns such as n a w bbly table r

sl ping surface, where it may fall r tip ver and cause injury.

If this stage has been dr pped r the case has been damaged, switch ff

the m t r p wer and then disc nnect the electr nics p wer supply.

C ntact y ur Newp rt service facility and request repairs.

WAR N IN G

D n t attempt t m dify this stage; this may cause an electric sh ck r

d wngrade its perf rmance.

WAR N IN G

D n t exceed the usable depth indicated n the m unting h les (see

secti n “Dimensi ns”). L nger screws can damage the mechanics r

cause a sh rt-circuit.

EDH0316En1031 — 11/18 viii

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

Caution

CAUTION

Do not place this stage in a hostile environment such as X-Rays, har

UV,… or in any vacuum environment.

CAUTION

Do not place this stage in a location affecte by ust, oil fumes, steam or

high humi ity. This may cause an electric shock.

CAUTION

Do not leave this stage in places subject to extremely high temperatures

or low temperatures. This may cause an electric shock.

• Operating temperature: +10 to +35 °C

• Storage temperature: -10 to +40 °C (in its original packaging)

CAUTION

Do not move this stage if its motor power is on.

Make sure that the cable to the electronics is isconnecte before

moving the stage. Failure to o so may amage the cable an cause an

electrical shock.

CAUTION

Be careful that the stage is not bumpe when it is being carrie . This

may cause it to malfunction.

CAUTION

When han ling this stage, always unplug the equipment from the power

source for safety.

CAUTION

When the carriage is in its en -of-run position, it is strongly recommen e

not to go beyon this point as this may amage the stage mechanism.

CAUTION

Contact your Newport service facility to request cleaning an

specification control every year.

1 EDH0316En1031 — 11/18

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

In egra ed Ver ical and Ro a ion S ages

for Wafer Posi ioning

ZVR Series

1.0 —Introduction

This manual provides operating instructions for the ZVR series stages:

ZVR stage.

RECOMMENDA ION

We recommend you read carefully the chapter “Connection to

electronics” before using the ZVR stage.

• ZVR-PC

(Stepper motor vertical, DC rotation)

• ZVR-PP

(Stepper motor vertical and rotation)

EDH0316En1031 — 11/18 2

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

2.0 —Description

Newport’s new ZVR stages are integrated vertical and rotation positioning

stages designed primarily to precisely elevate and rotate wafer chucks,

and other samples or objects that would require adjustments to align the

object's orientation or to focus. These applications are not limited to

inspection or laser machining.

The ZVR's design takes the unconventional approach of most vertical

(elevation) stage designs on the market today. The payload is supported

and driven at three points (separated by 120 degrees) along the outer

circumference of the stage. Ordinary designs use a single cam, wedge, or

screw located at the centre of the stage. Newport’s three point design

benefits applications that have slight to extreme unbalanced loading such

as wafer probing which can impart vertical forces at locations along the

outer edges of the chuck. Angular deflections due to these off-centre loads

are minimized and binding during vertical motion is eliminated. The ZVR’s

unique design also permits convenient height and tip/tilt adjustment, and

allows the centre of the stage to remain open through the bottom plate,

important for routing utilities to the wafer chuck. The clear aperture with

the integrated rotary stage is 50 mm in diameter.

Guiding the stage through its vertical trajectory are three miniature, ultra-

quiet, recirculating bearing guides. Like the drive screws that actuate

vertically, these three guides are located 120 degrees apart and are in-line

with the drive screws. The upper limit switch has a 4 mm adjustment

range enabling the user to set the upper limit of travel. The ZVR stages are

equipped with a hardware origin that serves as an absolute reference

(home) position.

For optimum performance and compatibility, use the Newport family of

controllers for these devices. The ZVR stages are ESP compatible allowing

the user to take advantage of Newport’s smart-stage features when used

with Newport controllers. Each stage axis is supplied with a 3-meter,

shielded cable with 25-pin sub-D connectors for direct connection to a

Newport motion controller (XPS, ESP301, S C100) or other OE motion

controller and driver.

2.1 Design Details

Base Material Aluminum and Stainless Steel

Bearings Stainless steel ball bearing

Drive Mechanism Vertical: 3 ballscrews with 1 mm pitch.

Rotation: Self-compensating, preloaded, precision worm gear with 1÷90 ratio

Reduction Gear ZVR-PC: Belt reduction 16÷44

Feedback ZVR-PC: 8,000 cts/rev. rotary encoder

Feedback (Vertical) ZVR-PP, ZVR-PC: Optional linear encoder 0.1 µm

Limit Switches Optical

±165° (Limit switches can be disabled)

Origin Centered on both rotation and vertical movements

Cable 3-meter, shielded cable

MTBF 20,000 hours

3 EDH0316En1031 — 11/18

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

3.0 —Characteristics

3.1 Definitions

Specificatio s of our products are established i refere ce to ISO 230

sta dard part II “Determi atio of accuracy a d repeatability of

positio i g umerically co trolled axes”.

This sta dard gives the defi itio of positio u certai ty which depe ds

o the 3 followi g parameters:

Absolute Accuracy

Differe ce betwee ideal positio a d real positio .

Accuracy

Differe ce betwee ideal positio a d real positio after the compe satio

of li ear errors.

Li ear errors i clude: cosi e errors, i accuracy of screw or li ear scale

pitch, a gular deviatio at the measuri g poi t (Abbe error) a d thermal

expa sio effects. All Newport motio electro ics ca compe sate for

li ear errors.

The relatio betwee absolute accuracy a d o -axis accuracy is as follows:

Absolute Accuracy = Accuracy + Correction Factor xTravel

Repeatability

Ability of a system to achieve a comma ded positio over ma y attempts.

Reversal Value (Hysteresis)

Differe ce betwee actual positio values obtai ed for a give target

positio whe approached from opposite directio s.

Minimum Incremental Motion (MIM or Sensitivity)

The smallest i creme t of motio a device is capable of deliveri g

co siste tly a d reliably.

Resolution

The smallest i creme t that a motio device ca theoretically move

a d/or detect. Resolutio is ot achievable, whereas MIM, is the real

output of a motio system.

Eccentricity

Displacement of the geometric center of a rotation stage from the rotation

axis in the plane defined by bearings.

Wobble

Tilt of rotation axis during rotation of a stage, measured on a reference

surface.

The testing of accuracy, repeatability, and reversal error are made

systematically with test e uipment in controlled environment (20 ±1 °C).

A linear cycle with 21 data points on the travel and 4 cycles in each

direction gives a total of 168 points.

G

EDH0316En1031 — 11/18 4

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

3.2 Mechanical Specifications

CAU ION

o reach specifications stated, stages must be fixed on a plane surface

with a flatness of 50 µm.

3.3 Load Specification Definitions

Normal Load Capacity (Cz)

aximum load a rotation stage can move while maintaining specifications.

This value is given with speed and acceleration specified for each rotation

stage, and with a load perpendicular to the bearings.

Off-Centered Load (Q)

aximum cantilever-load a rotation stage can move: Q ≤ Cz ÷ (1 + D/a)

D: Cantilever distance.

a: Construction parameter.

G

U

A

R

A

N

T

E

E

D

S

P

E

C

I

F

I

C

A

T

I

O

N

S

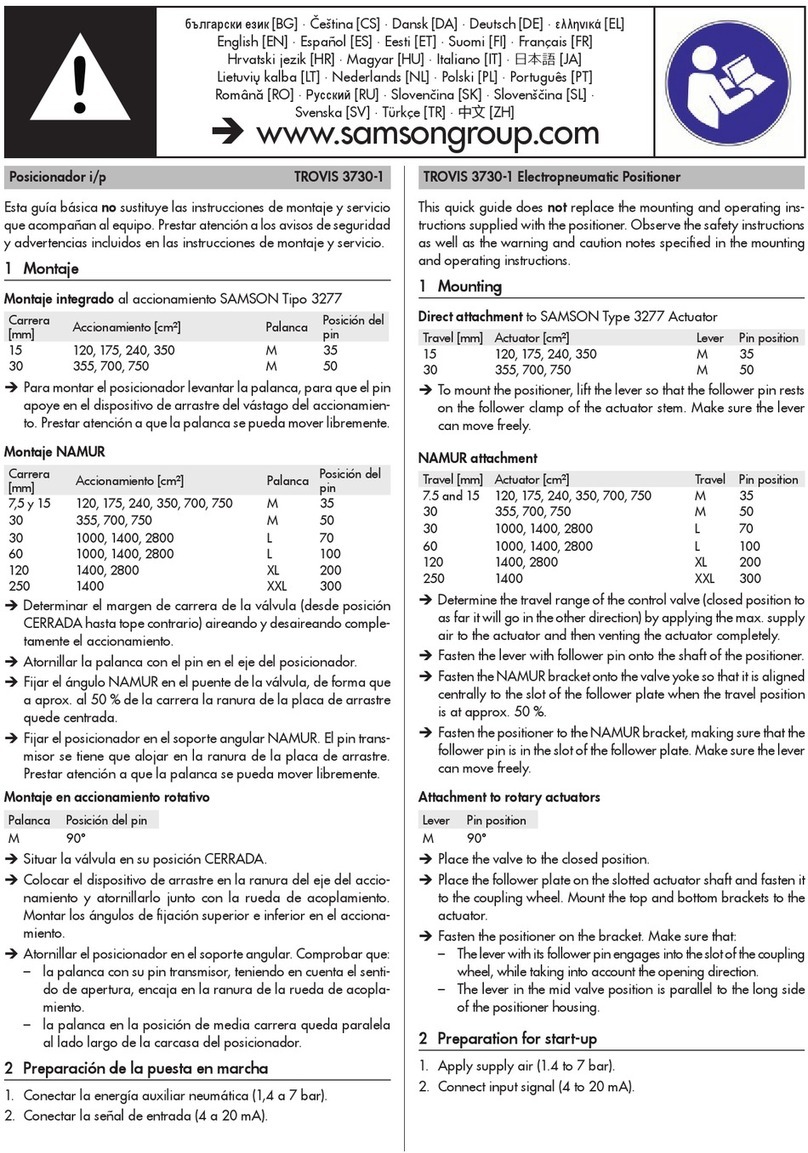

Theta Rotatio Stage Specificatio s ZVR-PP ZVR-PC

Travel Range (°) ±165 or continuous 360

Minimum Incremental Motion (1) (°) 0.0002 0.002

Accuracy (3), Typical (Guaranteed) (°) ±10 (±17) ±10 (±15)

Unidirectional Repeatability (3), Typical (Guaranteed) (°) ±0.001 (±0.0015) ±0.0005 (±0.0015)

Bidirectional Repeatability (3), Typical (Guaranteed) (°) ±0.003 (±0.006) ±0.0013 (±0.003)

Max. Speed (°/s) 40 80

Wobble (3), Typical (Guaranteed) (µrad) ±22 (±40)

Eccentricity (3), Typical (Guaranteed) (µm) ±2.2 (±4)

Z Vertical Stage Specificatio s

Travel (mm) 10

Minimum Incremental Motion (1) (µm) 0.5

Accuracy (3), Open Loop, Typical (Guaranteed) (µm) ±0.5 (±2)

Unidirectional Repeatability (3), Open Loop, Typical (Guaranteed) (µm) ±0.4 (±2)

Bidirectional Repeatability (3), Open Loop, Typical (Guaranteed) (µm) ±1.2 (±2)

XY Cross Talk (2), Typical (µm) ±0.1

Max. Speed (mm/s) 10

Pitch, Yaw (3)(4), Typical (Guaranteed) (µrad) ±17 (±35)

1)Depends on controller, see www.newport.co for ore infor ation.

2) XY deviation when Z direction of otion is reversed.

3)For the definition of Typical and Guaranteed specifications see “Motion Basics Ter inology & Standards” Tutorial

at www.newport.co

4)To obtain arcsec units, divide µrad value by 4.8.

Guaranteed and Typical Specifications

Guaranteed maximum performance values are verified per Newport's A167

metrology test procedure. For more information, please consult the

metrology tutorial section in the Newport catalog or at www.newport.com

5 EDH0316En1031 — 11/18

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

3.4 Load Characteristics and Stiffness

3.5 Stage Weights

The stage weight below does not include the cables.

The weight difference between drive units is not significant.

4.0 —Drives and Motors

4.1 Stepper Drive Axes

The ZVR-PP rotation axis and both ZVR-PP and ZVR-PC vertical axes are

equipped with a stepper motor.

Stepper Motor Performance Specifications and Characteristics

Command Signals for the Stepper Motor

Weight [lb (kg)]

ZVR 9.3 (4.2)

3-meter MSCABLE-3 Cable 0.66 (0.3)

Cz, ormal center load capacity on bearings 100

Mz, ominal torque 1 m

Jz, Max. load inertia 0.050 kg.m2

Q, Off-center load ( ) Q ≤ Cz ÷ (1 + D/40)

Where D = Cantilever distance (mm)

D

Cz

kα

Z

Mz

Q

Resolution Speed Angle y Step RMS Current Resistance Inductance

(°) per Phase (A) (Ω) (mH)

ZVR-PP Rotaio Axis 0.0002° (1) 40 °/s 1.8 0.71 1.7 2.8

ZVR-PP & PC Vertical Axis 50 nm (1) 10 mm/s 1.8 0.5 4.8 4.6

1) When used with an XPS otion controller.

0 2

-1

1

10.5 1.5

Step 1 2 3 4 5 8 7 8

+ Phase 1 + + – – + + – –

– Phase 1 – – + + – – + +

+ Phase 2 – + + – – + + –

– Phase 2 + – – + + – – +

Direction –MOTION +

+ Phase 1

– Phase 1

+ Phase 2

– Phase 2

Direction +

EDH0316En1031 — 11/18 6

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

4.2 DC-Servo Drive Axis

The ZVR-PC rotation axis is equipped with a DC-motor.

DC-Motor Performance Specifications and Characteristics

Command Signals for the DC-Motors

In the above drawings, + otor signal is referenced to – otor signal.

➀When the stage moves in + Direction, the + otor voltage is higher than

– otor voltage.

➁When the stage moves in – Direction, the + otor voltage is lower than

– otor voltage.

4.3 Sensor Position

End-of-Run and echanical Zero are 5 V open collector type.

The Index Pulse provides a repeatable Home Position at ±1 step.

CAU ION

“End-of-Run” and “Mechanical Zero” are active signals and should not

be connected to any other source.

Resolution Speed Nominal Max RMS Max. Peak Resistance Inductance Tachometer

(°) (°/s) Voltage (V) Current (A) Current (A) (Ω) (mH) Const. (V/krpm)

ZVR-PC Rotaio Axis 0.002 (1) 80 48 0.9 1.8 2.58 0.52 –

1) When used with an XPS otion controller.

Direction +

+V

+ Motor

– Motor –V

MOTION Direction +

MOTIONDirection –

– EOR Limit

Mechanical

Zero

Stage Travel Range

Index Pulse

Index Pulse

+EOR Limit

Home Position (Origin)

at Center of Travel Range

Direction – MOTION Direction +

7 EDH0316En1031 — 11/18

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

4.4 Feedback Signal Position

The incremental sensor consists of an optical scale and an encoder head.

When the carriage moves, the encoder head generates square signals in

quadrature and sends to pins #19, #20, #23 and #24 of the SUB-D25

connector.

“Encoder” and “Index Pulse” are “differential pair” (type RS-422) type

output signals. Using these signals permits a high immunity to noise.

Emission circuits generally used by Newport are 26LS31 or C3487.

Reception circuits to use are 26LS32 or C3486.

4.5 Pinouts

The pinout diagrams for the ZVR stages SUB-D15 connectors are shown

below.

Direction +

0

1

Encoder

Phase A

0

1

Encoder

Phase A

1234

0

1

Encoder

Phase B

0

1

Encoder

Phase B

Direction – MOTION Direction +

SUD-D25 OR SUB-D15

Encoder Phase A 19 13

Encoder Phase A 23 6

Encoder Phase B 20 14

Encoder Phase B 24 7

Index Pulse Phase I 15 15

Index Pulse Phase I 25 8

21 12

22 5

NEWPORT

STAGE USER

CONNECTOR PIN #

Output Signals

Encoders

& Sensors

Power Supply

+5 V 5%

150 mA max.

0 V

}

8

15

91

ZVR-PP

(Rotatio Axis)

1 + Phase 1

2 + Phase 2

3 Mechanical Zero

4 – End-of-Run

5 0 V

6 N.C.

7 N.C.

8 N.C.

9 – Phase 1

10 – Phase 2

11 + End-of-Run

12 +5 V

13 N.C.

14 N.C.

15 N.C.

ZVR-PP & ZVR-PC

(Vertical Axis)

1 + Phase 1

2 + Phase 2

3 Mechanical Zero

4 – End-of-Run

5 0 V

6 N.C.

7 N.C.

8 N.C.

9 – Phase 1

10 – Phase 2

11 + End-of-Run

12 +5 V

13 N.C.

14 N.C.

15 N.C.

ZVR-PC

(Rotatio Axis)

1 N.C.

2 + Motor

3 Mechanical Zero

4 – End-of-Run

5 0 V

6 Encoder Phase /A

7 Encoder Phase /B

8 Index Pulse /I

9 N.C.

10 – Motor

11 + End-of-Run

12 +5 V

13 Encoder Phase A

14 Encoder Phase B

15 Index Pulse I

EDH0316En1031 — 11/18 8

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

4.6 MCAB-3 Cable

Two 3-meter CAB-3 cables are supplied with each ZVR stage (see section

5.3: ”Cables”).

CONNECTED

TO THE CAP

CONNECTED

TO THE CAP

SUB-D25M

CONNECTOR

1

2

3

4

5

6

7

8

14

22

21

16

19

23

20

24

15

25

17

18

13

SUB-D25F

CONNECTOR

1

2

3

4

5

6

7

8

14

22

21

16

19

23

20

24

15

25

17

18

13

(0.6 MM2) WHITE 1

(0.6 MM2)WHITE 2

(0.6 MM2) WHITE 3

(0.6 MM2) WHITE 4

(0.6 MM2) WHITE 6

(0.6 MM2)WHITE 7

(0.6 MM2) WHITE 8

(0.6 MM2) WHITE 9

(0.6 MM2) WHITE 5

(0.6 MM2) WHITE 10

(0.6 MM2) WHITE 11

(0.6 MM2)WHITE 12

(0.09 MM2) WHITE

(0.09 MM2) BROWN

(0.09 MM2) GREEN

(0.09 MM2)YELLOW

(0.09 MM2) GREY

(0.09 MM2) PINK

(0.09 MM2) BLUE

(0.09 MM2) RED

(0.09 MM2)BLACK

(0.09 MM2) PURPLE

(0.09 MM2) ORANGE

(0.09 MM2) BLUE

(AWG20) WHITE 1

(AWG20) WHITE 2

(AWG20) WHITE 3

(AWG20) WHITE 4

(AWG20) WHITE 6

(AWG20) WHITE 7

(AWG20) WHITE 8

(AWG20) WHITE 9

(AWG20) WHITE 5

(AWG20) WHITE 10

(AWG20) WHITE 11

(AWG20) WHITE 12

(AWG28) WHITE

(AWG28) BROWN

(AWG28) GREEN

(AWG28) YELLOW

(AWG28) GREY

(AWG28) PINK

(AWG28) BLUE

(AWG28) RED

(AWG28) BLACK

(AWG28) PURPLE

(AWG28) ORANGE

(AWG28) BLUE

9 EDH0316En1031 — 11/18

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

5.0 —Connection to Newport Controllers

5.1 Warnings on Controllers

Controllers are intended for use by qualified personnel who recognize

shock hazards and are familiar with safety precautions required to avoid

possible injury. Read the controller user’s manual carefully before

operating the instrument and pay attention to all written warnings and

cautions.

WAR N IN G

Disconnect t e power plug under t e following circumstances:

• If t e power cord or any attac ed cables are frayed or damaged in

any way.

• If t e power plug is damaged in any way.

• If t e unit is exposed to rain, excessive moisture, or liquids are spilled

on t e unit.

• If t e unit as been dropped or t e case is damaged.

• If you suspect service or repair is required.

• W enever you clean t e electronics unit.

CAUTION

To protect t e unit from damage, be sure to:

• Keep all air vents free of dirt and dust.

• Keep all liquids away from t e unit.

• Do not expose t e unit to excessive moisture (85% umidity).

• Read t is manual before using t e unit for t e first time.

WAR N IN G

All attac ment plug receptacles in t e vicinity of t is unit are to be of

t e grounding type and properly polarized.

Contact your electrician to c eck your receptacles.

WAR N IN G

T is product is equipped wit a 3-wire grounding type plug.

Any interruption of t e grounding connection can create an electric

s ock azard.

If you are unable to insert t e plug into your wall plug receptacle,

contact your electrician to perform t e necessary alterations to ensure

t at t e green (green-yellow) wire is attac ed to eart ground.

WAR N IN G

T is product operates wit voltages t at can be let al.

Pus ing objects of any kind into cabinet slots or oles, or spilling any

liquid on t e product, may touc azardous voltage points or s ort out

parts.

EDH0316En1031 — 11/18 10

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

5.2 Connection

There is a label on every stage indicating its part and serial numbers.

WARNING

Always turn the controller's power OFF before connecting to a stage.

NO E

hese stages are ESP compatible. Enhanced System Performance is

Newport's exclusive technology that enables Newport ESP motion

controllers to recognize the connected Newport ESP stage and upload

the stage parameters. his ensures that the user can operate the motion

system quickly and safely.

5.3 Cables

All ZVR stages are delivered with two MSCABLE-3 3-meter cables with a

SUB-D25 connector for direct connection to Newport Controllers.

5.4 MSCABLE-3 Cable

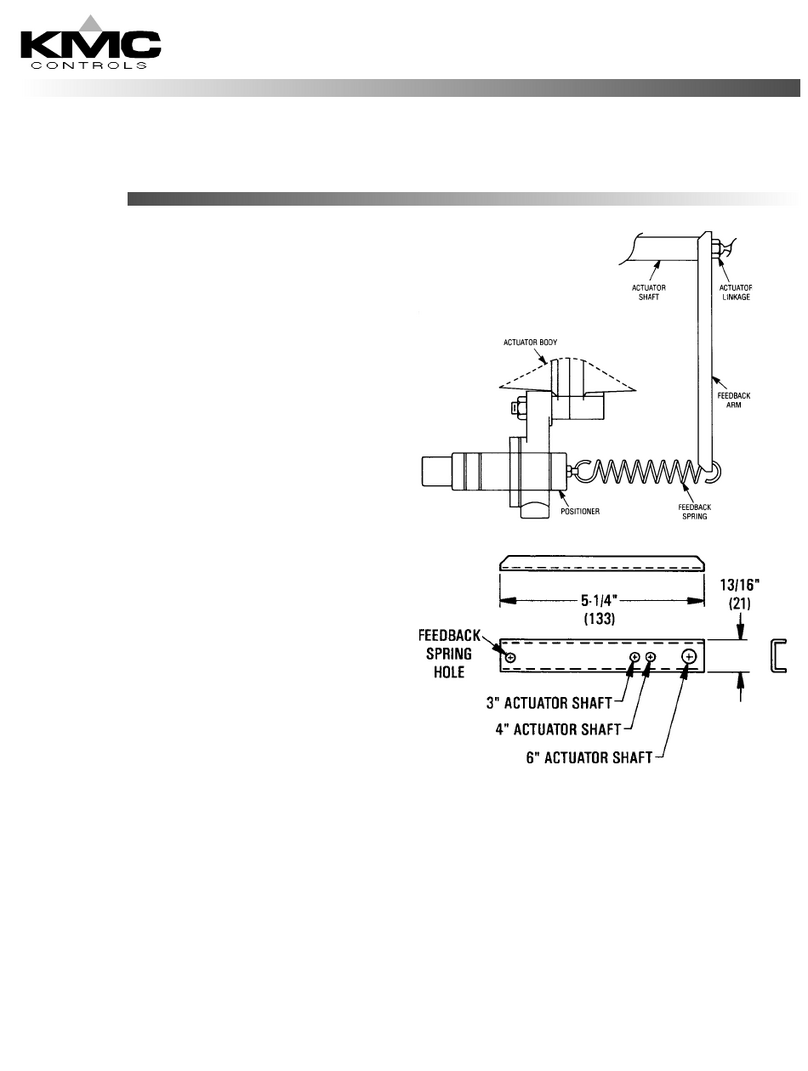

CABLE

CONNECTOR STAGE

BENDING

STATIC CABLE: ≥.94 (24)

CABLE IN MOTION: ≥2.76 (70)

LOCKING

KNOBS

2.24 (57)

DISCONNECTED

ø.24

(6)

SUB-D15 CONNECTOR SHOWN

DIMENSIONS IN INCHES (AND MILLIMETERS)

WAR N IN G

Th s cable s sh elded correctly. For a correct operat on, make sure to

lock connectors (ground cont nu ty prov ded by the cable).

For a lications where the standard 3-meter cable (MSCABLE-3) included

with your stage is not adequate, New ort offers a 10-m longer length cable

(MSCABLE-10) designed to ensure the integrity of your ositioning

a lication.

REMARK

The cross sect on of the MSCAB-10 cable s d fferent from the one of the

MSCABLE-3 cable to allow a longer length. The MSCAB-10 cable has the

same mechan cal propert es as the MCAB-10 cable.

These cables are s ecially shielded and terminated with New ort’s

standard SUB-D15 and SUB-D25 connectors.

WAR N IN G

Keep the motor cables at a safe d stance from other electr cal cables n

your env ronment to avo d potent al cross talk.

11 EDH0316En1031 — 11/18

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

6.0 —Connection to Non-Newport Electronics

6.1 Connections

WARNING

Newport is not responsible for malfunction or damage of ZVR stages

when used with non-Newport controllers.

WARNING

Newport guarantees “”compliance of ZVR stages only if used with

Newport cables and controllers.

It is the customer's responsibility to modify the cable and take care of

sensor signal connections, when using the stage with non-Newport

controllers.

End-of-Runs and Mechanical Zero are open collector type with a 5.6 V

protective Zener diode.

Iinmax.: 16 mA

V max.: 5.25 V

NEWPORT

STAGE

5.6 V

EDH0316En1031 — 11/18 12

ZVR Series In egra ed Ver ical and Ro a ion S ages for Wafer Posi ioning

7.0 —Disabling Limit Switches of the Rotation Axis

The rotation stage of the ZVR is equipped with optical limit switches set to

±165°. These limit switches can be disabled for continuous 360° rotation.

WARNING

he movement of objects of all types carries potential risks for operators.

Ensure the protection of operators by prohibiting access to the dangerous

area and by informing the personnel of the potential risks involved.

NO E

o access and activate or inhibit the limit switches, the Z-stage of the

ZVR must be in its highest position.

Disconnect the ZVR, then set the limit switch as required.

ACTIVED LIMIT SWITCHES:

±165° TRAVEL

INHIBITED LIMIT SWITCHES:

CONTINUOUS TRAVEL

This manual suits for next models

2

Table of contents

Other Newport Valve Positioner manuals