Order data

The order data provide an overview of standard configurations.

Please check the availability before ordering. Other configurations available on request.

Note: Pneumatic connecting components (union and compressed air tube) for the connection between the process valve and

positioner are included with each positioner.

Note: A valve specific mounting kit is required for assembly. For designing the mounting kit, the valve type, nominal size, control

function and actuator size must be stated.

Order codes

1 Type Code

2-wire 1441 cPos-X 1441

2 Fieldbus Code

Without 000

HART HAR

3 Accessory Code

Automation product A

4 Action Code

Single acting (fail safe) 1

Double acting (fail safe) 3

Single acting blocking (fail freeze) 5

Double acting blocking (fail freeze) 6

5 Device version Code

Positioner SA2

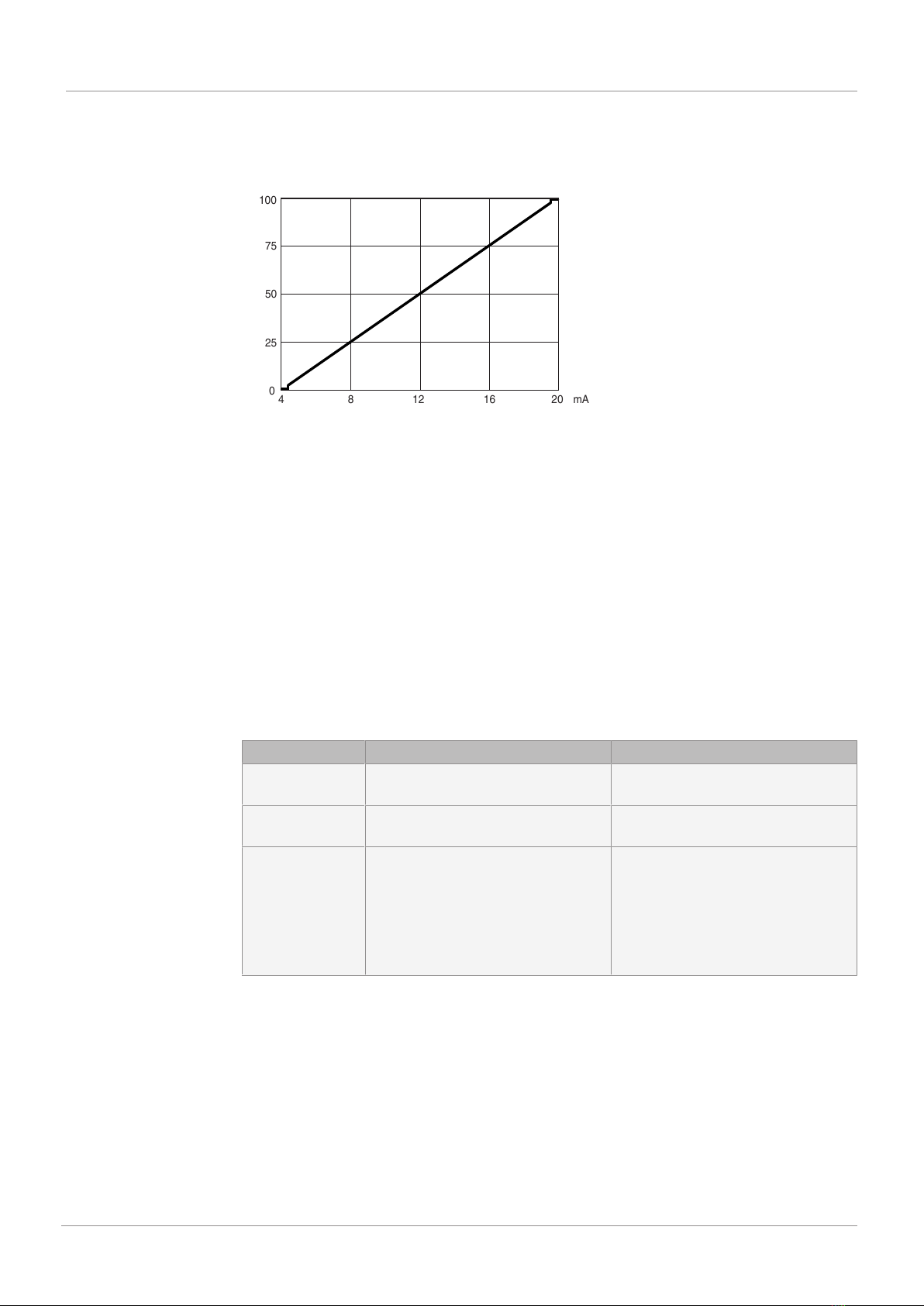

6 Signal type Code

4...20mA A

7 Pneumatic connection Code

G1/8 with 6mm plug-in coupling 3

G1/8 with 1/4" plug-in coupling U

8 Option Code

Analogue output, digital input and output C

9 Electrical connection Code

M12 plug 1

M16 x 1.5 cable gland 2

10 Flow rate Code

115 Nl/min 2

11 Travel sensor version Code

Potentiometer, 75 mm length 075

Remote potentiometer,

M12 connector

S01

12 Type of design Code

Without

Media wetted area cleaned to ensure suitability for paint

applications, parts sealed in plastic bag

0101

Inversed direction,

for quarter turn valves control function NO (2)

6960

13 CONEXO Code

Integrated RFID chip for electronic identification and

traceability

C

Order example

Ordering option Code Description

1 Type 1441 2-wire 1441 cPos-X

2 Fieldbus HAR HART

3 Accessory A Automation product

4 Action 1 Single acting (fail safe)

5 Device version SA2 Positioner

6 Signal type A 4...20mA

7 Pneumatic connection 3 G1/8 with 6mm plug-in coupling

8 Option C Analogue output, digital input and output

9 Electrical connection 1 M12 plug

10 Flow rate 2 115 Nl/min

11 Travel sensor version 075 Potentiometer, 75 mm length

12 Type of design Without

13 CONEXO C Integrated RFID chip for electronic identification and traceability

Order data

GEMÜ 1441

www.gemu-group.com 5 / 19