SMAR HART FY500 Owner's manual

FY500 HART – Operation, Maintenance, and Installation Manual

III

GENERAL

This operation and maintenance instruction manual provides installation, operating, calibration, and

maintenance information for the FY500.

The FY500 must only be installed, operated, and maintained by qualified personnel with fully trained

in field equipment installation.

For additional assistance or if there is any question concerning the instructions, contact SMAR.

Modifying this product, substituting non-factory parts, or using maintenance procedures other than

outlined could drastically affect performance and be hazardous to personnel and equipment, and

may void existing warranties.

NOTE

This manual is compatible with version 1.XX, where 1 indicates software version and XX

software release. The indication 1.XX means that this manual is compatible with any release of

software version 1.

SAFETY TERMS

To avoid personal injury or property damage, WARNING and CAUTION notes must be strictly

followed. Always follow the standard industry safety practices and cautions when working on this or

any process control product.

Refer to the appropriate instruction for hazardous area.

WARNING

Throughout the operation of the positioner, including self setup, do not touch the moving parts of

the valve/actuator/positioner set as they may unexpectedly move.

Do not remove FY500 from the valve while the valve is still pressurized. Make sure to disc

onnect

the electric power, control signal, or air supply before touching any moving parts.

Check with the

process or safety engineer for any additional measures that must be taken to

protect the process.

UNPACKING AND STORAGE

Although Smar takes steps to prevent damage in transport, such damage is possible and must be

discovered and reported before installing the FY500. Do not install the positioner that has been

damaged in transport or during storage.

FY500 HART – Operation, Maintenance, and Installation Manual

IV

Waiver of responsibility

The contents of this manual abides by the hardware and software used on the current equipment

version. Eventually there may occur divergencies between this manual and the equipment. The

information from this document are periodically reviewed and the necessary or identified corrections

will be included in the following editions. Suggestions for their improvement are welcome.

Warning

For more objectivity and clarity, this manual does not contain all the detailed information on the

product and, in addition, it does not cover every possible mounting, operation or maintenance

cases.

Before installing and utilizing the equipment, check if the model of the acquired equipment complies

with the technical requirements for the application. This checking is the user’s responsibility.

If the user needs more information, or on the event of specific problems not specified or treated in

this manual, the information should be sought from Smar. Furthermore, the user recognizes that the

contents of this manual by no means modify past or present agreements, confirmation or judicial

relationship, in whole or in part.

All of Smar’s obligation result from the purchasing agreement signed between the parties, which

includes the complete and sole valid warranty term. Contractual clauses related to the warranty are

not limited nor extended by virtue of the technical information contained in this manual.

Only qualified personnel are allowed to participate in the activities of mounting, electrical connection,

startup and maintenance of the equipment. Qualified personnel are understood to be the persons

familiar with the mounting, electrical connection, startup and operation of the equipment or other

similar apparatus that are technically fit for their work. Smar provides specific training to instruct and

qualify such professionals. However, each country must comply with the local safety procedures,

legal provisions and regulations for the mounting and operation of electrical installations, as well as

with the laws and regulations on classified areas, such as intrinsic safety, explosion proof, increased

safety and instrumented safety systems, among others.

The user is responsible for the incorrect or inadequate handling of equipments run with pneumatic

or hydraulic pressure or, still, subject to corrosive, aggressive or combustible products, since their

utilization may cause severe bodily harm and/or material damages.

The field equipment referred to in this manual, when acquired for classified or hazardous areas, has

its certification void when having its parts replaced or interchanged without functional and approval

tests by Smar or any of Smar authorized dealers, which are the competent companies for certifying

that the equipment in its entirety meets the applicable standards and regulations. The same is true

when converting the equipment of a communication protocol to another. In this case, it is necessary

sending the equipment to Smar or any of its authorized dealer. Moreover, the certificates are

different and the user is responsible for their correct use.

Always respect the instructions provided in the Manual. Smar is not responsible for any losses

and/or damages resulting from the inadequate use of its equipments. It is the user’s responsibility to

know and apply the safety practices in his country.

V

TABLE OF CONTENTS

SECTION 1 - INSTALLATION ...................................................................................................................1.1

SAFETY INSTRUCTIONS ...........................................................................................................................................1.1

MOUNTING..................................................................................................................................................................1.1

QUARTER TURN ROTARY ACTUATORS ......................................................................................................................... 1.2

LINEAR ACTUATOR........................................................................................................................................................... 1.7

PNEUMATIC CONNECTIONS ..................................................................................................................................1.13

DIMENSIONAL DRAWINGS......................................................................................................................................1.15

ELECTRICAL WIRING...............................................................................................................................................1.16

4 – 20 MA LOOP CONNECTIONS.................................................................................................................................... 1.16

TEST CONNECTIONS..................................................................................................................................................... .1.17

COMMUNICATION CONNECTIONS ................................................................................................................................ 1.18

FEEDBACK CONNECTIONS............................................................................................................................................ 1.18

ELECTRONIC HOUSING ROTATION ......................................................................................................................1.19

CHANGING THE DISPLAY POSITION .....................................................................................................................1.20

SPLIT-RANGE OPERATION ............................................................................................................................................ 1.22

INSTALLATION IN HAZARDOUS AREAS ................................................................................................................1.23

EXPLOSION/FLAME PROOF ........................................................................................................................................... 1.23

INTRINSICALLY SAFE ..................................................................................................................................................... 1.23

SECTION 2 - OPERATION ........................................................................................................................2.1

PRINCIPLE OF OPERATION ......................................................................................................................................2.1

DISPLAY ......................................................................................................................................................................2.2

SECTION 3 - TECHNICAL CHARACTERISTICS ......................................................................................3.1

FUNCTIONAL SPECIFICATIONS ...............................................................................................................................3.1

PERFORMANCE SPECIFICATIONS ..........................................................................................................................3.2

PHYSICAL SPECIFICATIONS ....................................................................................................................................3.2

ORDERING CODE ......................................................................................................................................................3.3

SECTION 4 - LOCAL PROGRAMMING ....................................................................................................4.1

LOCAL ADJUSTMENT ................................................................................................................................................4.1

JUMPERS SELECTION...............................................................................................................................................4.2

LOCAL PROGRAMMING TREE..................................................................................................................................4.3

CONFIGURABLE PARAMETERS ...............................................................................................................................4.4

RESTORE FACTORY SETTINGS...............................................................................................................................4.6

SECTION 5 - CONFIGURATION VIA HART®............................................................................................ 5.1

CONFIGURATION RESOURCES ...............................................................................................................................5.1

IDENTIFICATION AND MANUFACTURING DATA.....................................................................................................5.2

MONITORING ..............................................................................................................................................................5.2

DEVICE CONFIGURATION.........................................................................................................................................5.2

ADVANCED CONFIGURATION ..................................................................................................................................5.3

DEVICE MAINTENANCE.............................................................................................................................................5.3

TRIM.............................................................................................................................................................................5.4

AUTOMATIC CONFIGURATION.................................................................................................................................5.4

MULTIDROP CONFIGURATION.................................................................................................................................5.4

FACTORY ....................................................................................................................................................................5.4

SECTION 6 - MAINTENANCE ...................................................................................................................6.1

GENERAL INFORMATION..........................................................................................................................................6.1

CORRECTIVE MAINTENANCE ..................................................................................................................................6.1

PREVENTIVE MAINTENANCE ...................................................................................................................................6.1

DIAGNOSTICS WITHOUT HART INTERFACE ..........................................................................................................6.1

DIAGNOSTICS WITH HART INTERFACE..................................................................................................................6.3

ELECTRONIC HOUSING MODULE............................................................................................................................6.4

REMOVING ELECTRONIC HOUSING MODULE ............................................................................................................... 6.4

REPLACING ELECTRONIC HOUSING MODULE.............................................................................................................. 6.4

FY500 HART – Operation, Maintenance, and Installation Manual

VI

TRANSDUCER MODULE............................................................................................................................................6.5

CONNECTION MODULE .................................................................................................................................................... 6.5

I/P CONVERTER MODULE ................................................................................................................................................ 6.6

DIAPHRAGM MODULE ...................................................................................................................................................... 6.8

PNEUMATIC MODULE ....................................................................................................................................................... 6.8

FEEDBACK MODULE....................................................................................................................................................... 6.10

PACKAGE CONTENT ...............................................................................................................................................6.10

ACCESSORIES .........................................................................................................................................................6.10

EXPLODED VIEW .....................................................................................................................................................6.11

SPARE PARTS LIST .................................................................................................................................................6.12

DETAILED CODE FOR ORDERING SPARE PARTS...............................................................................................6.14

Section 1

1.1

INSTALLATION

Safety Instructions

This entire section should be read before proceeding with the installation.

•Operating limits are stated in section 3, Technical Characteristics, on this manual.

•The positioner must only be installed, operated, and maintained by qualified personnel with fully

trained in field equipment installation.

•Installation in hazardous areas must be in accordance with IEC60079-14 standard.

•Before starting any assembly or disassembly of the actuator/positioner set, the electrical supply

and pneumatic supply must be removed. The actuator line must also be emptied. Stay away from

moving parts to avoid serious injury.

•When test cycling the actuator and valve assembly by applying pressure to the pneumatic port, be

aware that there are moving parts can cause serious injuries.

•The positioner requires instrument air quality, following the best practices for pneumatic

installations. Consult the American National Standard "Quality Standard for Instrument Air"

(ANSI/ISA S7.0.01 or ISO 8573-1) for detailed information.

•Blow out all piping before connections are made to prevent dirt or debris from entering the

positioner. Do not use sealing tape on pneumatic connections. Liquid sealants are recommended

for the pipe threads.

•In areas subjected to high relative humidity, the O-rings for the electronic housing covers must be

correctly placed and the covers must be completely closed by tighten them by hand until you feel

the O-rings being compressed. Do not use tools to tight the covers. Removal of the electronics

cover in the field should be reduced to the minimum necessary, since each time it is removed; the

circuits are exposed to the humidity.

•The electronic circuit is protected by a humidity proof coating, but frequent exposures to humidity

may affect the protection provided. It is also important to keep the covers tightened in place. Every

time they are removed, the threads are exposed to corrosion, since painting cannot protect these

parts. Sealing methods should be employed on conduit entering of the positioner.

Mounting The FY500 housing is available in NAMUR and VDI/VDE mounting interfaces. It provides direct

mounting to various linear or rotary actuators depending on the actuator mounting method and

threaded connection type.

WARNING

The positioner must only be installed, operated, and maintained by qualified personnel

with fully trained in field equipment installation.

This product ships with plastic plugs in the conduit entries in an effort to protect the internal

components from debris during shipment and handling. Remove plastic plugs only during installation

to prevent the intrusion of debris or moisture.

It is the responsibility of the installer, or end user, to install this product in accordance with the

national or regional code defining proper practices.

FY500 HART –Operation, Maintenance, and Installation Manual

1.2

Figure 1.1 –Linear and rotary assemblies

WARNING

Modifying this product, substituting non-factory parts or using maintenance procedures

other than outlined could drastically affect performance and be hazardous to personnel

and equipment, and may void existing warranties.

On loss of instrument signal, valve will open or close. This identifies whether the valve is fully open

or fully closed when the input is 0%. When the input current is removed, the FY500 output 1 should

drop to zero.

The following procedures are guidelines to NAMUR linear mounting (DIN IEC 60534-6-1) and

NAMUR rotary mounting (VDI/VDE 3845) (DIN EN ISO 5211).

Quarter Turn Rotary Actuators

The FY500 can be mounted in any orientation. The mounting parts kit for the quarter turn actuator

contains a mounting bracket with NAMUR VDI/VDE 3845 (DIN EN ISO 5211) standard mounting

patterns. See figure 1.2 for the different quarter turn rotary actuator sizes.

Section 1 - Installation

1.3

Figure 1.2 –Quarter turn actuator sizes

WARNING

In case of a pneumatic or electrical failure, it is important to know the behavior of the

actuator. Before mounting the positioner on an actuator, the failsafe position and

direction of rotation of the actuator drive shaft should be verified.

WARNING

Before starting any assembly or disassembly of the actuator/positioner set, the electrical

supply and pneumatic supply must be removed. The actuator line must also be emptied.

Stay away from moving parts to avoid serious injury.

1. Visually check to make sure the valve is on the fail-safe position. The normal performance of the

quarter turn rotary actuators is clockwise-to-close and counterclockwise-to-open. However, this may

be inverted under request.

2. Position the rotary actuator to its approximately mid-travel position, using a handwheel or manual

loading regulator.

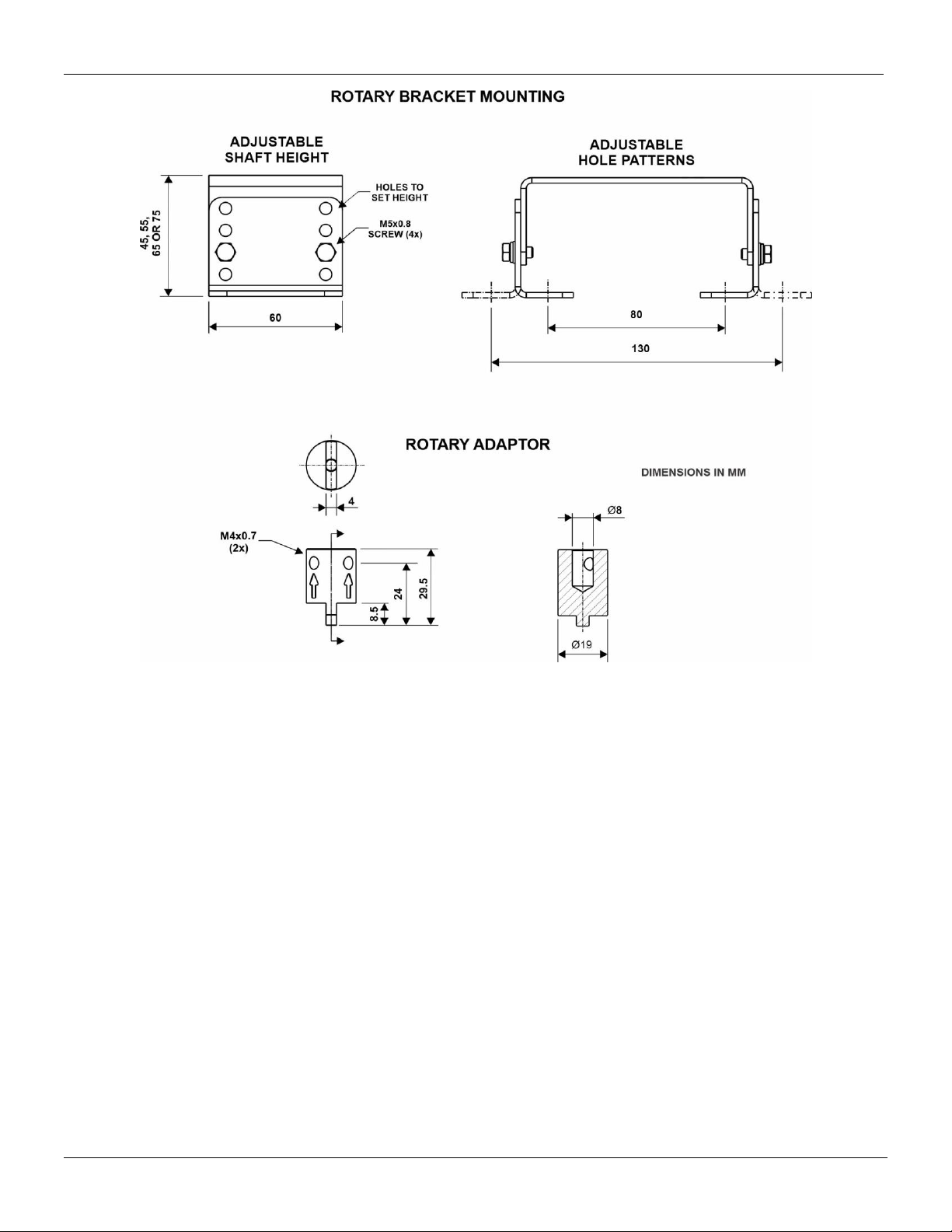

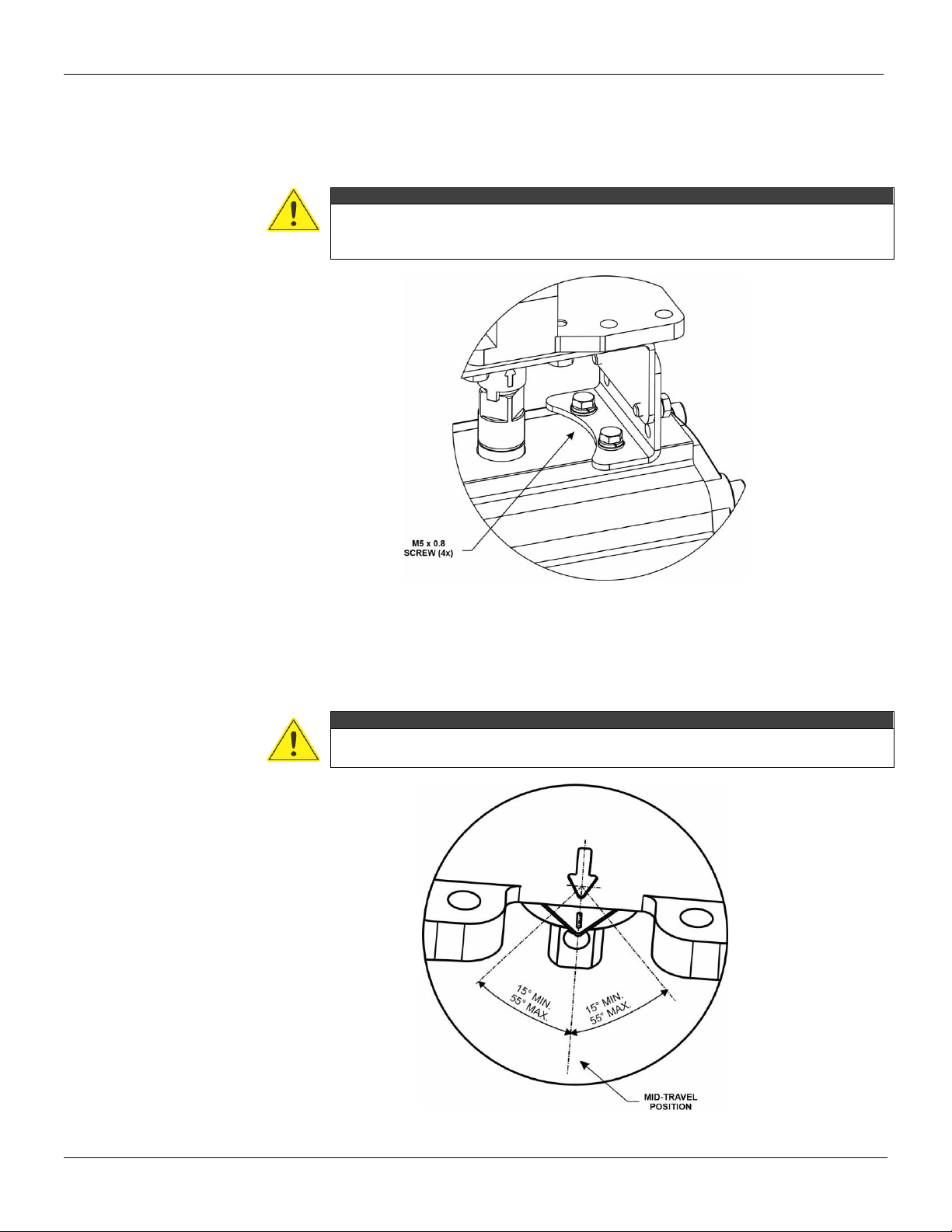

3. The rotary mounting bracket consists of three parts, which can be adjusted to the actuator by

different arrangements. Determine the configuration of the rotary bracket, according to dimensions a

specific actuator size, using four M5 screws, four lock washers, and four flat washers. as shown in

figure 1.3.

TIP

For ease of assembly, attach the L-shaped parts of the mounting bracket only after

installing/screwing the rotary adapter.

FY500 HART –Operation, Maintenance, and Installation Manual

1.4

Figure 1.3 –Rotary mounting bracket configuration

4. Before attaching the mounting bracket, determine the orientation of the FY500. It is ‘’IN-LINE’’ to

actuator mounting when the pneumatic connections are in the same direction as the longitudinal

drive axis of the actuator, or ‘’ACROSS” to actuator mounting when the pneumatic connections are

perpendicular direction as the longitudinal drive axis of the actuator.

5. Position the FY500 on the actuator mounting bracket and secure in place with four M6 x 1 bolts.

See figure 1.4.

Section 1 - Installation

1.5

Figure 1.4 –Positioner assembly orientation relative to actuator axis

6. Fit the rotary adaptor onto the feedback shaft of the FY500 and adjust its position on the actuator

shaft so that the arrow on the actuator lines up with the arrow mark on the back of the FY500

housing. See figure 1.5.

7. Attach the rotary adaptor to the feedback shaft with one M6 x 10 screw, as shown in figure 1.5.

Tighten until the screw fully enters the part.

Figure 1.5 –Rotary adaptor assembly orientation on actuator

8. Install the L-shaped parts of the mounting bracket to the FY500, using M6 screws, if not already

in place.

9. Install the mounting bracket on the actuator with four M5 x 0.8 screws and flat washers. See

figure 1.6. When attaching the FY500 rotary adaptor to the actuator shaft, ensure that the center pin

FY500 HART –Operation, Maintenance, and Installation Manual

1.6

is fully inserted into the actuator shaft and that the mounting bracket conforms to the configuration

shown in figure 1.3.

10. Tighten the mounting bracket screws securely, both those that make it up and those that secure

it to the actuator.

WARNING

After installation on the rotary actuator, check that the positioner feedback shaft, adapter

and actuator shaft are all aligned. This will avoid friction and other mechanical stresses

not designed for parts, increasing their useful life.

Figure 1.6 –Positioner quarter turn rotary actuator mounting

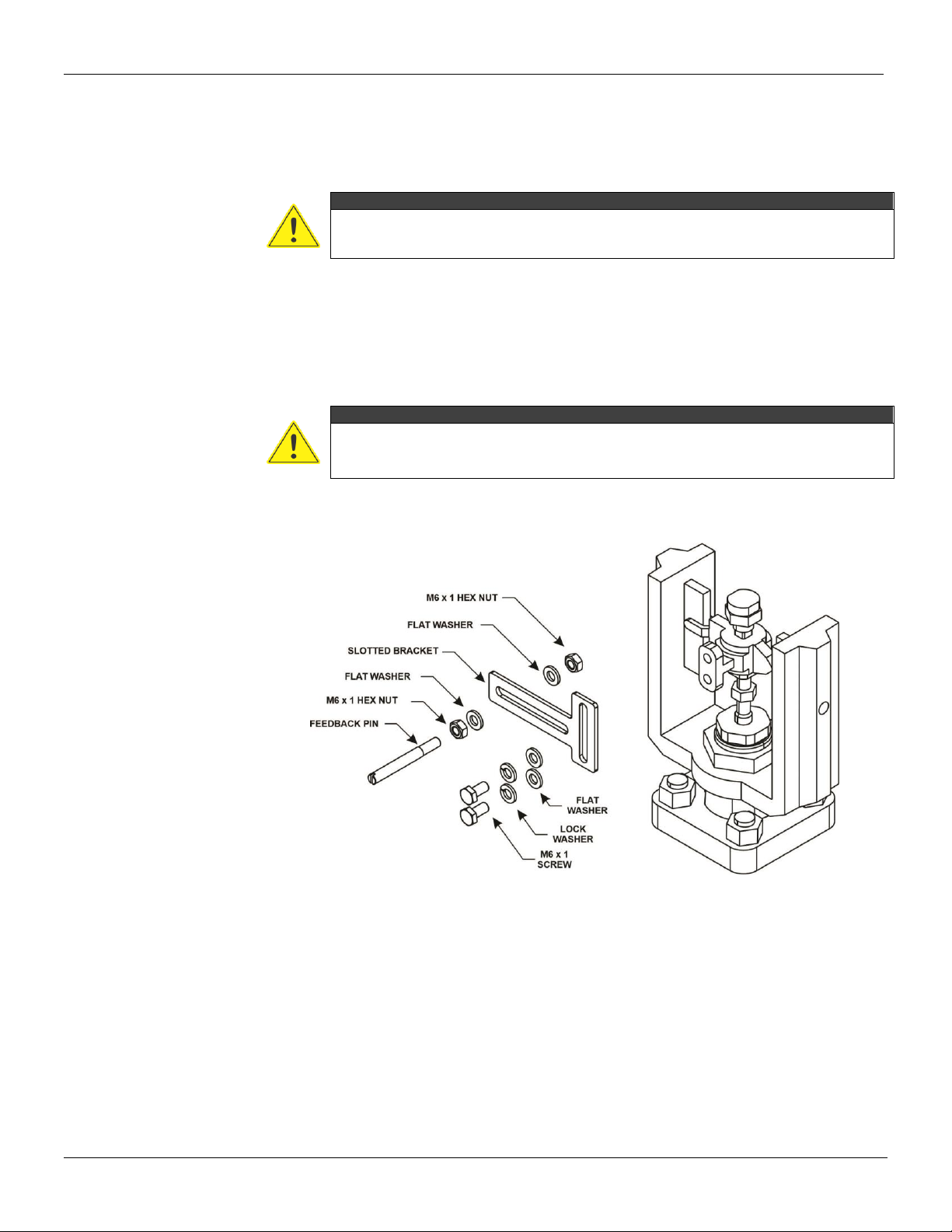

11. With the actuator at its mid-travel position, the travel indicator is aligned with mark arrow of the

housing .

12. Stroke the actuator to each end of its travel. Travel indicator must travel within the admissible

range, as shown in figure 1.7.

WARNING

When test cycling the actuator and valve assembly by applying pressure to the

pneumatic port, be aware that there are moving parts can cause serious injuries.

Figure 1.7 –Admissible range –rotary mounting bracket

Section 1 - Installation

1.7

Linear Actuator

The FY500 can be mounted in any orientation. The mounting parts kit for the linear actuator

contains a mounting bracket with NAMUR/IEC 60534-6-1 standard mounting patterns. Applicable to

actuators with cast yoke (with rib or plane surface design), or pillar yoke for U-bolt application.

WARNING

In case of a pneumatic or electrical failure, it is important to know the behavior of the

actuator. Before mounting the positioner on an actuator, the failsafe position and

direction of rotation of the actuator drive shaft should be verified.

The connection between the actuator stem and feedback arm is typically made using a slotted

bracket and a feedback pin. There are two ways to transfer the motion through the feedback pin, the

traditional mounting method, and the alternate mounting method.

The Traditional Method

The feedback pin is fixed in the slotted bracket and rides inside the feedback arm.

WARNING

Before starting any assembly or disassembly of the actuator/positioner set, the electrical

supply and pneumatic supply must be removed. The actuator line must also be emptied.

Stay away from moving parts to avoid serious injury.

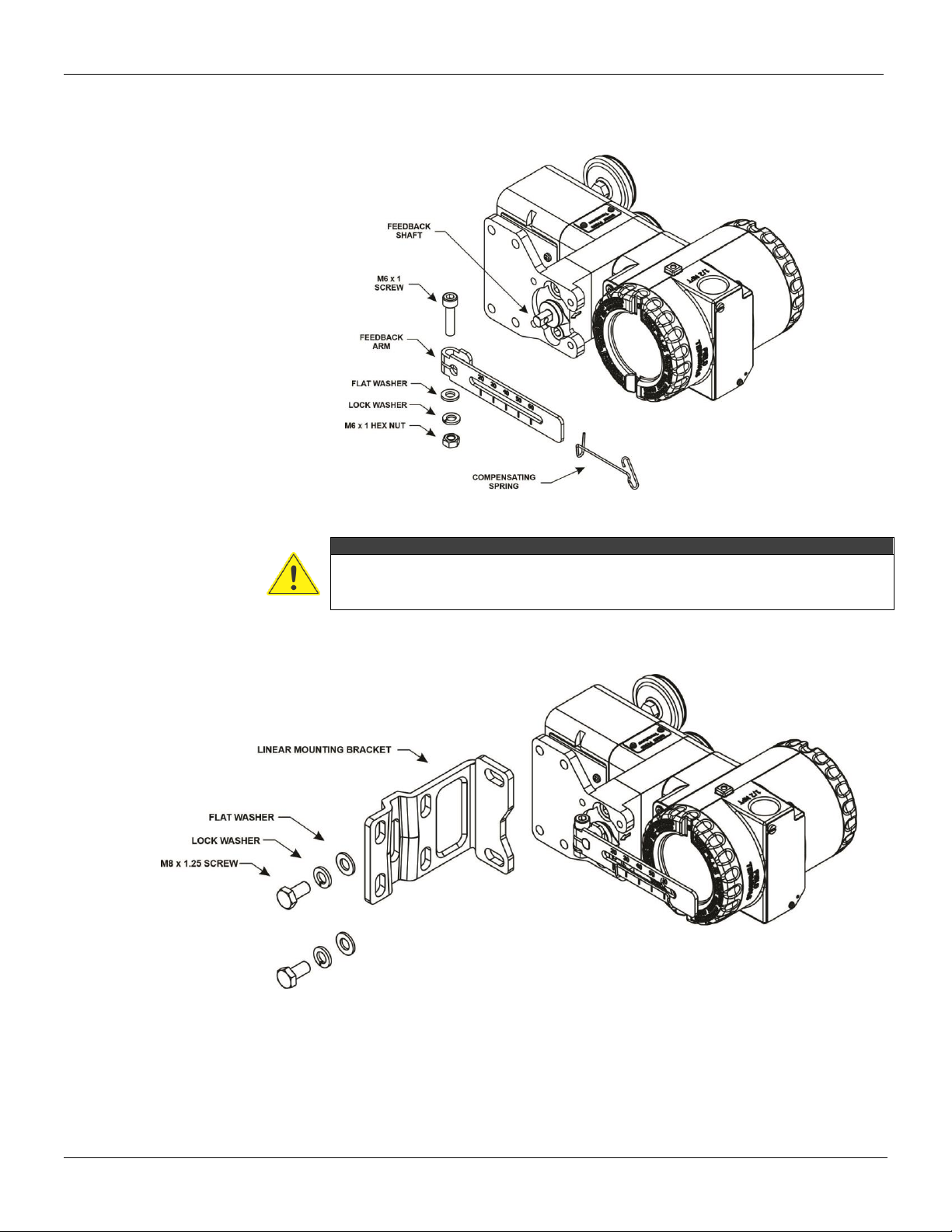

1. Attach the feedback pin to the slotted bracket with two M6x1 hex nuts, and two flat washers.

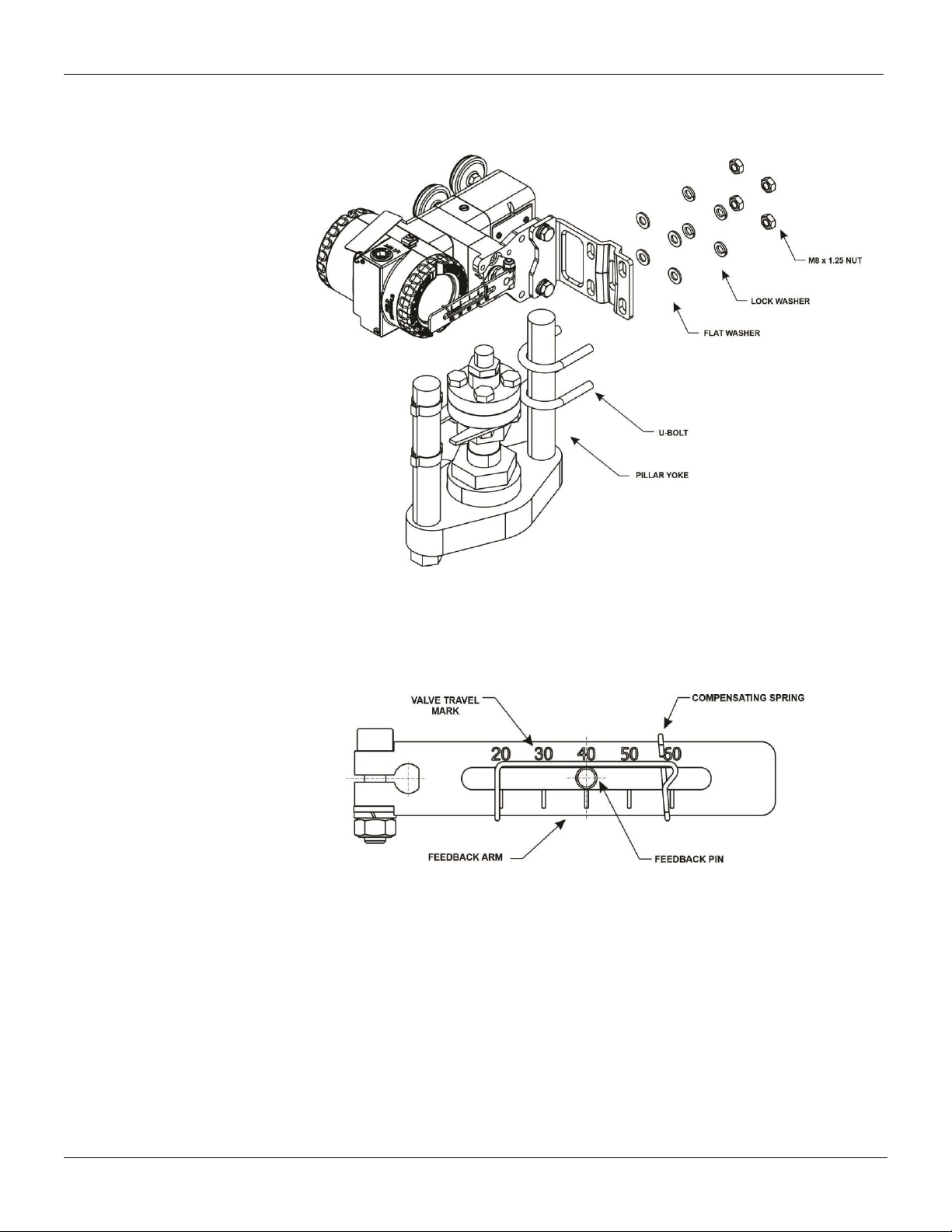

Leave the hex nut loose for later adjustment. See figure 1.8.

Figure 1.8 –Feedback assembly mounted on actuator stem

2. Attach slotted bracket to the actuator stem with two M6x1 screws, two lock washers, and two flat

washers, but do not tighten the fasteners because fine adjustment is required. See figure 1.8.

3. If required, a mounting adaptor is included in the mounting kit. Attach the mounting adaptor to the

actuator stem so that the mounting adaptor extends through the yoke leg, then attach the slotted

bracket to the adaptor, as shown in figure 1.9. The feedback pin must be on the opposite side of the

stem.

FY500 HART –Operation, Maintenance, and Installation Manual

1.8

Figure 1.9 –Feedback assembly mounted on mounting adaptor

WARNING

In some cases, attach the slotted bracket to the actuactor stem may not be possible,

and an mounting adaptor to actuator stem is required. This adaptor will be shipped to

the customers according to their purchase order.

4. The FY500 mounts on linear actuators with up to 200 mm (8 inch) travel. Refer to figure 1.10 for

the different travel feedback arm sizes depending upon travel of actuator be used.

Figure 1.10 –Feedback arm sizes

Section 1 - Installation

1.9

5. Attach the feedback arm to the end of the feedback shaft with M6x1 screw, M6 hex nuts, lock

washers, and flat washers. The markings on the feedback arm must be visible to the

operator/installer. Install the compensating spring on the feedback arm. See figure 1.11.

Figure 1.11 –Feedback arm assembly

WARNING

The compensating spring is used to hold the feedback pin securely against one side of

the feedback arm slot. This prevents excessive play in the linkage and limits the amount

of error introduced into the system through the linkage.

6. Refer to figure 1.12. Mount the positioner to the mounting bracket using two M8x1.25 screws, two

lock washers, and two flat washers.

Figure 1.12 –Positioner mounting bracket

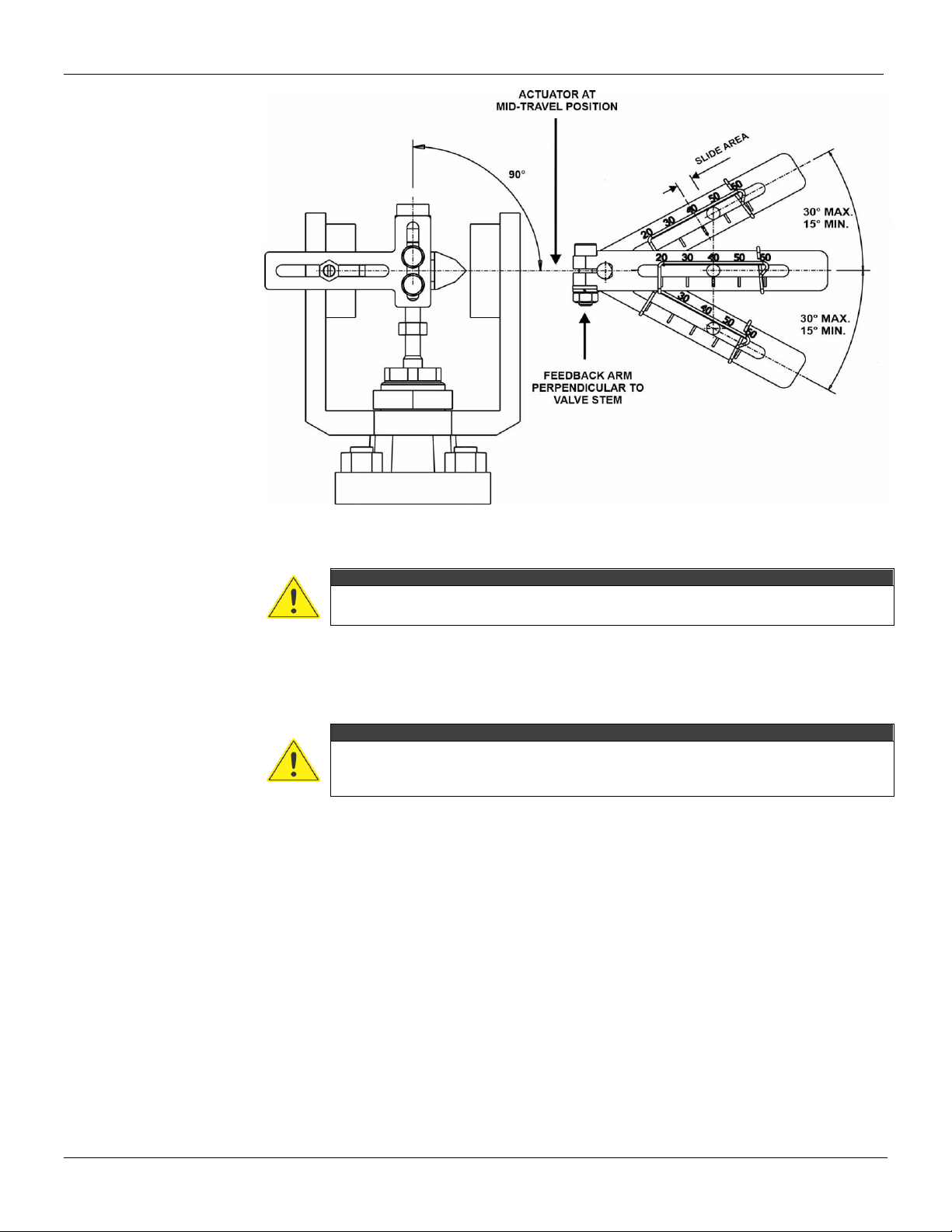

7. Position the actuator to its mid-travel position using a handwheel or manual loading regulator.

8. Adjust the vertical position of the slotted bracket so that the feedback arm and oblong arm are

horizontally aligned. The feedback pin must be in the mark on the feedback arm that indicates the

valve stroke size (see marking on cast yoke). Tighten the M6x1 screws.

9. Before installing the mounting bracket to the actuator yoke, slip the round end of the feedback pin

into the feedback arm slot. Make sure the feedback pin engages the slot in the feedback arm.

FY500 HART –Operation, Maintenance, and Installation Manual

1.10

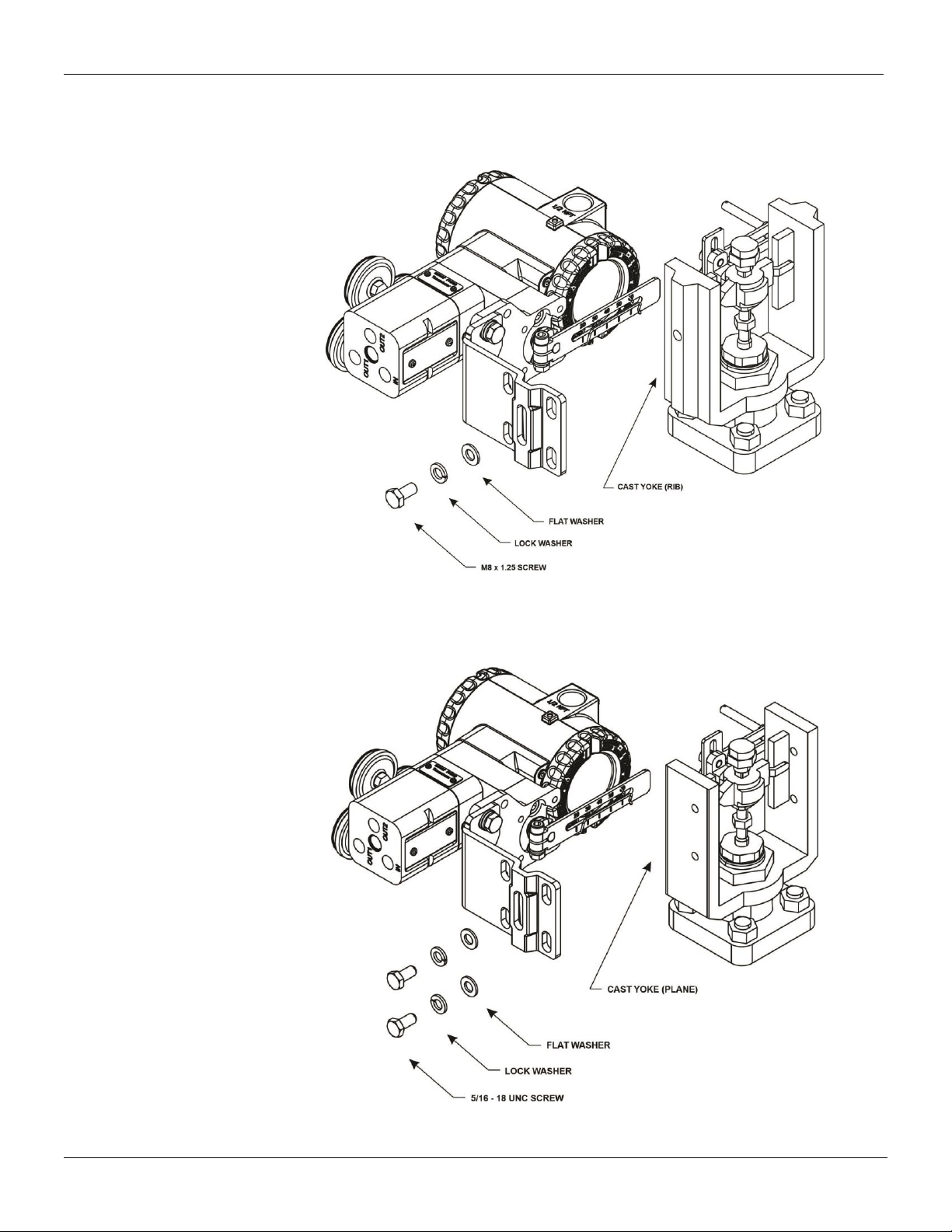

Secure the mounting bracket to the actuator yoke using the follow procedures:

- For actuators with cast yoke with rib surface application, using the M8x1.25 screw, lock

washer, and flat washer. See figure 1.13.

Figure 1.13 –Attachment to cast yoke with rib surface

- For actuators with cast yoke with plane suface application, using two 5/16 –18 UNC

screws, two lock washers, and two flat washers. See figure 1.14.

Figure 1.14 –Attachment to cast yoke with plane surface

Section 1 - Installation

1.11

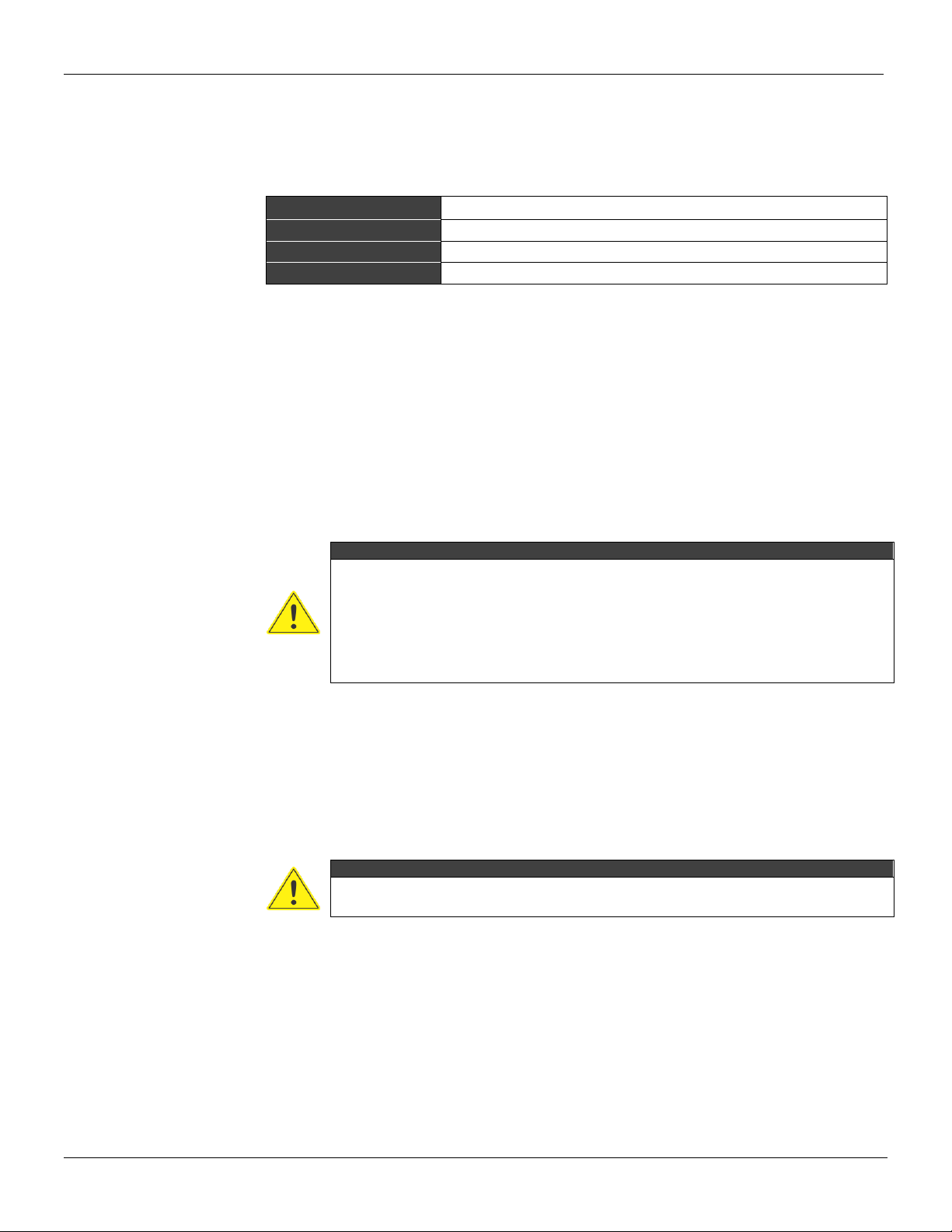

- For actuator with pillar yoke for U-bolt application, using two U-bolt, four lock washers,

and four flat washers, as shown in figure 1.15.

Figure 1.15 –Attachment to pillar yoke for U-bolt

10. Slide the adjustment feedback pin in the slot of the slotted bracket until the pin is in line with the

desired actuator travel marking on the feedback arm. The compensating spring must be

positioned such that the feedback pin sits in the central side of the compensating spring´s slide

area. Tighten the hex nuts. As shown in figure 1.16.

Figure 1.16 –Positioning feedback pin in feedback arm

11. With the actuator at its mid- travel position, adjust the mounting bracket location vertically so

that the feedback arm is perpendicular to the stem, as shown in figure 1.17.

12. Stroke the actuator from the top stop to the bottom stop. Travel indicator must travel within the

admissible range. See figure 1.17.

FY500 HART –Operation, Maintenance, and Installation Manual

1.12

Figure 1.17 –Admissible range –linear mounting bracket

WARNING

When test cycling the actuator and valve assembly by applying pressure to the

pneumatic port, be aware that there are moving parts can cause serious injuries.

The Alternate Method

The feedback pin is fixed in the feedback arm and have it ride freely inside the slotted bracket.

WARNING

Before starting any assembly or disassembly of the actuator/positioner set, the electrical

supply and pneumatic supply must be removed. The actuator line must also be emptied.

Stay away from moving parts to avoid serious injury.

1. Install the compensating spring on the slotted bracket.

2. Attach the feedback pin to the feedback arm with two M6x1 hex nuts, and two flat washers.

Adjust the position of the feeback pin so that the center aligns with the appropriate travel mark on

the feedback arm.

3. Complete the assembly procedure described in The Traditional Method topic of this manual.

Section 1 - Installation

1.13

Pneumatic Connections

The FY500 requires instrument air quality, following the best practices for pneumatic installations.

Consult the American National Standard “Quality Standard for Instrument Air”(ANSI/ISA S7.0.01 –

1996) for detailed information. Instrument air shall the following characteristics:

Dew point

10ºC below minimum instrument temperature.

Size of particles

40 µm (maximum).

Oil content

1 ppm w/w (maximum).

Contaminants

Free of corrosive contaminants and hazardous gases.

The instrument air quality shall be superior to that of industrial compressed air. Humidity, suspended

particles and oil contamination, even lubricating oil, may impair the instrument operation, either

temporarily or permanently in case of internal parts wearing.

The mentioned standard recommends to place the compressor intake in an environment free from

process spills, contaminants, and to use adequate filters. Also, the compressors must be of non-

lubricated type to prevent the present of lubrificants. When using lubricated compressors, the plant

must have resources to remove the lubricant from the instrument air supplied.

The supply pressure varies from 2 bar (30 psi) minimum, to 10.3 bar (150 psi) maximum. The

FY500 requires sufficient supply pressure to stroke the actuator to each end of its travel.

Maximum allowable air supply pressure to the positioner must not exceed 10.3 bar (150 psi). For

actuator pressure refer to the appropriate actuator instruction manual.

WARNING

•Never exceed maximum supply pressure. Injury personnel or damage to the

equipment may result.

•Supply pressure to positioner should not exceed actuator maximum pressure rating.

•Blow out all piping before connections are made to prevent dirt, chips, or debris to

entering to the positioner.

•Use a pipe sealant sparingly and only on male threads. It is not recommended a

sealing tape on pneumatic connections.

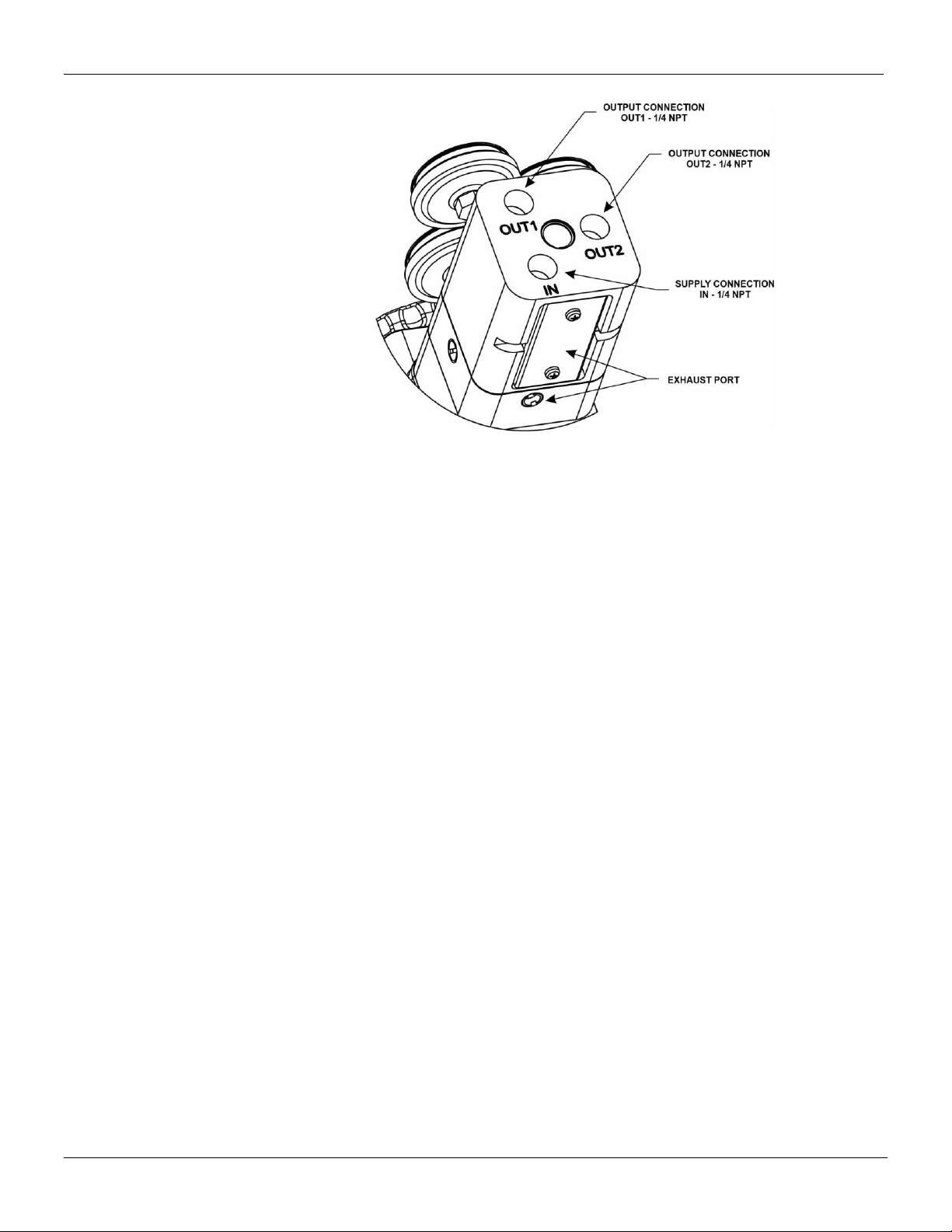

The positioner vents the supply medium into the surrounding atmosphere through holes located in

the positioner vent cover, as shown in figure 1.18. The positioner does not have an external vent

connection. Do not restrict the vent opening. Restricting the vent opening can produce a pressure

buildup in the positioner valve spool and degrade positioner performance. Ensure that the housing

vent opening is open and free of debris to prevent pressure buildup under the cover.

Connect the power supply to the 1/4 NPT IN connection on the positioner. The output connections

1/4 NPT OUT1 and OUT2 must be connected to the actuator. For best response times use tubing of

3/8- inch minimum size. See figure 1.18.

WARNING

When the input current is removed, the FY500 OUT1 should drop to zero and OUT2

register full pressure.

When using a positioner on a single acting actuator, close OUT2 and connect OUT1 to the actuator

pneumatic input.

When using a positioner on a double acting actuator, connect OUT1 and OUT2 to the appropriate

actuator pneumatic input. When the input current is removed, the FY500 OUT1 should drop to zero

and OUT2 register full pressure.

FY500 HART –Operation, Maintenance, and Installation Manual

1.14

Figure 1.18 –Pneumatic connections

Table of contents

Other SMAR Valve Positioner manuals

Popular Valve Positioner manuals by other brands

Bray

Bray 6A series Advanced setup guide

Parker

Parker 404XE Series product manual

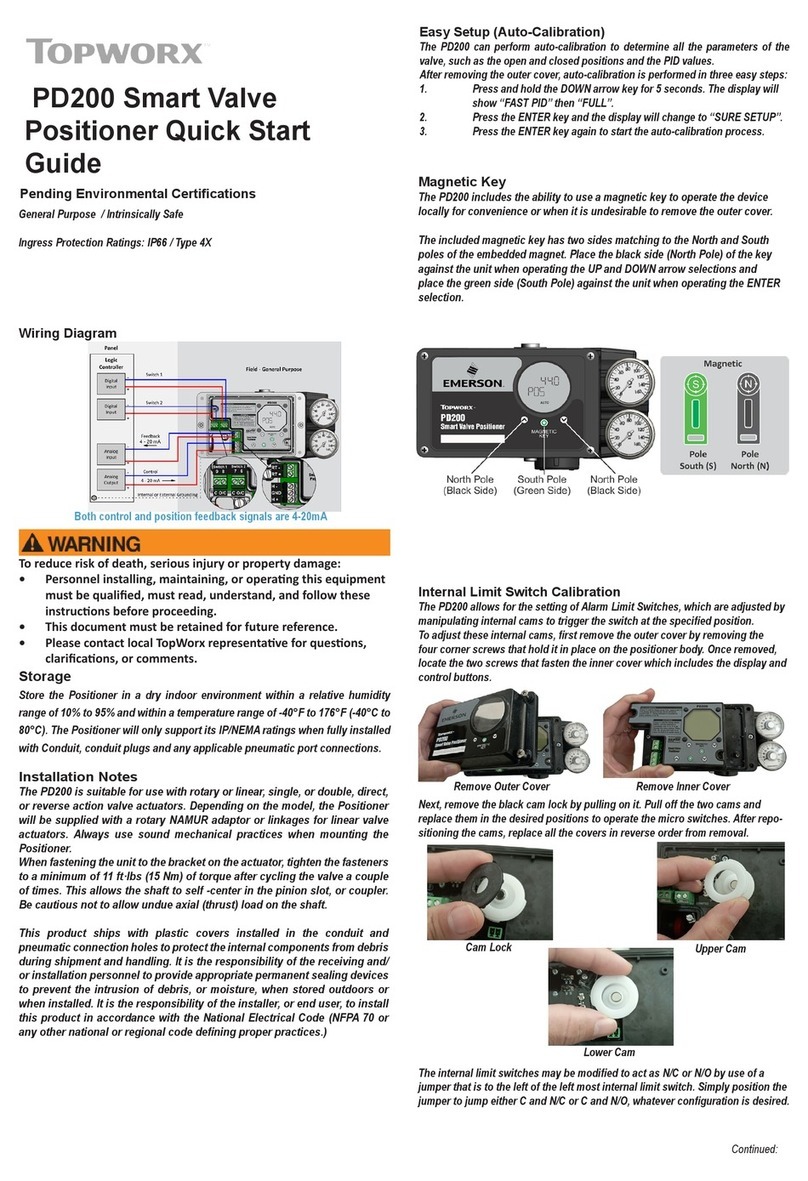

Topworx

Topworx PD200 quick start guide

Baker Hughes

Baker Hughes Masoneilan 4700E instruction manual

Emerson

Emerson Fisher 3660 instruction manual

Avid Technology

Avid Technology SmartCal Series Installation and operating instructions

Flowserve

Flowserve XL90 Series Installation, operation & maintenance instructions

Winradio

Winradio WR-ARP-ELAZ-100 Technical user guide

Spirax Sarco

Spirax Sarco SP200 Installation and maintenance instructions

Lincoln Electric

Lincoln Electric POSIMATIC PS30 Safety instruction for use and maintenance

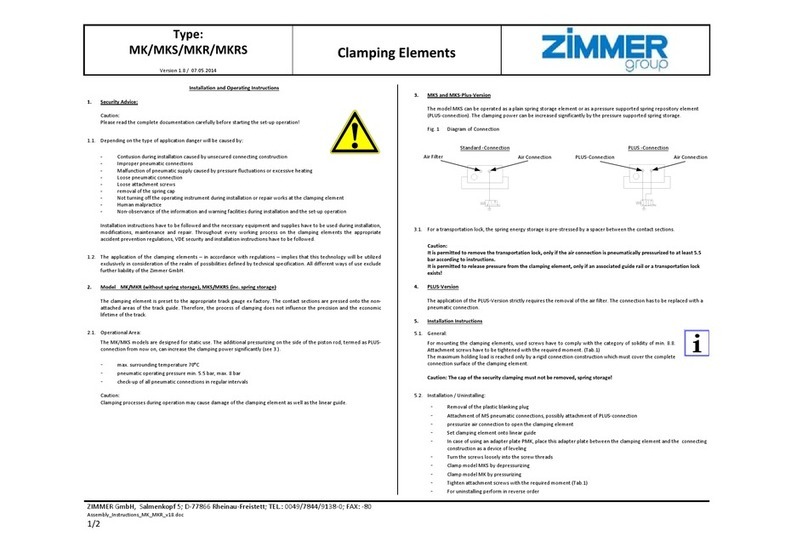

Zimmer

Zimmer MK series Assembly instructions

Courion

Courion iLEARN System manual