Intelligent Valve Positioner 1500 Series User’s Manual

Contents

1 Overview...................................................................................................1

1.1. Product structure..........................................................................1

1.2. Product description and application .............................................2

2. Installation ................................................................................................3

2.1. Mechanical dimensions................................................................3

2.2. Actuator combination ...................................................................5

2.2.1. Actuator of line stroke............................................................5

2.2.2. Actuator of angle stroke.........................................................7

2.3. Interface angle adjustment...........................................................9

3. Connection description........................................................................... 11

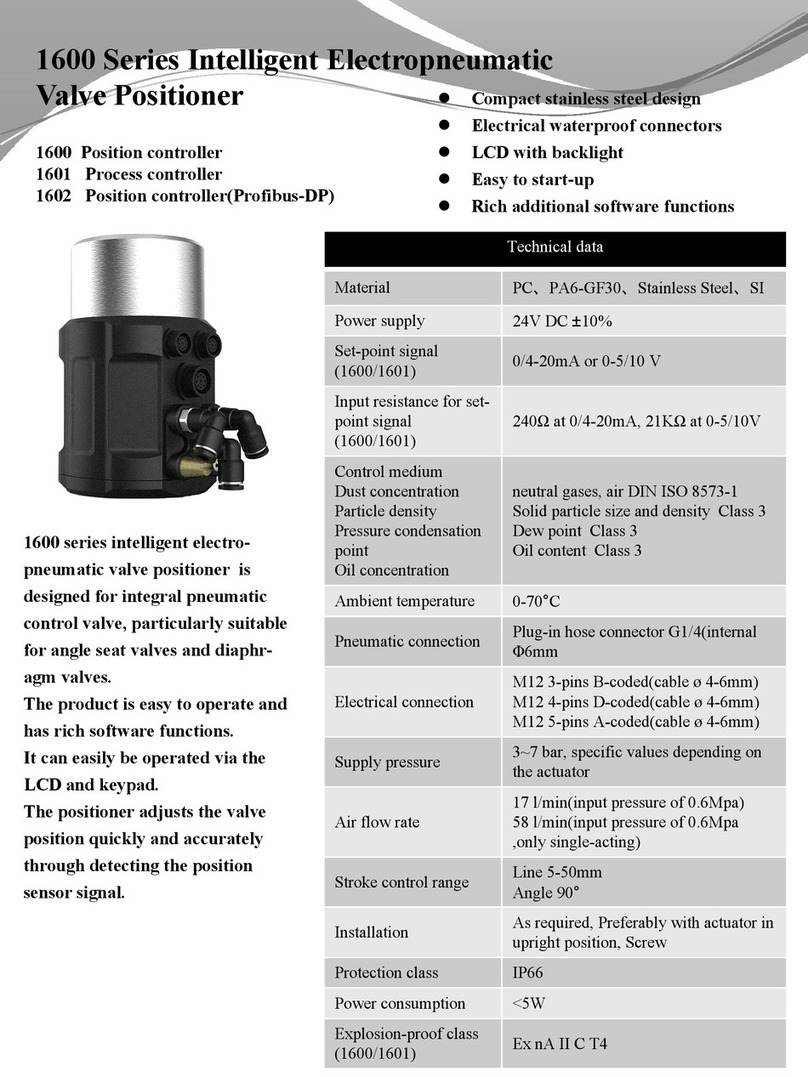

4. Technical data.........................................................................................12

4.1. Working data..............................................................................12

4.2. Electrical data.............................................................................12

4.3. Mechanical data.........................................................................12

4.4. Pneumatic data..........................................................................13

5. Operation................................................................................................13

5.1. Interface description...................................................................13

5.2. Operating mode .........................................................................14

5.2.1. Initial mode ..........................................................................14

5.2.2. Automatic mode...................................................................14

5.2.3. Manual mode.......................................................................15

5.3. Function instruction....................................................................15

5.3.1. Auto-tuning ..........................................................................15

5.3.2. Dead band setting................................................................16

5.3.3. Factory setting .....................................................................17

5.3.4. Input signal error detection ..................................................17

5.3.5. Analogue signal output (optional) ........................................17

6. Trouble shooting..................................................................................... 18

7. Attention .................................................................................................18

8. Warranty terms.......................................................................................22

9. Product type selection ............................................................................23