NewTeam 902-T Mounting instructions

Installation Instructions

and User Guide

PLEASE KEEP THIS BOOKLET

FOR FUTURE REFERENCE

NEWTEAM 902-T

THERMOSTATIC MIXER SHOWER

DEAR INSTALLER WHEN YOU HAVE READ THESE INSTRUCTIONS

PLEASE ENSURE YOU LEAVE THEM WITH THE USER

IN THE EVENT OF ANY QUERY PLEASE CONTACT

THE NEWTEAM CUSTOMER HELPLINE

Tel : 01536 264 012

Product Features

1NEWTEAM 902-T SHOWER VALVE

NewTeam 902-T

902-T

Contents

2

NEWTEAM 902-T SHOWER VALVE

Please read this booklet carefully and ensure a competent person undertakes the

installation.

Note: Following the headings in sequence will guide you through the installation

and operation of your NewTeam 902-T Mixer Shower.

INTRODUCTION

• Plumbing

CLEANING

ADJUSTING MAXIMUM TEMPERATURE

•902-T Mixer Valve

FITTING YOUR SHOWER

•Important Notes

•General

•Fitting the Shower

•Fitting the Riser Rail

Refer to back cover for Guarantee, Customer Service and Replacement Parts Policy.

In the event of any query regarding installation please contact the NewTeam Customer

Service Department

Tel: 01536 264 012 • Fax: 01536 409 201

In line with our policy of continual product development the specifications may be

varied and product design altered. We reserve the right to depart from the details

given in this manual without prior notice.

3

Pages

4 - 7

8

9

Installation and Operating Instructions

for NewTeam Thermostatic Mixer Shower

• 902-T

TROUBLESHOOTING 9

SPARE PARTS LIST 9

GUARANTEE 10

Introduction

3NEWTEAM 902-T SHOWER VALVE

902-T

The 902-T shower valve is thermostatically controlled.

The NewTeam 902-T Mixer Valve is suitable for the following:

•High Pressure systems to a maximum of 8.0 Bar (50 Metre Head).

•Low Pressure systems with a minimum pressure of 0.1 Bar

(1 Metre Head).

•Pumped Pressure.

•Mains Pressure.

Ideally the supplies should be independent of any other draw offs (e.g.

bath/basin taps).

The Thermostatic Valve includes a Temperature Limit Stop which is

pre-set at approximately 38˚C thus preventing accidental selection of

a shower temperature which is too hot.

If the minimum operating pressure cannot be achieved or you wish to

improve the performance of your shower, NewTeam Booster Pumps

are available.

IMPORTANT:

When connecting pipework do not solder within 300mm (12”) of the

valve or expose parts to excessive heat.

NOTE - That at temperatures above 65ºC air can be expelled from the

water, which can cause poor performance, particularly with pumped

systems, where damage to a pump could occur.

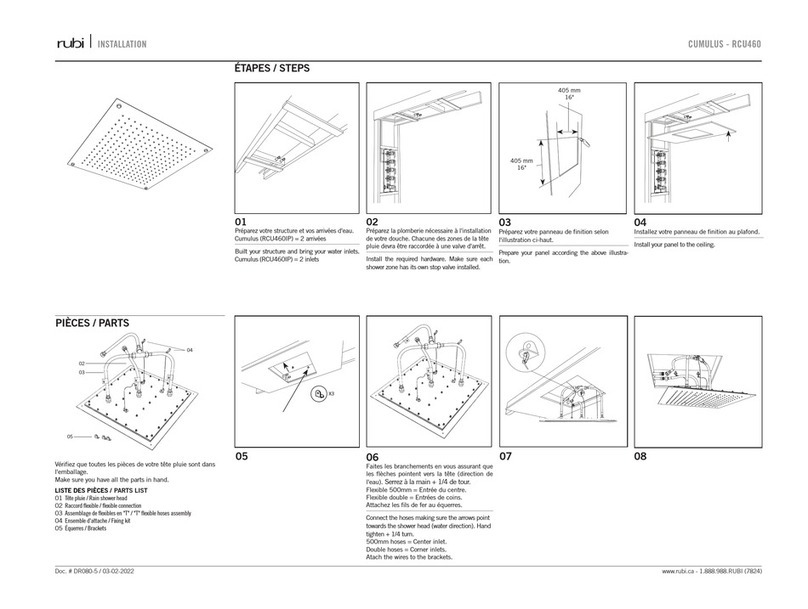

Plumbing - Fig 1

Please ensure compliance with all Water Supply (Water Fitting) Regulations,

paying particular attention to Clause 15 in Water Regulations, when connecting

directly to incoming cold water mains.

The Mixer Valve must be sited to provide easy access for use and maintenance.

Install non-restrictive full flow isolating valves on the hot and cold supplies to the

Mixer Valve.

Ensure the Mixer Valve is not positioned in an area subject to freezing.

Make the connection into the hot water supply pipe from the cylinder ensuring

that it is the first draw off on the vertical pipe below the expansion pipe tee. If this

is not possible a direct connection must be made from the hot water cylinder with

an Essex flange.

The cold water supply should be taken directly from the cold water storage tank

positioned 60mm below the cold connection which feeds the hot water cylinder.

Hot Water Tank

Cold Water Storage Tank

1m. (39”) min.

Fig 1 - Typical Gravity Shower Installation

1 Metre

Min.

60mm

Mains

Water

Supply

Fitting Your Shower

4

NEWTEAM 902-T SHOWER VALVE

•The hot and cold feeds must be at nominally the same pressure. The valve must

not be fed from a low pressure (gravity system) hot supply and a mains pressure

cold supply.

•All pipework should be as short and direct as possible, using swept bends rather

than elbows where practical, to avoid trapping air. Do not tee off the upper surface

of a hot water pipe, especially near to a hot water cylinder, as this will often

contain air bubbles which will adversely affect the operation of the valves. Where

the shower is fed from a gravity system the use of 22mm diameter pipework is

strongly recommended.

•The combination boiler or gas multipoint boiler must be capable of raising the

temperature of 8 litres/min of incoming cold water by 45ºC. This requires a boiler

rating of 25kW (85300 Btu/h).

•The valves must be installed with the outlet pointing downwards, the HOT water

coming in on the left and the COLD on the right as you view the shower on the

wall. The valve will not operate if the connections are reversed.

IMPORTANT:

Modern solder fluxes are extremely corrosive and can damage the valves. It is

essential that all pipework is thoroughly flushed through before connecting the

valve. This is so that flux, debris and swarf, which could permanently damage the

valve, are removed from the pipes.

•Plan the whole installation before you start. Cut the necessary pipework to length,

assemble and offer up to the installation before making and soldered joints.

•Carry out any cutting with a pipe cutter in preference to a hacksaw, to minimise

swarf. Always remove sharp edges.

Important Notes

Cold

Hot

Mixer

Fitting Your Shower

5NEWTEAM 902-T SHOWER VALVE

General:

IMPORTANT

THE 902-T MIXER SHOWER IS HELD IN POSITION BY THE PIPEWORK. IT IS

ESSENTIAL THAT THE PIPEWORK IS RIGIDLY SUPPORTED CLOSE TO THE VALVE.

A CONCEALED WALL MOUNT FIXING IS INCLUDED WITHIN THE SHOWER BOX.

PLEASE REFER TO PAGE 6 OF THIS MANUAL.

The NT902 should only be fitted where water supply pipes are behind a panel or

studwork wall.

This method of fixing requires good access behind the wall or panel.

•Offer up the valve to the wall and mark the required positions of the hot and cold

inlet connections. When positioning the valve make sure to take into account the

intended position of the accessories riser rail.

Ensure there are no services such as gas, water pipes, electrical or telephone

cables beneath the surface of the wall before drilling.

•On plasterboard (studwork) or panel walls, make two holes on 150mm centres to

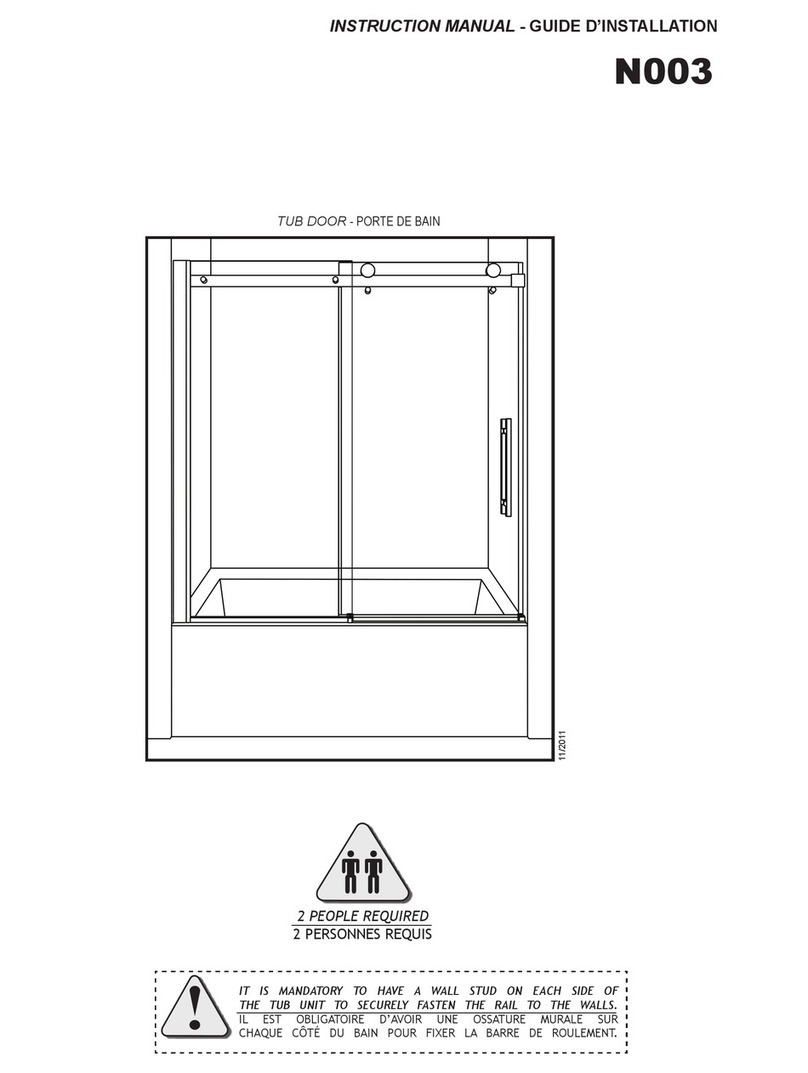

accept the 1/2”BSP end fitting (see Fig. 3).

•On an internal rendered brick or block wall, drill two 23mm diameter holes on

150mm centres with counterbores to accept the 1/2”BSP end fitting. If 15mm

pipework is used, drill 16mm holes (see Fig. 3).

Cut two pieces of pipe, equal in length to the thickness of the wall plus an allowance

for connection at the rear of the wall, terminate the pipework using a 15mm to 1/2”

BSP, or 22mm to 1/2”BSP female straight tap connector to suit the pipe diameter

used. (The tap connector should include a rotational hexagon nut and washer).

Tighten the 1/2”to 3/4”BSP ‘dog leg’connector to the pipework, loosely fit the two

cover plates half way along the 3/4”BSP thread.

Temporarily block the open ends of the pipework and pass through th

wall until the cover plates are hard against the wall, fit the pipework at the rear of the

wall and secure rigidly, ensuring the two outlets are level and the centres match

those of the valve inlets.

•Flush out the pipework and fit the valve with the outlet

connection downwards, without cover plates and check the

system for leaks.

•Refit cover plate.

•Screw the valve to the pipework ensuring the washer and

filter are inserted, then fully tighten.

•Adjust the cover plates to take up any slack and stiffen the

assembly.

Note: If the non-return valves have to be removed at any time,

please note the bushes are Left hand thread

NB: Hot on the left, cold on the right. Fig 3 - To install on a panel or studwork wall

Fig 2 Fitting Your Shower

NB: The following instructions are for fitting the shower without the

installation bracket (Fig 3).

6

NEWTEAM 902-T SHOWER VALVE

Fitting The Shower

NB: The following instructions are for fitting the shower with the

installation bracket (Fig 4).

The NT902 should only be fitted where water supply pipes are behind a panel or

studwork wall.

•Identify all components and check for completeness, particularly before

arranging fitting.

•Fix the mounting plate to the internal wall or studding using suitable fixings

(not supplied). Use a spacing batten or similar as necessary. Connect the hot and

cold water supplies using 15mm copper pipe with the nuts and olives (supplied).

Supplies can come from above or below making sure Hot is on the left and

Cold is on the right when viewed from the front.

•Finish the wall and push-fit the shrouds as shown. Note! A small bead of silicon

sealant between the wall finish and the spigot diameter under the shroud should

prevent any moisture entering the wall.

•Fit the mixer body to the 3/4”BSP mounting spigots using the large sealing

washers supplied with your fitting.

Fig 4 - To install using installation bracket

Fitting the Riser Rail

7NEWTEAM 902-T SHOWER VALVE

Before proceeding with fitting the rail, identify each of the itemssupplied using

the illustration.

The slider must not be removed from the rail during fitting. The top of the slider has

a smooth profile, whereas the underside has a recess revealing the grooves on the

handset holder.

Fit the rail through the friction sleeve on the soap/gel dish with the sleeve towards

the lower end of the rail.

Fit the rail ends onto the ends of the rail.

Position the rail on the wall, bearing in mind the heights of people

likely to use the shower, and mark the wall to indicate the upper and lower fixing

screw positions. Drill the wall at one of the marked fixing positions using a 6 mm drill.

Loosely fix the appropriate rail end and check that the other fixing screw mark is in

the correct position.

Secure the rail to the wall. Ensure that the rail is vertical before finally tightening both

fixing screws.

Fit the rail end caps.

When fitting the hose, it should pass through the centre hole of the soap dish.

NOTE - The hose nut, and not the handset handle, fits into the slider, and the slider

moves more freely on the rail, if gripped next to the rail rather than at the handset.

Shower Rail Kit - Fig 5

No Part Description

1 Rail end

2 Rail end caps

3 & 4 Rail with slider attached

5 Soap dish

Rail fixing screws &

wall plugs

Fig 5

•These mixer valves have been calibrated at the factory using

balanced pressure hot and cold supplies and a hot water supply

temperature of 65ºC.

•When the installation conditions of the mixer valve are different to

the factory settings, the temperature of the mixed water obtained

from the mixer valve may not correspond exactly with the

temperatures shown on the valve.

If required, the valve can be adjusted to ensure that the indicated temperature

is the same as the temperature obtained from the mixer. To do this, carry

out the following steps:-

1. Rotate the temperature control knob so that the water

issuing from the mixer is at 38ºC.

2. Without moving the temperature control knob, remove the

screw cover from the end of the knob and unscrew the

fixing screw.

3. Remove the control knob, complete with the black ring

containing the temperature figures.

4. Refit the end of the control knob so that the figure 38

corresponds to the indicator on the mixer body.

5. Replace the fixing screw and refit the screw cover.

Note. To set a different temperature at the limit stop position,

follow the above steps but adjust the temperature of the

water to correspond to the limiting temperature required

before the temperature control knob.

Adjusting Maximum Temperature

8

NEWTEAM 902-T SHOWER VALVE

Fig 6

902-T Mixer Valve - Fig 6

Cleaning

9NEWTEAM 902-T SHOWER VALVE

Do not at anytime use bath cleaning liquids, powders or specified non-scratch

cleaners on surface finishes. In order to avoid surface wear on any of your shower

fittings when cleaning, always use a damp cloth. For persistent stains or marks, you

may use a domestic washing-up liquid.

In the unlikely event of a problem, consult the trouble shooting chart below and

follow the order below. If you are unable to remedy the problem, CONTACT YOUR

INSTALLER IN THE FIRST INSTANCE.

Do not attempt any plumbing work unless you are competent to do so.

Cleaning

Troubleshooting

Fault

After installation shower will only run HOT

or COLD.

Low or reduced flow.

Maximum temperature too low or too high.

Solution

Hot and Cold supplies are plumbed in the

wrong way round.

(a) Debris/scale in shower handset. Clean

handset.

(b) Servicing valves not fully open. Open

valves.

(c) Filters partly blocked. Turn off servicing

valves, remove mixer valve and clean

filters.

Re-adjust maximum temperature. See

Adjusting Maximum Temperature.

1. SP-245-0001-CP Rail Ends

2. SP-280-0302-CP Rail & Slider

3. SP-168-0211-CP Zag Handset

4. SP-285-0820-CP Hose

Spare Parts List

Guarantee/Service Policy

10 NEWTEAM 902-T SHOWER VALVE

Part No. 404-0129 Issue 10/03

Guarantee

Thank you for purchasing a NewTeam product, which has been designed, manufactured and

tested, in the U.K., to the highest standards.

Guarantee. 2 Years - First Year - Parts and Labour, Second Year - Parts Only

This guarantee applies to products purchased within the United Kingdom or Republic of

Ireland, but does not apply to products used commercially.

This is provided that:

1. The guarantee registration card is completed and returned within ten days complete with a copy

of proof of purchase.

2. The product is installed and operated in accordance with our instructions and has not been

misused or damaged.

This in no way affects your statutory rights as a consumer.

The information on the Guarantee card helps NewTeam to process any claims and contact you about

your product and its maintenance if required. The registration of your personal details is

purely for NewTeam use, and the other information helps us to make products for the future.

NewTeam Shower products are designed, manufactured and tested to the highest standards.

Should a complaint arise, products are guaranteed against faulty workmanship and materials for a

period of 12 months from the date of purchase, when in domestic use (second year guarantee is parts

only). For your guarantee to be valid, your shower must be installed by a competent person,

in accordance with the instruction manual. Failure to do so will result in a service call charge

being levied.

Home visits are made between 8.30am and 5.00pm Monday to Friday. Visits may be available

outside these hours at our discretion, in which case a premium will be charged.

NewTeam will repair or replace (at our option), free of charge, any faulty components during the

guarantee period, provided it has been maintained and operated in accordance with our

instructions, and has not been misused or damaged.

Modification or repair of this product by person(s) not authorised by NewTeam will invalidate

this guarantee.

This guarantee does not affect your statutory rights.

Service Policy - Replacement Parts Policy

IMPORTANT:

In the event of product or component malfunction, DO NOT tamper with or remove the

product from site. Telephone NewTeam Customer Service Department on 01536 264 012 and

be prepared with the date of purchase, model number and a description of the complaint.

Our service staff are fully qualified to advise on correct installation procedures and will be able

to diagnose whether the fault will require a replacement part or a visit from a NewTeam engineer.

If required, a service call will be booked, and either yourself or an appointed representative (who

should be a person of 18 years or over) must be present during the visit.

All site visits to product within the guarantee period will be carried out free of any parts or

labour charges provided the conditions of the guarantee have been adhered to. (Second year

guarantee is parts only)

All site visits to product out of guarantee will be subject to charges for parts and labour which

is payable by you or your appointed representative at the time of the visit. Charges will also be

levied on cancelled appointments, unless advised to NewTeam at least 24 hours in advance of

the agreed date and time.

We reserve the right not to undertake work where payment cannot be made to our engineer at

the time of the visit.

NewTeam hold stocks of components for all their range of products and these will be

maintained for the duration of their life.

Should a product be discontinued, spare parts stocks will be maintained, but in the event of a

part becoming unavailable NewTeam reserve the right to supply a substitute of equal quality.

The following payment methods can be used to obtain spare parts:

By post, pre-payment of proforma invoice by cheque or postal order.

By telephone quoting credit card (Mastercard, Visa or Visa Delta) details.

REPLACEMENT PARTS:

CUSTOMER SERVICE HOTLINE:

Guarantee

11

NEWTEAM 902-T SHOWER VALVE

Please post immediately enclosing a copy of proof of purchase

GUARANTEECARD

NewTeam Mixer Shower

902-T ❑

Proof of purchase enclosed

YES ❐NO ❐

NAME:

ADDRESS:

POSTCODE:

DATE OF PURCHASE:

PRODUCT PURCHASED FROM:

TOWN:

NewTeam’s philosophy is to offer outstanding products with quality and integrity,

please help us by taking the time to answer the following questions. Thank you.

POST BACK

FOLD AND TAPE AS INSTRUCTED OVERLEAF

MARKETING INFORMATION

1. Please state your profession: Plumber ❒Builder ❒Electrician ❒Customer ❒

Other ❒(please specify) ______________________________________________________________

2. Please state the reason for purchasing a shower: New Build ❒Replacement ❒

Renovation ❒Other ❒ (please specify) ________________________________________________

3. If the product is a replacement shower, please state the type and make of the shower it is

replacing: ____________________________________________________________________________

4. What influenced you to purchase the 902-T Mixer Shower Advertisement ❒

Trade Press ❒Recommendation from Stockist ❒Recommendation from Installer ❒

Other ❒(please specify) ______________________________________________________________

5. Please state your main reason for purchasing the 902-T Mixer Shower

NewTeam Product Knowledge ❒Product Features ❒Product Styling ❒Price ❒

Other ❒(please specify) ______________________________________________________________

Please tick here if you do not require any further information or product updates from NewTeam ❒

FOR NEWTEAM USE

This label identifies your product and

provides all the information needed

AFFIX PRODUCT LABEL HERE

✁

NewTeam Ltd.

Customer Service Dept.

Brunel Road

Earlstrees Industrial Estate

Corby

Northants

NN17 4JW

NewTeam Ltd.

Customer Service Dept.

Brunel Road

Earlstrees Industrial Estate

Corby

Northants

NN17 4JW

1st Fold

2nd Fold

3rd Fold

✁

Please tape down

Please tape down

Affix

Stamp

Table of contents

Other NewTeam Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

Signature Hardware

Signature Hardware PINECREST 946627 quick start guide

Kinedo

Kinedo KINEMAGIC ROYAL 2 installation instructions

Villeroy & Boch

Villeroy & Boch 36 015 960 installation instructions

Kohler Mira

Kohler Mira AGILE installation guide

Zenith

Zenith 2423WW Assembly instructions

Excellent

Excellent LAVANO BREX.1102 Series installation manual

KEUCO

KEUCO Axess 35006 010801 Mounting instruction

Relax

Relax Smart 0801-A Assembly instructions

Hans Grohe

Hans Grohe Ecos 32126000 Instructions for use/assembly instructions

INR

INR LINC 21 installation instructions

Villeroy & Boch

Villeroy & Boch Subway 3.0 Waste Overflow installation instructions

Crosswater

Crosswater ISLSC1200 installation instructions