Newtons4th PPA45 Series User guide

PPA45xx series

START UP GUIDE

Firmware v2_169

06th November 2017

PPA45xx Quick User Guide

Page 1

CONTENTS

Contents

......................................................................

Page.1

1.

Getting Started................................................

Page.2

1.1

Unpacking and Contents....................................

Page.3

1.2

Handle Fitment.................................................

Pages.4-5

2.

Safety.............................................................

Page.6

2.1

Safety Instructions...........................................

Page.6

2.2

Cautions.........................................................

Page.7

2.3

Warranty.........................................................

Page.8

3.

Front Panel Layout Diagram...............................

Page.9

3.1

Front Panel Display Key Functions......................

Pages.10-28

4.

Rear Panel Layout Diagram................................

Page.29

5.

Basic Key Operation..........................................

Page.30

5.1

Set up to start.................................................

Page.30

5.2

Setting the Time..............................................

Page.30

5.3

Setting the Date..............................................

Page.31

5.4

Adjusting the Screen Brightness........................

Page.31

5.5

Adjusting Keyboard Beep..................................

Page.31

5.6

Setting User Data............................................

Page.32

6.

Quick User Guide.............................................

Page.33

6.1

Wiring............................................................

Pages.33-36

6.2

Start Up.........................................................

Page.37

6.3

6.3.1

6.4

6.4.1

Zoom Functions...............................................

Analogue Output..............................................

Speed & Smoothing..........................................

Efficiency........................................................

Pages.38-39

Page.40-43

Pages.44-46

Page.47

6.5

Application Modes............................................

Page.48

6.5.1

PWM Motor Drive Mode.....................................

Pages.49-55

6.5.2

6.5.3

6.5.4

6.5.5

6.5.6

6.5.7

6.5.8

6.5.9

Lighting Ballast Mode........................................

Inrush Current Mode........................................

Transformer Mode............................................

Standby Power Mode........................................

Calibration Mode..............................................

Oscilloscope Mode............................................

Interharmonic Sweeps......................................

HF Current Shunts / Rogowski Coil.....................

Page.56

Pages.57-63

Pages.64-69

Pages.70-72

Page.73

Pages.74-77

Pages.78-83

Pages.84-89

PPA45xx Quick User Guide

Page 2

7.

7.1

7.1.1

7.2

Remote Settings..............................................

Transferring Internal Datalogs to USB Memory Stick

Data Logging to USB Memory Stick....................

Program Store / Recall / Delete.........................

Pages.90-92

Pages.93-94

Pages.95-96

Pages.97-100

8.

8.1

9.

10.

Repair / Recalibration.......................................

Basic Functionality Check..................................

Specifications..................................................

PPA Comparison Table......................................

Page.101

Page.102-118

Page.119-122

Page.123

PPA45xx Quick User Guide

Page 3

1 Getting Started

1.1 Unpacking

When you receive your product, check that the following items are included for

the appropriate PPA. Refer to the contents list below for each model. If any item

is missing or damaged during transportation, immediately contact your local

sales distributor or N4L office

CONTENTS

MODEL

Mains

Lead

4mm

Yellow

Lead

4mm

Black

Lead

4mm

Red

Lead

Yellow

Croc

Clip

Black

Croc

Clip

Red

Croc

Clip

N4L

2GB

Memory

Stick

Start

Up

Guide

Manual

Comms

Manual

PPA4510

1

1

2

1

1

2

1

1

1

1

PPA4520

1

2

4

2

2

4

2

1

1

1

PPA4530

1

3

6

3

3

6

3

1

1

1

Communication Cables

USB

Filtered USB 2.0 A male to B male 2m lead

RS232

9 pin to 9 pin null modem cable

PPA45xx Quick User Guide

Page 4

1.2 Fitment of the PPA series Carry/Tilt handle

PPA5/15/45/55 series power analyzers are supplied with a Carry/Tilt Handle that

is located within the accessory pack..............................................................

The handle allows a user to position the instrument upwards at one of two angles

for easier viewing when the instrument is positioned below the line of sight. The

design also allows storage under the unit without obstruction of the rubber feet

so that instruments can be stacked and is easily removed to allow the connection

of rack mounting brackets without the need to remove instrument covers.

Correct installation of the handle is important to ensure the correct operation

and long life the handle.

The following pictures illustrate correct and incorrect handle fitment:

Correct 1/2 –Correct fitting is from the top of the unit as shown here

Correct 1 Correct 2

A coloured dot for identification and alignment purposes can be found on the

handle and mounting bush on the instrument

PPA45xx Quick User Guide

Page 5

Correct 3 Correct 4

A correctly fitted handle will have the ‘N4L Newtons4th’ wording in the correct

reading plane when the handle is to the front of the instrument (Pic. 3)

Also, a correctly fitted handle will allow storage under the unit (Pic. 4)

Using the coloured dots for alignment will ensure a correctly fitting handle

Incorrect 1 Incorrect 2

Fitting the handle from the bottom of the unit as shown here is wrong...

(Incorrect 1)

Incorrect fitting can be seen because the handle does not fit correctly under the

unit and handle sides do not fit flush with the registration washer (Incorrect 2)

PPA45xx Quick User Guide

Page 6

2 Safety

2.1 IMPORTANT SAFETY INSTRUCTIONS

This equipment is designed to comply with BSEN 61010-1 (2001) (Safety

requirements for electrical equipment for measurement, control, and laboratory

use) –observe the following precautions:

Ensure that the supply voltage agrees with the rating of the instrument

printed on the back panel before connecting the mains cord to the supply

This appliance must be earthed. Ensure that the instrument is powered from

a properly grounded supply

The inputs are rated at 1kV rms or dc cat II; 600V rms or dc cat III. Do not

exceed the rated input

Keep the ventilation holes on the underneath and rear free from obstruction

There are no user serviceable parts inside the instrument –do not attempt to

open the instrument, refer service to the manufacturer or his appointed agent

Note: Newtons4th Ltd shall not be liable for any consequential damages,

losses, costs or expenses arising from the use or misuse of this product

however caused

PPA45xx Quick User Guide

Page 7

2.2 CAUTIONS

Do not use a damaged power cord or cables

Doing so may cause an electric shock or a fire

Do not place any object on this instrument

Do not use this instrument if faulty

If you suspect the instrument to be faulty, contact your local N4L office or

representative for repair (see section 8)

PPA45xx Quick User Guide

Page 8

2.3 Warranty

This product is guaranteed to be free from defects in materials and workmanship

for a period of 36 months from the date of purchase

In the unlikely event of a problem within this guarantee period, first contact

Newtons4th Ltd or your local representative to give a description of the problem.

Please have as much relative information to hand as possible –particularly the

serial number and release number these can be found by pressing the SYSTEM

button then the “Left Arrow”

If the problem cannot be resolved directly then you will be given an RMA number

and asked to return the unit. The instrument will be repaired or replaced at the

sole discretion of Newtons4th Ltd

This guarantee is limited to the cost of the PPA45xx itself and does not extend to

any consequential damage or losses whatsoever including, but not limited to,

any loss of earnings arising from a failure of the product or software

In the event of any problem with the instrument outside of the guarantee period,

Newtons4th Ltd offers a full repair and re-calibration service. Contact your local

representative. It is recommended that the PPA45xx be re-calibrated annually

PPA45xx Quick User Guide

Page 9

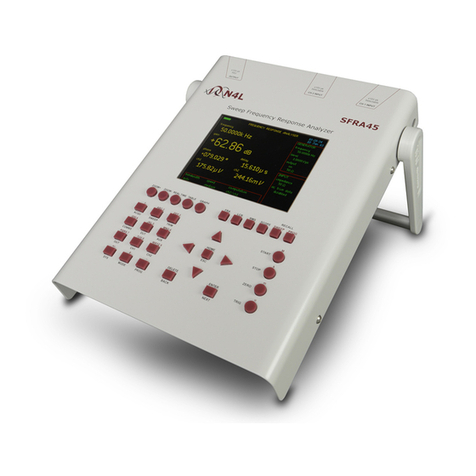

3 Front Panel Layout

1. Display Screen

2. Screen Display Function Buttons

3. Power Analyzer Mode Buttons

4. Handle

5. Measurement Control Function Keys

6. Rubber Feet

7. Menu Selection and Cursor Controls

8. Measurement Settings Buttons

9. Front USB Port

10. Power On / Off Button

1 2 3

4

5

10 9 8 7 6

PPA45xx Quick User Guide

Page 10

3.1 PPA45xx Display Key Functions

Key & Sub Categories

Description

ACQU

Wiring:

Acquisition Control: Used for configuring inputs

appropriate to source and nature of signals being

analyzed

Single Phase 1

In single phase 1 configuration, (phase 2 & phase 3)

inputs are disabled and the selected phase acts as a

completely independent single phase power analyzer

2 Phase 2 Wattmeter

In the 2 phase 2 wattmeter configuration, the

voltages are measured relative to each individual

phase input, with a single frequency reference

selected within the frequency reference parameter

(see page 8)

3 Phase 2 Wattmeter

In the 3 phase 2 wattmeter configurations, the

voltages are measured relative to phase 3. Typically

the phase 1 voltage input is connected across phase 1

and phase 3, and phase 2 voltage input is connected

across phase 2 and phase 3, thus measuring phase to

phase voltage directly. Phase 1 and 2 current inputs

are connected normally. There is no need to measure

the current in phase 3 as phase 3 has no voltage

relative to itself so the power contribution is zero. In

this mode, the neutral channel displays the

synthesized phase 3 current. The advantage of this

connection method is that 3 phase power can be

measured with only 2 wattmeters

3 Phase 3 Wattmeter

With the 3 phase 3 wattmeter configuration, each

measurement phase is connected to a phase of the

load with the voltage low inputs measuring to neutral.

In this mode, phase to neutral voltages are measured

directly and phase to phase voltages are also

computed

Single Phase 2

In single phase 2 mode, (phase 1 & phase 3) inputs

are disabled and the selected phase acts as a

completely independent single phase power analyzer

Single Phase 3

In single phase 3 mode, (phase 1 & phase 2) inputs

are disabled and the selected phase acts as a

completely independent single phase power analyzer

3 Phase 2 Wattmeter +

PH3

As above(3 phase, 2 wattmeter) but with the option

to use PH3 as an independent meter i.e., use PH3 to

measure a DC bus plus Phase’s 2 & 3 to measure a 3

phase inverter output. PH3 can be set as an

additional connection for Torque & Speed to

supplement the existing "EXT" BNC connections on

the rear panel. This mode essentially facilitates

independent frequency synchronisation of PH3

Independent

In independent wiring mode each phase can be

selected as an individual analyzer enabling the ability

to select its own frequency, coupling ranging etc

PPA45xx Quick User Guide

Page 11

Speed

In normal acquisition mode the window over which

the measurements are computed is adjusted to give

an integral number of cycles of the input waveform.

The results from each window are passed through a

smoothing filter. There are 5 pre set speed options

that adjust the nominal size of the window, and

therefore the update rate and time constant of the

filter. Greater stability is achieved at a slower speed at

the expense of a slower update rate

Very Slow

Update rate = 10s. Results window size will update

every 10 seconds

Slow

Update rate = 2.5s. Results window size will update

every 2.5 seconds

Medium

Update rate = 1/3s. Results window size will update 3

times per second

Fast

Update rate = 1/20s. Results window size will update

20 times per second

Very Fast

Update rate = 1/80s. Results window size will update

80 times per second

Window

The window application will allow the user to input

their own speed settings different to any of the 5 pre

set settings above

Smoothing

Smoothing filter will gather the data and average out

over a sliding window time scale. This is very useful

when gathering data which could be affected by

noise. Each speed above has its own time constant

for filtering and data updates

Normal

With Normal smoothing applied the following update

windows will apply to the relevant speed selected.

V.Fast =0.05s, Fast = 0.2s, Medium = 1.5s,

Slow = 12s, V.Slow = 48s

Slow

With Slow smoothing selected all results are X4

greater than in normal smoothing mode

None

With no smoothing to computed results the data

update will be dictated by the speed only

PPA45xx Quick User Guide

Page 12

Smoothing Response

Auto Reset

The smoothing response is by default set to “auto

reset” where the filtering described in “smoothing” is

reset in response to a significant change in data such

as frequency, voltage and current levels. This speeds

up the response of the instrument to changing

conditions

Fixed Time

Auto reset can be disabled so that the filtering has a

fixed time constant, which would have an exponential

response to a step change, this is useful for PWM

inverter drive evaluation where variable frequency

tracking is required

Frequency Reference

The frequency may be measured from any of the

following inputs:

Voltage

Select Voltage to detect frequency from the input

voltage

Current

Select Current to detect frequency from the input

current

Speed Input

Select speed input to frequency detection to set

frequency via “speed input” BNC

AC line

Select ac line to read frequency from the ac line

input, measured from power inlet to PPA

Frequency Reference

On a multi-phase instrument, any channel may be

selected for the frequency measurement

Phase 1

Select this option to detect frequency from phase 1

Phase 2

Select this option to detect frequency from phase 2

Phase 3

Select this option to detect frequency from phase 3

Phase Angle Reference

Phase angle measurements must be made with

reference to a specific input

Voltage

Phase 1 voltage is by default set as the input

reference channel

Current

The phase angle reference can be set to current

which is useful if operating the instrument with only

current inputs, or with low level voltage inputs

PPA45xx Quick User Guide

Page 13

Frequency Filter

A parallel digital frequency filter of low-pass may be

selected to filter out the HF carrier component of a

PWM waveform ensuring measurements are carried

out on the fundamental frequency, further filter

settings for PWM waveforms can be found within the

APP/PWM section

Off

No frequency filter selected

On

Switches On frequency filter (4kHz)

Low Frequency

Normal frequency measurement is from 5Hz upwards

so that there is not a very long delay if measuring dc.

There is a low frequency option that extends the

frequency measurement down to 20mHz. This low

frequency option also applies a digital filter, which

can be useful when measuring in a low frequency,

noisy environment

Off

Select to switch this mode Off

On

Select to switch this mode On

ADVANCED OPTIONS

DFT Selectivity

Analysis of the fundamental component uses a DFT

(Discrete Fourier Transform) algorithm. The

selectivity of the DFT analysis is a compromise

between noise rejection of frequencies close to the

frequency of the fundamental component and the

required stability of the frequency component

Normal

Default settings for the fundamental calculations

Narrow

Selecting “narrow” increases the selectivity of the

DFT analysis (reducing the effective bandwidth at

each component) which has the effect of improving

the noise rejection. It does however require that the

frequency of the fundamental component is more

stable

Ignore Overload

In a noisy application any spikes present on the signal

may push the instrument onto a higher range than is

necessary for the signal being measured. If the

nature of the spurious spikes are such that they do

not contribute to the measurement and can safely be

ignored then the range can be manually set to the

appropriate range for the signal to be measured and

the instrument can be told to ignore any overload. If

using this mode it is wise to check the signal on the

oscilloscope to be sure that the signal being measured

is not genuinely over range

Off

Select to switch this mode Off

On

Select to switch this mode On

PPA45xx Quick User Guide

Page 14

Frequency Lock

In a very noisy application, where the frequency of

the signal is known but the instrument is unable to

measure the frequency even with PWM filters or low

frequency mode filters applied, it is possible to

manually enter the frequency to be used for analysis

Normal

Utilises N4L unique signal processing techniques for

fundamental frequency synchronisation including

hysteresis to increase frequency noise immunity

Constant

Constant selection will allow the user to overwrite the

present measured frequency with the known

frequency. This entered frequency is then used for all

the analysis and the frequency of the input signal is

not measured

Dynamic

As per “Normal” without hysteresis. This option

should not be used when DC only coupling is selected

in the Coupling menu.

High Speed

High speed mode can be selected for data log speeds

less than 100ms

Disabled

Disable high speed function

Enabled

Activate high speed data log function

COUPLING

Coupling

There are three coupling options - AC only, AC+DC,

or DC only. AC+DC coupling is the default option and

should be used where possible. AC coupling should be

used for measuring signals that are biased on a dc

level (such as an amplifier operating on a single

supply or the output of a dc PSU). DC coupling should

be selected when making DC measurements as it

prevents noise from resetting the frequency

measurement algorithm. The coupling option does not

affect the bandwidth of the instrument only the

frequency detection

ac + dc

Will allow both ac and dc signals to be calculated in all

measurements

ac

AC Coupling only allows ac signals to be measured

and will filter out all dc components

dc

DC coupling should be selected when making DC

measurements as it prevents noise from resetting the

frequency measurement algorithm, the bandwidth of

the instrument is not affected. When DC coupling is

selected “Dynamic” Frequency lock has no meaning

and so should not be used.

PPA45xx Quick User Guide

Page 15

Bandwidth

The bandwidth setting dictates the frequency range of

the instrument. This selection sets an inline analogue

filter as per the selection

Wide (dc - 2MHz)

HC Version (dc –1MHz)

Wide bandwidth will offer the full range of frequency

components available for analysis

Low (dc - 200KHz)

Low bandwidth may be useful in noisy applications for

example where there are switching spikes

superimposed on the waveform of interest. The

switching spikes may push the input channels onto a

higher range than is necessary for the measurement.

Selecting low bandwidth puts a hardware filter in the

analogue input path to eliminate unwanted high

frequency components

dc (dc –5Hz)

The DC only bandwidth option applies a dc-accurate

low pass filter of around 10Hz to reduce the ac signal.

This is particularly useful when accurately measuring

the dc content of an ac waveform such as the output

of a UPS (uninterruptible Power Supply). A 50Hz or

60Hz ac signal would not be removed entirely so that

the measurement may still be synchronised to the

waveform, but the amplitude would be greatly

reduced so that the instrument would be on a more

appropriate range for the dc component

PPA45xx Quick User Guide

Page 16

Noise Filter

In signal processing, a “FILTER” is a device or process

that removes from a signal some unwanted

component or feature. The noise filter is a digitally

selectable in line filter which will alter the bandwidth

of the processed signal

Off

Select to switch this mode off

On

Select to switch this mode on

The following screenshots are taken from the “Scope” display with the PPA set in

PWM application mode

Noise filter set to OFF the scope display shows a PWM switching Voltage

waveform with noise distortion

Noise filter activated and bandwidth set to 1KHz the Voltage waveform is now

displayed and is smoother and more sinusoidal

PPA45xx Quick User Guide

Page 17

RANGE

Input channel options

Voltage Input

Internal

The internal voltage attenuator selects the 4mm

connections on the rear of the instrument and has a

max input of 3000Vpk

External Attenuator

(for connection to a HF

shunt).....etc

An External Sensor / Shunt can be connected to the

instrument which will give the operator more

versatility in selecting the Input range required. Note:

if this option is selected then the resulting data is

scaled by the appropriate value within the attenuator

and scale factor sub section. Max input of 3Vpk

Autoranging

Full Autorange

Default setting. Full autoranging will be selected and

implemented within the instrument

Range up only

Selecting this option will allow the test being carried

out to find the highest range via peak detection and

hold on this range. Once this value has been found

another test can be carried out by pressing the

"Trigger" button which will restart from the minimum

value set parameter use for "Low”Frequency

measurements

Manual

Selecting this option will allow the user to set up the

range from the configured measurements available,

this is useful for inrush testing when a mid-analysis

range change is not desirable

Minimum Range

Pre set Input Voltage minimum range

1V

Minimum Input Voltage range will not be below 1v

3V

Minimum Input Voltage range will not be below 3v

10V

Minimum Input Voltage range will not be below 10v

30V

Minimum Input Voltage range will not be below 30v

100V

Minimum Input Voltage range will not be below 100v

300V

Minimum Input Voltage range will not be below 300v

1Kv

Minimum Input Voltage range will not be below 1Kv

3Kv

Minimum Input Voltage range will not be below 3Kv

Scale Factor

Manually set the scale factor required, normally used

in conjunction with current transformers

PPA45xx Quick User Guide

Page 18

Current Input

Internal

The internal current shunt selects the 4mm

connections on the rear of the instrument. Max Apk is

dependent upon model type; LC (10A rms),

Standard (30A rms) or HC (50Arms)

External Shunt

An External Shunt can be connected to the instrument

which will give the operator more versatility in

selecting the Input range required. Note: if this option

is selected then the resulting data is scaled by the

appropriate value within the scale factor and shunt

value sub section

Autoranging

Full Autorange

Default setting. Full autoranging will be selected and

implemented within the instrument

Range up only

Selecting this option will allow the test being carried

out to find the highest range via peak detection and

hold on this range. Once this value has been found

another test can be carried out by pressing the

"Trigger" button which will restart from the minimum

value set parameter

Manual

Selecting this option will allow the user to set up the

minimum range from the configured measurements

available

Minimum Range

Pre set current input minimum range

10mA LC Version Only

Minimum Input Current range will not be below 10mA

30mA LC

Minimum Input Current range will not be below 30mA

100mA LC, SC

Minimum Input Current range will not be below

100mA

300mA LC, SC, HC

Minimum Input Current range will not be below

300mA

1A LC, SC, HC

Minimum Input Current range will not be below 1A

3A LC, SC, HC

Minimum Input Current range will not be below 3A

10A LC, SC, HC

Minimum Input Current range will not be below 10A

30A LC, SC, HC

Minimum Input Current range will not be below 30A

100A SC, HC

Minimum Input Current range will not be below 100A

300A SC, HC

Minimum Input Current range will not be below 300A

1000A HC Version Only

Minimum Input Current range will not be below

1000A

Scale Factor

Manually set the scale factor required

DC offset

Used to trim out DC offset commonly found on

external current transducers

PPA45xx Quick User Guide

Page 19

DATALOG

Datalog

Interrogation and extraction of information resulting

from a test log in a specified time scale and at a set

speed

Disabled

No memory selected

RAM

Instruments internal memory selected for data

storage, this offers the fastest performance

Internal Flash

Utilises 200MB internal memory

USB memory stick

External USB memory stick selected for data storage

APP

Mode

Application function to be selected

Normal

Using the Normal Application the default settings

within the instrument will be applied to all

measurements, useful for general measurements

Default Settings

All default parameters will be selected when “ENTER”

is pressed

PWM Motor Drive

The nature of the waveforms in a PWM motor drive

application makes measurement of the fundamental

frequency difficult. The application mode for PWM

motor drives applies a selectable filter which is a

parallel digital filter and will not affect the bandwidth

of the instrument; it is only used for frequency

detection. The best filter to use for a given application

should be selected by experiment. The filter does not

change the measured data at all. PWM application

mode also allows torque and speed to be

simultaneously measured so that efficiency can be

computed

Default Settings

All default parameters will be selected when “ENTER”

is pressed

Frequency Filter

Pre selectable filter options 64Hz, 250Hz, 1KHz,

4KHz, 16KHz, 64KHz, 250KHz

Frequency Reference

Select which parameter frequency reference will be

detected from input signal

Low Frequency

Can be selected as On or Off if “On” is selected

manually enter the minimum frequency required

Torque + Speed

Power Measurement function can be set to disabled or

enable to measure the desired function from

analogue, pulsed speed, pulsed torque, or pulsed.

Once enabled a scale factor / offset will require

setting in relation to either Voltage or Frequency

Efficiency

(Not applicable to the PPA4510) Efficiency can be

measured between selected channels from the drop

down menu

This manual suits for next models

2

Table of contents

Other Newtons4th Measuring Instrument manuals

Newtons4th

Newtons4th PSM1700 Use and care manual

Newtons4th

Newtons4th N4L PPA500/1500 User manual

Newtons4th

Newtons4th PPA 5500 KinetiQ Use and care manual

Newtons4th

Newtons4th SLM3505 Use and care manual

Newtons4th

Newtons4th PPA 5500 KinetiQ User manual

Newtons4th

Newtons4th PPA55 Series User guide

Newtons4th

Newtons4th PSM3750 NumetriQ Use and care manual

Newtons4th

Newtons4th PPA4500 User guide

Newtons4th

Newtons4th SFRA45 Operator's manual

Newtons4th

Newtons4th PPA2500 Use and care manual