Nexion Molnar CM245-A User manual

Date: 09.10.2022

CM245-A

CM255-A

Installation Instructions

Read the operating

instructions before

working with the

unit

ALWAYS KEEP

operating instructions

ready to hand on the

unit

Before

taking into operation

check system compo-

nents, control, emer-

gency stop and safety

equipment for conditi-

on, damage and

correct function!

2 / 40

CM245/55-A

Please read this manual before you get started.

You must read and understand the precautions for safety purposes and any damages that may occur

to your property.

If these installation instructions are not followed strictly, the hoist is not covered by warranty.

Address: 3 Graham Street

Export Park

South Australia 5950

Ph:

Fax:

Email:

Web:

+61 (08) 8234 3611

+61 (08) 8234 4322

www.molnarhoists.com.au

Specifications/images subject to change without prior notice, Images and sketches are for illustration purposes only.

3 / 40

CM245/55-A

For further information - please see the foundation instructions:

Model Foundation instructions

CM245-A CM255-A T82346

These instructions indicate step by step how you ensure a trouble-free installation and a satisfactory operation. It

is therefore of vital importance that you take the necessary time and care in order to ensure that the installation

tolerances are not exceeded, otherwise the hoist will not function effectively and you will not benefit fully from

your purchase of the hoist.

NB: Note this arrow → .The hoist will throughout these instructions be shown from the drive-on direction.

NB: If these installation instructions are not followed strictly, the hoist is not covered by warranty.

Information for construction engineer or architect:

Model Quality of concrete according to EN206-1: Depth:

CM245-A

CM255-A

C25/30 (Fcyl = 25 N/mm² / Fcube = 30 N/mm²)

(B25 = 25 N/mm²)

160mm. (HILTI HST3)

Information for fitter:

The hoist has to be installed on an even floor and must not be installed in or close to construction joints

(min. distance = 200 mm). The thickness of the wearing surface on the raw concrete and clinkers, if any, must

be added to the length of the expansion bolts.

Expansion bolts used for the installation of the hoist in not-cracked concrete:

Model Expansion bolt

CM245-A CM255-A Hilti HST3 M16x145 45/25 *

*If alternative attachment is used the properties of this attachment must correspond to the Hilti bolt mentioned.

(The expansion bolts are not included in the delivery).

CM245-AS

Max. lifting capacity 4,500 kg

Lifting time 40 sec.

Lowering time 40 sec.

Lifting height 2013 mm

Stroke 1900 mm

Operation temperature ÷10°...60°

Noise level (measured at control unit at 1.6 m height) 85 dB (A)

Mains voltage Power

Revolutions/min

230-400/3/50+N +PE 3,0 kW

1400 rpm

400/3/60+N +PE 3,0 kW

1630 rpm

Pre-fuse 16A Class C (slow)

Max. operating pressure 210 bar

Setting of pressure control valve max. 230 bar

Output (at 50 Hz) 8.8 l/min

Output (at 60 Hz) 10.6 l/min

Oil contents approx. 8.4 L of 46

Oil displacement 4.8 L

3.4 Technical specifications

4 / 40

CM245/55-A

1. Tools requested.

2. Place all components as shown.

Remove transport plates from each column.

5 / 40

CM245/55-A

1

2

7 / 40

CM245/55-A

3

Max. portal height

M8x16

Min. portal height

M8x16

4

M6x25

8 / 40

CM245/55-A

5. Fit the prefitted safety ratchets on both posts.

6. Fit bracket with top limit switch in control post.

Re-tightening and adjustment of top limit switch is made at step 41.

9 / 40

CM245/55-A

5

6

M6x16

M12x25

10 / 40

CM245/55-A

7. Fill in oil on pump unit (see above specifications).

8. Fit bent bracket for pump unit on control post.

9. Fit pump unit on bracket.

10. The short hydraulic hose is fitted on pump and connected to the hydraulic hose on control post.

11 / 40

CM245/55-A

7

9

8

10

OIL

M6x25

M10x25

12 / 40

CM245/55-A

11. Fit plug for solenoid valve. (You will find the pre-wired plug tucked inside the post)

12. Fit motor cable on pump unit. For correct cable connection according to mains supply, see sketch.

13. Fit portal corners on posts as shown.

NOTE ! Pull the pre-fitted cables and hydraulic hoses out through the top of the extensions before raising

the posts.

13 / 40

CM245/55-A

11

13

12

Control post Opposite post

M8x20

( )

( )

3x230V

3x400V

14 / 40

CM245/55-A

14. Raise posts by means of straps.

Place posts as shown.

NOTE: The requirements of the local authorities concerning installation of hoists must always be

respected.

AS/NZS 1418.9 Section 3.4 Location of Vehicle Hoists

Vehicle hoists should be positioned so that any moving part of the hoist or the load is not less than

600mm away from the nearest fixed structure. Where a vehicle hoist is installed adjacent to any other

equipment which moves, the minimum clearance between any part of the hoist or the load and that

equipment shall be 600mm.

15. Drill holes for 2 expansion bolts in each post (to ensure that posts do not tilt during installation). Drill ho-

les through base plate. Fasten posts by means of expansion bolts - do not tighten bolts yet as definitive

adjustment of post position will take place later on (see step 20).

15 / 40

CM245/55-A

14

15

Min. 600 3250

Min. 2800

90°

16 / 40

CM245/55-A

16. Assemble portal.

Note ! Screws are not tightened before step 20.

17. Fit 4 pipe clamps loosely along the portal.

17 / 40

CM245/55-A

16

17

M8x20

1

4

2

3

M6x16

18 / 40

CM245/55-A

18. Fit bracket with height limit switch on left portal member.

19. Push rod for height limit switch into left portal member and fasten it on right portal member.

19 / 40

CM245/55-A

18

19

M8x20

M6x16

20 / 40

CM245/55-A

20. Raise portal and place on posts.

Adjust distance between posts if necessary.

Fasten portal - adjust distance between portal members if necessary - tighten bolts.

21. Check distance between posts and that posts are plumb - shim up if necessary.

22. Drill holes through base plate for remaining expansion bolts. Tighten all expansion bolts.

Torque for expansion bolts: 110 Nm.

NOTE!

Shim up base plates so that posts are vertical. As much base plate surface should be in

contact with the floor as possible. Molnar recommends at least 75% surface/shim to floor

contact, specifically in the middle of the base plate which must be in contact with the floor or

shimmed.

21 / 40

CM245/55-A

20

21

M8x20

22

Other manuals for Molnar CM245-A

1

This manual suits for next models

2

Table of contents

Other Nexion Lifting System manuals

Popular Lifting System manuals by other brands

ThyssenKrupp

ThyssenKrupp orion user manual

morse

morse 195AM-A Operator's manual

Custom Equipment

Custom Equipment Hy-Brid Lifts I Series MAINTENANCE & TROUBLESHOOTING MANUAL

BGS technic

BGS technic 9239 manual

Ranger Products

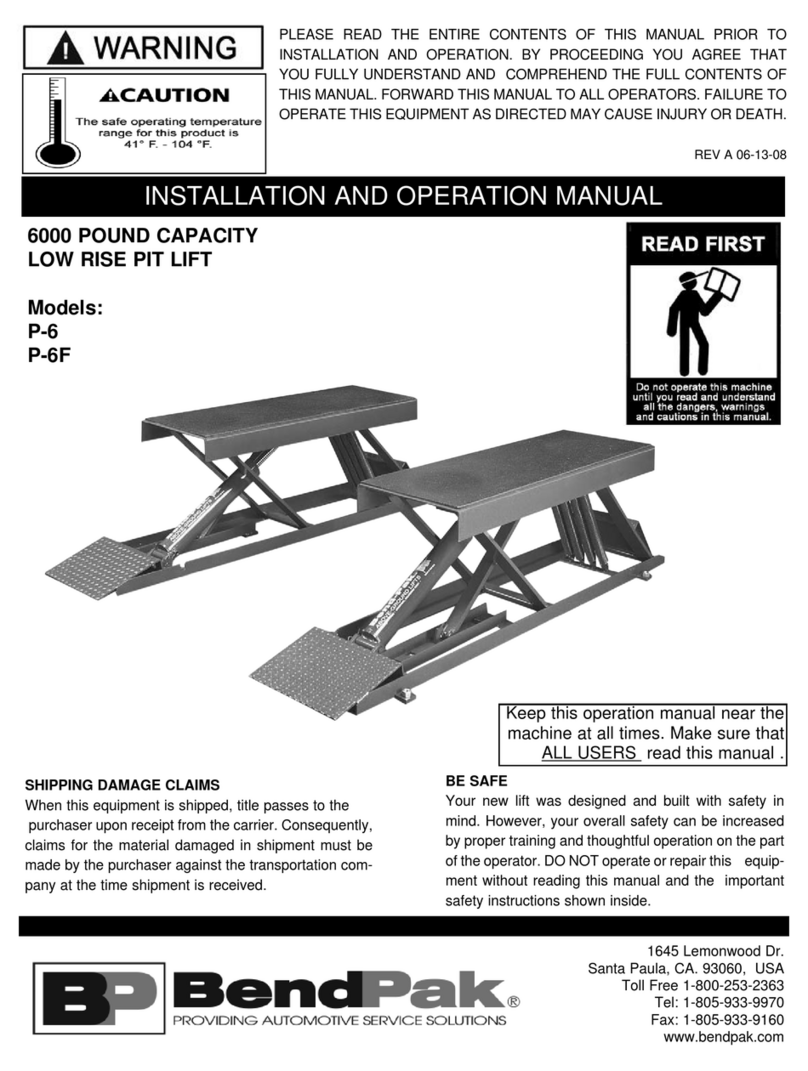

Ranger Products BendPak P-6 Installation and operation manual

stertil-KONI

stertil-KONI SKY-200 Installation, operation and maintenance instructions