TERRY TSL1000 User manual

TSL1000 Platform Lift

Original instructions

CONTENTS

Introduction 4

Description 5

General Do’s and Don’ts 6

Controls 7

Operating the Lift 8

Emergency procedures 9

Emergency gate lock override 10

Maintenance & Servicing 10

Fault finding 11

Safety feature checks 12

Service history record 13

Declaration of conformity 14

Lift specification 15

3

INTRODUCTION

Thank you for choosing the Terry TSL1000 lift, designed and

manufactured in the U.K. using the latest technology from Terry

Group Ltd. We want you to get the most out of your TSL1000 Lift

and to help in this aim, we have produced this small booklet on

operation and maintenance of the equipment which we trust you

will find helpful.

It is hoped that any queries you may have during day to day

operation will be answered in the text but if you do have any

problems our technical help service is only a phone call away.

We hope that our product gives you many years of reliable

service.

Peter Morrey

Managing Director

DESCRIPTION

The Terry TSL1000 Lift is designed to transport a single person

in a wheelchair between two floor levels up to 1 metre apart.

To provide the lifting force the lift uses a hydraulic cylinder under

the platform, fed via a hose from a pump unit mounted under

the power pack cover on the platform. Principal features of the

design are its low closed height and silent smooth operation. The

low closed height eliminates the need for a pit.

Control stations are provided on the platform power pack and

at the upper and/or lower levels depending on requirements. A

remote control enabler option is also available to limit the use of

the lift to authorised users only.

4

It is most important that before operating the lift you read these

instructions fully and are familiar with the controls and operating

procedure.

Our policy is one of continous product development and the

Company reserves the right to change specification without

notice.

If a change of use of the lift is required, this should be discussed

with the manufacturer/supplier as certain alterations may be

needed.

Examples of changes of use are:

a) change of type, size and/or weight of wheelchair;

b) change of user disability;

c) change of user;

d) removal of the homelift and reinstallation at another site;

e) change of duty cycle.

All changes of use should entail a review of the installation.

5

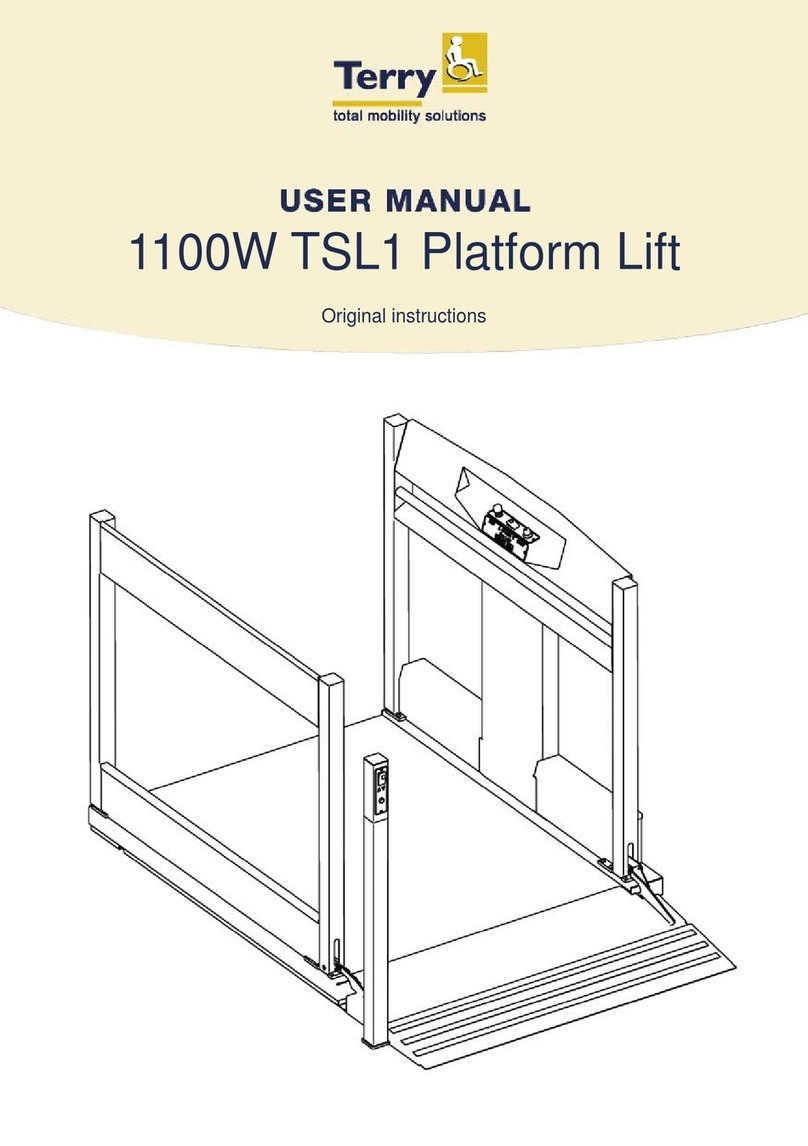

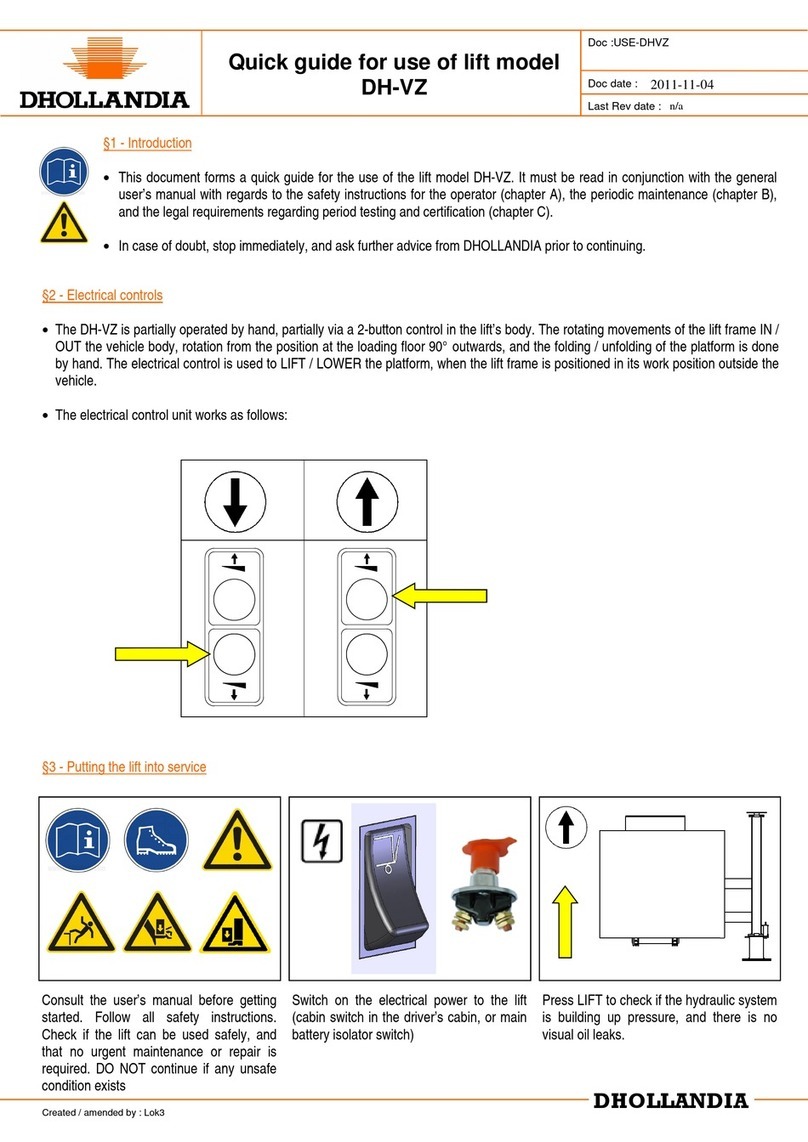

Standard model

Control Post Platform controls

Power pack

Ground ramp

Side Entry Model

GENERAL DO’S AND DON’TS

• Always leave the power supply to the lift switched on, even

when you go away. The lift control circuits are fed by a battery,

which must be kept constantly charging.

• Never allow children to play on or around the lift.

• Ensure that the area around the lift is kept clear from debris

(e.g. litter and leaves).

• Do not exceed the maximum lifting capacity of 39 stone (250

kg).

• Always treat your lift with respect that should be shown to

electrical and mechanical equipment.

WARNING! As recommended by the Medicines and Healthcare

products Regulatory Agency (MHRA), great care should be

exercised whilst manoeuvring on and off the platform ramp, to

avoid the risk of tipping over rearwards. Information can be found

at www.mhra.gov.uk

6

CONTROLS

Location

• Lower level control switch(standard installation)-mounted on

control post.

Or

• Lower level control switch (pit installation / side entry)

mounted on the building structure at the lower level.

• Platform control switch-mounted on lift platform power pack

cover (mounted on handrail if side entry).

• Upper level control switch (no upper level gate) mounted on

the building structure at the upper level.

Or

• Upper level control switch (upper level gate) integral with the

gate frame.

Function

• All controls are of the “hold to run” type. Maintain pressure

on the switch until the lift reaches the upper or lower level.

To travel in the opposite direction, release the switch, wait 2

seconds and press again.

• A master switch, which “locks” all controls to prevent

unauthorised use is fitted to the charger box.

• If the lift has been supplied with a remote control lift enabler

unit the lift will remain disabled until key fob is pressed.

Pressing the key fob will allow the lift to be operated by the

up/down control in the normal way. 3 minutes after pressing

the key fob the lift will automatically revert back to its disabled

mode preventing further use. The lift can then only be

reactivated for use by repressing the key fob.

7

OPERATING THE LIFT

If the radio control enabler option is fitted press the key fob to

activate the control stations.

The lift can be called by maintaining pressure on the call button

and waiting for it to stop at the appropriate level. Move on to the

platform and apply the wheelchair brakes. Press and maintain

pressure on the control button to operate the lift until it stops at

the required level.

The upper level gate will automatically release for up to 10

seconds when the lift reaches the upper level. Alternatively

pressing the ‘gate open’ button on the platform or on the upper

call station will also release the gate. Note that the lift can only be

lowered when the upper level gate is fully shut.

If necessary, the lift can be stopped at any time by releasing the

control button.

The underside of the lift is fitted with a platform safety device

which automatically stops the lift if an obstruction is present

beneath the platform. Once the obstruction has been removed

the lift will continue to operate as normal.

We recommend that the lift is kept at the lower level when

not in use.

8

9

EMERGENCY PROCEDURES

a) Isolation of the batteries on the lift is

achieved by removing a fuse. This is

located at the ramp end of the power

pack box on the platform, behind a round

blanking plug. Remove the plug to gain

access to the fuse, which can simply be

pulled out to isolate the batteries.

b) In the unlikely event that the lift stops

part-way through its travel and will not

restart, it can be lowered by removing a

round blanking cover on the top of the

power pack box on the platform and

pulling the chord, located beneath.

Please Note: If the platform is at the

upper level and will not lower, it will be

necessary to first remove the fuse as per

emergency procedure a) before following

emergency procedure b).

In the interest of safety, ensure that the

upper level gate is closed before the lift is

manually lowered.

Be aware that the platform safety device

does not function when manually lowering

the lift. Ensure that people are away

from the platform and that there are no

obstructions.

c) The Isolator switch is situated on top

of the charger pack (located indoors),

should be switched on at all times.

NOTE: A competent person will need to be

called to restore the safety functions of the lift

before re-use.

EMERGENCY GATE LOCK OVERRIDE

Upper level gate (if fitted)

MAINTENANCE & SERVICING

Provided the operating instructions are observed the lift will give

many years of trouble free service. Terry Group Ltd. can quote for

servicing on request.

Dependent on frequency of use, this lifting platform should

be serviced at least every 6 months. This service should be

conducted by competent persons trained in the service and

repair of the product.

If a lifting platform is to be installed in an adverse environment,

the specifier and supplier shall determine the measures needed

to ensure that safe operations are achieved including more

regular service intervals.

Note: Adverse environments are those that could affect safe

operation. Examples include; the effects of humidity, atmospheric

pollution, solar radiation, swimming pool environs (this product

is not suitable for use in chlorinated environments), extreme

temperatures, etc.

If in any doubt about the operation of the lift please contact the

installation company for advice.

10

FAULT FINDING

The table below should help solve any problems, which may be

stopping your lift from operating correctly. If, however, your lift

still does not operate correctly after referring to this table please

do not hesitate to call the number on the back of this booklet for

further advice.

Lift

Position Problem Cause Remedy

Lower level Lift will not

operate

Charger isolation

switch disabling

lift

Remote control

enabler(if fitted)

not activated.

Ensure charger

isolation switch

is on.

Activate remote

control enabler

with key fob.

Lift rises short

distance then

stops Obstruction on

ramp

Remove

obstruction on

ramp

Upper level Lift will not

operate

Charger isolation

switch disabling

lift.

Remote control

enabler(if fitted)

not activated

Ensure charger

isolation switch

is on.

Activate remote

control enabler

with key fob

Upper level

gate not closed

properly (where

fitted)

Ensure gate is

fully closed

Platform safe

edge obstructed Remove

obstruction

below the lift

Lift operates but

stops before the

lower level

Platform safe

edge obstructed Remove

obstruction

below the lift

11

SAFETY FEATURE CHECKS

As a precautionary measure it is advised that you check the

safety features built into the lift on a weekly basis. Carry out the

ckecks as discribed below: -

• Platform safe edge - With the lift at the upper level call the lift

down and once it is moving obstruct the platform safe edge,

the lift should stop.

These tests may require the help of another person: -

• Folding ramp upper safe edge - With the lift at lower level

obstruct the upper surface of the ramp and send the lift up,

the lift should stop within 300mm of travel.

• Upper level gate - With the lift at the upper level open the

upper level gate and attempt to call the lift down from the

lower level. The lift should remain stationary.

All of these tests should be carried out with the lift

unoccupied.

If any of these tests fail, the lift MUST NOT be used and advice

sought by calling the number on the back of this booklet

12

SERVICE HISTORY RECORD

An entry should be added to the following table every time the lift

is serviced.

Date Engineer Company Comments

13

14

DECLARATION OF CONFORMITY

Lift Type: STEPLIFT 1000

This lift was manufactured by TERRY GROUP Ltd., who declare

that this lift fulfils all the relevant provisions of the following

Directives:

2004/108/EEC EMC Specifications

2006/42/EC Machinery Directive

This lift also fulfils all the relevant provisions of the following

Standards:

BSEN 12015:2004 Electromagnetic Compatibility. Product family

standard for lifts, escalators and moving walks.

Emission.

BSEN 12016:2004

+A1:2008 Electromagnetic Compatibility. Product family

standard for lifts, escalators and moving walks.

Immunity.

BS6440:2011 Powered lifting platforms for use by disabled persons

Person authorised to compile Technical File:

Greg Gnyp, Terry Group Ltd., Longridge Trading Estate,

Knutsford, Cheshire, WA16 8PR

This declaration was completed at Terry Group Ltd., Longridge

Trading Estate, Knutsford, Cheshire, WA16 8PR, in September

2011.

This compliance is only valid if the installation test Certificate

has been completed and signed by a competent lift engineer

which confirms that it has been installed to the latest installation

instructions.

TERRY GROUP Ltd.

P.Morrey (Managing Director)

LIFT SPECIFICATION

Address of manufacturer:

Terry Group Ltd.

Unit 1 Longridge Trading Estate

Knutsford, Cheshire, England

WA16 8PR

Lift serial No. Year of manufacture

Maximum load 250Kg (39 stone)

Maximum travel 1 metres

Power supply 240V AC ~ 50/60 Hz

Control voltage 24V DC

Hydraulic pump power

consumption 600W maximum

Hydraulic oil grade T22

Standards Designed and manufactured to

BS6440

Our policy is one of continuous product development and the

Company reserves the right to change specification without

notice.

15

This Steplift 1000 has been supplied by:

10199b

Table of contents

Other TERRY Lifting System manuals