nextys NISO-20 How to use

1

Short Form Installation User’s Manual

Models

NISO-20 – 800W DC/DC DIN Rail Isolation Module

File No.:

I.M.NISO-20

Rev.:

1.0

Nextys SA. Via Luserte Sud 6, 6572 Quartino – Switzerland

Phone: +41-(0)91 8401446 / 8401448; Fax: +41-(0)91 8401447

READ THIS CAREFULLY BEFORE INSTALLATION!

LEGGERE ATTENTAMENTE PRIMA DELL’INSTALLAZIONE!

A LIRE ATTENTIVEMENT AVANT L’INSTALLATION!

Before operating, read this document thoroughly and retain it for

future reference.

Non-respect of these instructions may reduce performances and

safety of the devices and cause danger for people and property.

The products must be installed, operated, serviced and maintained

by qualified personnel in compliance with applicable standards

and regulations.

Don’t open the device, it does not contain replaceable

components, the tripping of the internal fuse (if included) is

caused by an internal failure.

Don’t repair or modify the device, if malfunction or failure should

occur during operation, send unit to the factory for inspection. No

responsibility is assumed by Nextys SA for any consequences

deriving from the use of this material.

Prima dell’installazione, leggere attentamente questo documento

istruzioni e conservarle per future consultazioni.

L’inosservanza delle presenti istruzioni può compromettere le

caratteristiche e la sicurezza dell’apparecchio e causare pericolo per le

persone e le cose.

Il prodotto deve essere installato, utilizzato e riparato da personale

qualificato e nel rispetto delle normative vigenti.

Non aprire il prodotto, esso non contiene componenti sostituibili, il

guasto del fusibile interno (se previsto) è causato da un guasto interno.

Non tentare di riparare o modificare il prodotto, se durante il

funzionamento si verificano guasti o anomalie, inviarlo al produttore per

il controllo.

Nextys SA non si assume nessuna responsabilità per qualunque

conseguenza derivante dall’uso di questo materiale.

Lire ces instructions avant l'installation, conserver ce manuel pour

référence future.

Défaut de se conformer à ces instructions peut affecter les

caractéristiques et la sécurité du dispositif, et causer du danger aux

personnes ou aux biens.

Les produits doivent être installés, exploités et entretenus par du

personnel qualifié et en conformité avec les règlements.

N'ouvrez pas le produit, il ne contient aucune pièce réparable, le

déclenchement du fusible interne (le cas échéant) est causé par un

défaut interne. Ne pas essayer de réparer ou modifier le produit ; si

des défaillances se produisent pendant le fonctionnement, retourner

le produit au fabricant pour inspection. Nextys SA n'assume aucune

responsabilité des conséquences éventuelles découlant de

l'utilisation des produits.

CAUTION

ATTENZIONE

AVVERTISSEMENT

RISK OF BURNS, EXPLOSION, FIRE, ELECTRICAL SHOCK, PERSONAL

INJURY.

Never carry out work on live parts! Danger of fatal injury! The

product’s enclosure may be hot, allow time for cooling product

before touching it. Do not allow liquids or foreign objects to enter

into the products.

To avoid sparks, do not connect or disconnect the device before

having previously turned-off input power and wait for internal

capacitors discharge (minimum 1 minute).

RISCHIO USTIONI, ESPLOSIONE, INCENDIO, SCOSSA, LESIONI GRAVI.

Non effettuare mai operazioni sulle parti sotto tensione! Pericolo di

lesioni letali! Il contenitore può scottare, lasciar quindi raffreddare il

dispositivo prima di toccarlo. Non far entrare liquidi o oggetti estranei

nel dispositivo.

Per evitare scintille, non collegare o scollegare l'apparecchiatura prima

di avere tolto tensione di ingresso e prima che sia avvenuta la scarica

dei condensatori interni (min. 1 minuto).

RISQUE DE BRULURES, EXPLOSION, INCENDIE, ELECTROCUTION,

DOMMAGE AUX PERSONNES.

Ne jamais effectuer des opérations sur les parties sous tension!

Danger de mort! Le boîtier peut produire des brûlures, le laisser

refroidir avant de toucher l'appareil. Ne faire pas pénétrer des

liquides ou des corps étrangers dans l'appareil. Pour éviter des

étincelles, ne pas connecter ou déconnecter l'équipement jusqu'à ce

que la tension d'entrée a été supprimée et avant qu'il n'ait eut lieu la

décharge des condensateurs internes (minimum 1 minute).

INTENDED USE

USO PREVISTO

UTILISATION

These are isolated devices suitable for SELV and PELV circuitry and

are designed to be mounted on DIN rail and installed inside a

protective enclosure. They are intended for general use such as in

industrial control, communication, and instrumentation

equipment.

Don’t use these devices in applications where malfunction may

cause injury or death.

I dispositivi sono isolati, adatti per applicazioni SELV e PELV, sono dotati

di aggancio per il montaggio su guida DIN all’interno di quadri elettrici o

contenitori di protezione, per l’utilizzo con controllori industriali, unità

di comunicazione o apparecchi di misura.

Non utilizzare in applicazioni in cui un eventuale guasto può comportare

rischio di lesioni o di morte.

Les produits sont isolés, appropriés pour les circuits TBTS et TBTP et

sont équipés d'un crochet pour montage sur rail DIN dans des

armoires ou conteneurs de protection, pour utilisation avec les

contrôleurs industriels, des modules de communication ou des unités

de mesure.

Ne pas utiliser ces dispositifs dans une application où un

dysfonctionnement pourrait entraîner le risque des blessures ou de

mort.

ENVIRONMENTAL CHARACTERISTICS

CARATTERISTICHE AMBIENTALI

CARACTÉRISTIQUES ENVIRONMENTALES

Installation in a Pollution Degree 2 environment, Overvoltage

Category I, according to IEC60664-1.

Do not use in wet area or subject to moisture.

Carefully recycle the product and related batteries according to

local regulations.

Usare in ambienti con Grado di Inquinamento 2 e Categoria di

Sovratensione I, secondo IEC60664-1.

Non far funzionare l'apparecchio in un ambiente umido o soggetto a

formazione di condensa. Riciclare il prodotto e le batterie collegate, nel

rispetto delle normative locali vigenti.

Utiliser les produits dans des environnements avec degré de pollution

2, catégorie de surtension I selon IECN60664-1.

Ne pas employer l'appareil dans un environnement humide ou

soumis à la condensation. Recycler les produits et les batteries,

conformément à la réglementation locale..

Declaration of Conformity

NEXTYS SA.

Via Luserte Sud 6, 6572 Quartino - Switzerland

Phone: +41-(0)91 840 14 46 / 840 14 48; Fax: +41-(0)91 840 14 47

E-mail: [email protected]

This Declaration of Conformity is suitable to the European Standard EN45014 "General criteria for supplier’s declaration of conformity".

We declare under our sole responsibility that the device included in this box, has passed all processing inspections and the final test and it is in conformity with the product requirements,

including all reference codes and supply specifications.

ROHS compliance: the product respects the EC requirements related to ROHS substances, according to “Restriction of Hazardous Substances” as per document 2011/65/UE

REACH compliance: the product respects the EC requirements related to REACH SVHC directive (2015)

Note: all the reported information comes from our suppliers, NEXTYS SA. has not run any test to evaluate if the specific elements are present.

All indicated devices are designed according to the latest Reference standards, if not expressly indicated through the official documents or files, they have been tested through our internal pre-

compliance testing. Consult directly on www.nextys.com the reference standards applied to each model.

Code Description

NISO-20 DC/DC Insulation Module IN 12...48Vdc - 20A / OUT 12…48Vdc - 20A

Certifications and approvals

Reference standards

2014/35/EU (2014) (Low Voltage Directive)

2014/30/EU (2014) (EMC directive)

UL508 (Safety Standards)

EN60255-27 (Safety Standards)

IEC60664-1 (Safety Standards)

EN50178 (Safety Standards)

EN61000-6-2 (Generic immunity standard for industrial environments)

- EN61000-4-2 (Electrostatic discharge immunity test)

- EN61000-4-3 (Radiated, radio-frequency, electromagnetic field immunity test)

- EN61000-4-4 (Electrical fast transient/burst immunity test)

- EN61000-4-5 (Surge immunity test)

EN61000-6-4 (Generic emission standard for industrial environments)

- EN55022 (CISPR22 - EMC)

- EN55011 (CISPR11 - EMC)

Date: 30.01.2017

Place: Quartino, Switzerland

The product manager

Marius Ciorica

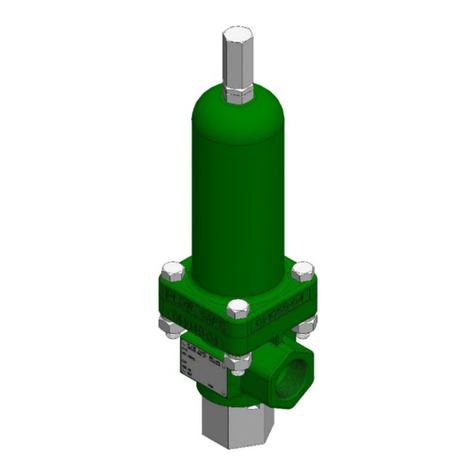

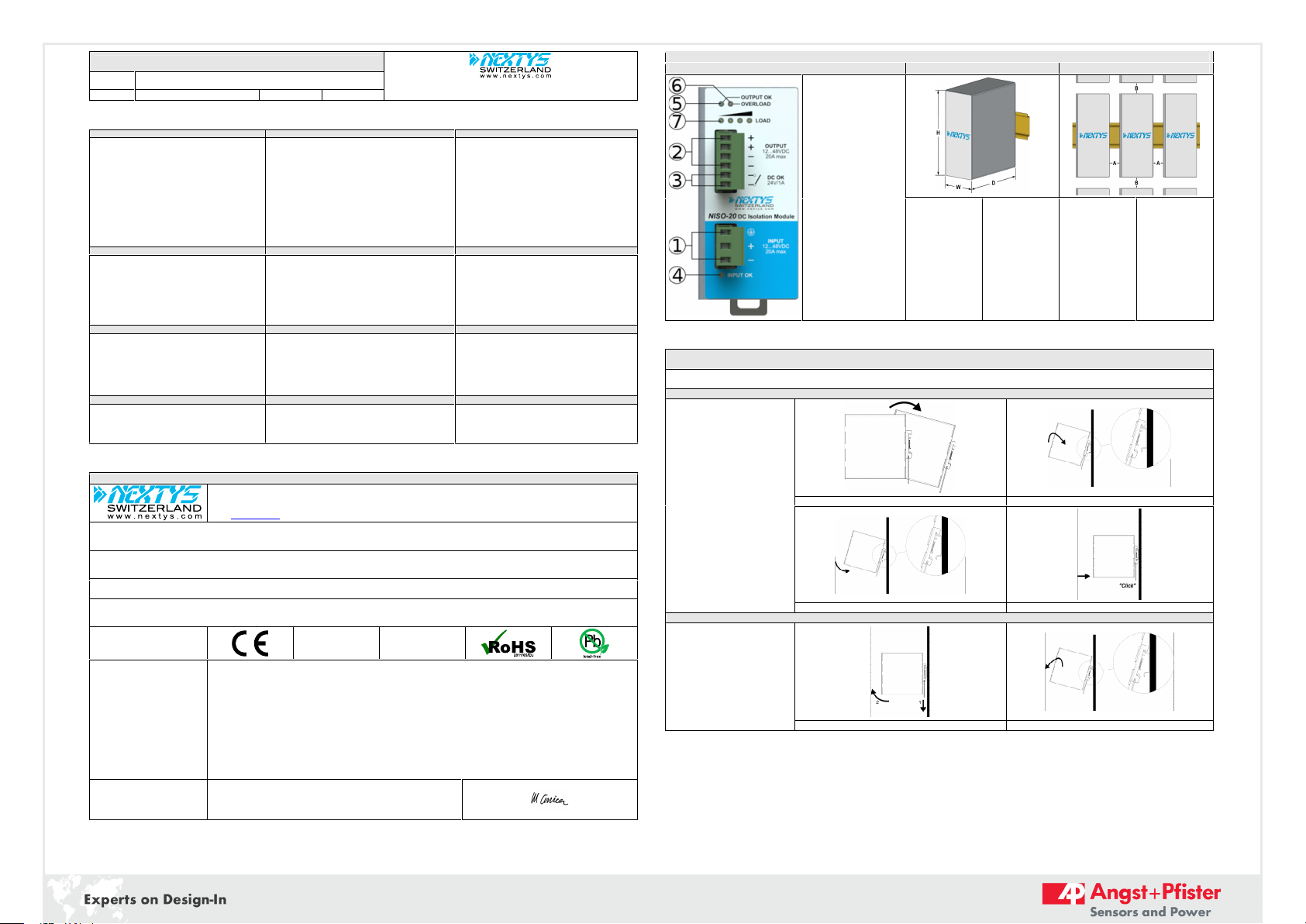

Connections and User interface

Fig.1

Fig.2

Fig.3

(1) DC input

(2) DC output (Load)

(3) Diagnostic Output

(dry contacts, NO)

(4) Green LED: Input OK

(5) Green LED: Output OK

(6) Red LED: Overload

(7) Yellow LEDs: Load status

bargraph display

Dimension

W

D

H

mm

54.0

115.0

110.0

Distance

A

B

mm

20

50

Mounting / Dismounting Instructions

Fig.4

For DIN rail mounting according to IEC 60715 TH35-7.5(-15). Mounting as shown in figure, with input terminals on lower side, with suitable cooling and maintaining a

proper distance between adjacent devices as specified in the User manual.

Mounting

1

2

1.Tilt the unit slightly backwards.

2.Fit the unit over the top edge of the

rail.

3.Slide it downward until it hits the

stop.

4.Press against the bottom for locking.

3

4

Dismounting

1.Pull down the slide clamp lever.

2.Tilt the unit upward.

3.Unhook the unit from the rail.

1 & 2

3

1 NISO-20_1680-21539-0003-E-1117

2

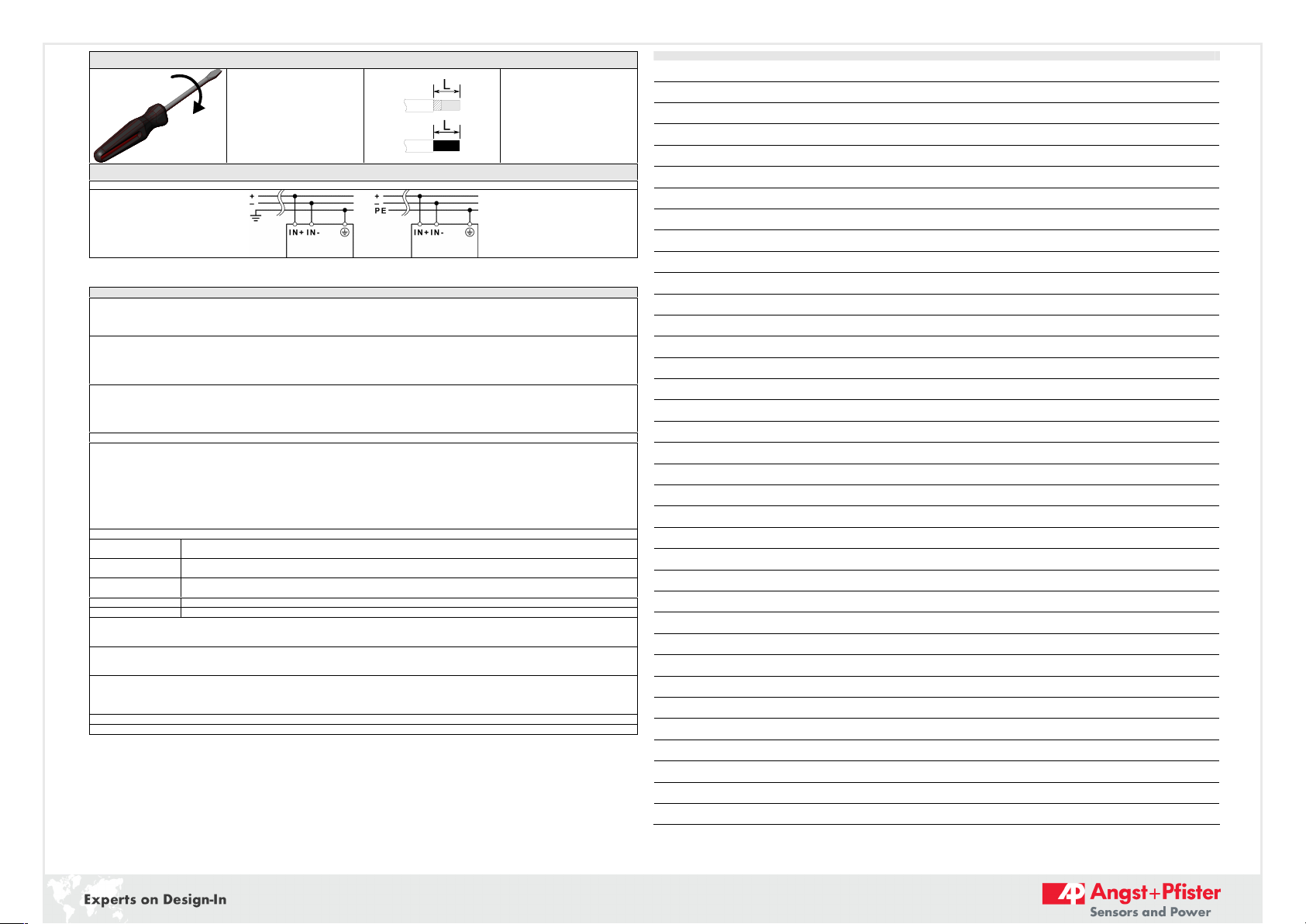

Recommended connecting cable

Fig.5

Recommended Tightening torque

0.5-0.6Nm

4.42-5.30 lbf in

Input / output connections

Solid: 2.5mm² / 12AWG

Stranded:1.5mm² / 12AWG

L: 6.0-7.5mm / 0.24-0.30in

Input connection

Fig.7

DC Line

INSTRUCTIONS

1) Description: NISO-20 can be supplied with any voltage between 10Vdc and 55Vdc, please respect the polarity. The output voltage will track the input voltage as

specified in the product datasheet.

To prevent damage in case of reverse polarity, the device is protected by an internal not replaceable fuse.

NISO-20 can be used in SELV and PELV circuits.

2) Installation: use DIN-rails according to EN 60715. Installation should be made vertically (see Fig.4). For better device stability fix the rail to the wall close to the point

where the device is to be mounted. In order to guarantee sufficient convection, we recommend observing a minimum distance to other modules (see Fig.3).

The device is provided with a thermal protection, a limited air flow can cause the thermal protection tripping.

The device automatically restarts after cooling.

To get normal operation reduce the temperature of the air surrounding the unit, increase the ventilation or reduce the load.

3) Connections: the device is equipped with pluggable screw terminals. To avoid sparks, do not connect or disconnect the connectors before having previously turned-off

input power and waited for capacitors discharge.

In order to comply with local certification, use appropriate copper cables of indicated cross section, designed for an operating temperatures of 60°C (for ambient <45°C)

and 75°C (for ambient < 60°C). Strip the connecting ends of the wires according to the indication on Fig.5 and ensure that all strands of a stranded wire enter the

terminal connection.

4) DC Input protection: NISO-20 is equipped with internal fuse, ratings of DC line protection devices must be coordinated with input current indicated on the data sheet.

5) Overload (OL) / short circuit (SC) / overvolatge (OVP) / overtemperature (OTP) protections: Hiccup auto-reset and over temperature protection.

OL exceeding the limits indicated on the data sheet, if applied to the device will make the output operate at on/off duty-cycle variable depending on OL value, air

temperature and device temperature.

Overload behaviour: Up to the overload limit there is no reduction of the output voltage. For output currents >Ilim the output is shut down and the Overload red LED

will be on.

Short circuit behaviour: The device enters into hiccup mode protecting the unit and the connected load.

Input/output overvoltage protection: the unit is protected against external overvoltage applied to the input; for input voltages greater than 62V the device will shut

down. In case of an internal failure, a double protection circuit switch off the output and avoid output voltage higher than 62V potentially dangerous for the supplied

devices.

6) Status Signals:

“Input OK” green LED:

on = the input voltage is present and within the product specified input voltage range

off = the input voltage is not present, check wiring

“Output OK” green LED:

on = the output voltage is present and within the product specified output voltage regulation range

off = output overload, direct short circuit on the output, input voltage not present, OVT/OVP shut down or device internal failure.

“OVERLOAD” red LED:

on = output overload, direct short circuit on the output, OVT/OVP shut down or device internal failure.

off = normal operation

“DC OK” relay contact:

Contact closes when the output voltage is present and within the product specified output voltage regulation range

“LOAD” LEDs bargraph

Each LED corresponds to about 4.5A of load current, all 4 LEDs are on when the output current exceeds about 18A

7) Redundant and parallel connection: For redundant connection, an external isolating diode must be used. Nextys OR20 or OR50 products are recommended.

Parallel connection for power increase can be achieved connecting the output of the devices in parallel. Please keep the length of the input and output cables of the 2

paralleled units the same length and cross section to achieve the best possible current balancing. Avoid exceeding 80% of the total available output current

10) Feeding DC motors: it is possible to feed DC motors considering that when a motor starts-up under effort its consumption is much higher than the nominal current

and it can trigger overcurrent protection.

NOTE: motors can generate high conducted noise on the DC line. Therefore it is not recommended to feed on the same line motors and equipment sensitive to noise.

11) Warranty: power supplies are guaranteed free from factory defects for the time specified in the “Sales Conditions”.

Failures caused by misuse, external and/or abnormal events (i.e. overvoltage, over temperatures) or non-respect of above parameters and standards, are not covered by

warranty.

Opening the housing of the product makes warranty to be no longer valid.

In order to improve the products Nextys SA reserves the right to change product specifications, ratings and data without previous advice.

NOTES

2 NISO-20_1680-21539-0003-E-1117

Headquarter Switzerland:

Angst+Pfister Sensors and Power AG

Thurgauerstrasse 66

CH-8050 Zurich

Phone +41 44 877 35 00

sensorsandpower@angst-pfister.com

Office Germany:

Angst+Pfister Sensors and Power Deutschland GmbH

Edisonstraße 16

D-85716 Unterschleißheim

Phone +49 89 374 288 87 0

sensorsandpower.de@angst-pfister.com

Power supplies

Sebastiano Leggio

Phone + 41 44 877 35 06

sebastiano.leggio@angst-pfister.com

Accelerometers

Sensor elements

Christoph Kleye

Phone +49 89 374 288 87 61

christoph.kleye@angst-pfister.com

Harald Thomas

Phone +49 89 374 288 87 23

harald.thomas@angst-pfister.com

Flow / Level / Medical products

Dr. Adriano Pittarelli

Phone +49 89 374 288 87 67

adriano.pittarelli@angst-pfister.com

Drive technology

CH Postcode 1000 – 4999 / AT / IT / FR

Christian Mohrenstecher

Phone +41 76 444 57 93

christian.mohrenstecher@angst-pfister.com

Gas sensors

Gas sensor modules

Dr. Thomas Clausen

Phone + 49 89 374 288 87 24

thomas.clausen@angst-pfister.com

Drive technology

CH Postcode 5000 – 9999 / DE

Roman Homa

Phone + 41 76 444 00 86

roman.homa@angst-pfister.com

Pressure Sensors

Load Cells

Philipp Kistler

Phone + 41 44 877 35 03

philipp.kistler@angst-pfister.com

Linear position sensors

Angle sensors

Eric Letsch

Phone + 41 44 877 35 14

eric.letsch@angst-pfister.com

Sales Other Countries / Product Management

Sales International Key Accounts

Peter Felder

Phone + 41 44 877 35 05

peter.felder@angst-pfister.com

Postcode 1000 – 2999

Christian Mohrenstecher

Phone +41 76 444 57 93

christian.mohrenstecher@angst-pfister.com

Sales Switzerland & Liechtenstein

Postcode 3000 – 9999

Basil Frei

Phone + 41 44 877 35 18

basil.frei@angst-pfister.com

Gas sensors and modules

Peter Felder

Phone +41 44 877 35 05

peter.felder@angst-pfister.com

Pressure sensors

Other products

Gerhard Vetter

Phone + 49 89 374 288 87 26

gerhard.vetter@angst-pfister.com

Sales Germany & Austria

Geometrical sensors

Other products

Kurt Stritzelberger

Phone + 49 89 374 288 87 22

kurt.stritzelberger@angst-pfister.com

We are here for you. Addresses and Contacts.

Experts on Design-In

for sensors and power solutions

Other nextys Control Unit manuals

Popular Control Unit manuals by other brands

SIGMA TEK

SIGMA TEK CP 102 instruction manual

Delta

Delta DVP04AD-H2 instruction sheet

Control Technologies

Control Technologies CTI 2554-A Installation and operation guide

GiBiDi

GiBiDi BE24 Instructions for installation

alphainnoTec

alphainnoTec RBE operating manual

B meters

B meters IWM-PL4 Quick user guide